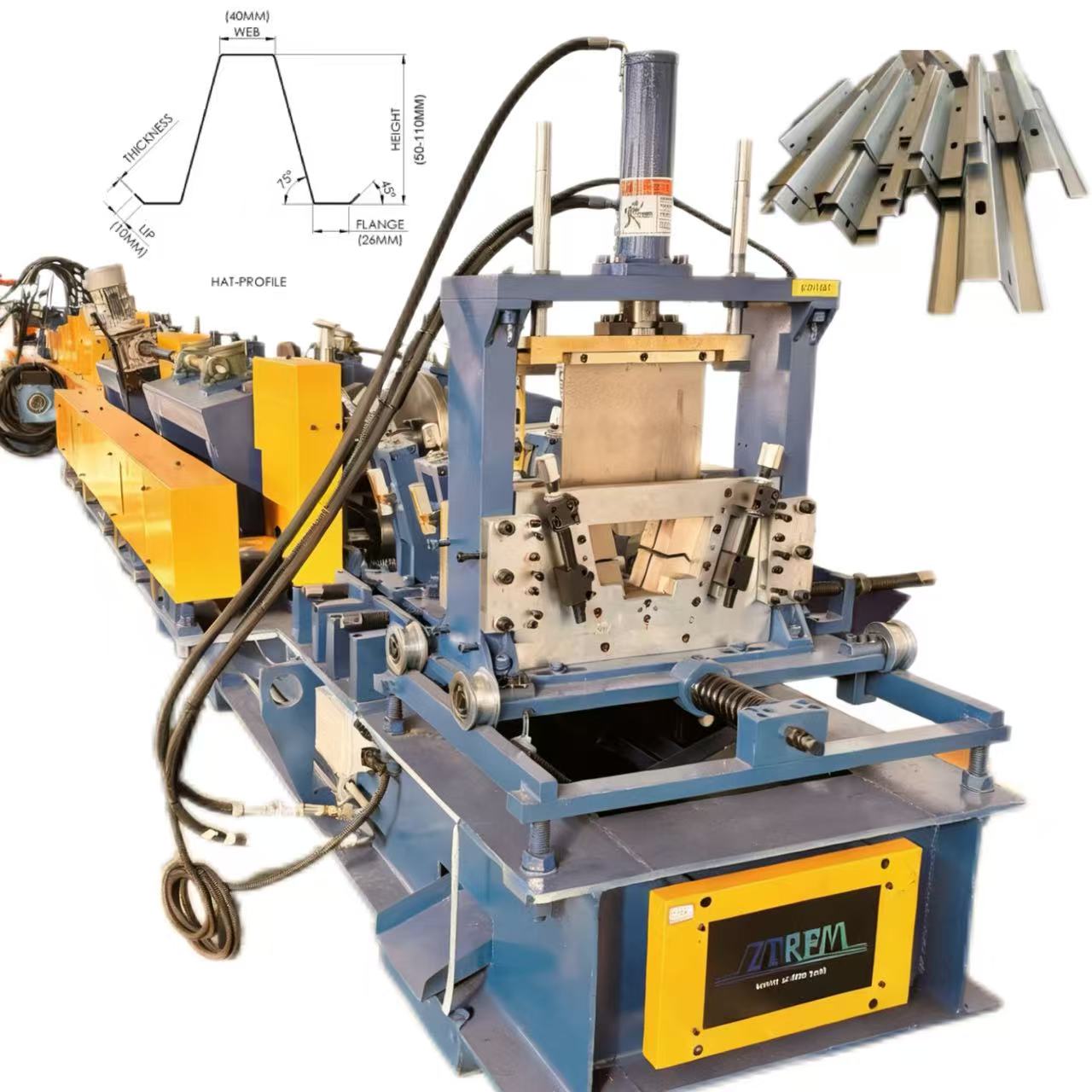

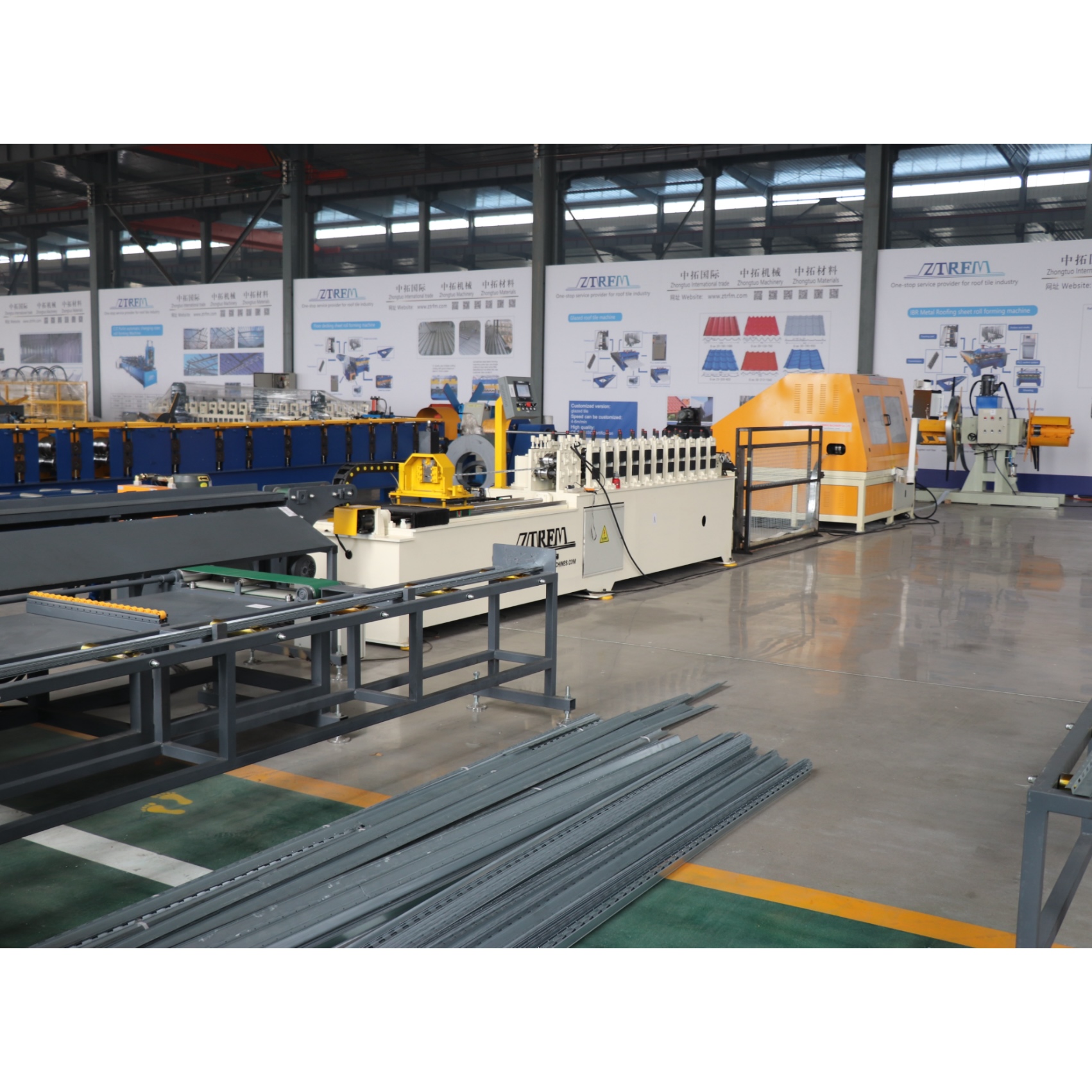

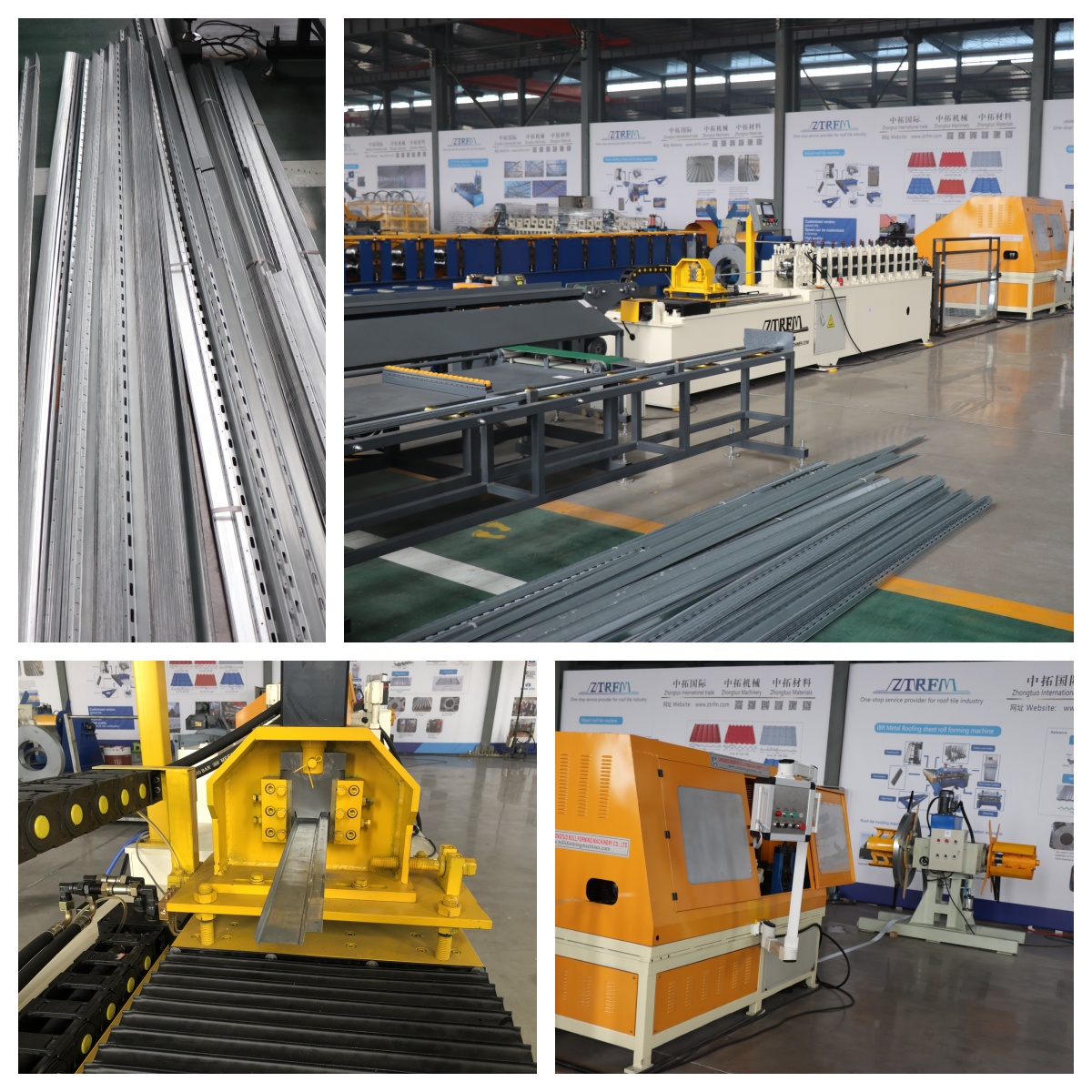

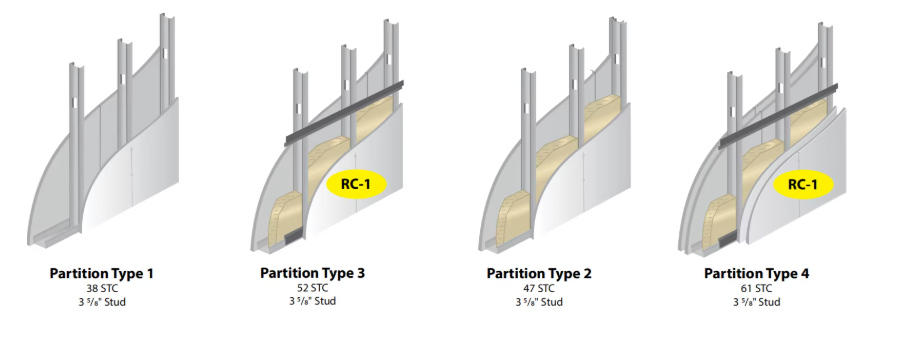

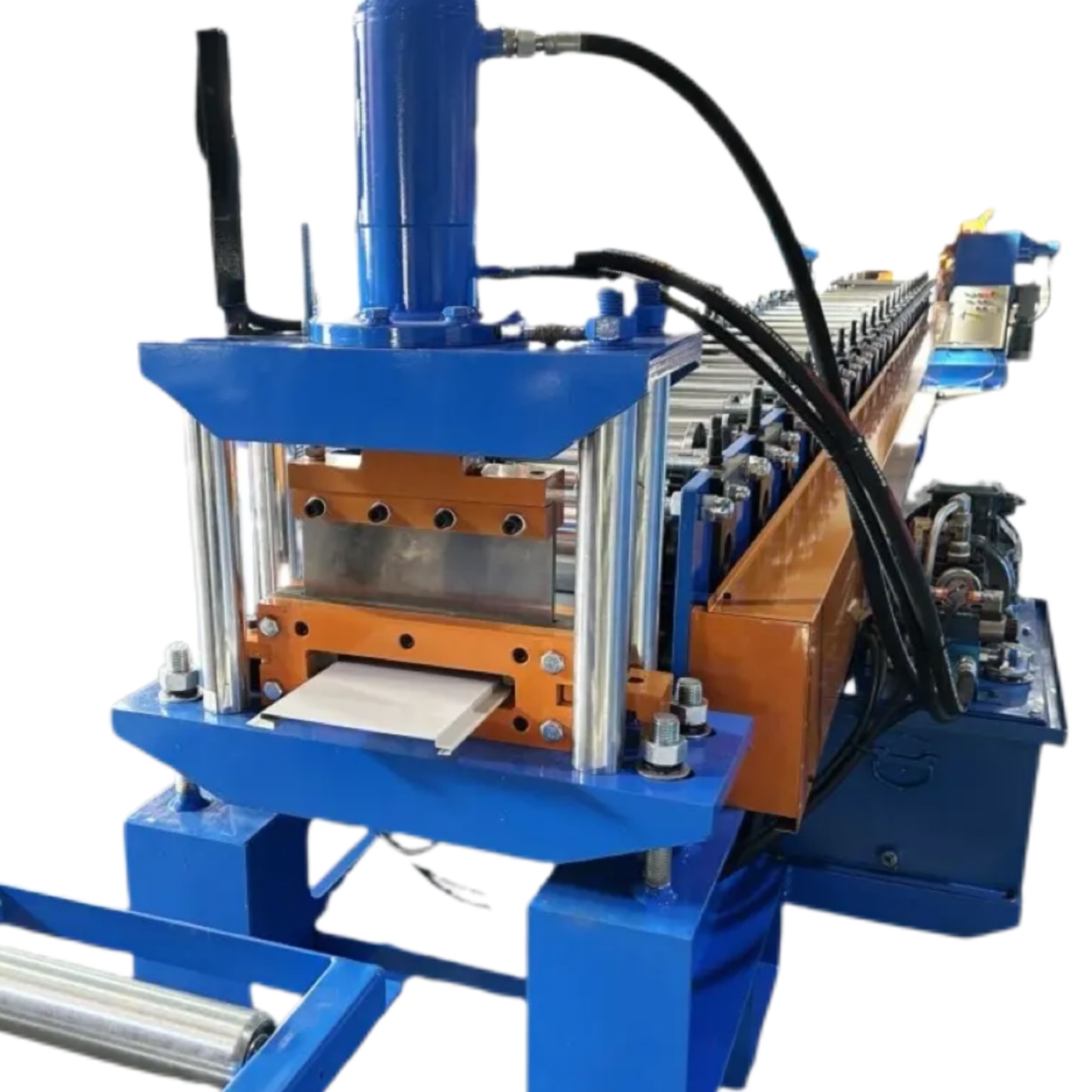

Furring Channel rotary punching rolling forming machine is a specialized equipment for producing metal keels through rolling and stamping technology. It is mainly used in the manufacturing of non load bearing partition wall systems and ceiling keel frames in the construction field. It can produce different types of keel profiles such as C-shaped keel, U-shaped keel, T-shaped keel, and L-shaped keel, which are widely used in the production of steel structure buildings, light steel keels, painted keels, card keels and other products. In steel structure buildings, steel has advantages such as structural stability, precise manufacturing, energy conservation and environmental protection, and can achieve 100% recycling, which is environmentally friendly. In addition, steel has excellent physical properties, is not easily deformed, and is easy to modify, providing designers with great flexibility. At the same time, the installation process is simple, saving a lot of time and manpower.

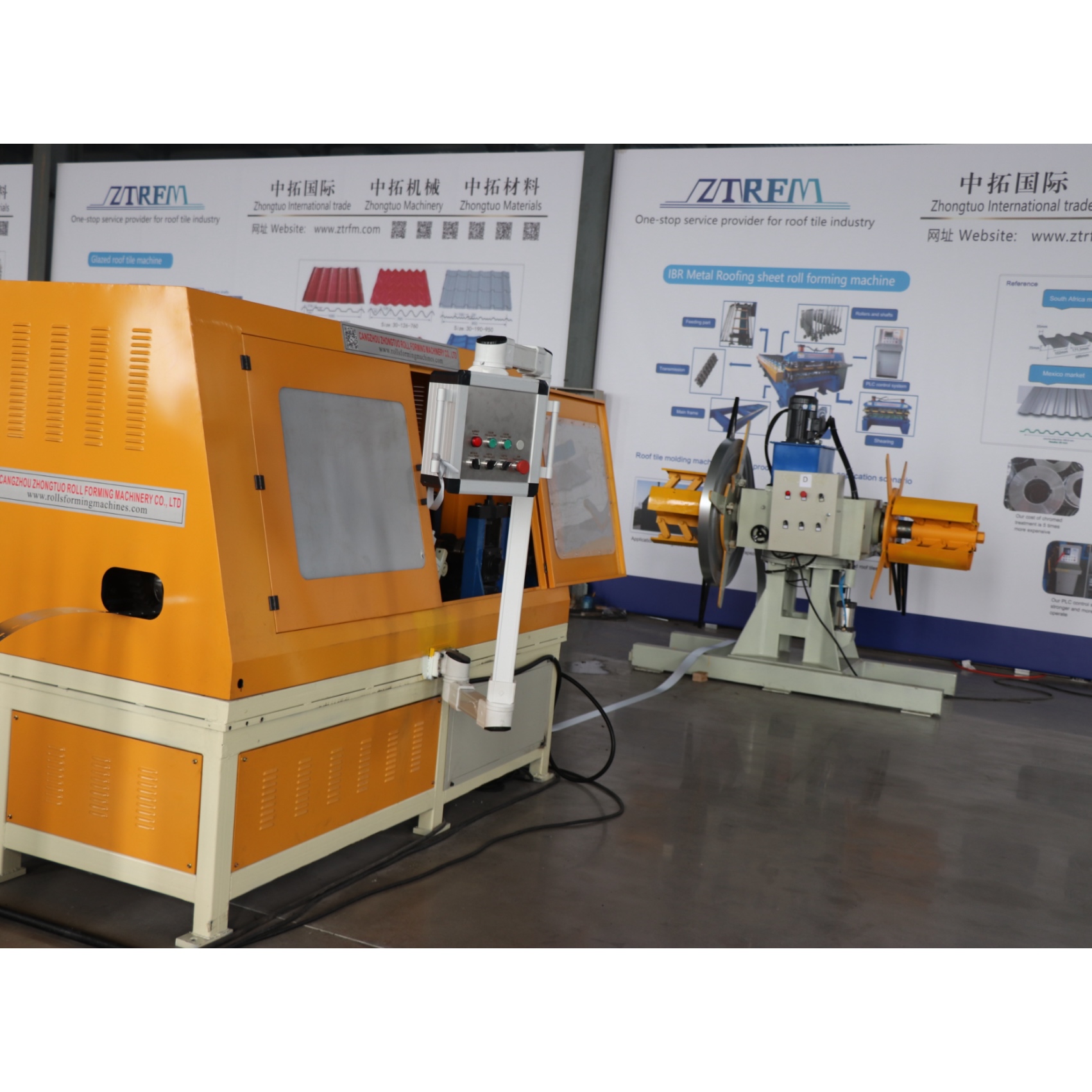

Equipment features:

- Efficient production:

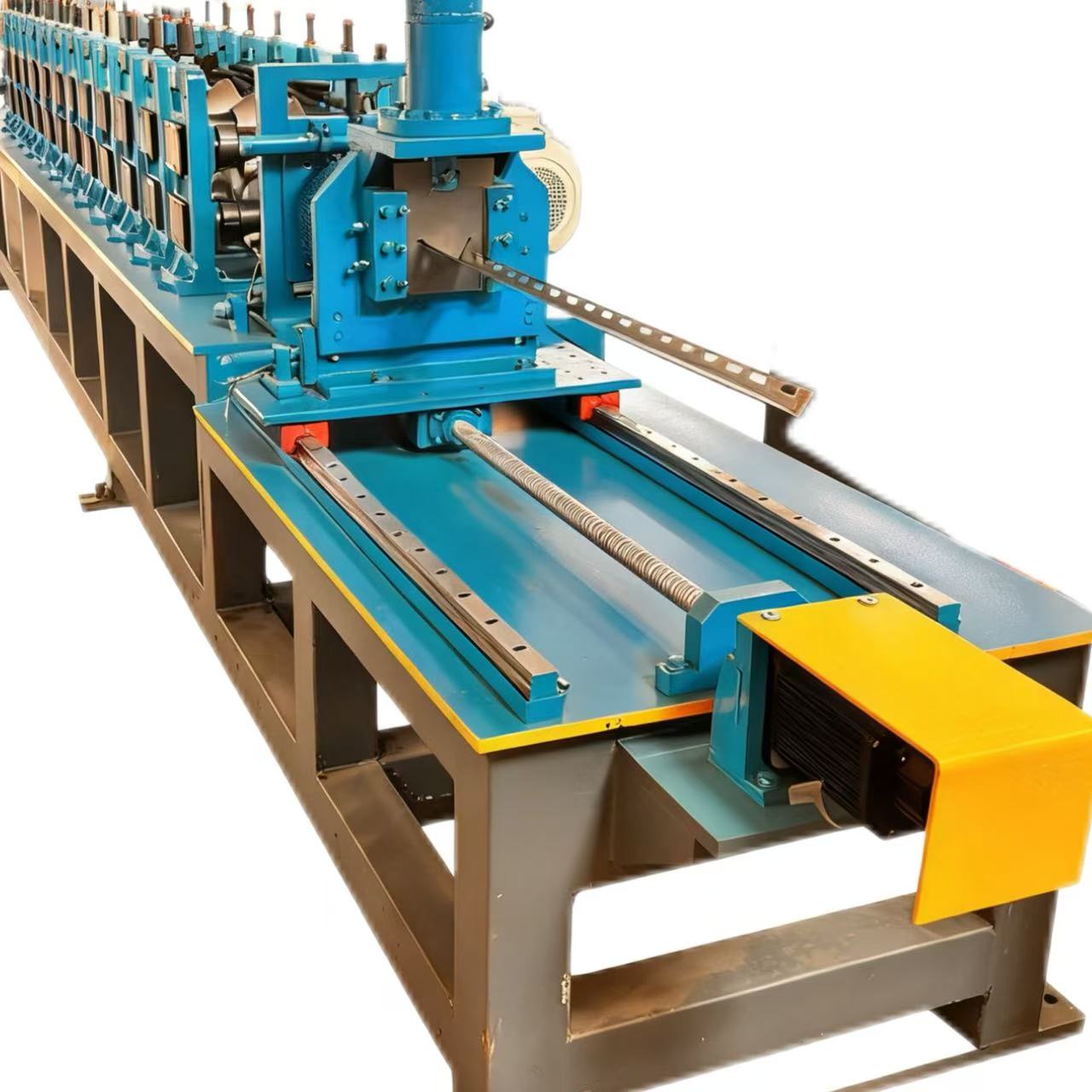

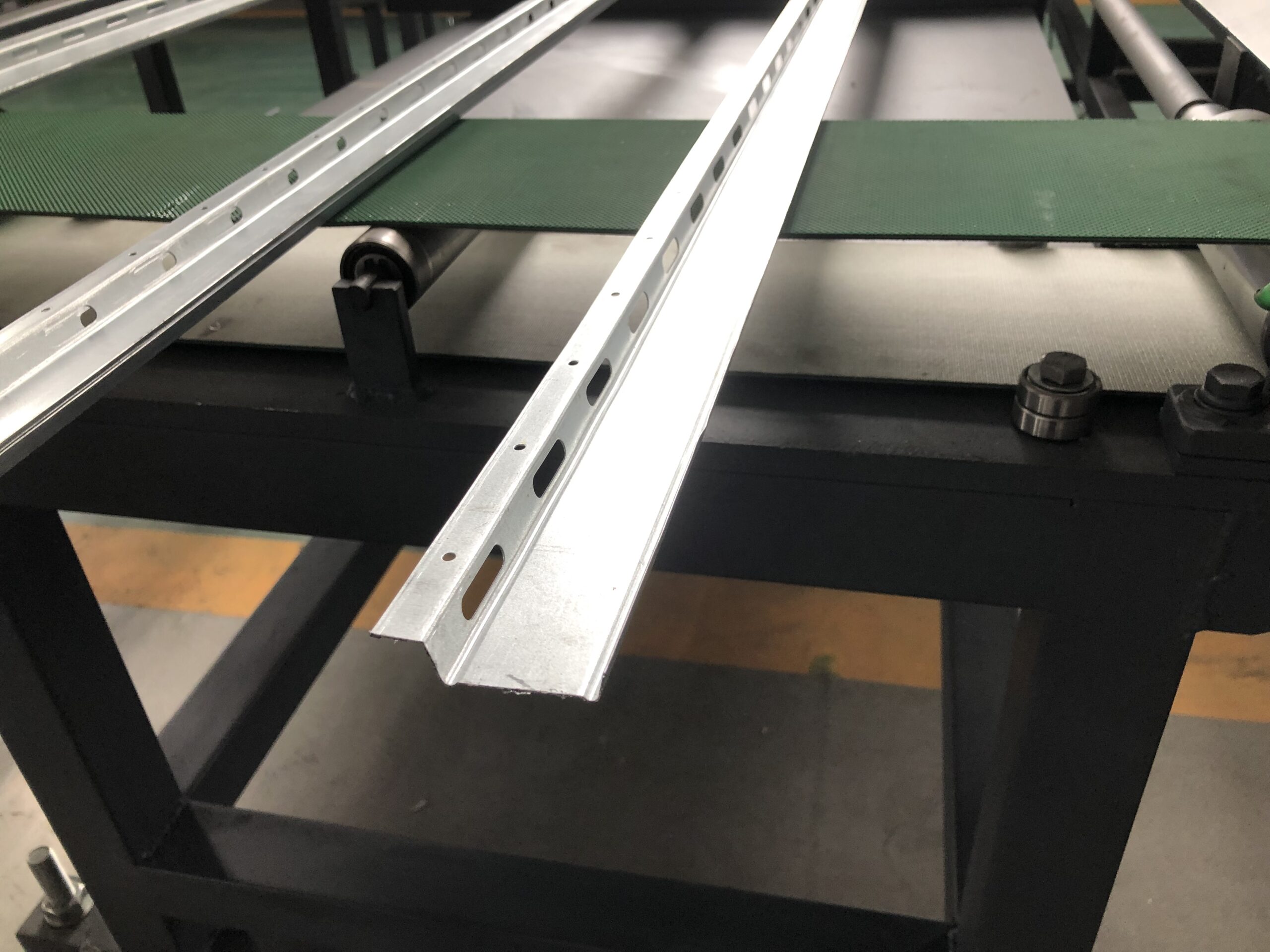

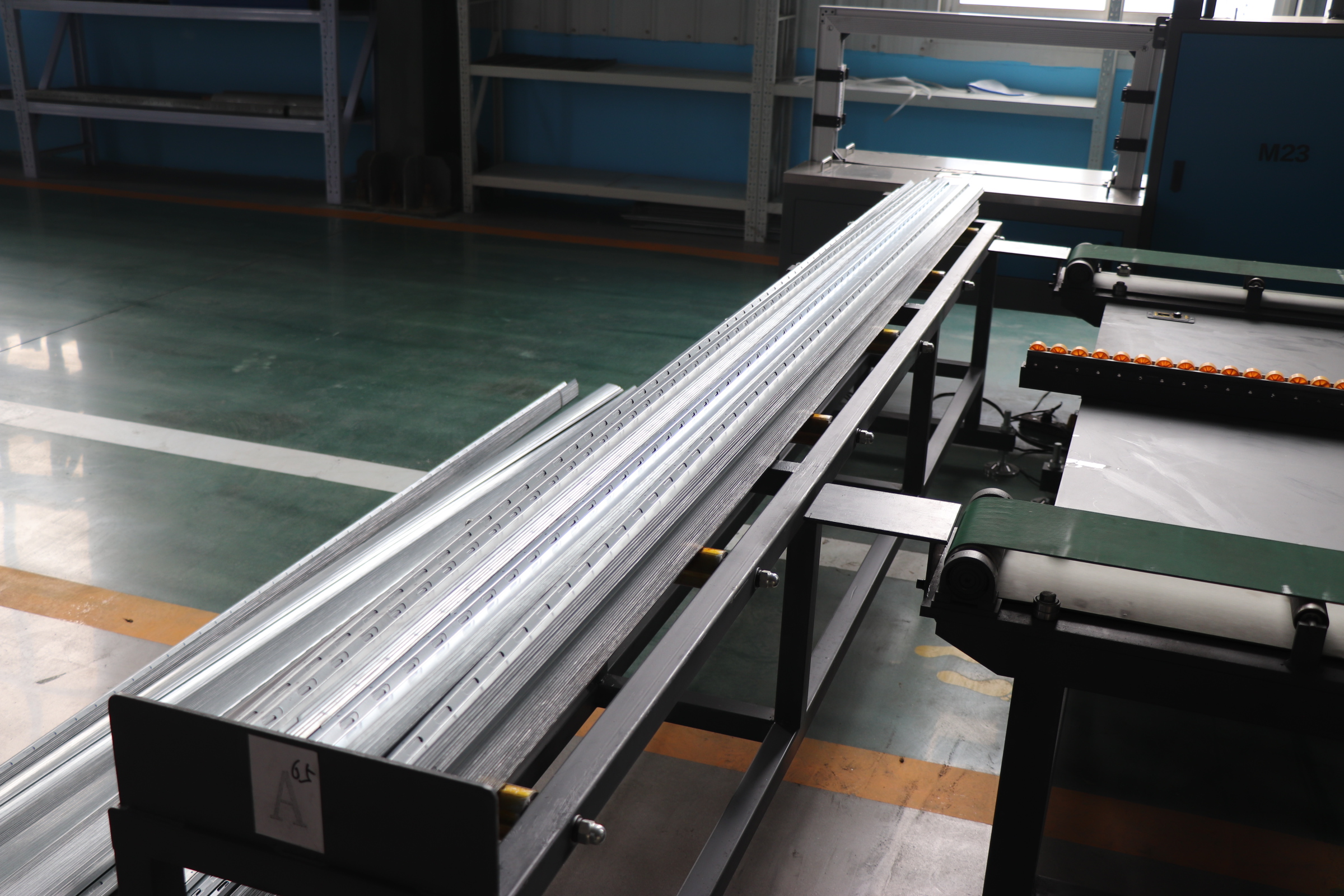

Using high-speed rolling technology, the punching speed can reach 1000-2000 pieces/minute (about 50-100 meters/minute), which is 2-5 times that of traditional automatic punching machines. The molding speed can also reach 50 meters per minute. - Low noise and low vibration:

Compared with traditional stamping equipment, the rolling process has less vibration and low noise during operation. - High precision and flexibility:

By using a servo control system, the synchronous movement of the mold and the plate can be ensured, and holes with different geometric shapes can be machined. Simply replace the mold to change the shape of the hole. - High degree of automation:

equipped with PLC control system to achieve automatic feeding, forming, punching and cutting, reducing manual intervention.

Application areas:

1.Construction industry:

used for producing light steel keel, baked paint keel, card type keel, etc., widely used in suspended ceilings, partition walls, shelf columns, photovoltaic brackets and other fields.2.Industrial manufacturing:

suitable for the production of seismic brackets, corner guards, steel back ribs and other profiles.Advantages:

1.Cost saving:

Compared to traditional stamping equipment, the rolling process reduces mold costs and production line investment. Meanwhile, automated production reduces labor costs.2.Small footprint:

The compact structural design allows it to perform efficiently within a limited space.3.Safe and environmentally friendly:

No vibration during operation, low noise, and no need for complex protective measures.Product Attributes :

1.Formed MaterialGI/GLThickness:0.4-0.8mm2.DecoilerHydraulic automatic decoilerManual decoiler(will give you as free)3.Punching devicePunching typeHigh speed rotary punch4.Main bodyRoller station12 rows(As your requirement)Diameter of shaft50mm solid shaftMaterial of rollers45# steel, hard chrome plated on the surfaceMachine body frameMetal steel weldedDriveGearbox transmissionDimension(L*W*H)5500*800*1200(customize)WeightAbout 3T5.Cutting deviceCutting typeHydraulic servo motor drived flying shear6.PowerMotor Power7.5KW*2 setsHydraulic system power7.5KW7.Voltage380V 50Hz 3PhaseAs your requirement8.Control systemElectric BoxCustomized(famous brand)LanguageEnglish(Support multiple languages)PLCAutomatic production of the whole machine. Can set batch, length, quantity, etc.9.Forming Speedmax 70m/min include punching holesSpeed is adjustable according to customer’s requestHere is the working video of this machine for everyone to watch: