Slitting & Cutting to Length Line are core equipment in the metal sheet processing industry. They process wide coils into narrow strips or single sheets that meet specific size requirements through longitudinal shearing (slitting) and transverse shearing (leveling). These machines are widely used in industries such as automobile manufacturing, home appliance production, steel structure construction, and electrical cabinet manufacturing. Their processing accuracy directly affects the quality of subsequent stamping, bending, and welding processes. Based on functional differences, slitter and leveling machines can be divided into slitter lines and leveling lines, both of which together constitute a crucial link in the pre-processing of metal sheets.

Main components:

| Item | Description of Item | Unit | Quantity |

| 1 | 12T Hydraulic decoiler with loading car | set | 1 |

| 2 | Leveling & slitting & cutting device | set | 1 |

| 3 | Waste rewinder | set | 2 |

| 4 | Conveyor | set | 1 |

| 5 | Auto stacker | set | 1 |

| 6 | Tension stand | set | 1 |

| 7 | Recoiler with unloading car | set | 1 |

| 8 | Control system | set | 1 |

| 9 | Hydraulic system | set | 1 |

Working flow:

Uncoiling → Feeding material into machine →Leveling →Slitting (Waste rewinder) →Cutting(Optional) → Conveyor→Auto stacker →Tension stand→Recoiler

Machine Introduction:

Part 1: 12T Hydraulic decoiler with loading car

1. Capacity :12 tons

2.Coil inner diameter :480-520mm,It adopts the hydraulic oil cylinder to make the decoiler expandable and fit to the inner diameter of coils.

3. Coil width :Max 1250mm

4. Hydraulic power: 5.5 kw

5. Motor power :7.5 kw

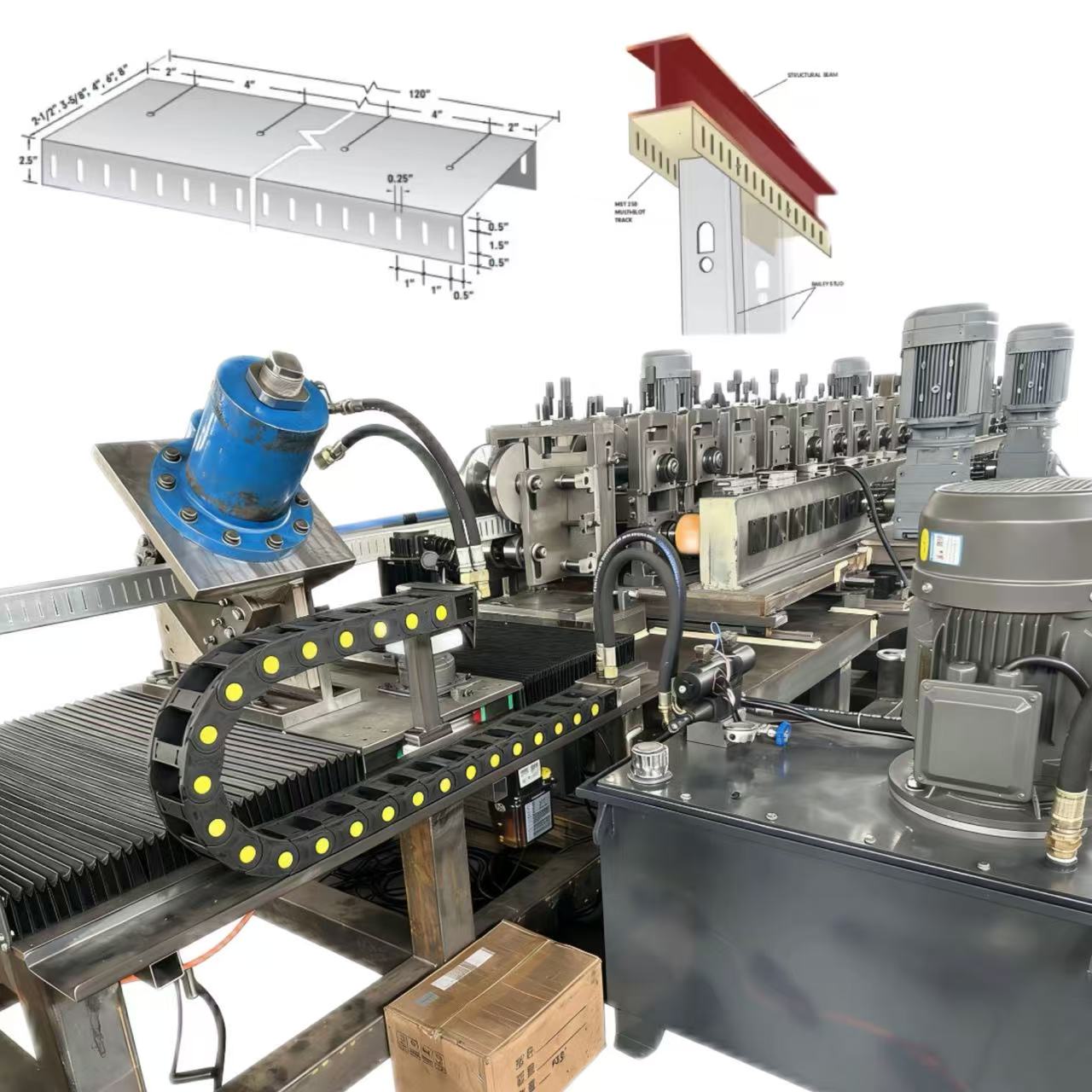

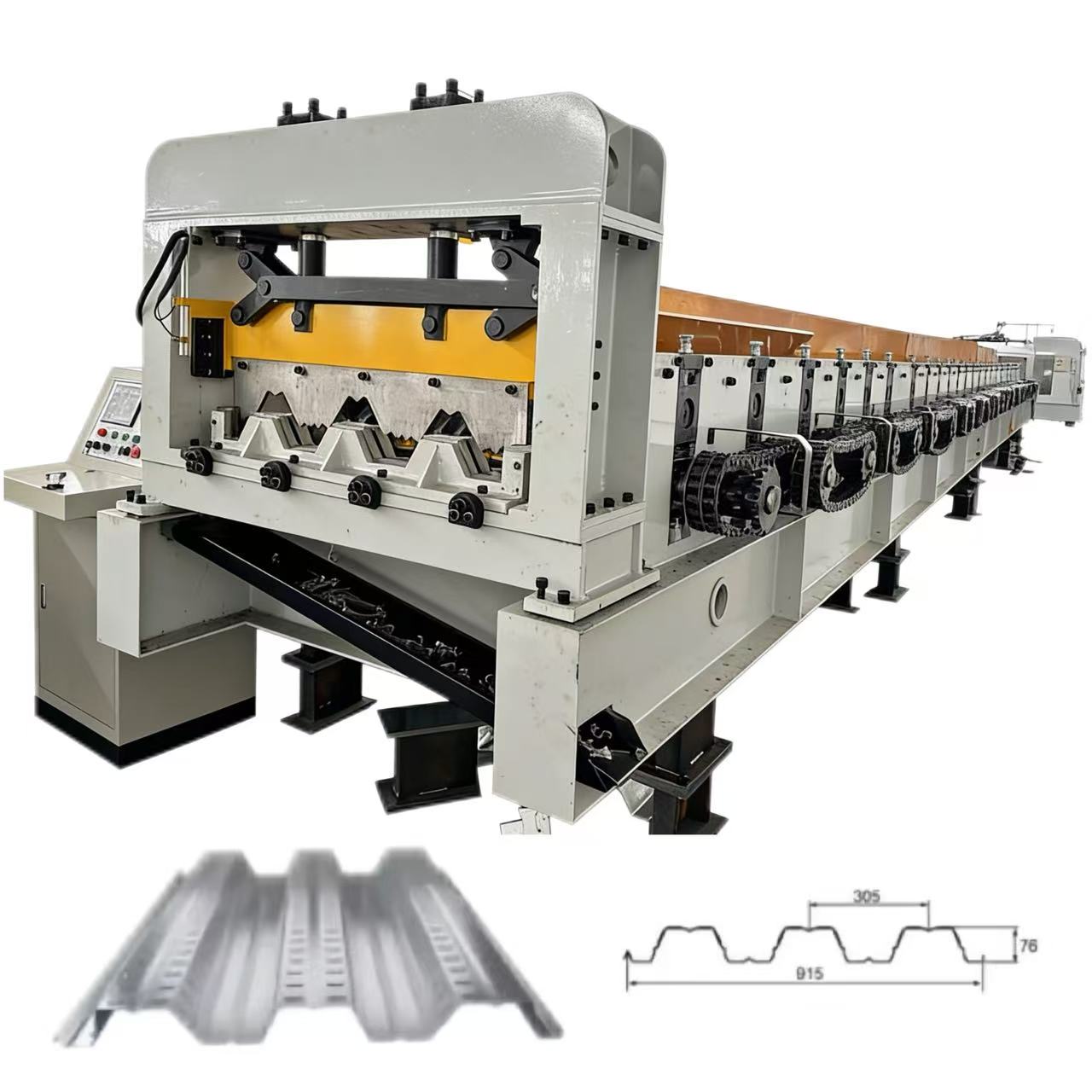

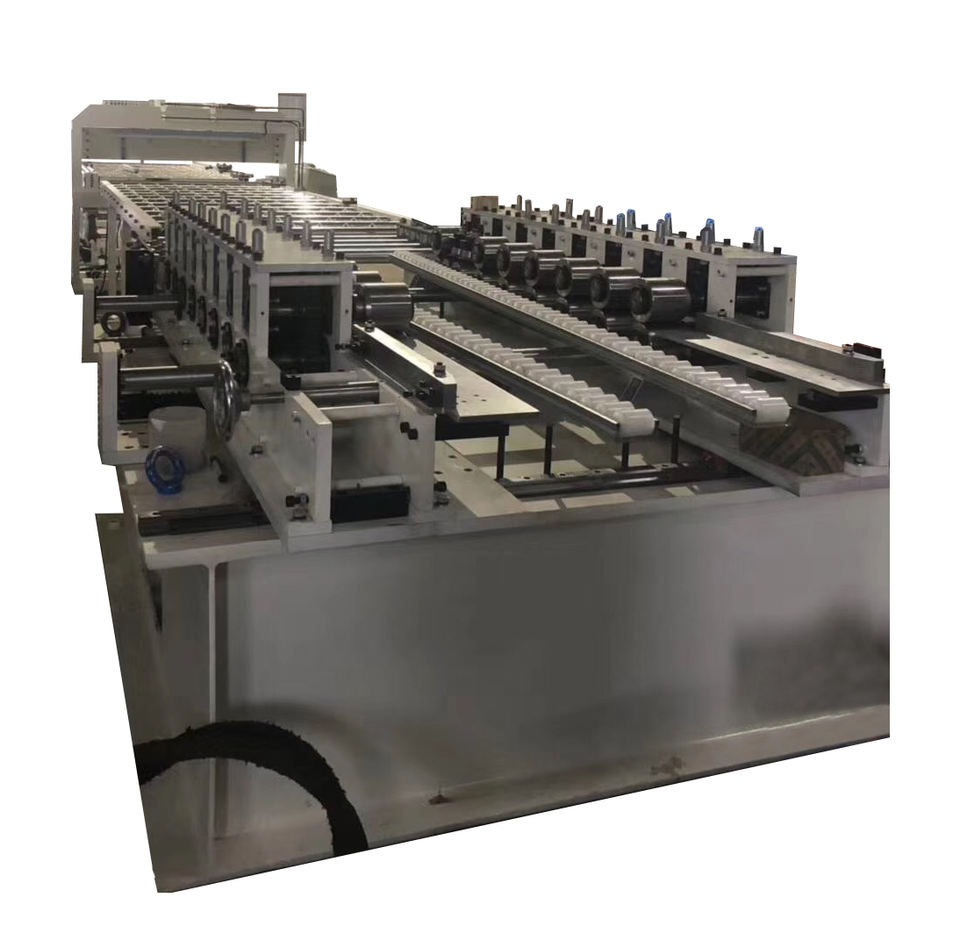

Part 2: Leveling & Slitting & Cutting to length Machine

1. Function :To make the sheet flat and cut the material during work if needed.

2.Leveling roller quantity: 17 pcs, up 7 down 8 with one pair of rubber roller,with the back up rollers

3.Leveling roller gap adjustment type: Motorized.

4.Main leveling roller diameter: 100mm

5.Back-up roller diameter: 90mm

6.Roller material: 40Cr steel with treatment, surface chromed

7.Power: 15 kw

8.Remote control: Equipped with remote control for easy operation.

9.Slitting blade quantity: 13 pcs, the width is adjustable. Min slit width is 20mm, max slit strip is 12 pcs.

10Slitting blade material: Cr12Mov

11.Slitting blade size: Φ220mm× Φ330mm×B

12.Power: 22 kw

13.Speed: 0-25m/min

14.Cutting type: Hydraulic

15.Cutting blade material: Cr12mov with quenched treatment

16.Power: 7.5 kw

Part 3: Conveyor

Part 3: Conveyor

1. Function To convey the sheet to auto stacker

Part 4: Auto stacker

Part 4: Auto stacker

1. Function :To receive the sheet and make them orderly.

2. Length :Max 3 meters

3. Working type: Pneumatic