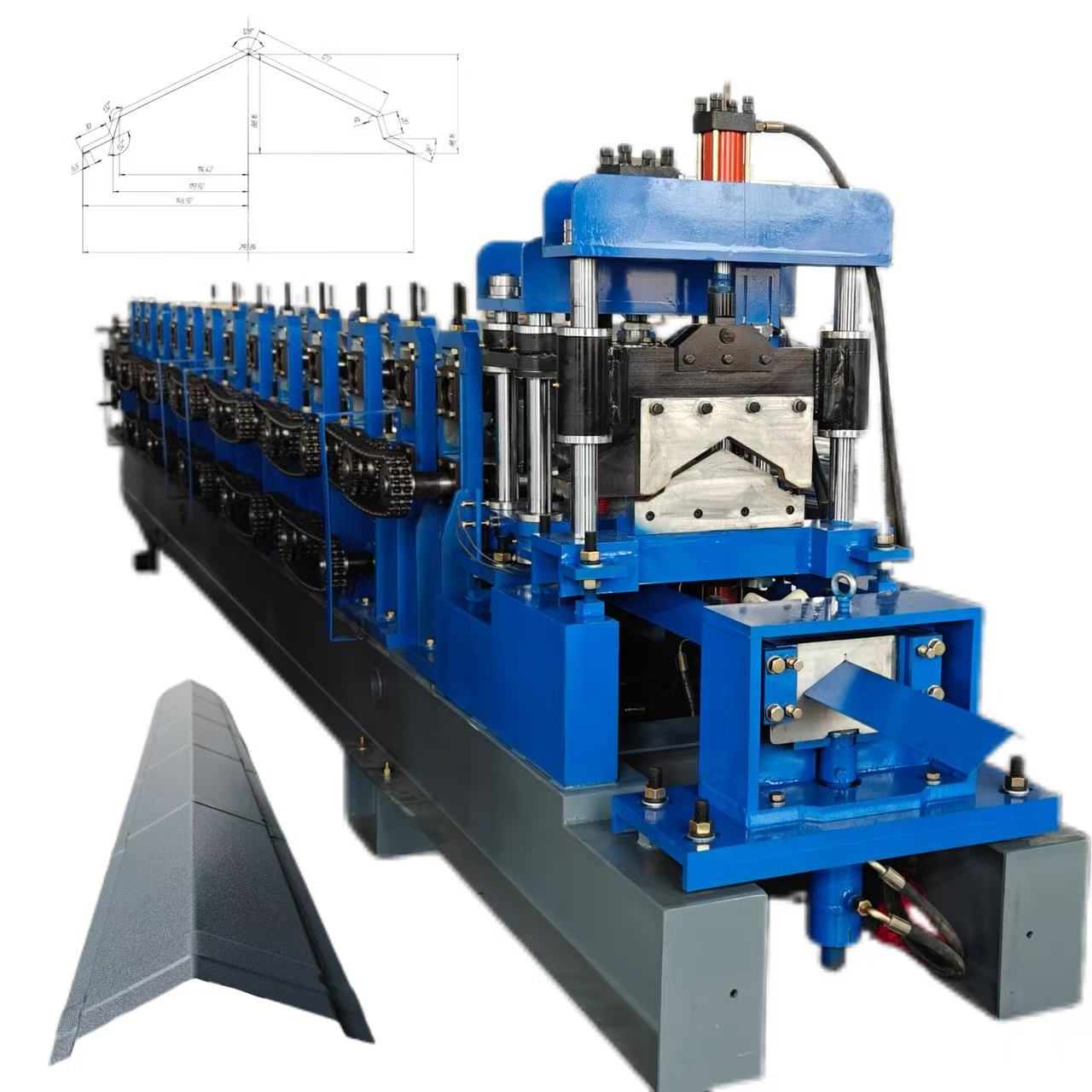

Galvanized Steel Metal Soffit Panel Wall Cladding Roll Forming Machine, also known as new composite wall panel machine or lightweight composite wall panel equipment, is a mechanical device used for producing environmentally friendly and energy-saving large wall panels. It is primarily applied in scenarios such as building walls, roof insulation, cold storage, and airport floors, and is compatible with building systems like frame structures and steel structures

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-0.8mm

|

||

|

2.Decoiler

|

Hydraulic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

28 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600mm

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

Core advantages of the product:

1. Automated production significantly improves efficiency

Traditional wall construction relies heavily on manpower, resulting in low efficiency and difficulty in ensuring quality. The wall panel machine achieves unmanned operation throughout the entire process from raw material mixing to finished product board output through an automated production line.

2. Intelligent control ensures stable quality

The equipment is equipped with an advanced intelligent control system that can monitor key parameters such as temperature, humidity, and pressure in real-time during the production process, automatically adjust the production process, and ensure stable quality of the wall panels. This intelligent design enables the compressive strength, sound insulation effect, and fire resistance of the wall panels to reach industry-leading levels, meeting the stringent requirements of high-end building projects.

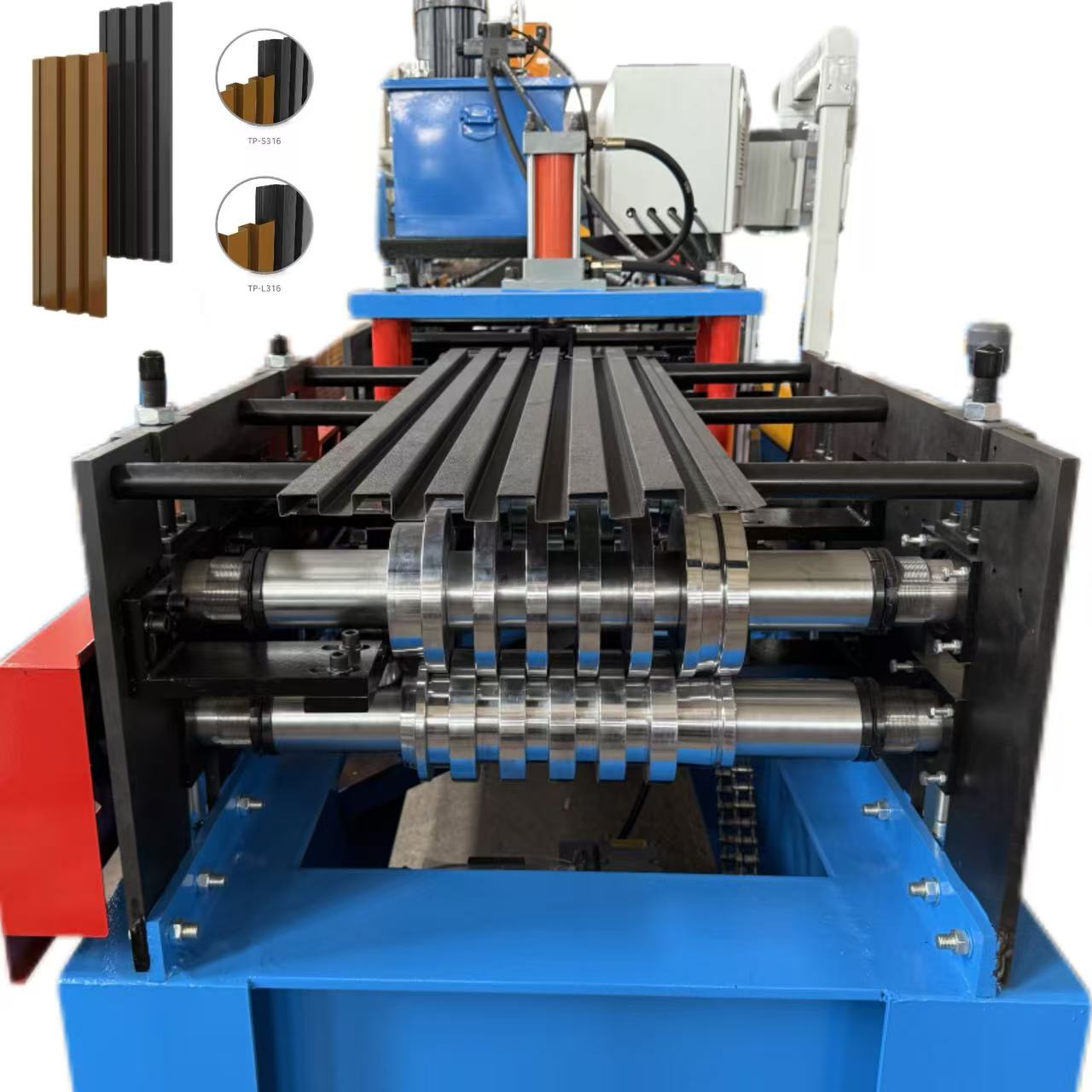

Pattern diagram:

Widely applicable scenarios:

• Residential buildings

In the residential field, the lightweight and high-strength wall panels produced by the wall panel machine not only accelerate the construction speed, but also improve the comfort of living. Its sound insulation and thermal insulation performance make residential buildings quieter and more energy-efficient, and have been favored by a large number of consumers.

• Commercial buildings

Commercial buildings have higher requirements for space utilization and construction efficiency. The large-sized customization capability of the wall panel machine meets the flexible layout requirements of commercial spaces, and its fast construction characteristics enable commercial projects to be put into operation faster, creating economic benefits.

• Industrial buildings

Industrial buildings typically need to withstand significant mechanical vibrations and impacts. The wall panels produced by the wall panel machine have excellent seismic and impact resistance, ensuring the safe and stable operation of industrial facilities.