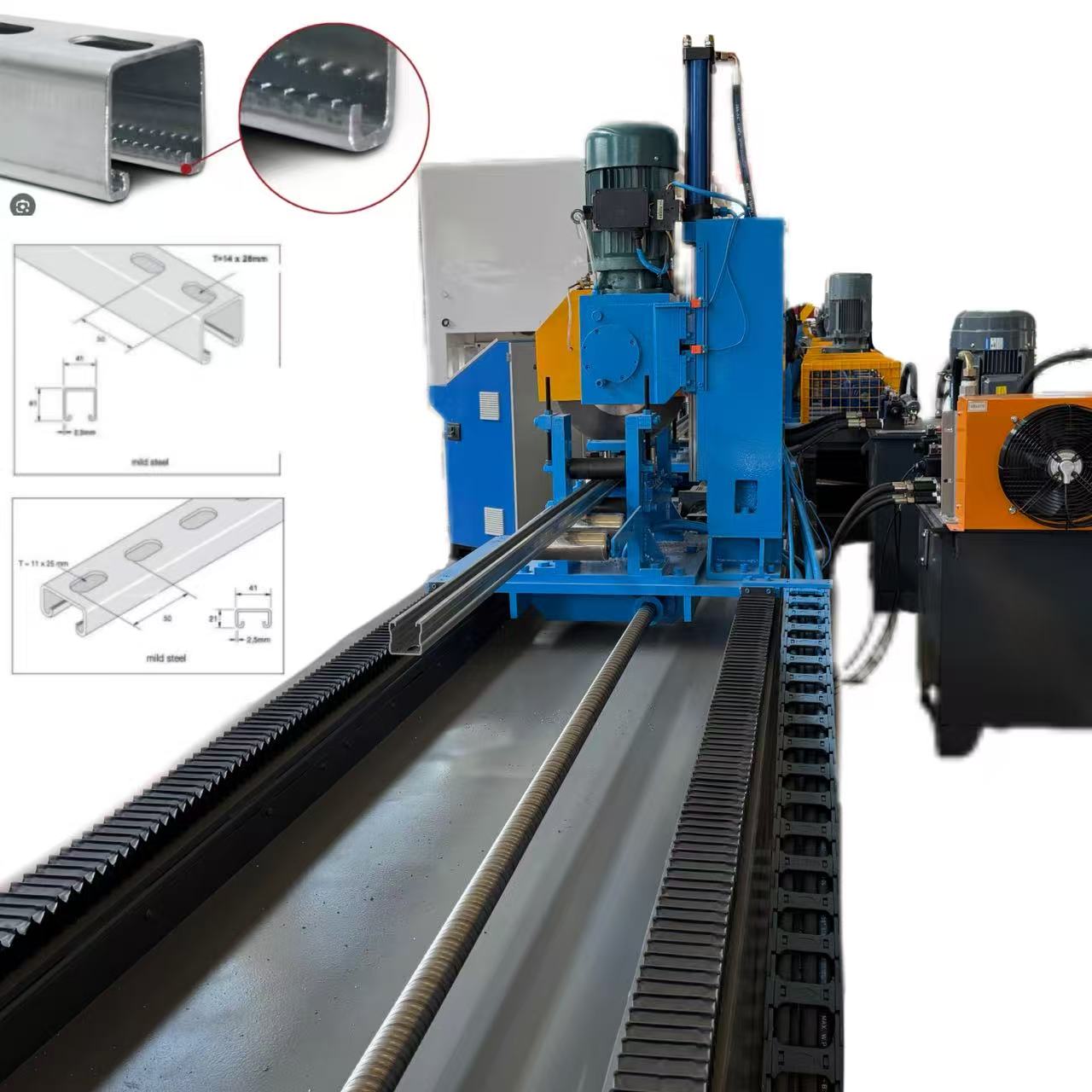

In the wave of global energy structure transformation, the photovoltaic industry, as the core force of renewable energy, is flourishing at an unprecedented speed. However, the long-term stable operation of photovoltaic power plants not only relies on efficient photovoltaic modules, but also on robust and reliable photovoltaic support systems. Especially in earthquake prone areas, traditional brackets are difficult to resist the invasion of natural disasters, resulting in damage to photovoltaic systems and power generation interruptions. The emergence of Full Automatic Strut Channel Solar Panel Photovoltaic Bracket Forming Machine provides innovative solutions to this problem and has become a key technology to ensure the safety of photovoltaic power plants and improve energy utilization efficiency.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

60mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

About 6.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

20m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

working flow:

Pattern diagram:

Core advantages :

1. Excellent seismic performance: a sturdy barrier against natural disasters

By optimizing the mechanical structure and using high-strength materials, these supports can accurately adapt to the installation needs of photovoltaic panels, ensuring stability in extreme weather conditions such as strong wind, rainstorm, snow pressure, etc. More importantly, they can effectively resist the longitudinal and transverse waves generated by earthquakes, prevent bracket distortion and deformation, and thus protect photovoltaic modules from damage. This independent support design significantly enhances the reliability of photovoltaic systems in complex environments, providing a solid guarantee for the long-term operation of power plants.

2. Innovative design and efficient installation: improving overall system performance

Adopting modular design, the bracket system can quickly adapt to different terrains and installation angles, simplify the installation process, and reduce construction costs. At the same time, the application of intelligent tracking and automatic adjustment technology enables the bracket to adjust its angle according to changes in the sun’s position, maximizing the power generation efficiency of the photovoltaic panel. This design not only improves energy efficiency, but also reduces the need for manual intervention, laying the foundation for intelligent management of photovoltaic power plants.

3. Durability and Environmental Protection: Extend lifespan and reduce maintenance

The Full Automatic Strut Channel Solar Panel Photovoltaic Bracket Forming Machine adopts corrosion-resistant materials, which can withstand complex and changing outdoor environmental conditions, significantly extending the service life of the photovoltaic system. This durability reduces the need for frequent replacement and maintenance, and lowers long-term operating costs. In addition, the production process of the bracket focuses on environmental protection, using energy-saving motors and hydraulic systems to reduce energy consumption and carbon emissions, in line with the trend of green manufacturing. This environmental characteristic is highly compatible with the sustainable development goals of the photovoltaic industry, contributing to the global carbon neutrality process.

Widely applicable scenarios:

Full Automatic Strut Channel Solar Panel Photovoltaic Bracket Forming Machine has been widely used in various photovoltaic projects, including large-scale ground power stations, rooftop distributed systems, and power stations in special terrains such as mountains and deserts. Its excellent performance and adaptability make it the preferred solution for photovoltaic construction in earthquake prone areas.