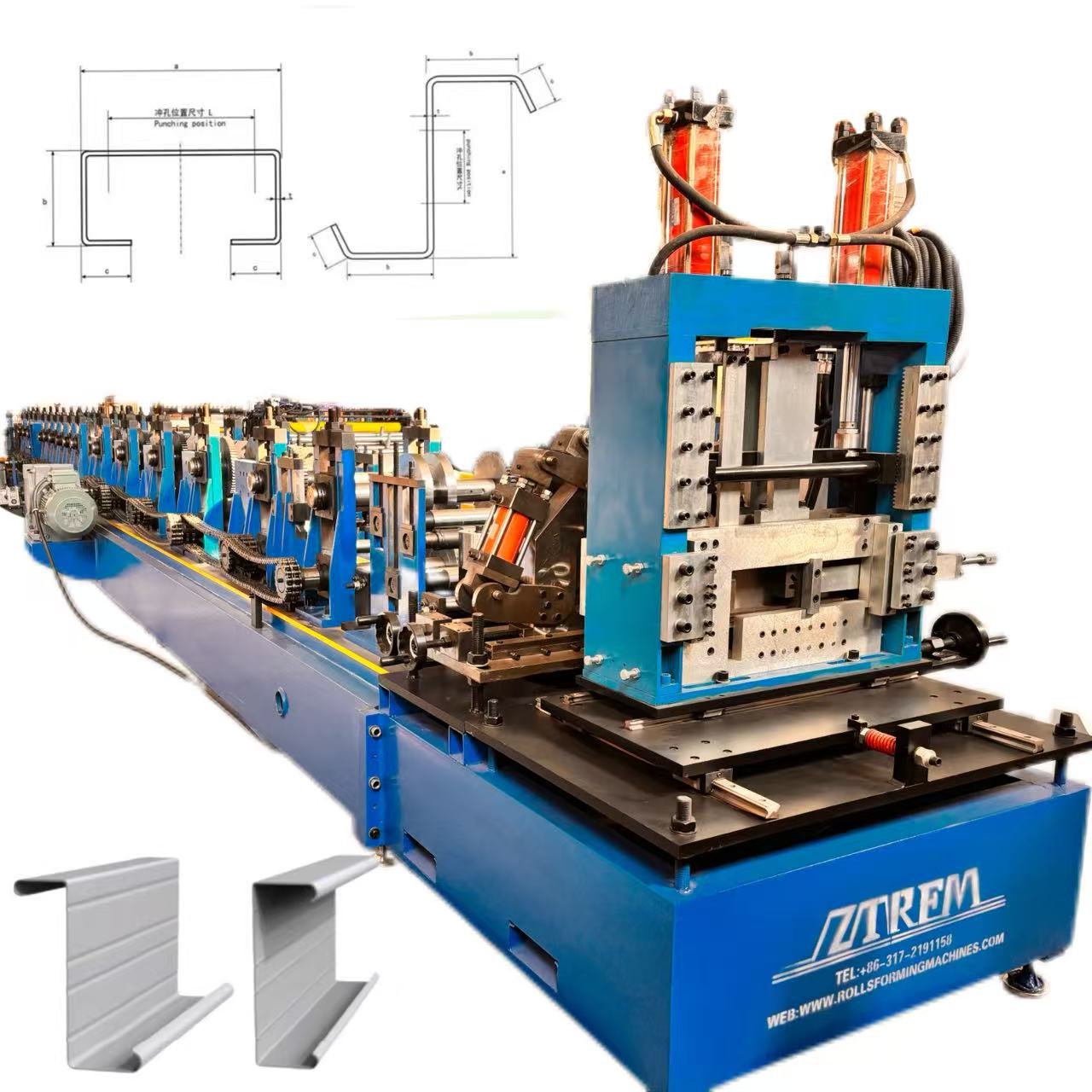

In the rapidly developing construction industry, Stainless Steel C Purlin Roll Forming Machine for Steel Structure Buildings is becoming a key force driving the dual improvement of efficiency and quality. As a professional manufacturer of C Purlins, our equipment uses rollers to cold bend steel plates or strips into C Purlins, which are widely used in industrial plants, warehouses, exhibition halls and other building structures.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

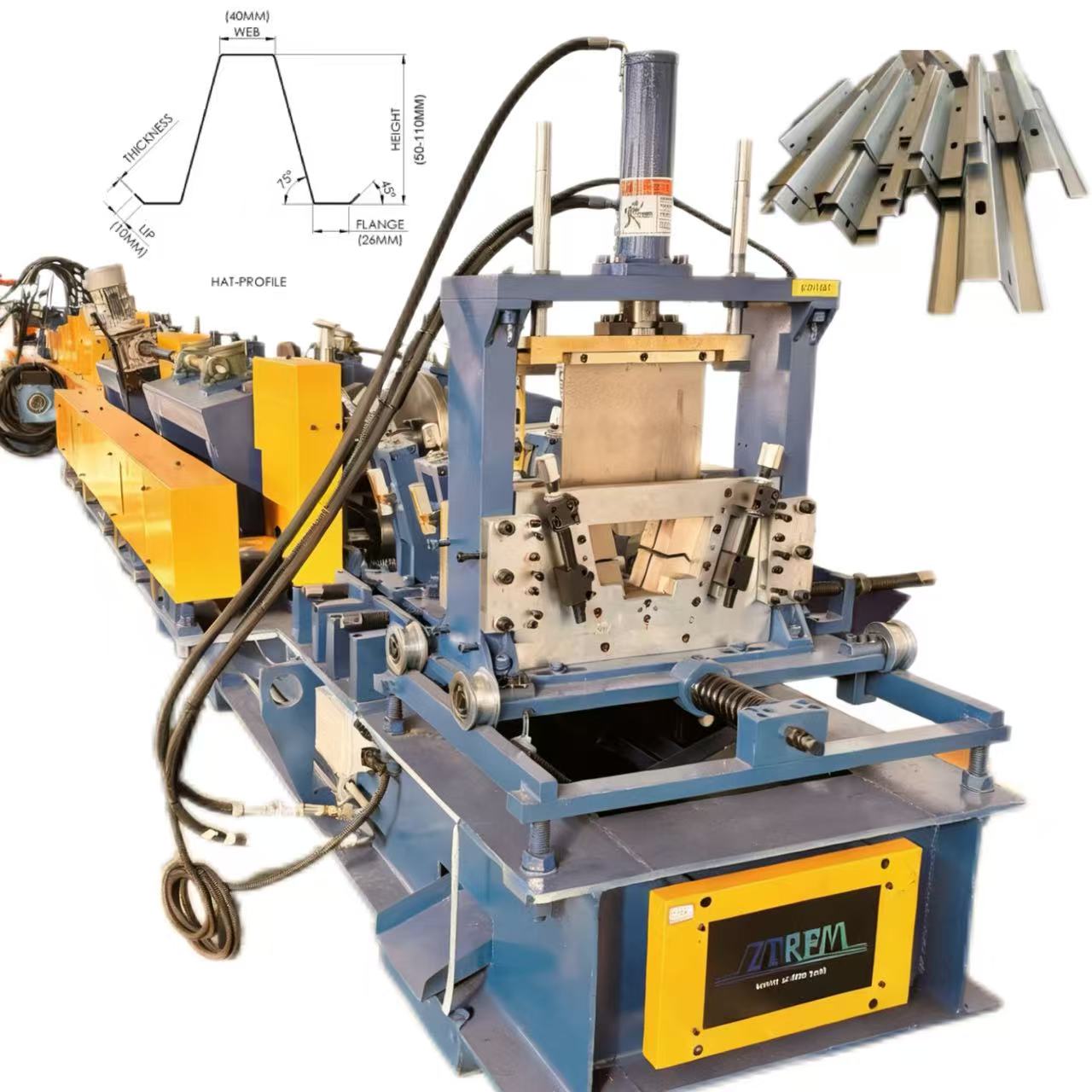

Profile drawing as below:

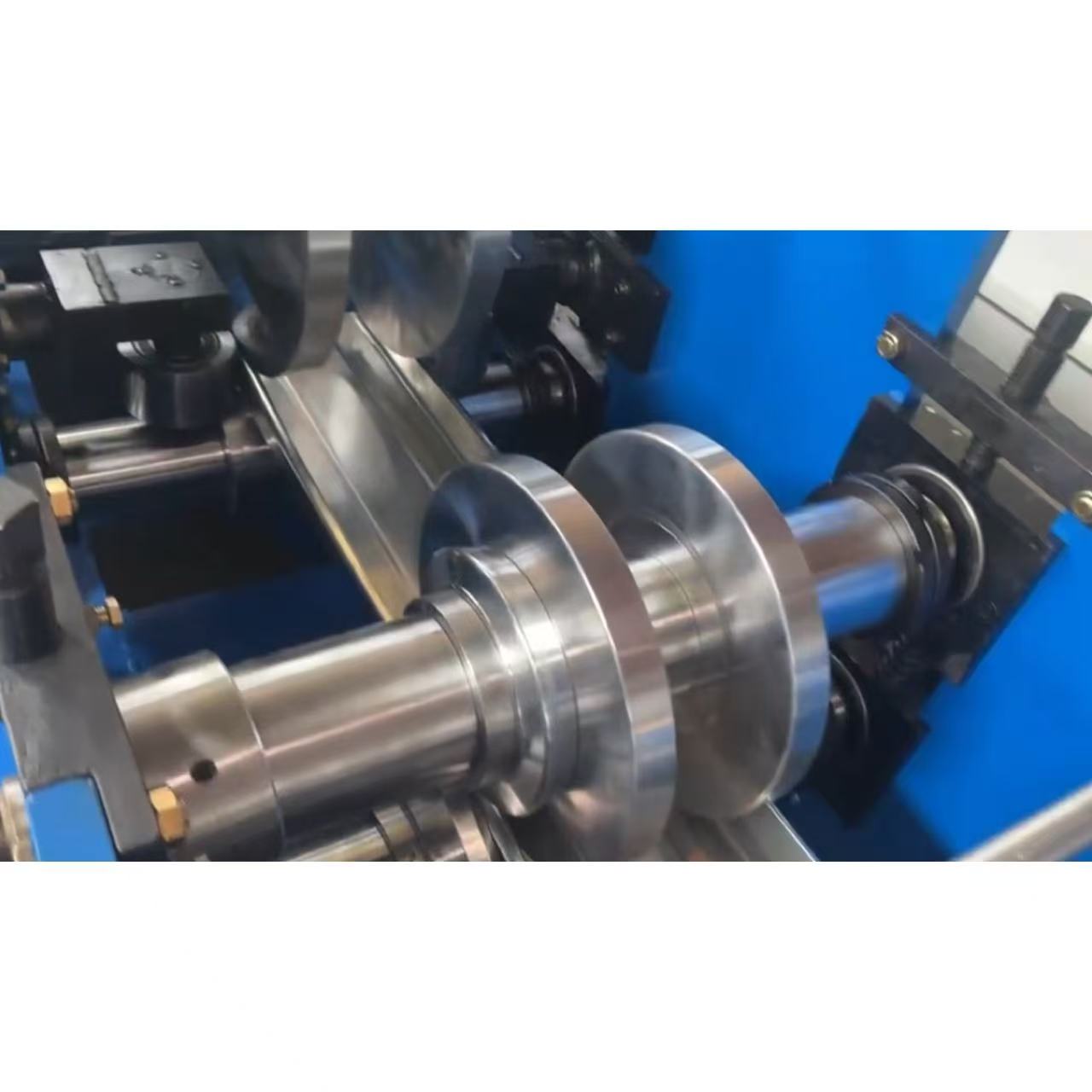

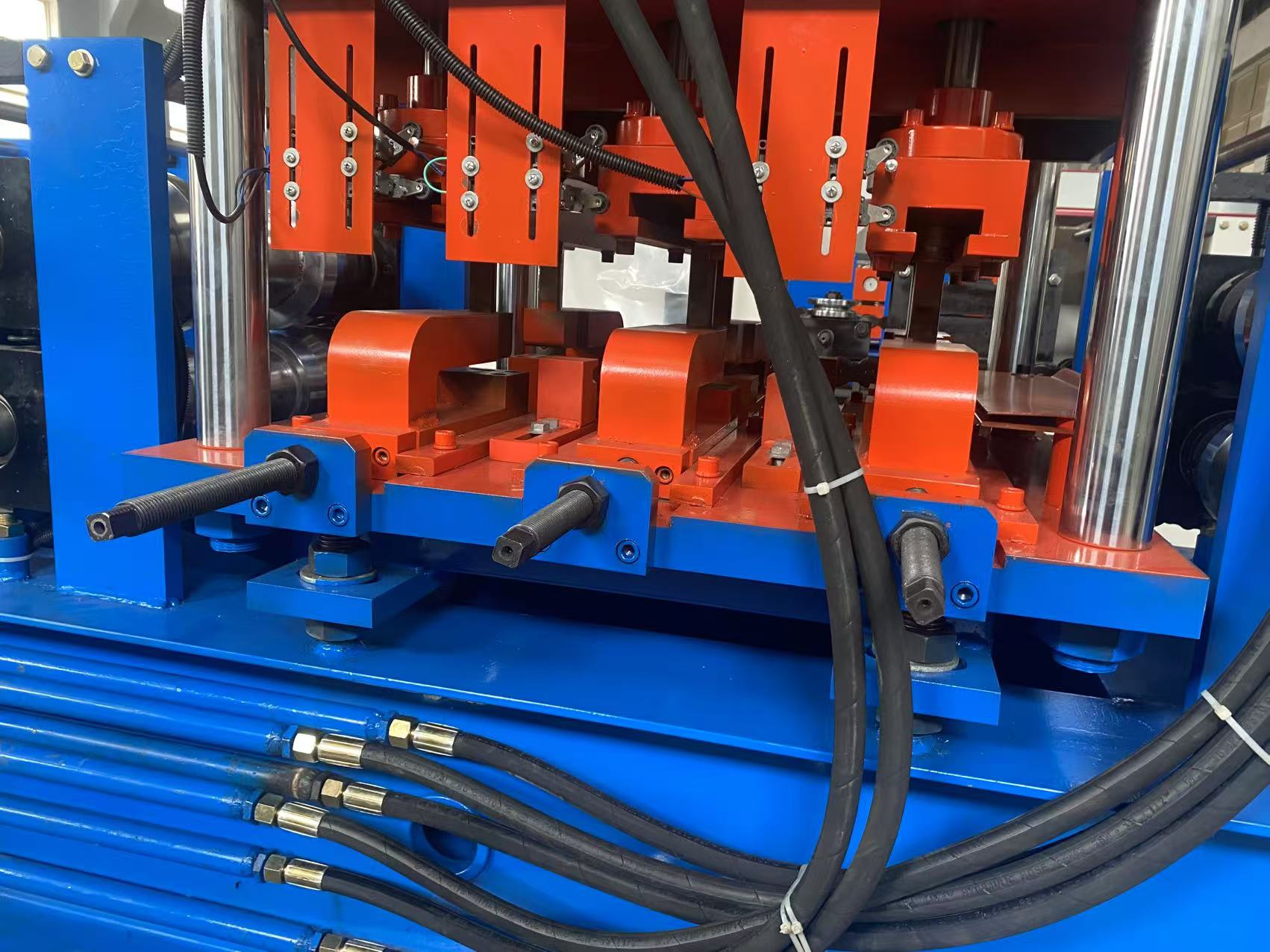

Equipment core advantages: efficiency, precision, and durability

1. Automation and efficient production

The core advantage of Stainless Steel C Purlin Roll Forming Machine lies in its high degree of automation. From the feeding and leveling of raw material rolls, to continuous punching and forming, and then to fixed length cutting, the entire process is fully automated.

2. Precise molding and quality control

The equipment adopts multi pass rolling mill continuous rolling technology to ensure high accuracy and small deformation when the material is bent into a C-shaped section. The molding speed is usually 8-9 meters per minute, balancing efficiency and quality. The punching device accurately punches installation holes on the material, reducing subsequent processing steps. The hydraulic station and computer control system provide stable power and precise process control to ensure product consistency.

3. Durability and long-term value

The rolling mill adopts bearing steel (GR15) forging and annealing treatment, which has excellent wear resistance and extends the service life of the equipment. The passive loading rack and leveling device are designed to be sturdy and suitable for high-intensity production environments. The cutting device ensures accurate length of the finished product and reduces material waste.

Finished product image:

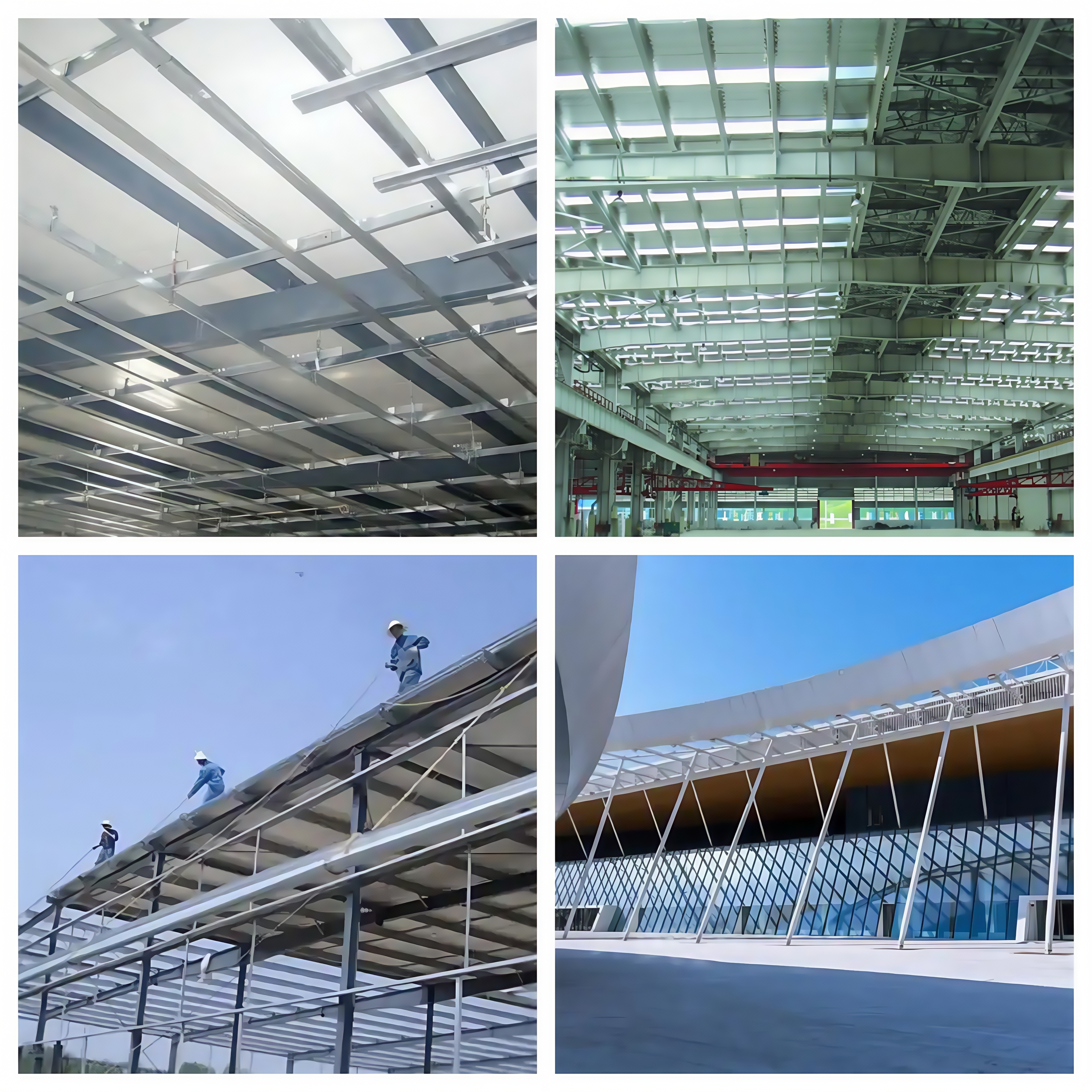

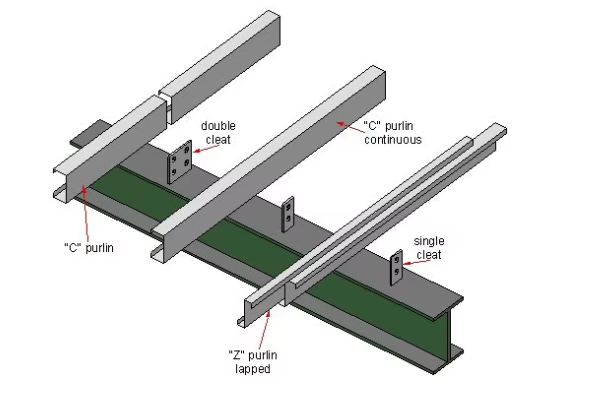

Application scenario: Widely covering building needs

1. Traditional architecture field

The purlins produced by C-shaped steel equipment are widely used in the roof and wall structures of industrial plants, warehouses, and exhibition halls. Its lightweight design reduces building load while providing high strength and stability. In lightweight steel structure buildings, serving as beam column supports enhances the overall structural stability.

2. Expansion into Emerging Markets

With the rise of green energy, C-shaped steel equipment plays an important role in the production line of photovoltaic brackets. Photovoltaic brackets require lightweight and durable materials, and C-shaped steel purlins perfectly meet the requirements.