Standing seam multi-seam roofing panel rolling machine is designed to make roofing panel in batch fully automatically.

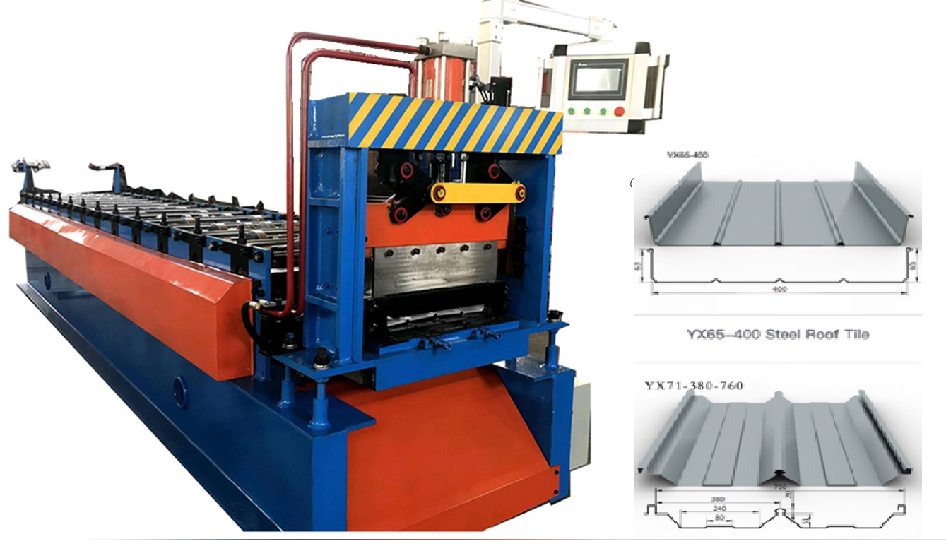

Standing seam multi-seam roofing panel rolling machine

Standing seam multi-seam roofing panel rolling machine is designed to make roofing panel in batch fully automatically. Single Length Sheet up to 100 mts. The Multi-Seam sheets are custom rolled to any transportable length maximum up to 13 meters. Zhongtuo On-Site Roll Forming enables single length sheet up to 100mts long, without end laps. Here is the drawing profile for your reference:

Advantages of Standing seam multi-seam roofing panel:

Multi-Seam Roof System is a steel membrane like structure covering entire building with panels joined together with a double lock standing seam and a uniquely designed clip formed into the seam at the building site in a unique manner that requires no

through fasteners or holes. The panels are joined and sealed together by a portable electric seamer.

This roof system is attached to the building with a unique clip arrangement that requires no through panel fasteners yet is securely attached to prevent wind blow off while allowing the roof sheet to move up to 60 mm with thermal expansion and

contraction without sacrificing structural integrity.

- Double lock seam-WEATHER TIGHHT:

Standing seam multi-seam roofing panel are permanently seamed together with a full 3600 double lock seam to keep moisture out and designed as water and dust barrier. The raised seam assists drainage by the following tools:

Easy to installation:

Roof clips securely attach the roof panels to the supporting structural by stainless steel

tabs which are roll formed into the panel seam.Stainless steel tabs are 50% stronger than other galvanized standing seam tabs.

The clip design allows for 32 mm of movement in either direction to accommodate

expansion and contraction forces. This permits buildings up to 500 feet wide without the need for special expansion joints.

Now comes to the Standing seam multi-seam roofing panel rolling machine design:

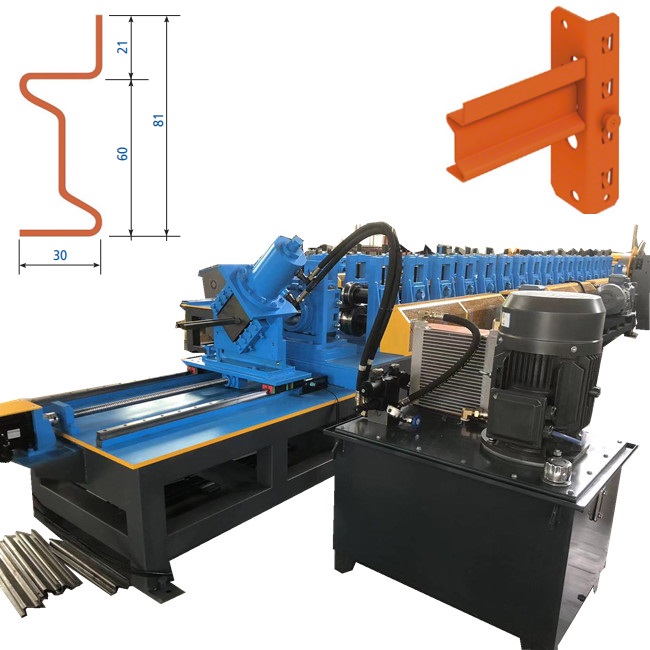

For this Standing seam multi-seam roofing panel rolling machine design we have two types:

Option A: Onsite operation rolling machine, powered by hydraulic station, not depends on electricity.

Option B: Normally running machine at workshop, higher speed.

For both two types, ZHONGTUO cold rolling forming machinery also can supply for you.

For those machines, if you want to know more information, please contact us at any time.