In modern architecture and manufacturing, steel structures have become a widely used structural form due to their advantages of high strength, light weight, and convenient construction. As an important component of steel structures, CZ steel plays a crucial role in supporting and connecting various types of buildings and industrial facilities. As the core equipment for producing CZ steel, the performance and technical level of CZ steel machines directly affect the quality and production efficiency of CZ steel, and play a crucial role in the development of the industry.

Working principle

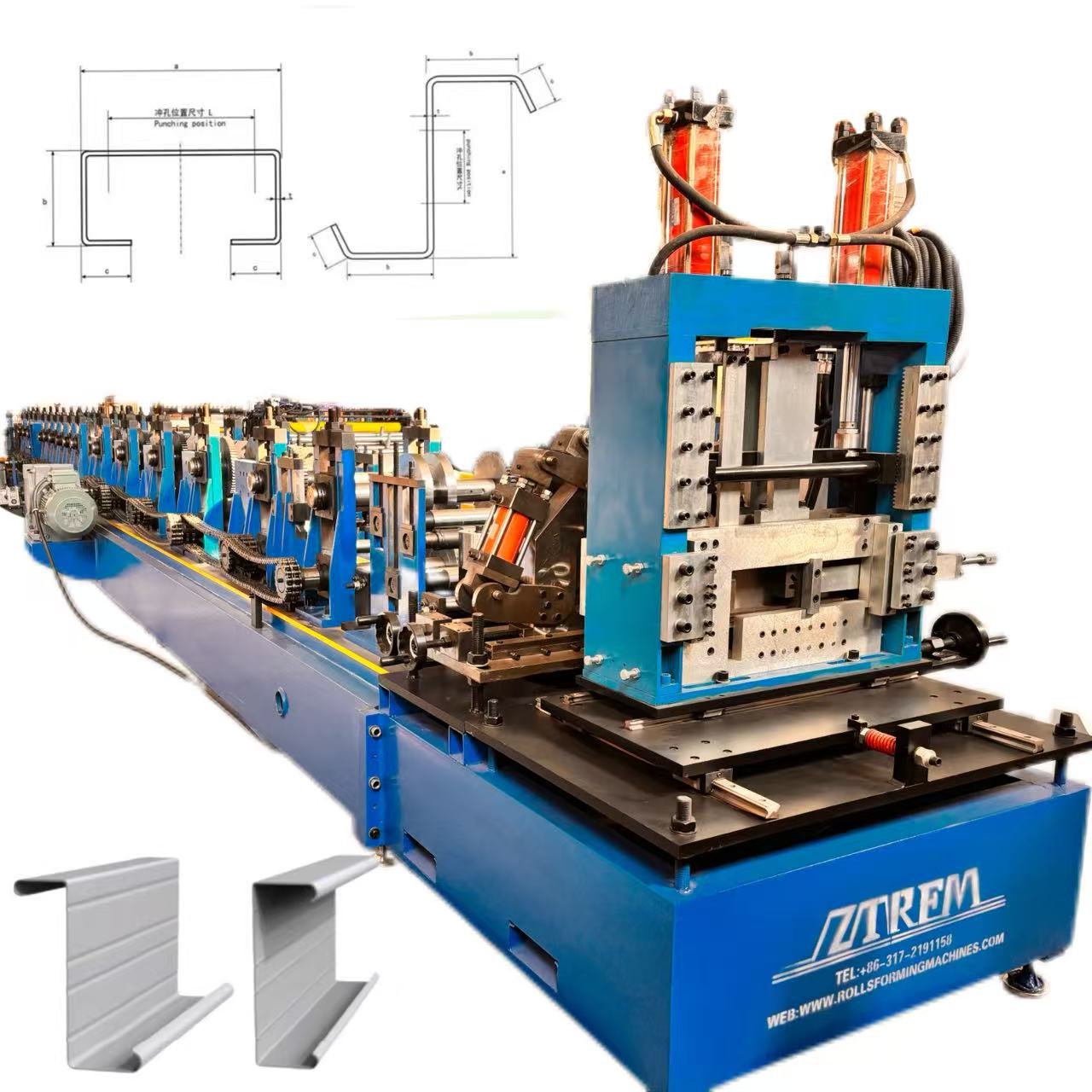

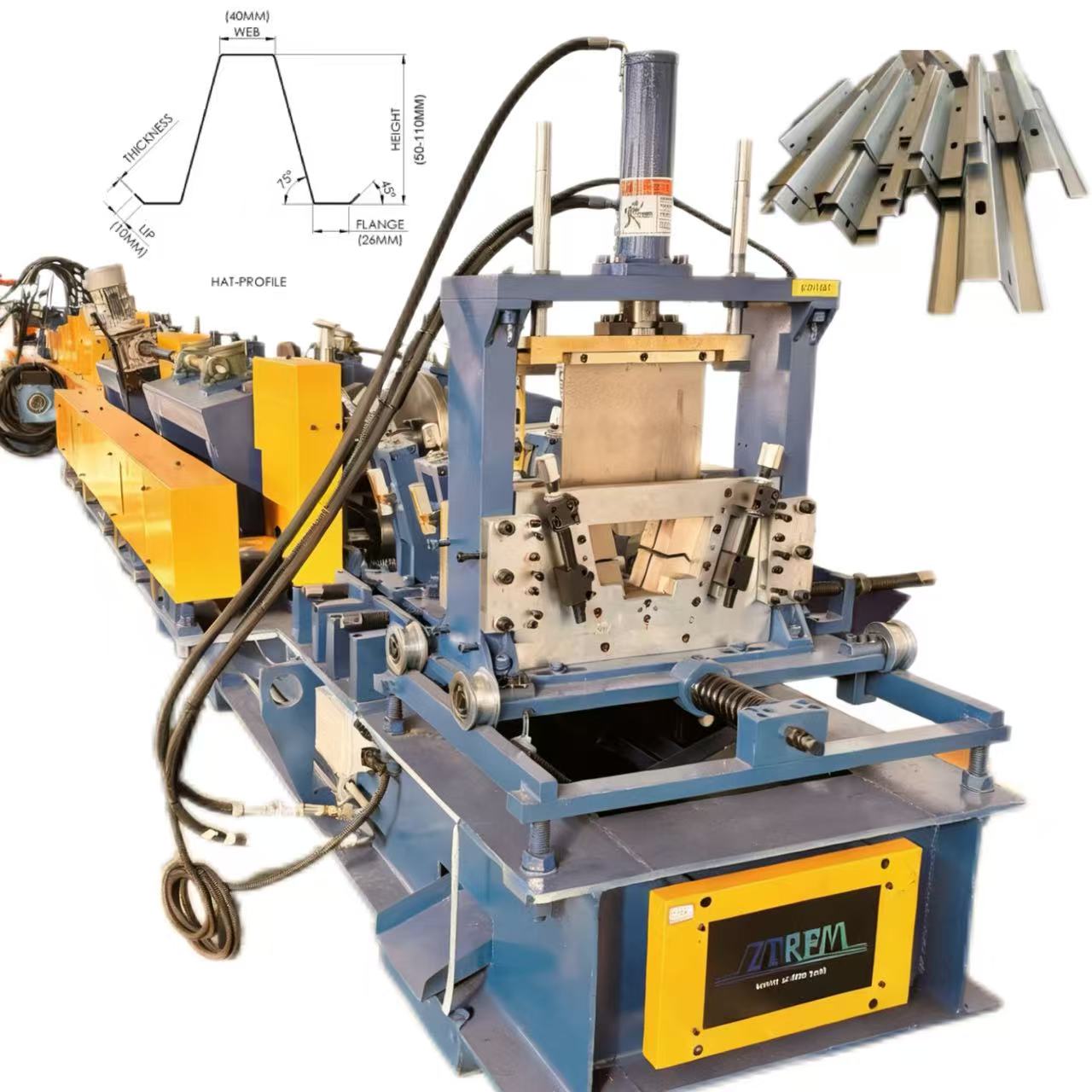

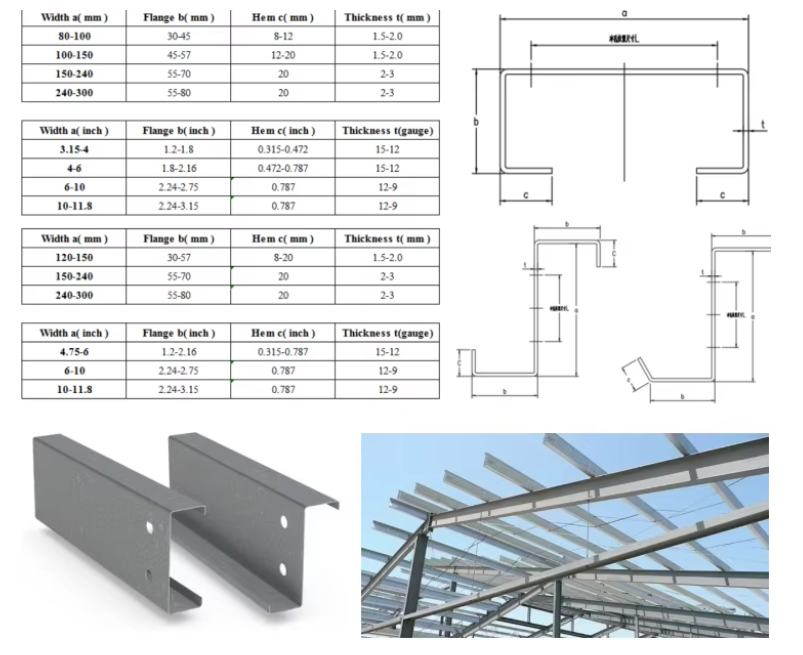

The CZ steel machine mainly operates based on cold bending forming technology. After the equipment is started, the coiled steel strip is first smoothly unfolded by the unwinding machine and accurately fed into the leveling machine through the guiding device. The leveling machine uses multiple sets of rollers to apply pressure to the steel strip, eliminating the unevenness generated during rolling and transportation, ensuring that the steel strip enters the subsequent processing stage in a flat state. Subsequently, the steel strip enters the forming unit of the main engine. The host is the core component of the CZ steel machine, with multiple carefully designed sets of rollers arranged and combined according to the pre-set C-shaped or Z-shaped cross-sectional shape. When the steel strip passes through the forming unit, it gradually undergoes plastic deformation under the continuous cold bending action of the rolling mill, ultimately forming the required basic shape of CZ steel. To meet the diverse needs of different users for CZ steel specifications, some advanced CZ steel machines are also equipped with CNC systems. Operators can precisely adjust parameters such as roll spacing and angle through programming, achieving the production of CZ steel with different web heights, flange widths, and thicknesses. After completing the forming process, CZ steel will be transported to the cutting device. The cutting device precisely cuts continuous CZ steel according to the set length using high-speed cutting tools to obtain finished products that meet the size requirements. Throughout the entire production process, the automation control system monitors the real-time operation status of the equipment, such as the conveying speed, forming pressure, and cutting accuracy of the steel strip, to ensure the coordinated operation of each process and the stable and efficient production of high-quality CZ steel products.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Application scenarios

1.In the field of architecture:

CZ steel is often used as roof and wall purlins in industrial plant construction. Its good structural strength and load-bearing capacity can support roof and wall covering materials, ensuring the stability of the plant. In warehouse construction, the use of CZ steel can effectively improve space utilization and is easy to install, enabling the rapid construction of sturdy storage structures. In terms of residential buildings, especially some light steel villas, CZ steel as the main structural material not only reduces the weight of the house, but also meets diverse building design needs due to its flexible design characteristics. At the same time, it has good seismic performance, providing residents with a safe and comfortable living environment.

2.Agricultural facilities:

In the construction of agricultural greenhouses, CZ steel can be used to make the skeleton of the greenhouse. Its corrosion resistance (if produced with galvanized steel strip) can adapt to humidity changes in agricultural environments and extend the service life of greenhouses. Moreover, the shape and size of CZ steel can be customized according to the requirements of greenhouse design, making it easy to build agricultural greenhouses of different sizes and shapes, providing a suitable spatial environment for crop growth.

3.Transportation:

In some temporary or movable transportation facilities, such as toll booths on highways and temporary fences on construction sites, CZ steel has become an ideal structural material due to its lightweight, easy to install, and reusable characteristics. The structure constructed with CZ steel can be quickly assembled and disassembled to meet the temporary and flexible needs of transportation facilities.

Advantages

1.High production efficiency:

The CZ steel machine adopts an automated production process, from strip unwinding, leveling, forming to cutting, the entire process can be operated continuously, greatly shortening the production cycle. Compared to traditional manual processing or semi-automatic equipment, production efficiency has been significantly improved. For example, in large-scale construction projects, high-speed CZ steel machines can quickly supply the required CZ steel materials to ensure project progress.

2.High product accuracy:

Advanced CNC systems and precise rolling processes enable CZ steel machines to produce products with extremely high dimensional accuracy. Whether it is the height of the web plate, the width of the flange, or the length dimension, they can all be strictly controlled within the specified tolerance range. High precision products are beneficial for improving the installation quality of steel structures, reducing on-site repair workload, and lowering construction costs.

3.High material utilization rate:

The CZ steel machine is designed with full consideration for the rational utilization of materials, and by optimizing the forming process and mold design, the waste generated during the production process is reduced. While meeting the requirements of different specifications of products, it can maximize the utilization of steel strips, reduce raw material costs, and conform to the concept of sustainable development.

4.Product diversification:

With the flexible programming function of the CNC system, CZ steel machines can quickly switch between producing different specifications of C-shaped and Z-shaped steel, and even customize non-standard products according to customers’ special requirements. The diversified production capacity of this product enables enterprises to better adapt to market demand and expand their business scope.

Maintenance points

1.Roll maintenance:

Roll is a key component of CZ steel machine, which directly affects the quality of product forming. In daily maintenance, it is necessary to regularly check the surface of the rolling mill for wear, scratches, or deformation. Every certain production cycle, the rollers should be cleaned and lubricated, and special lubricants should be applied to the surface of the rollers to reduce friction and extend their service life. If severe wear is found on the rolling mill, it should be replaced in a timely manner to ensure the dimensional accuracy and forming quality of the product.

2.Maintenance of transmission system:

The transmission system of the machine includes components such as chains, gears, reducers, etc. Regularly check the tension of the chain to ensure smooth operation without looseness or jamming. Lubricate the gears to prevent gear wear and noise generation. The gearbox needs to regularly replace the lubricating oil, check whether the oil level is normal, observe whether there is abnormal heating or vibration during the operation of the gearbox, and promptly investigate and handle any problems to ensure the stable operation of the transmission system and provide reliable power transmission for the equipment.

3.Electrical system maintenance:

The electrical system of CZ steel machines is complex, involving numerous sensors, controllers, motors, and other equipment. Regularly clean the dust inside the electrical cabinet to prevent dust accumulation from affecting the performance of electrical components. Check if all electrical connections are loose to ensure reliable circuit connections. Backup the parameters of the control system to prevent equipment failure caused by parameter loss. At the same time, regularly maintain the motor, check its operating current, temperature and other parameters to ensure normal operation.

4.Lubrication system maintenance:

The lubrication system of the equipment is crucial for the normal operation of all moving parts. Regularly check the working status of the lubrication pump to ensure that the lubricating oil can be delivered to each lubrication point normally. When replacing lubricating oil, choose oil that meets the equipment requirements and thoroughly clean the lubrication system to prevent impurities from entering, ensure lubrication effect, and reduce equipment wear.

With the continuous advancement of technology, CZ steel machines are also constantly innovating and developing. In the future, intelligence and automation will become its main development trends. For example, by introducing artificial intelligence technology, devices can achieve self diagnosis and fault warning, detect potential problems in advance and perform automatic repairs, further improving the stability and reliability of production. At the same time, more energy-efficient and environmentally friendly technologies will also be applied to CZ steel machines, reducing energy consumption and minimizing environmental impact, providing strong support for the sustainable development of the steel structure industry.