Steel Panel Type MZ Profile Roll Forming Machine Widely used in Vietnam

The demand for high-quality, high-tech, environmentally friendly and energy-saving building materials in the Vietnamese market is increasing, and technological innovation is becoming increasingly important. The Steel Panel Type MZ Profile Roll Forming Machine, as a key equipment for producing environmentally friendly and energy-saving building materials, has also become increasingly popular in the Vietnamese market.

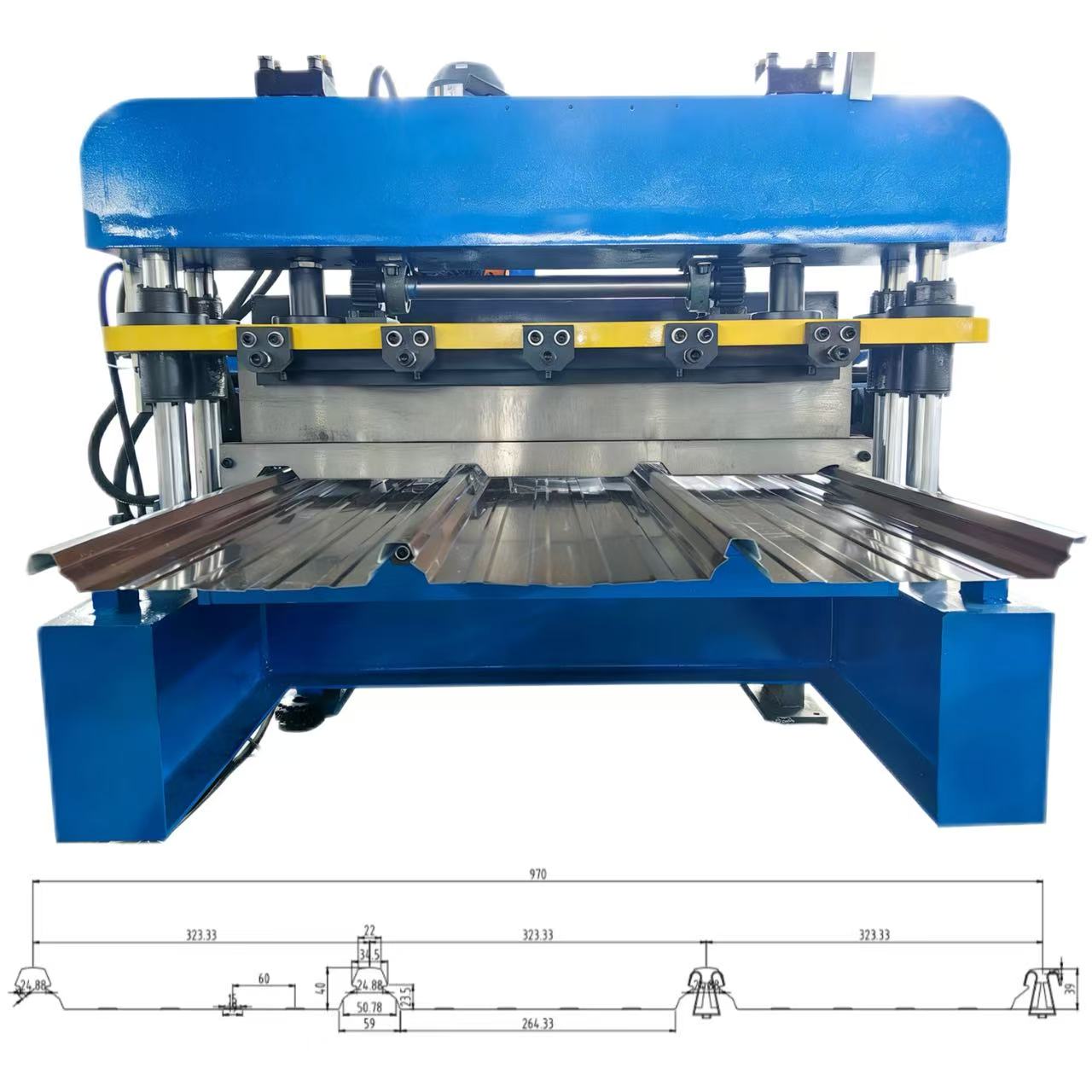

Type MZ Profile drawing:

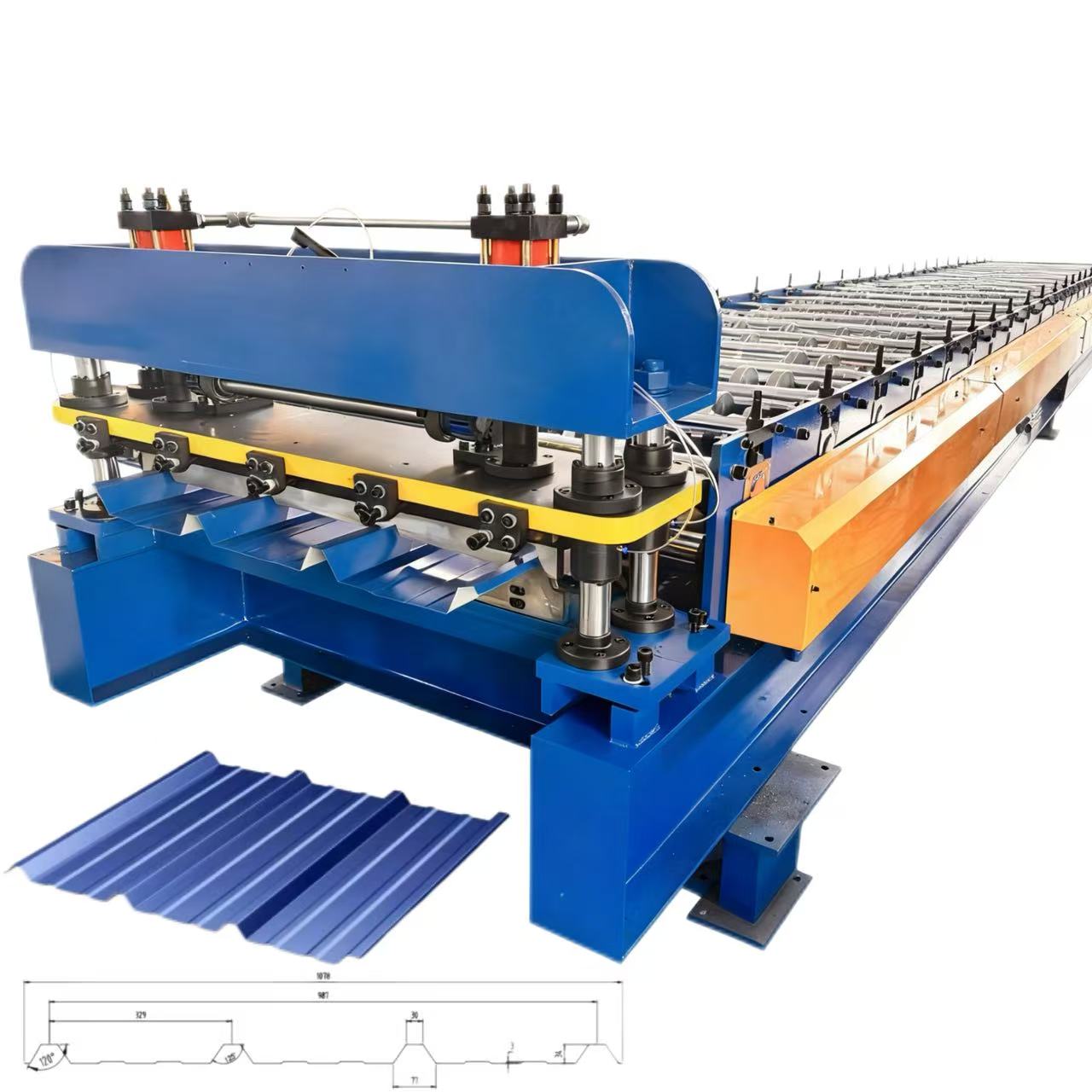

Here are photos of Steel Panel Type MZ Profile Roll Forming Machine:

We have other pattern designs for you to choose from:

Packing list of the Steel Panel Type MZ Profile Roll Forming Machine:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Steel Panel Type MZ Profile Roll Forming Machine:

| Item | Name | Specifications |

| 1 | Raw material | PPGI & GI |

| 2 | Raw material thickness | 0.5-1mm |

| 3 | Decoiler | 10T |

| 4 | Felt device | Available |

| 5 | Roller station | 34stations |

| 6 | Roller material | Gcr15 |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | High grade 45#, all shafts are tooled by grinding machine for two times to ensure the precision of final product. |

| 9 | Transmission | By double chains with cover |

| 10 | Motor power | 7.5kw |

| 11 | Machine frame | 350mm H beam structure |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 7.5kw |

| 14 | Cutting blade material | Gcr12 quenched treatment |

| 15 | Cutting tolerance | +/0.3mm |

| 16 | Control system | Delta/ Siemens PLC |