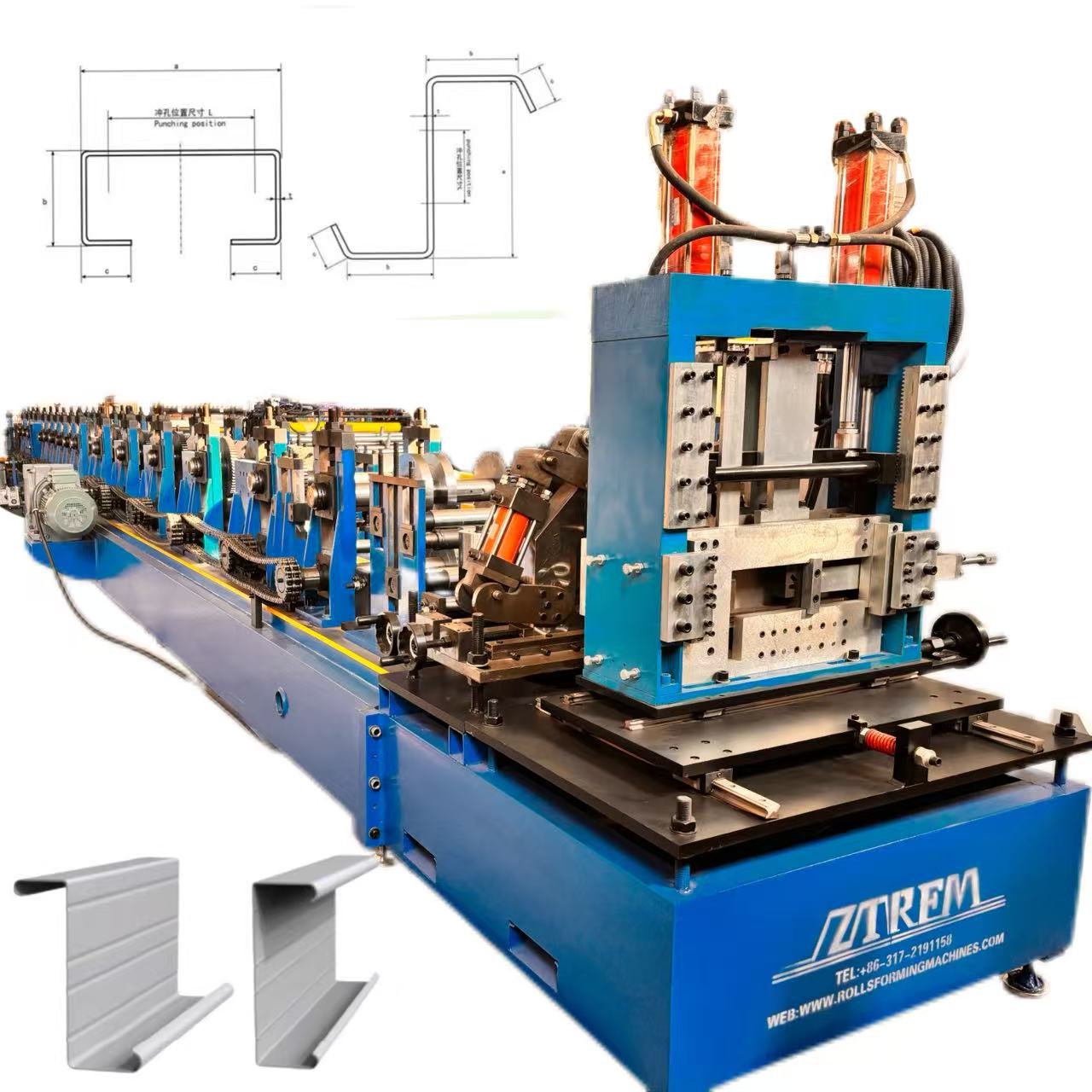

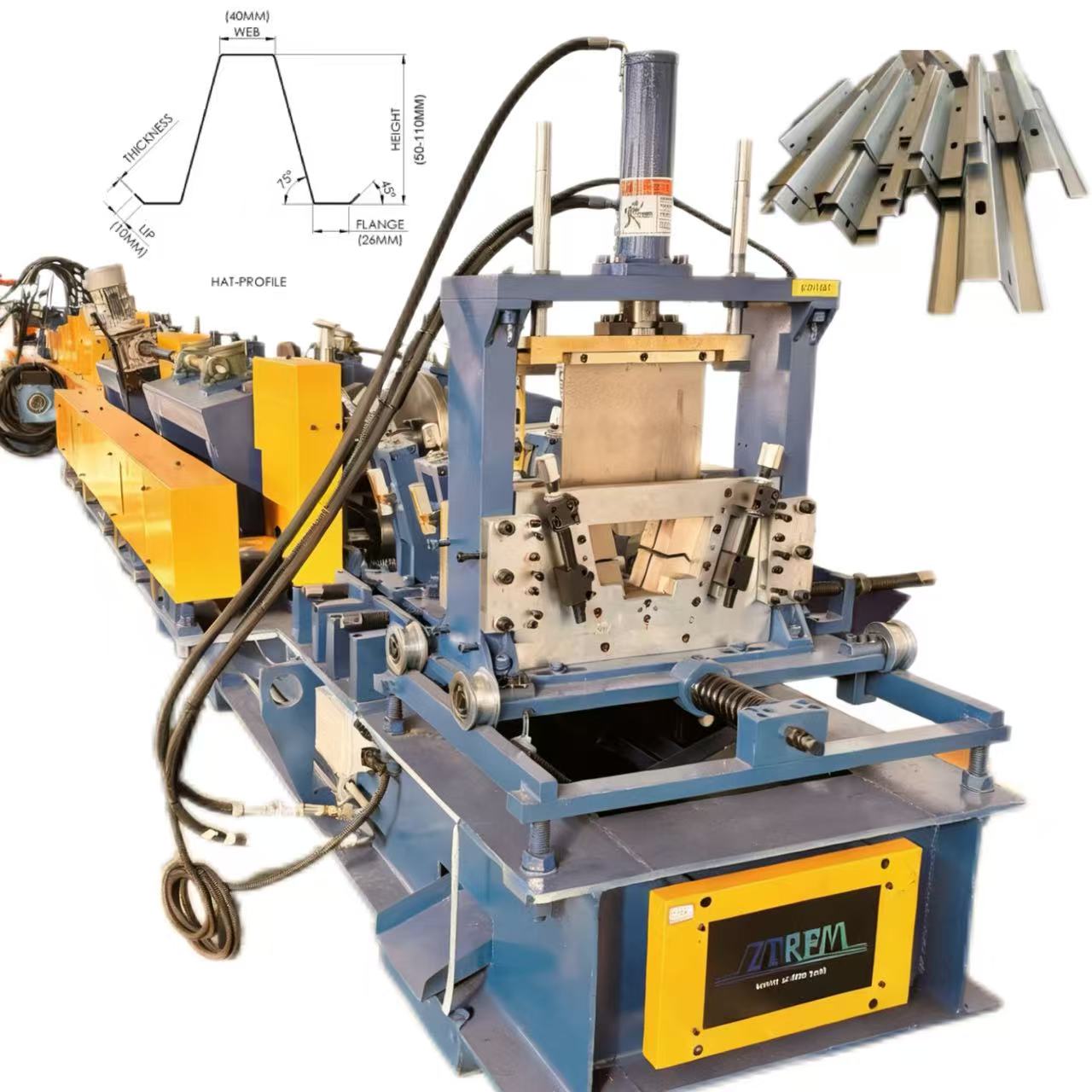

In industrial fields such as construction, mine support, and warehouse shelving, U-shaped purlin serve as critical structural materials, where their processing accuracy and production efficiency directly impact project quality and cost. As specialized cold-forming equipment, Steel U Shape Purlin Galvanized Steel Profile Strut Channel Roll Forming Machine are driving industry transformation through technological innovation.

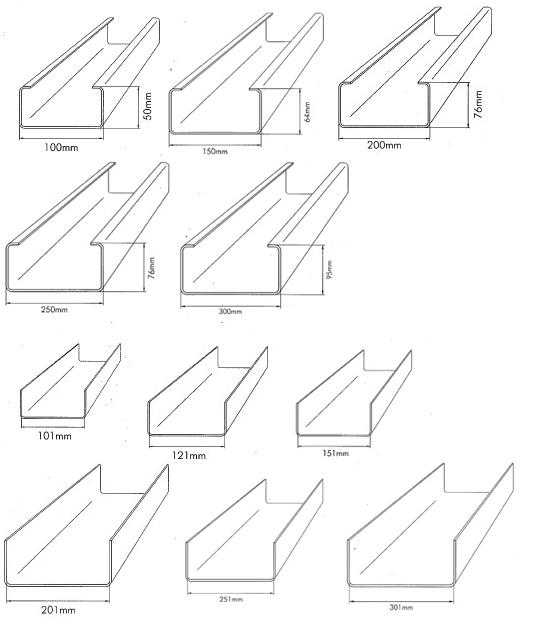

Finished product image:

Application scenario: Multi industry empowerment cases

• Construction field: the core tool for upgrading steel structures

In high-rise buildings, U-shaped steel is used to make stair treads, window frames, and beam supports.

• Mine support: a balanced solution between safety and economy

In response to the demand for roadway support, the U-shaped steel bending arch machine can quickly form arch structures.

• Warehousing and Logistics: A Benchmark Practice for Automated Production

In shelf manufacturing, U-shaped steel machines achieve continuous production of columns and guide rails.

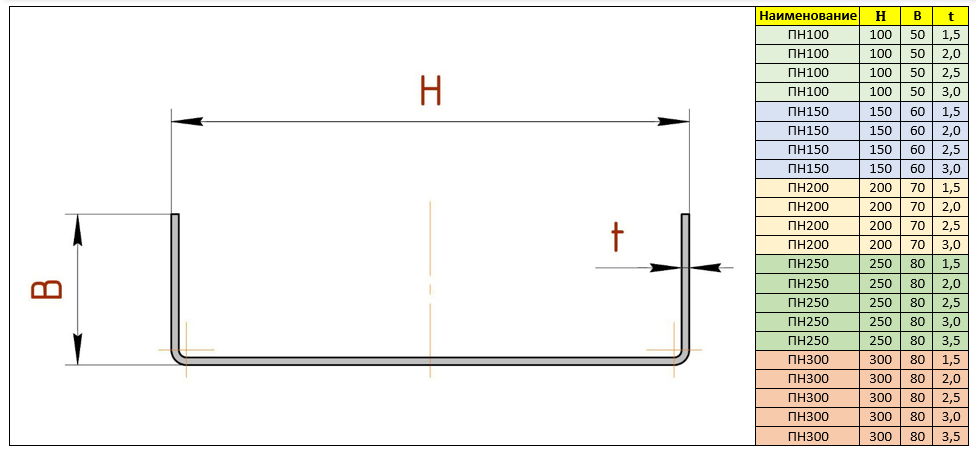

Profile drawing as below:

Equipment Advantage: Dual Breakthrough in Accuracy and Efficiency

The Steel U Shape Purlin Galvanized Steel Profile Strut Channel Roll Forming Machine uses hydraulic or mechanical pressure systems to accurately bend metal sheets into a U-shaped arc, and its core advantages are reflected in:

1.High precision molding:

using CNC programming and servo motor drive to ensure that the arc error is controlled within ± 0.5mm, meeting the strict requirements of building curtain walls, precision shelves and other scenarios.

2.Efficient production mode:

The fully automatic model integrates feeding, bending, and cutting functions, with a single shift production capacity of 300-500 pieces, which is three times more efficient than traditional processes.

3.Wide material adaptability:

Supports various materials such as carbon steel, stainless steel, aluminum alloy, etc., with a thickness range of 1.5-6mm, meeting the requirements of lightweight and high-strength.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 4.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

11KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

We also have the economic type machine with lower speed

|

||