Machine video:

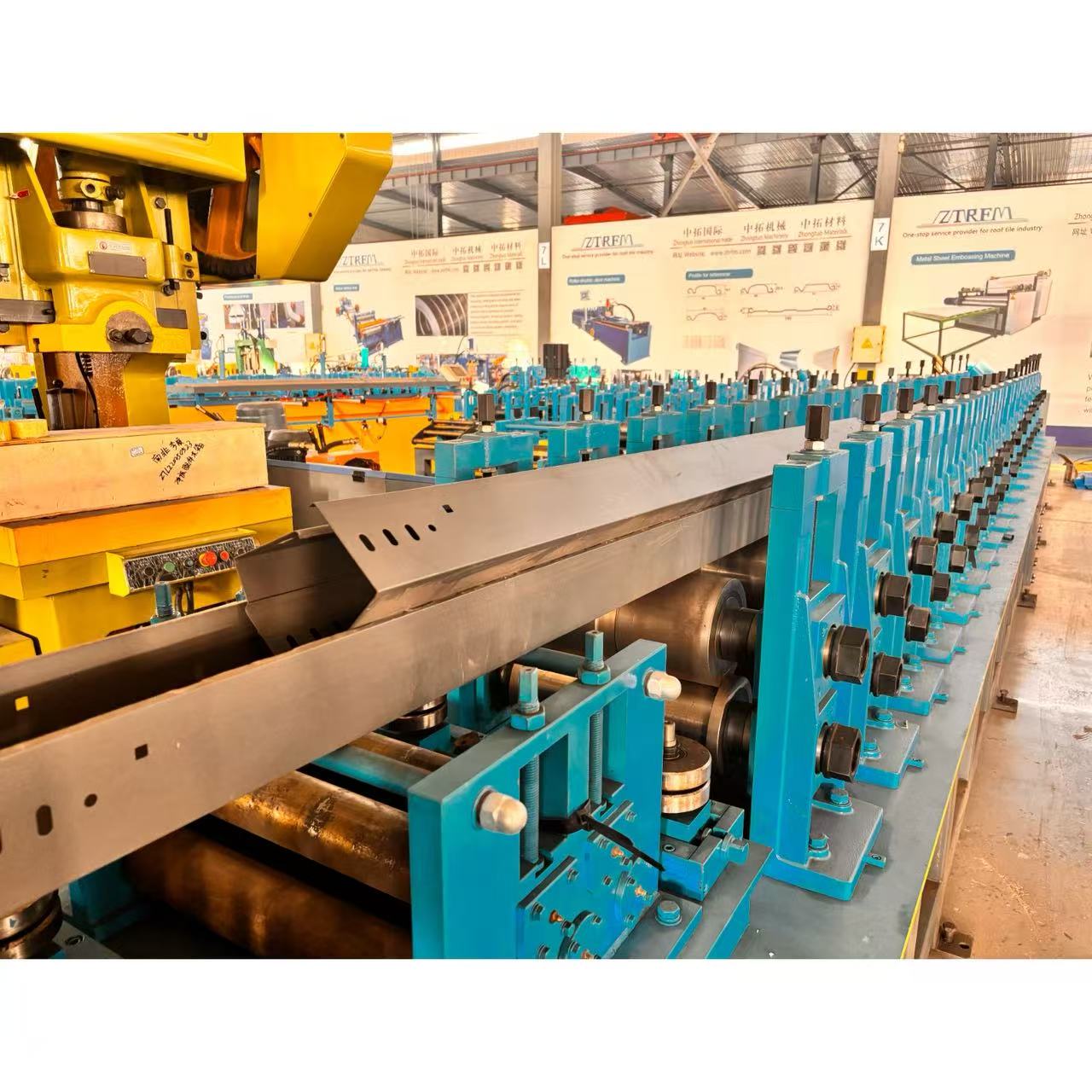

When the shelf columns become the “load-bearing skeleton” of the storage system, their cross-sectional accuracy, hole tolerance, and production efficiency directly determine storage safety and operating costs. The Supermarket Storage Rack Shelf Panel Making Machine is based on full process automation technology, accurately matching the production needs of light, medium, and heavy columns, providing an integrated solution from steel to finished products for e-commerce warehousing, logistics hubs, and manufacturing factories, making high-quality column production more efficient, flexible, and economical.

Full process automation, bidirectional optimization of production capacity and cost

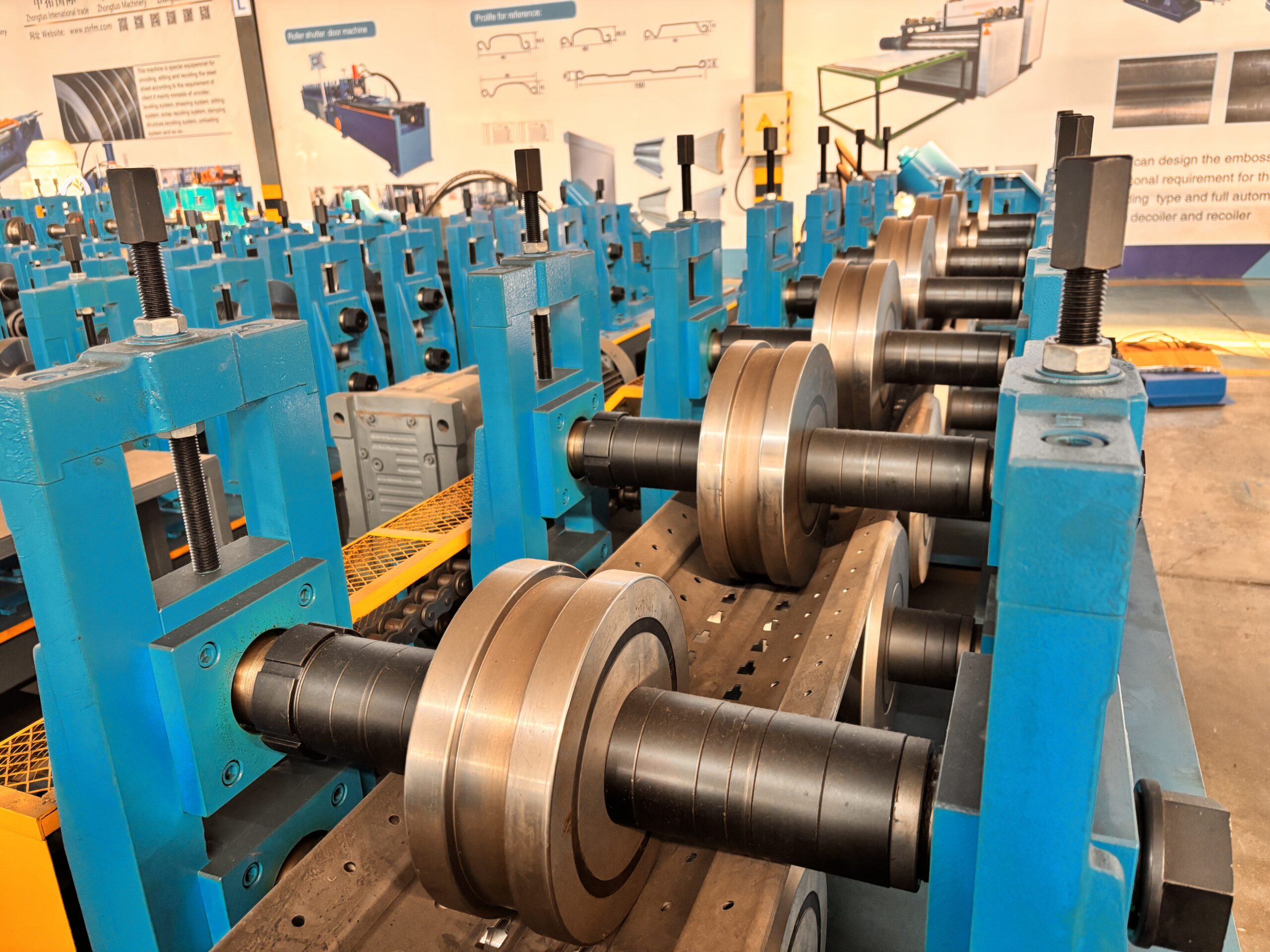

Traditional column production requires 5-6 manual processes, with low efficiency and large quality fluctuations. The molding machine achieves efficiency revolution through an integrated production line:

1.High speed continuous production:

integrating six modules including uncoiling, leveling, punching, forming, cutting, and receiving, the production speed of lightweight columns can reach 15 meters/minute, and heavy-duty columns can reach 10 meters/minute. The daily production capacity can reach up to 150 tons, which is 50% higher than traditional equipment. Taking the 50 × 30mm lightweight column commonly used in e-commerce warehousing as an example, a single production line can meet the daily production demand of 3000 sets of shelves.

2.Ultimate cost control:

The servo feeding system increases material utilization to 98%, coupled with an automatic waste recycling device, reducing steel loss by over 20 tons annually; The entire process only requires one person to operate, reducing labor costs by 70% and energy consumption per unit product by 20% compared to traditional equipment, achieving a production upgrade of “doubling production capacity and halving costs”.

3.24-hour stable operation:

using gantry independent gearbox transmission and Schneider Electric components, the failure shutdown rate is less than 0.5%, and the equipment life is over 10 years, adapting to the continuous production needs of logistics peak season and avoiding the risk of order delivery delays.

Flexible adaptation to the entire scene, responding to diversified production needs

Faced with the differentiated needs of different industries for pillars, the molding machine achieves “one machine for multiple uses” through highly flexible design:

• Multi specification quick switching:

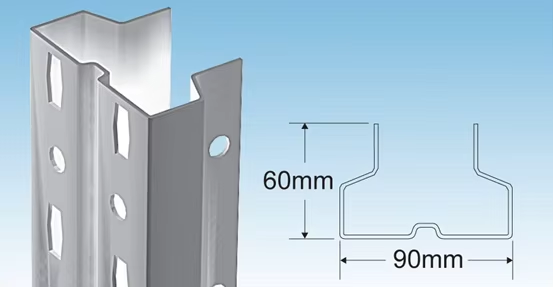

Through modular mold design, equipment parameters can be quickly adjusted to achieve production switching of columns with a thickness of 0.8-3.0mm steel and a cross-section of 50 × 30mm to 100 × 60mm. The mold changing time is shortened to within 30 minutes, making it easy to handle diversified orders for light electronic component shelves and heavy mold shelves.

• Customized production in special environments:

For special scenarios such as cold storage and chemical industry, it can be adapted to the processing of galvanized steel strip and low-temperature resistant Q345ND steel, and combined with non-destructive forming technology to ensure that the surface coating adhesion of the column meets the GB/T 9286-1998 Level 1 standard and meets the requirement of no corrosion after 48 hours of salt spray.

• Personalized process integration:

supports customized functions such as continuous dense hole punching and folded plate head forming. More than 200 production programs can be preset according to customer drawings, ranging from 3-meter short columns to 12 meter long columns, which can be accurately processed and adapted to special storage scenarios such as high-rise three-dimensional shelves and shuttle car shelves.

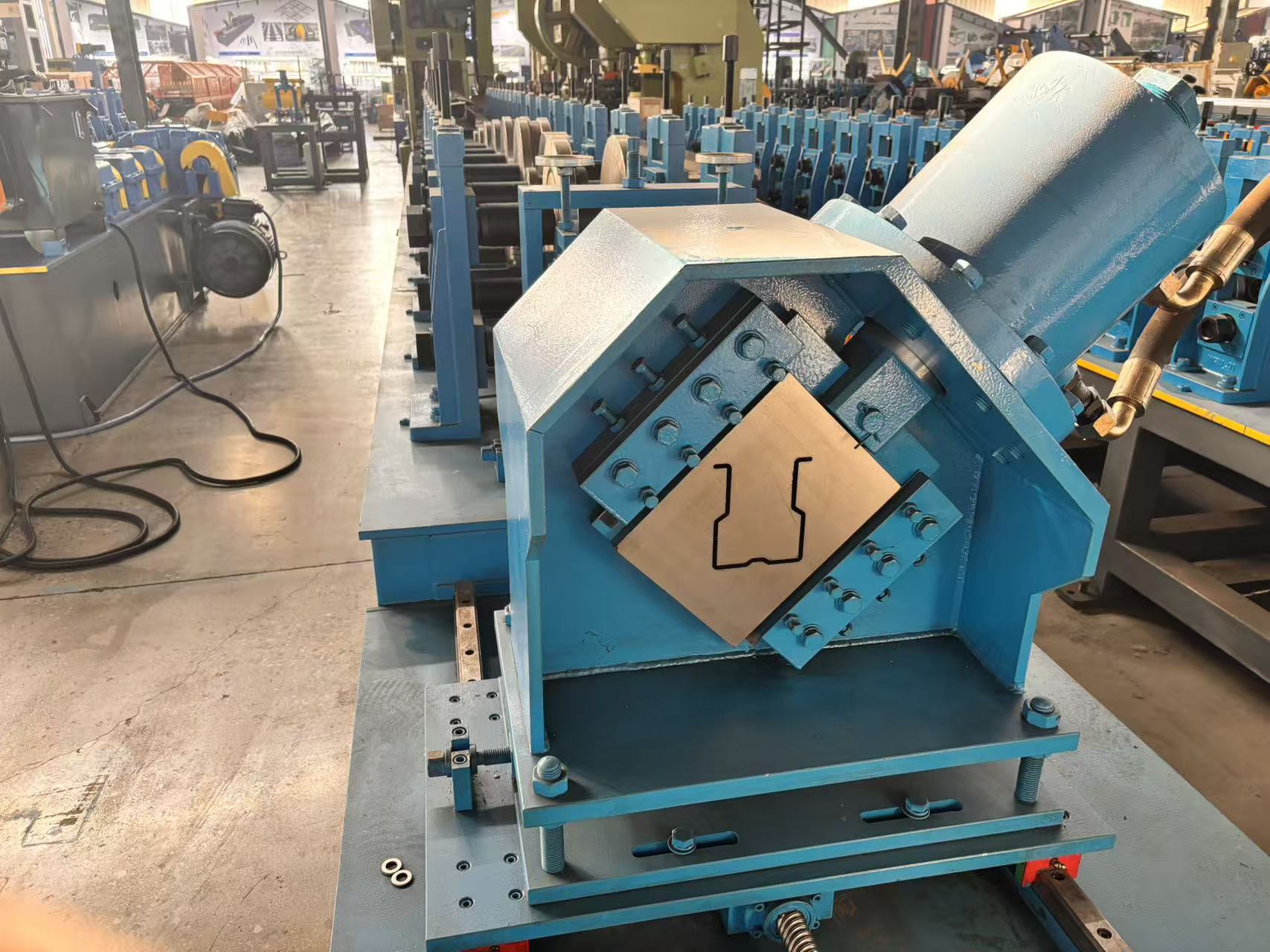

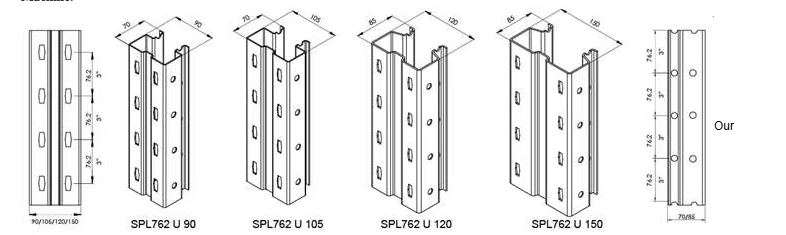

Pattern diagram:

Finished product image:

Finished product image:

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-2.7mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

will give you as free

|

||

|

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

As your requirement

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

About 75T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

customized

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Finished product image:

Finished product image: