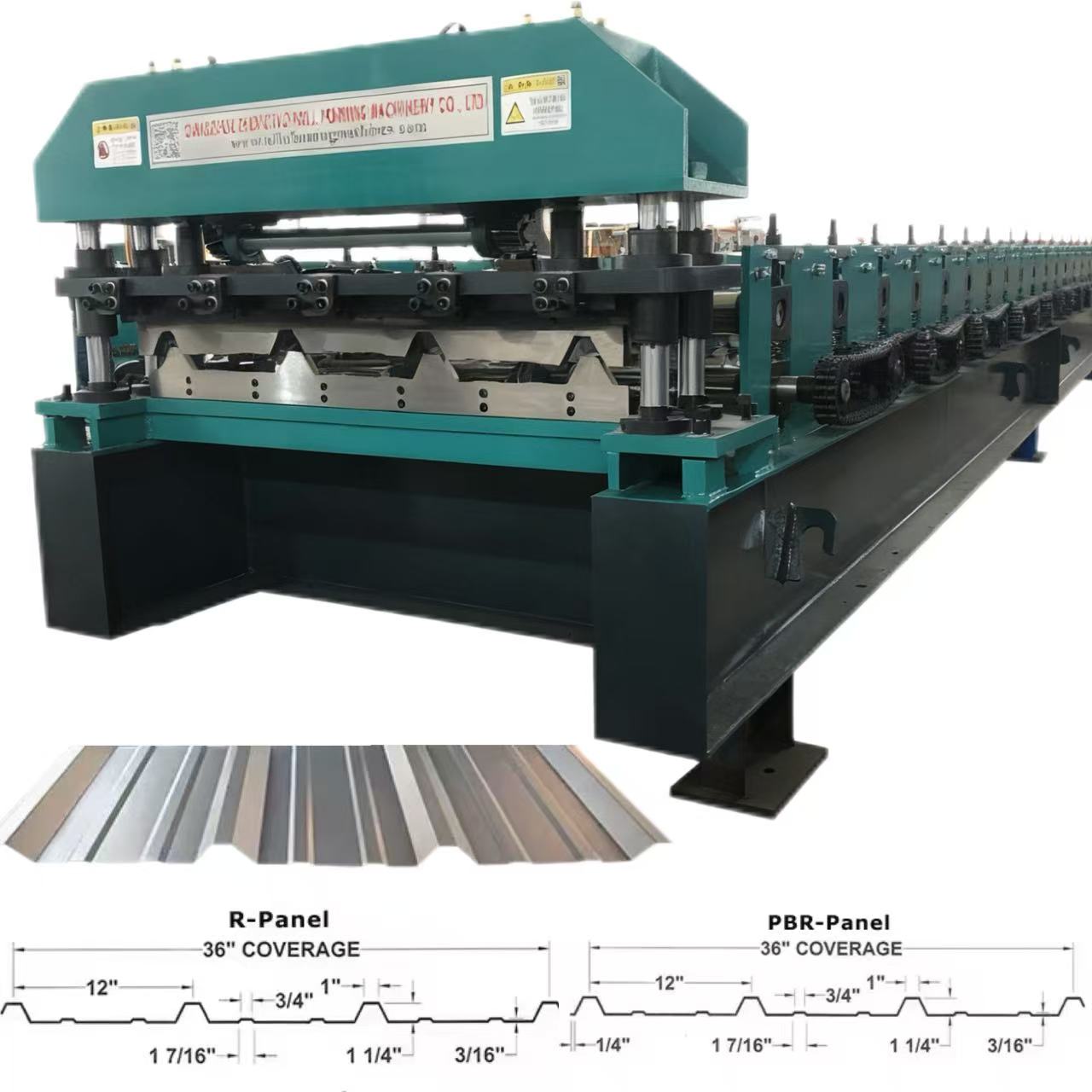

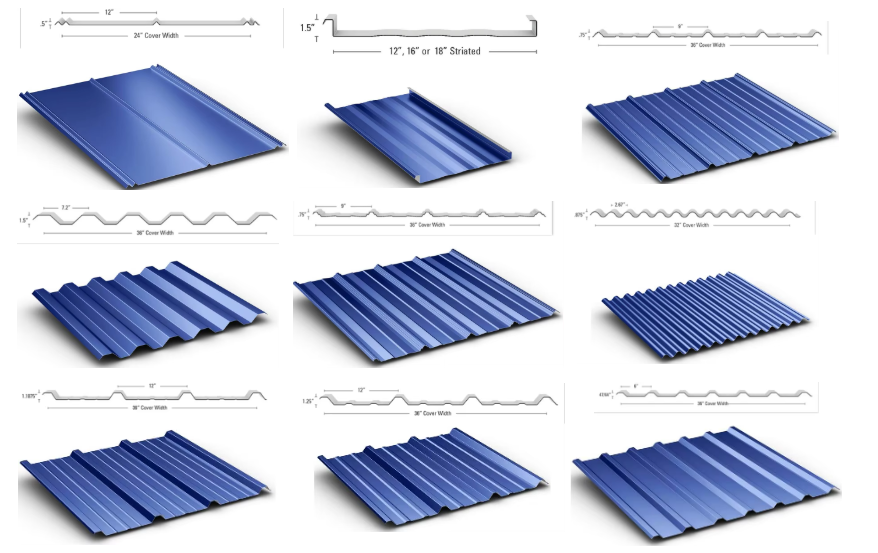

In today’s rapidly developing construction industry, roof tiles as a crucial component of buildings not only impact their aesthetic appeal but also directly influence durability and functionality. Traditional tiles face issues such as complex installation and high maintenance costs, while trapezoidal roof tiles have emerged as a modern favorite due to their unique structural advantages. As the core tool for producing this innovative product, Full Automatic Galvanized Tile Trapezoid Roofing Sheet Roll Forming Machine is driving the transformation and upgrading of the construction industry.

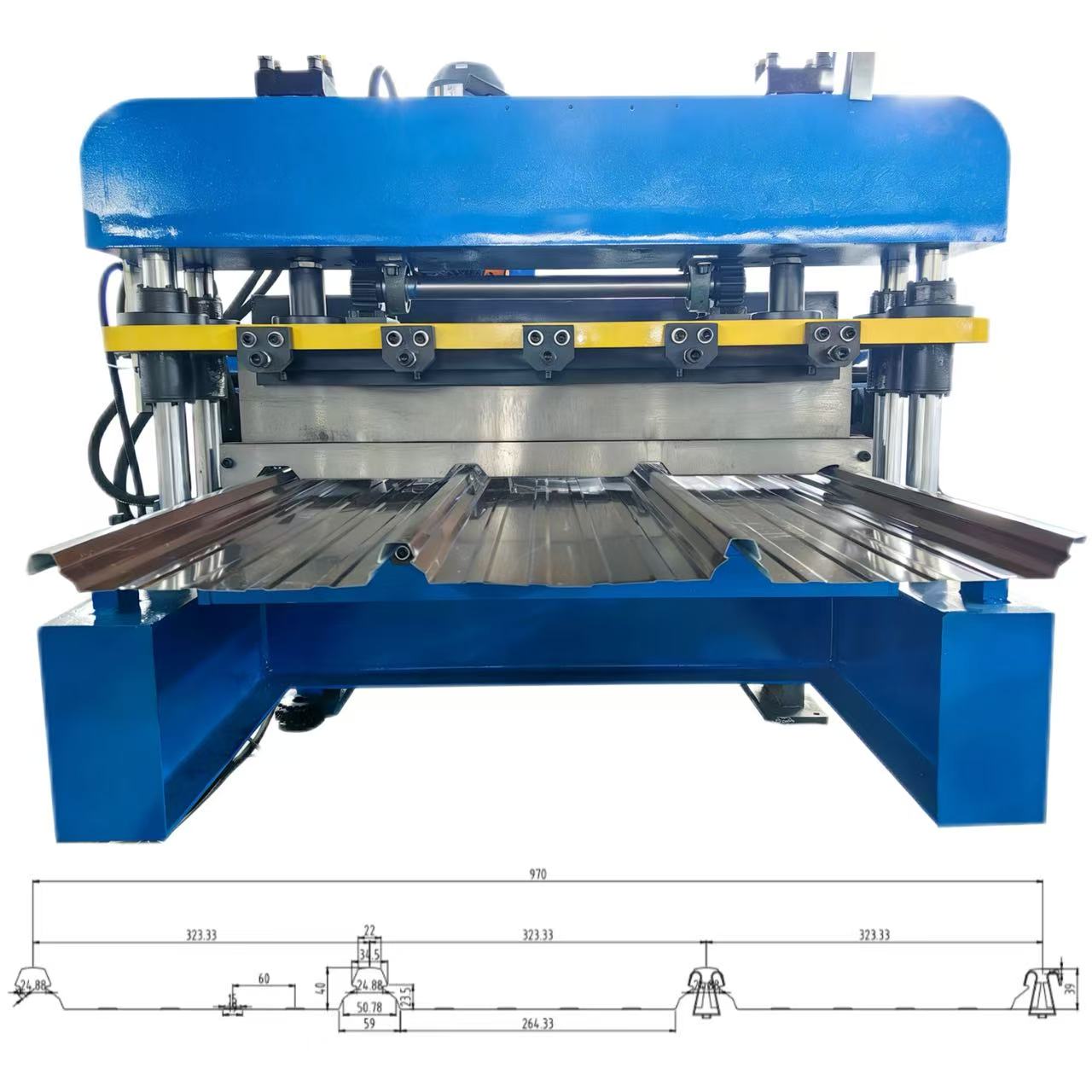

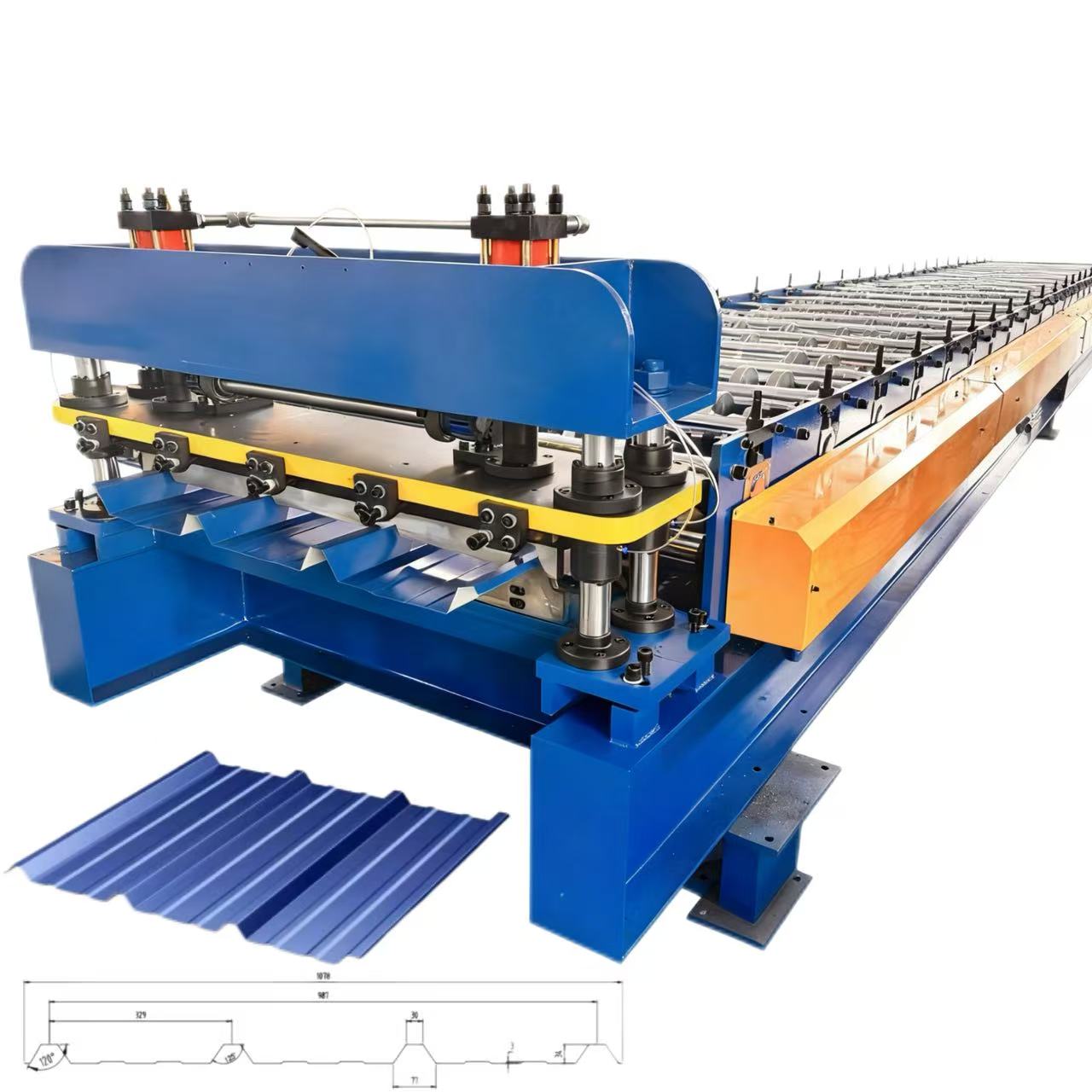

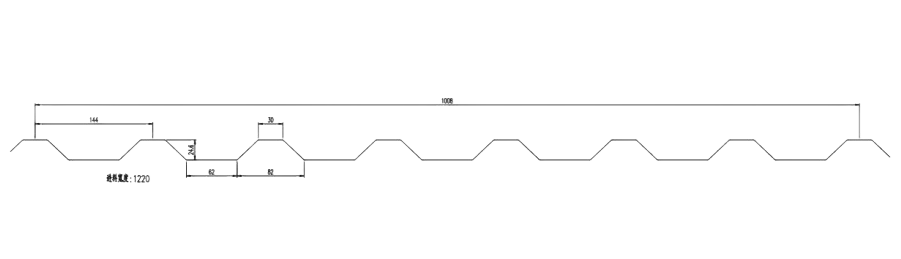

Profile drawing as below:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness(0.3-0.8mm) Width 912mm/1220mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Ordinary decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

21 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive chain

|

1.2inch(As your requirement)

|

|||

|

Dimension(L*W*H)

|

8500*1400*1300(customize)

|

|||

|

Weight

|

9 tons

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

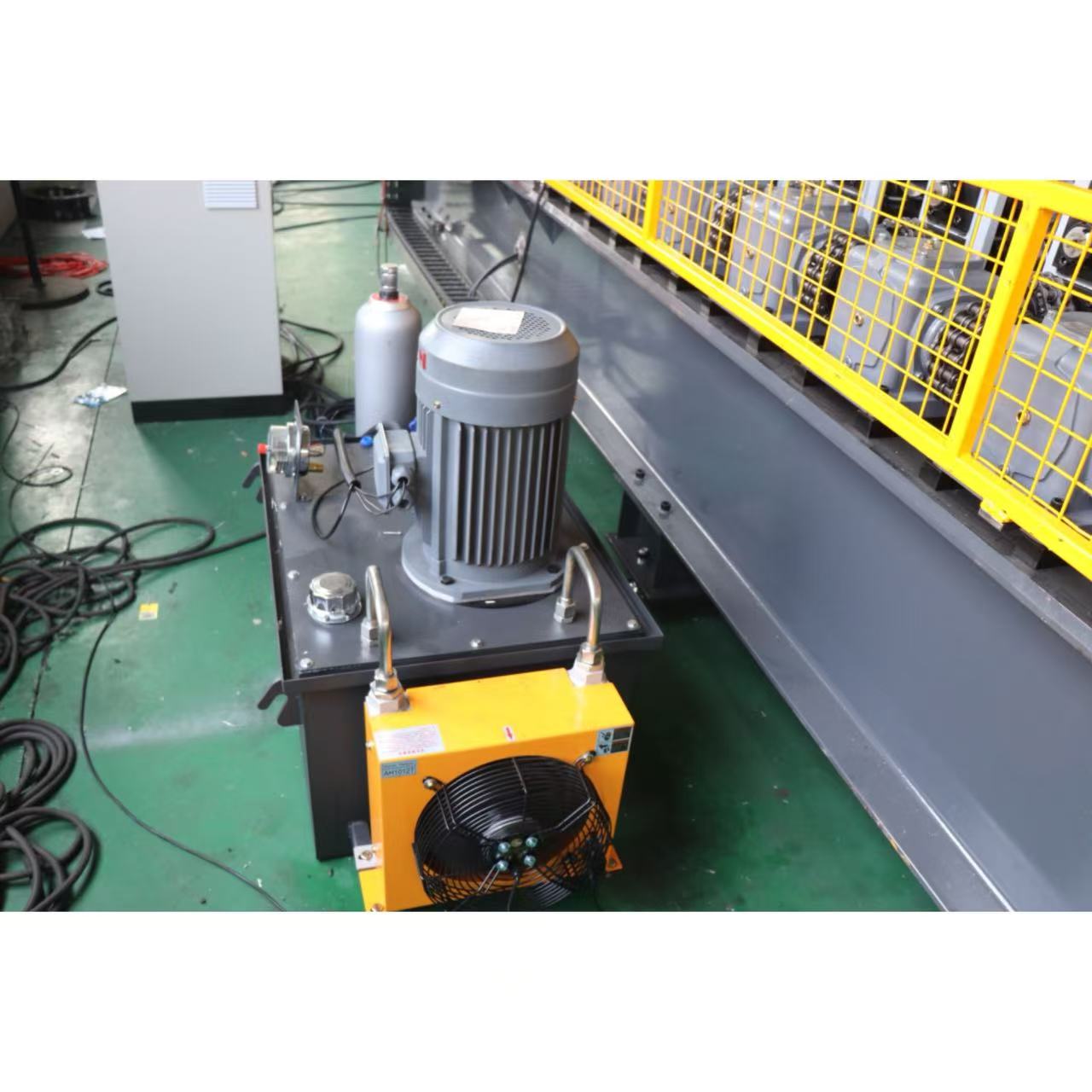

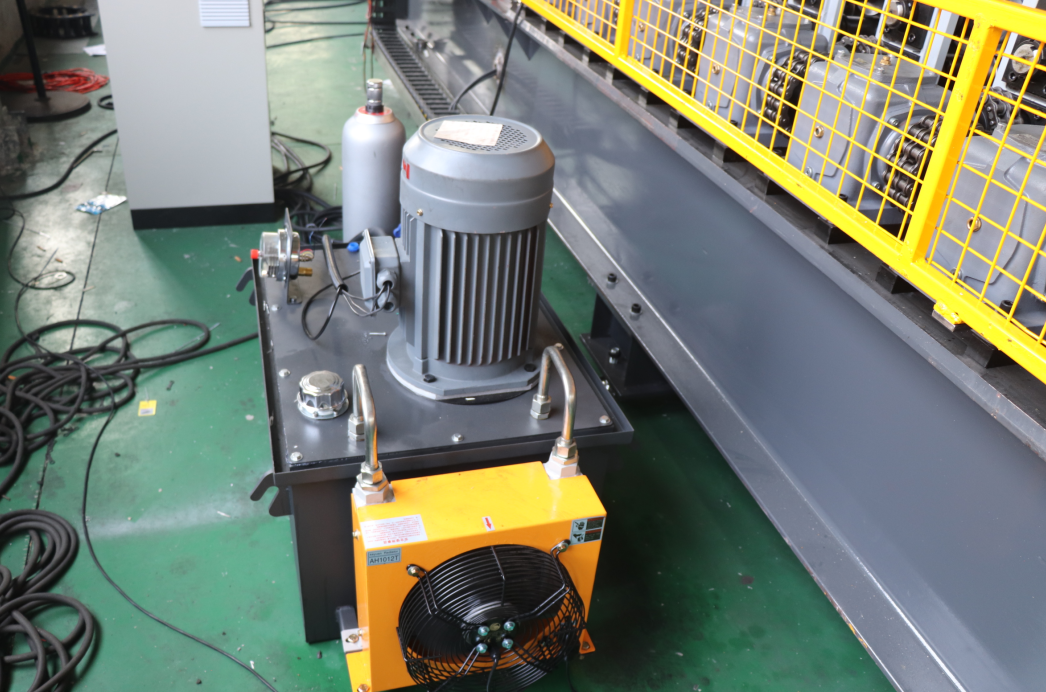

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Spanish/English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

15-20m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

The core value of the machine: High-efficiency production and quality assurance

The Full Automatic Galvanized Tile Trapezoid Roofing Sheet Roll Forming Machine is the key to producing high-quality trapezoidal tiles, with its core value reflected in the following aspects:

1. High-Efficiency Production:

Utilizing advanced steel plate pressing technology, the equipment can rapidly form color steel or galvanized steel plates, significantly enhancing production efficiency to meet the demands of large-scale construction projects.

2. Quality Assurance:

With precision-forming rollers and PLC control systems, the dimensions and surface finish of the tiles are ensured to be accurate and smooth, thereby enhancing the overall aesthetic appeal and durability of the building.

3.Cost-effectiveness:

Automated operations reduce manual intervention, lowering production costs while the durable design of the equipment extends its service life, delivering long-term benefits for manufacturers.

Market applications and successful cases: widely recognized practical effects

Full Automatic Galvanized Tile Trapezoid Roofing Sheet Roll Forming Machine has been widely used in residential, commercial, and industrial construction fields, and its products have performed well in multiple projects:

• Residential buildings:

In villa and apartment projects, trapezoidal tiles enhance the aesthetics and waterproofing performance of the building, receiving unanimous praise from owners and designers.

• Commercial buildings:

In the application of shopping malls and office buildings, their lightweight and wind resistance characteristics ensure the safety and stability of buildings, making them the preferred choice for modern commercial design.

• Industrial buildings:

In factory and warehouse construction, the durability and low-cost maintenance advantages of trapezoidal tiles are significant, reducing long-term operating costs.