Machine video:

Working under the scorching sun, traditional processing is slow as a snail?

Panel dimensional deviations, edge sealing leaks, and post-installation maintenance headaches?

Rising labor costs and staggering transportation losses devour profits layer by layer?

Don’t worry! This High Quality Trapezoidal Roof Panel Roll Forming Machine is specifically designed to address your pain points, making every construction project “efficient, hassle-free, and profitable”!

Product Attributes:

|

No.

|

Item

|

Specification

|

||

|

Material

|

Raw material

|

Galvanized steel or PPGI,PPGL,AI

|

||

|

Thickness

|

0.3-0.8 mm

|

|||

|

Decoiler

|

Operation

|

Manual(buy machine give you free) Or Hydraulic

|

||

|

Weight capacity

|

3T 5T 7T 10T

|

|||

|

Machine

|

Roller station

|

10-18(depend on customer’ drawing)

|

||

|

Shaft diameter

|

70-80mm

|

|||

|

Body frame

|

350H steel

|

|||

|

Roller material

|

Cr12

|

|||

|

Machine size

|

About 6.5*1.5*1.2 m

|

|||

|

Machine weight

|

4-8 tons

|

|||

|

Drive

|

gear and Double Chain or gearbox

|

|||

|

Working speed

|

12-60 m/min

|

|||

|

Hydraulic Cutting

|

Cutter Hardness

|

50-65 HRC

|

||

|

Cutter Material

|

Cr12

|

|||

|

Cutting tolerance

|

± 1mm

|

|||

|

Power

|

Main motor

|

5.5kw

|

||

|

Pump motor for cutter

|

7.5kw

|

|||

|

Control system

|

PLC brand

|

Delta or Siemens

|

||

|

Touch screen

|

Delta or Siemens

|

|||

|

Language

|

6000+ languages customized according to customer needs

|

|||

|

Voltage

|

380V/50HZ, 3P

|

customized according to customer needs

|

||

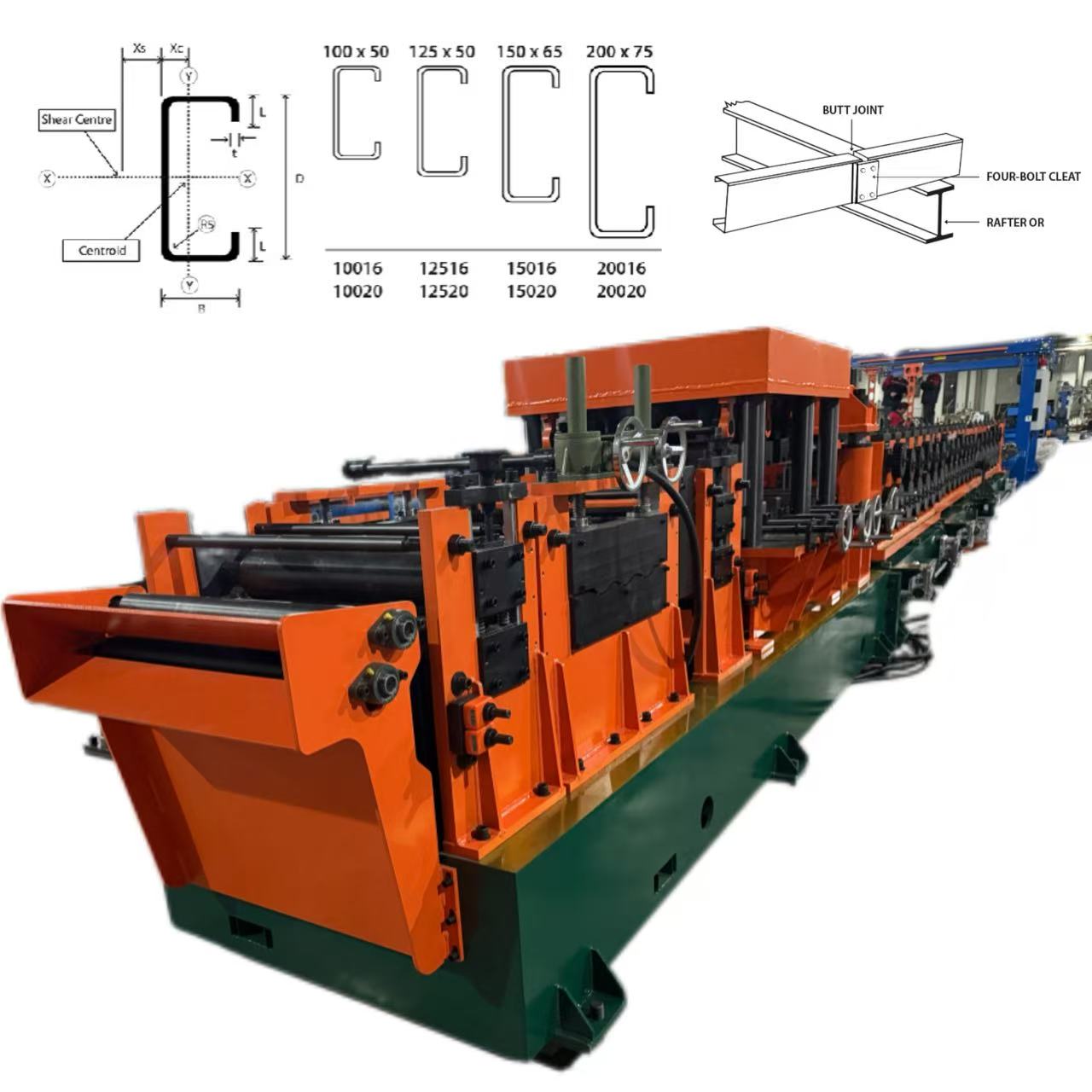

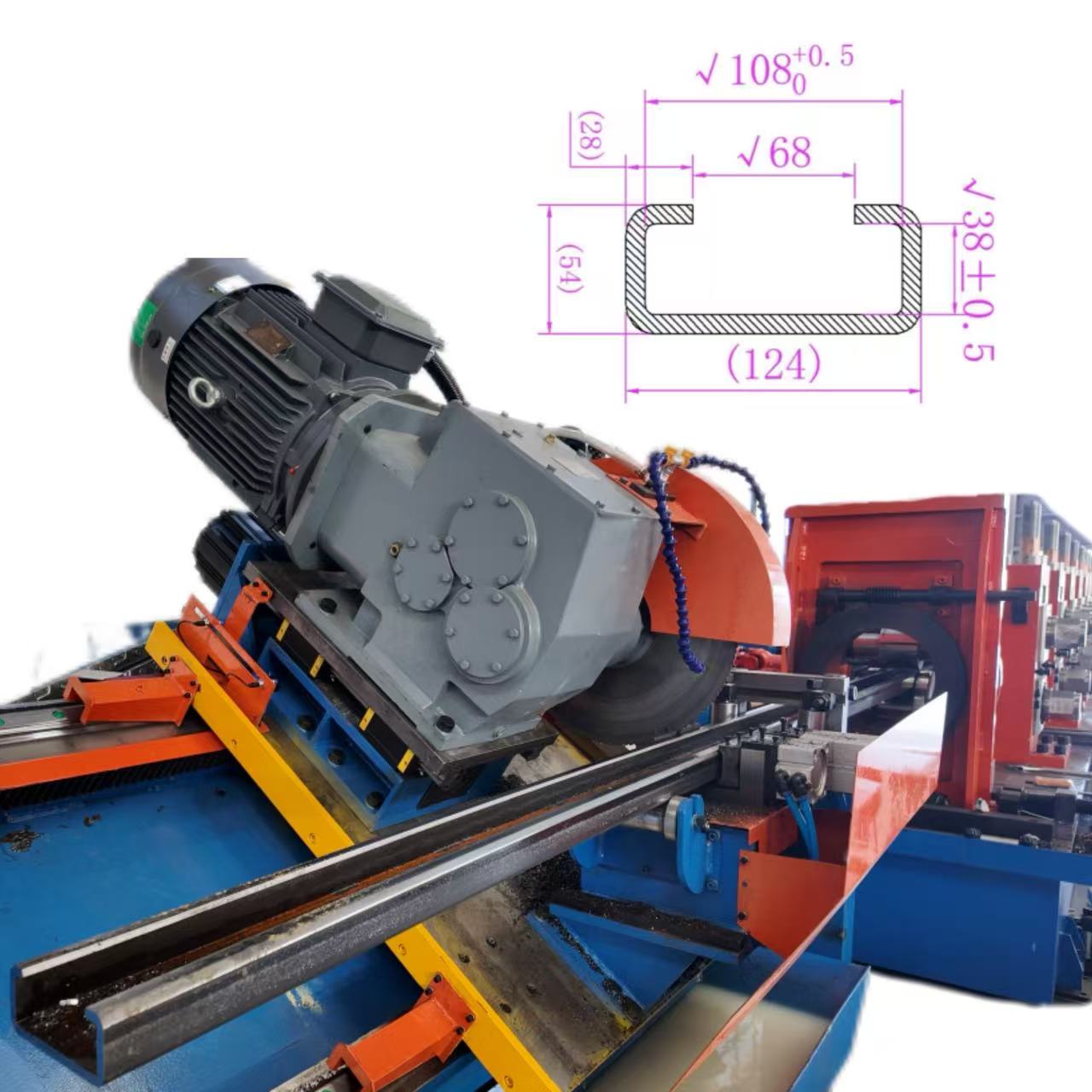

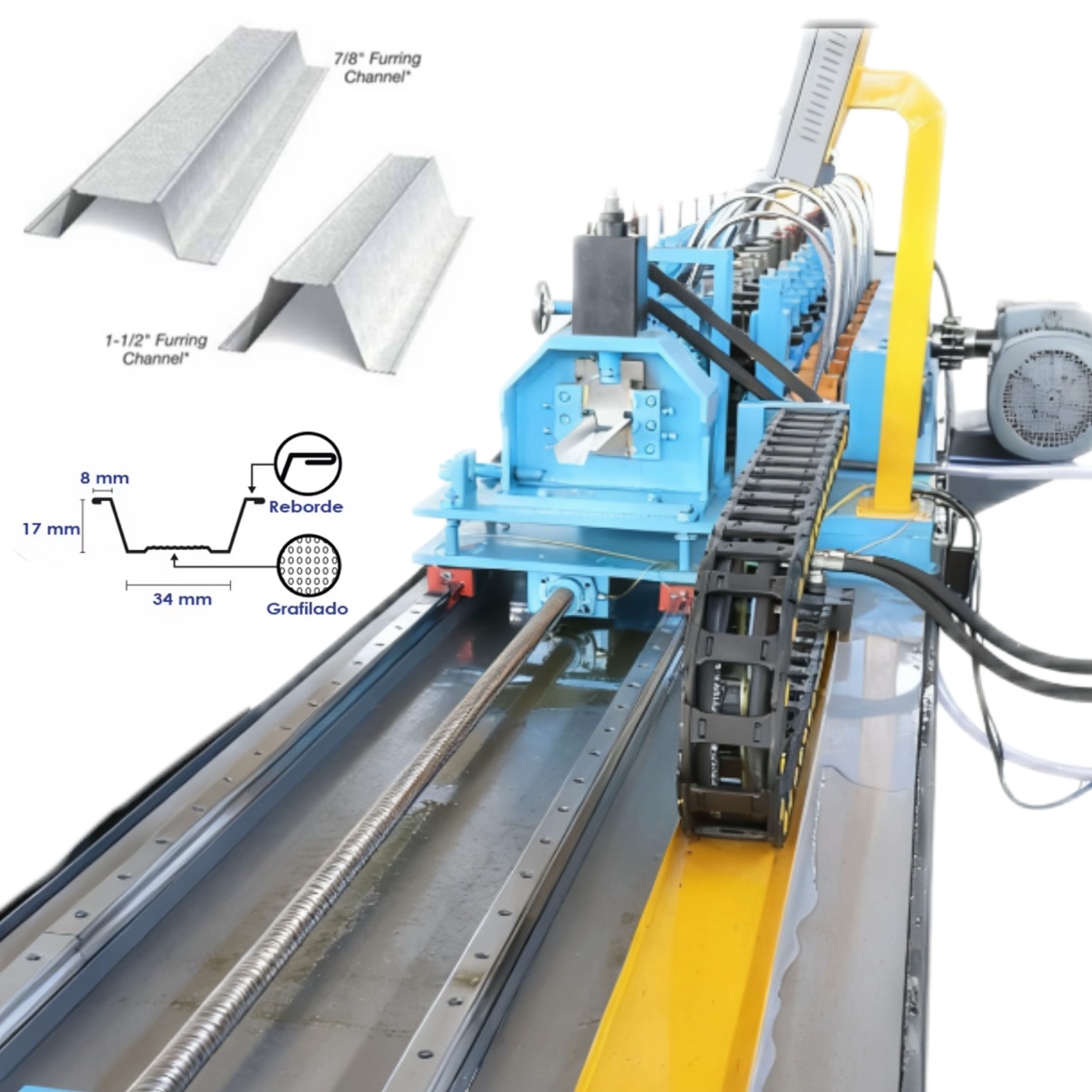

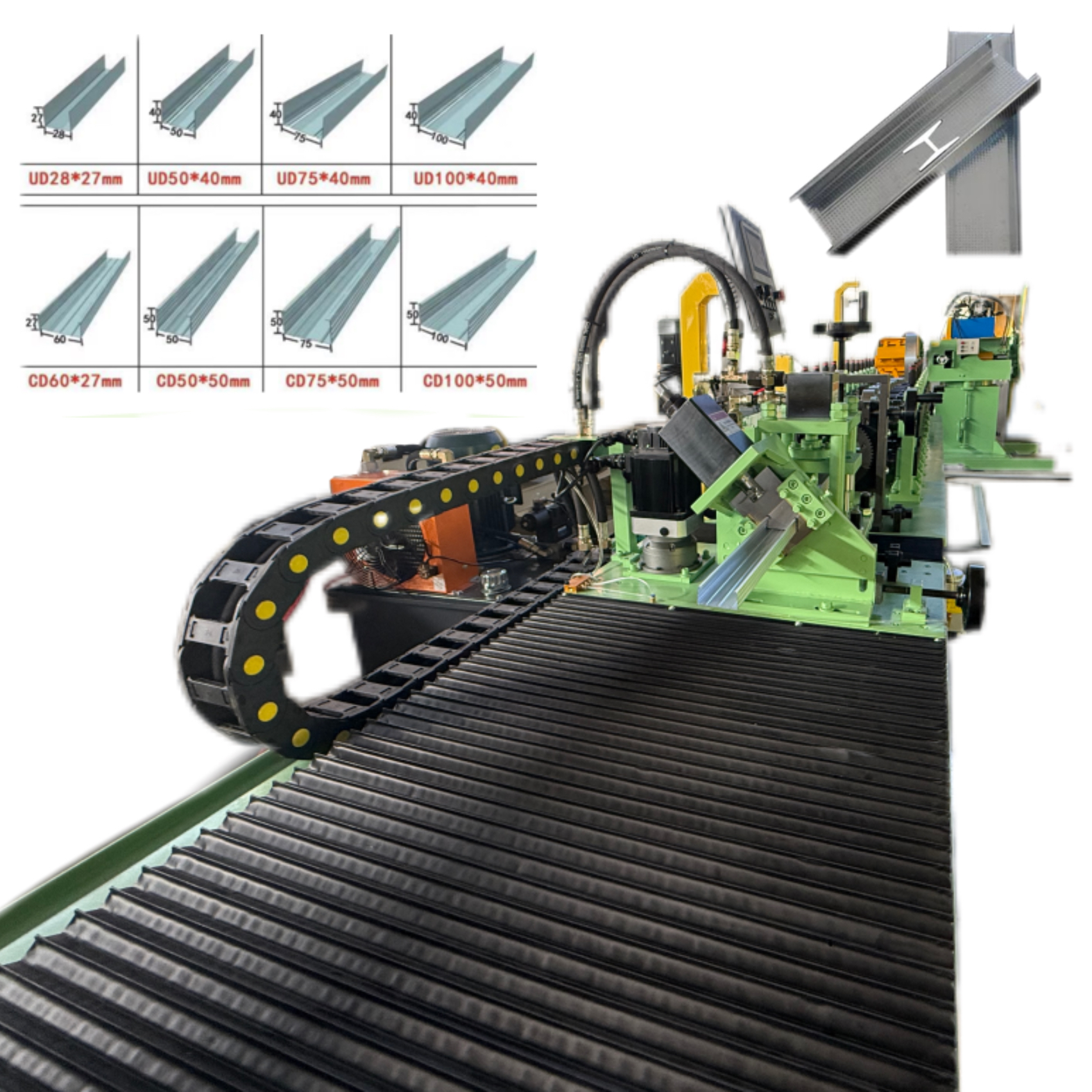

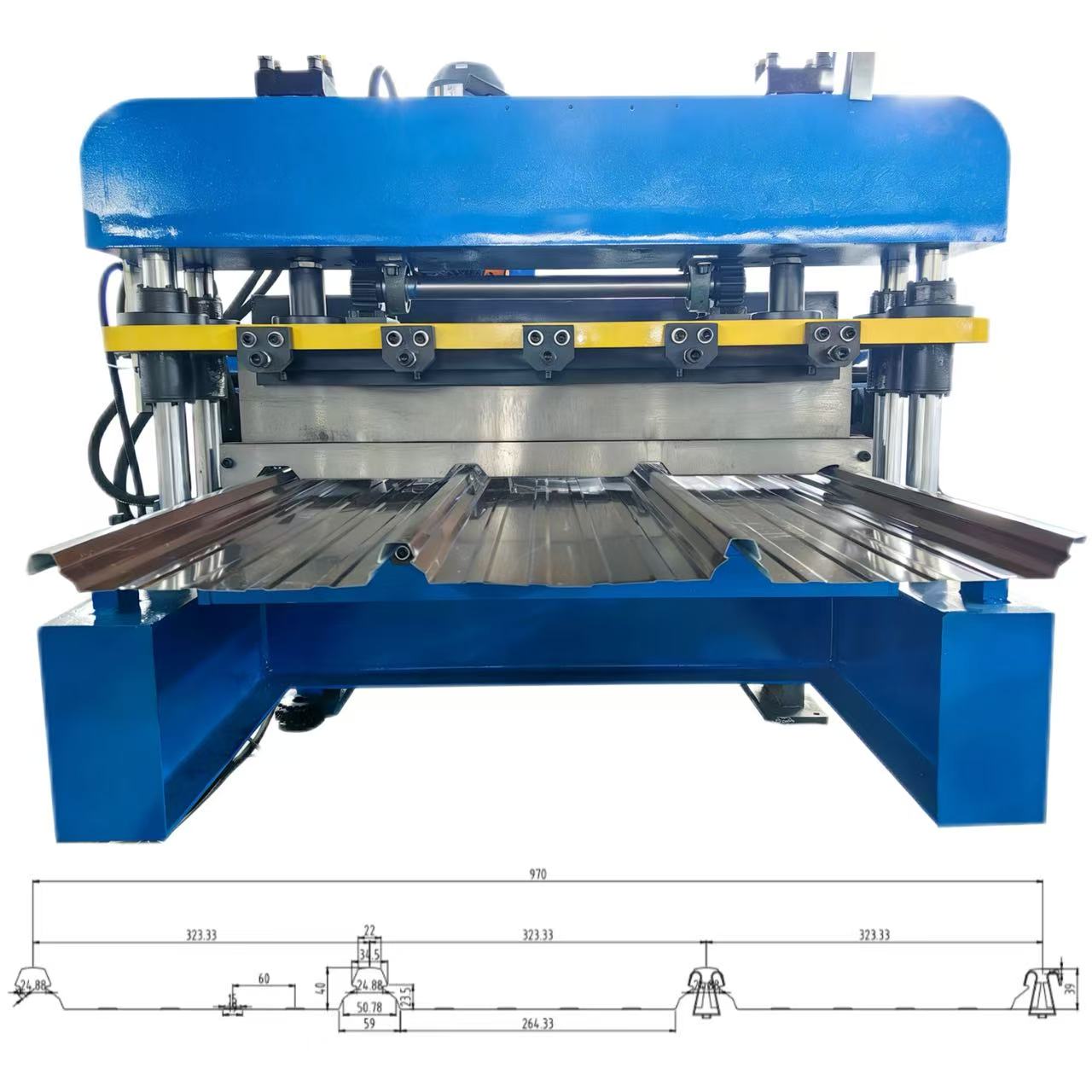

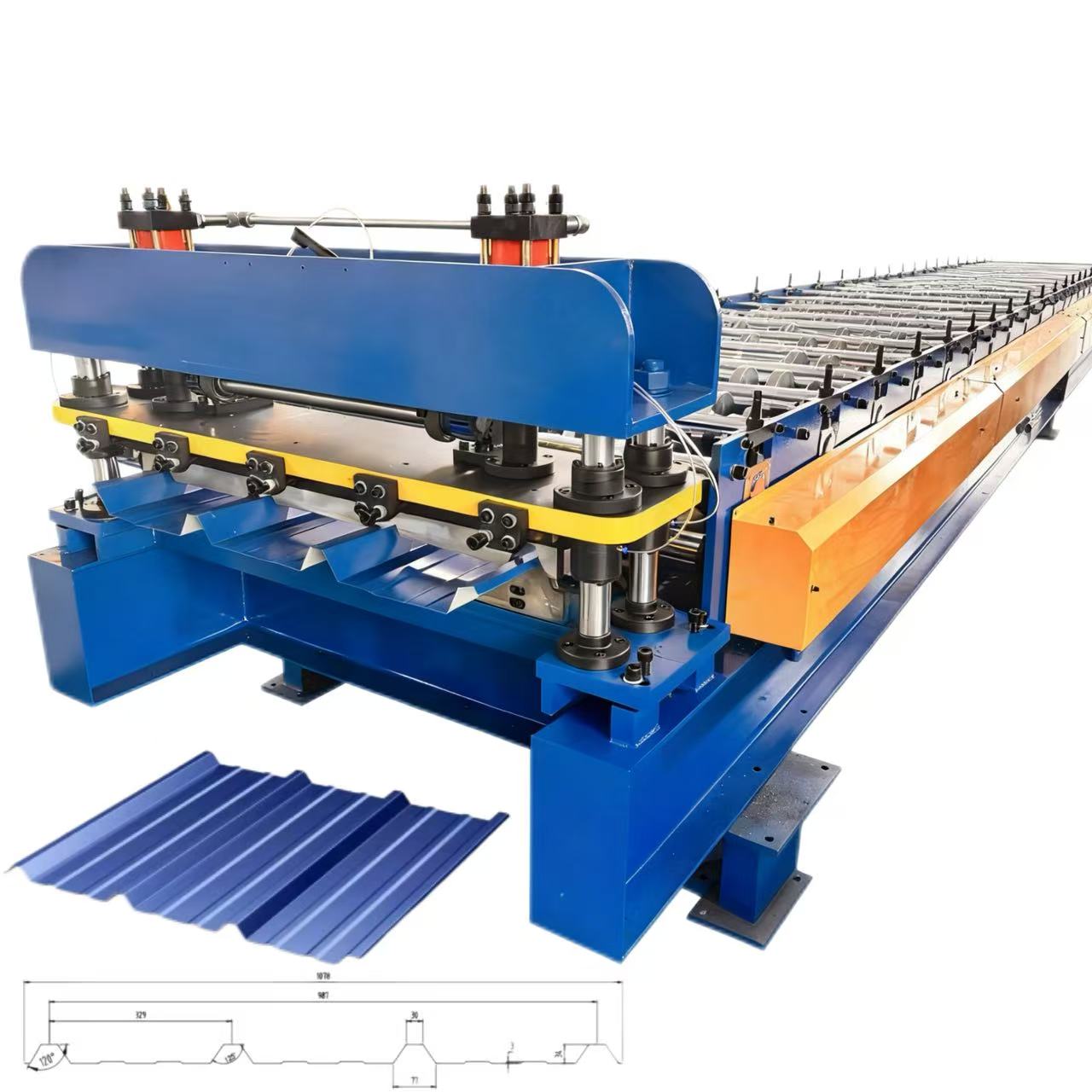

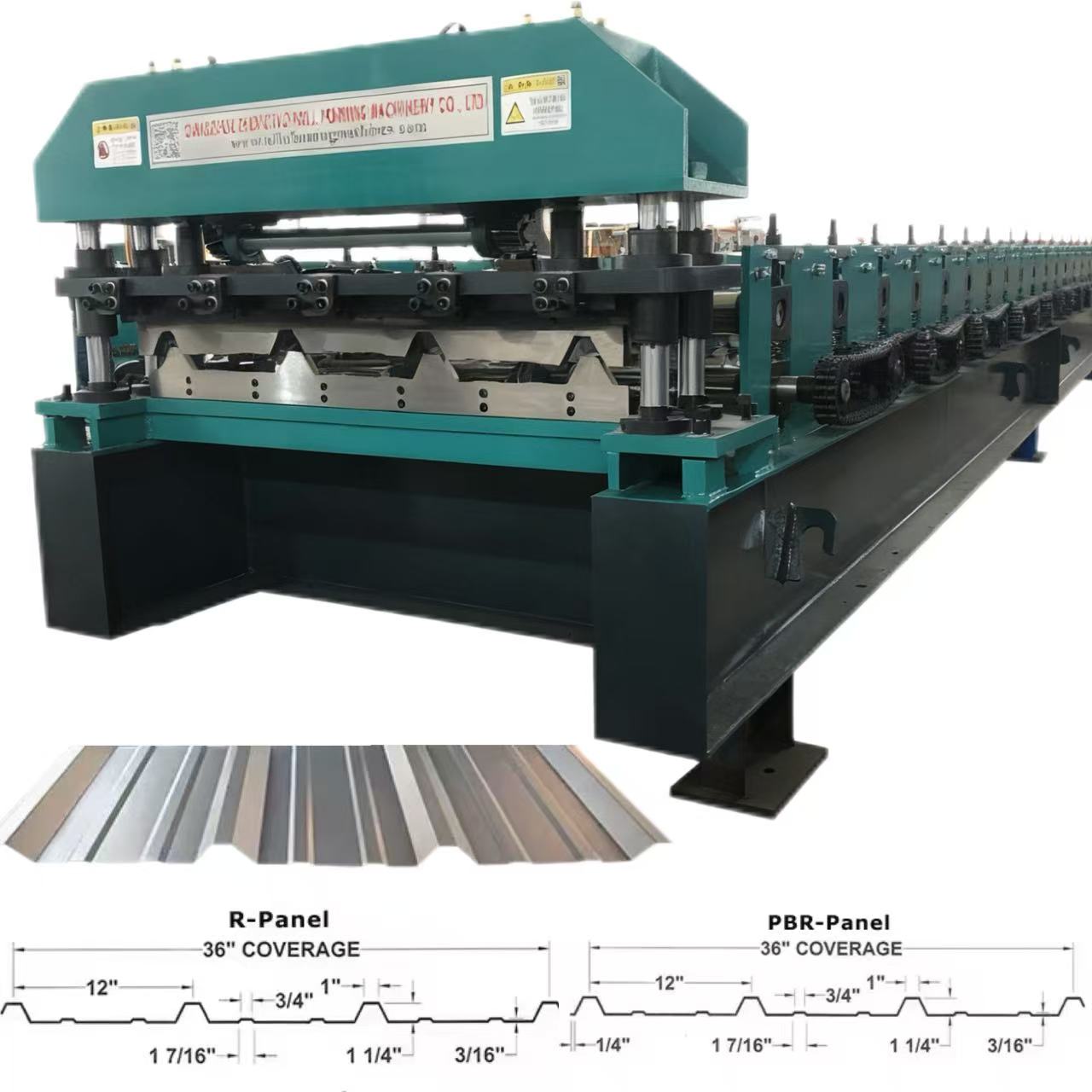

Pattern diagram:

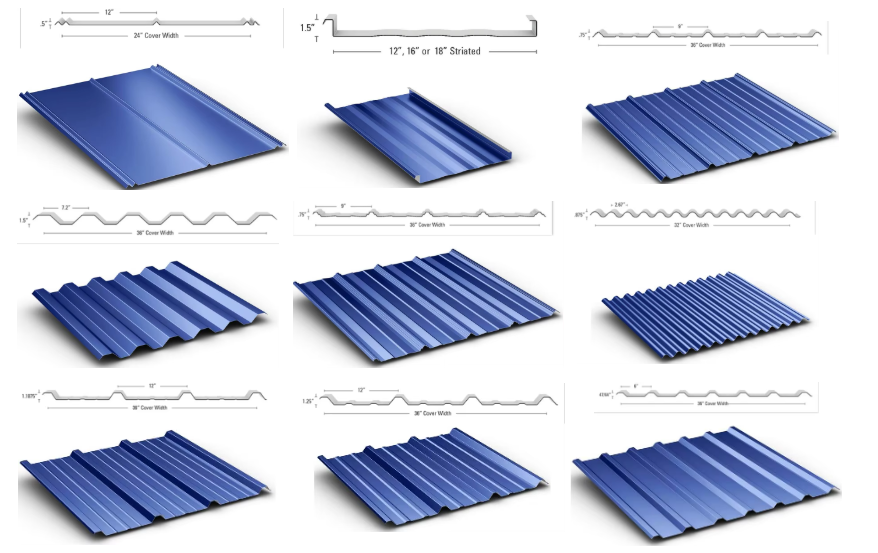

Core strengths:

1. Production capacity skyrockets! No longer have to “stay up all night” to rush to work

Engineers are often troubled by project deadlines, and traditional manual processing has low efficiency, with 10 people busy for a week making it difficult to complete tasks. And this machine is equipped with a new generation of cold bending forming technology, with a high-speed output of 15-25 meters per minute and a daily production capacity of over 3000 square meters. It can cover half of a standard factory roof in one hour. The original workload of 10 people and 10 days can now be completed in 1-2 people and 2 days, reducing the construction period by 50%. Timely delivery can also earn bonuses.

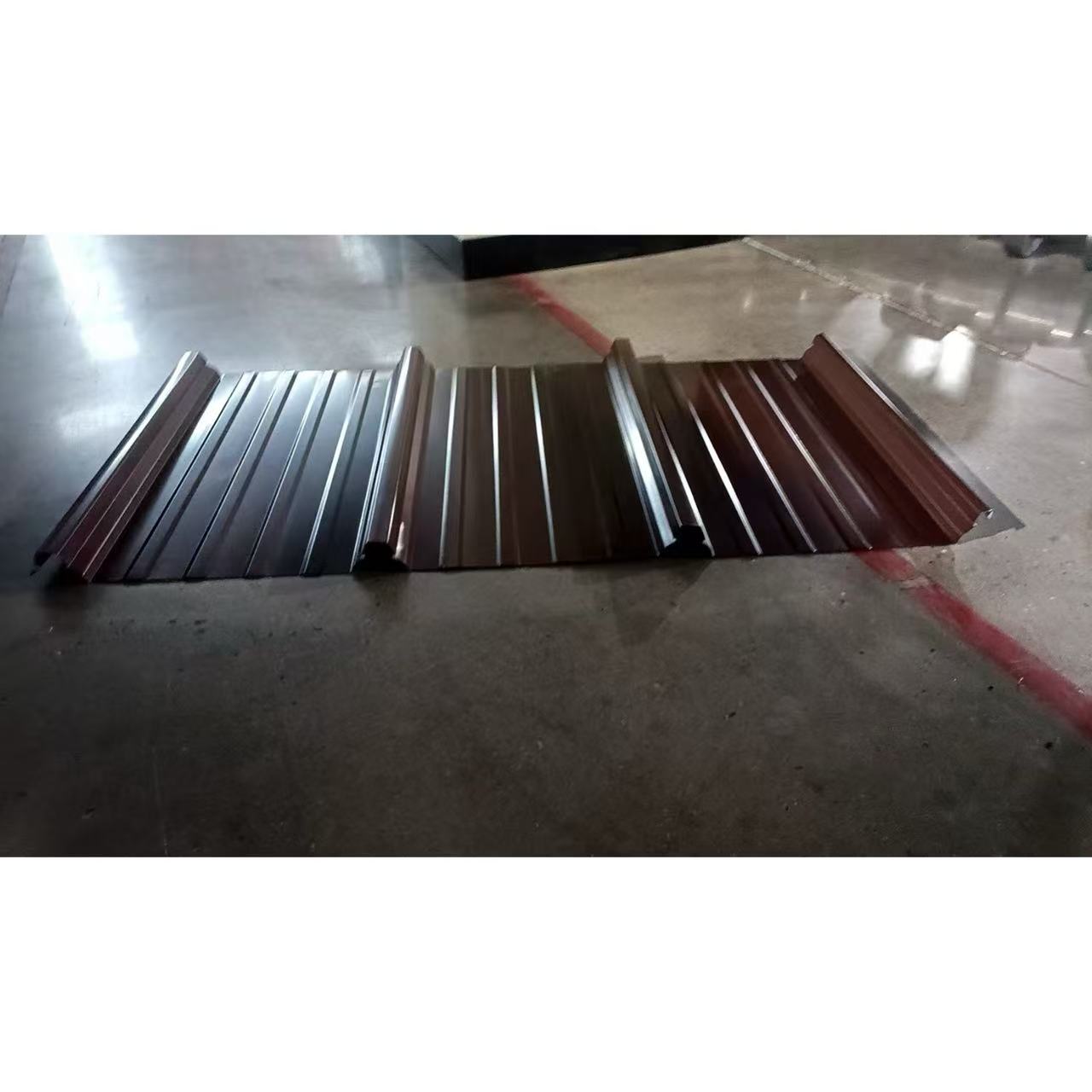

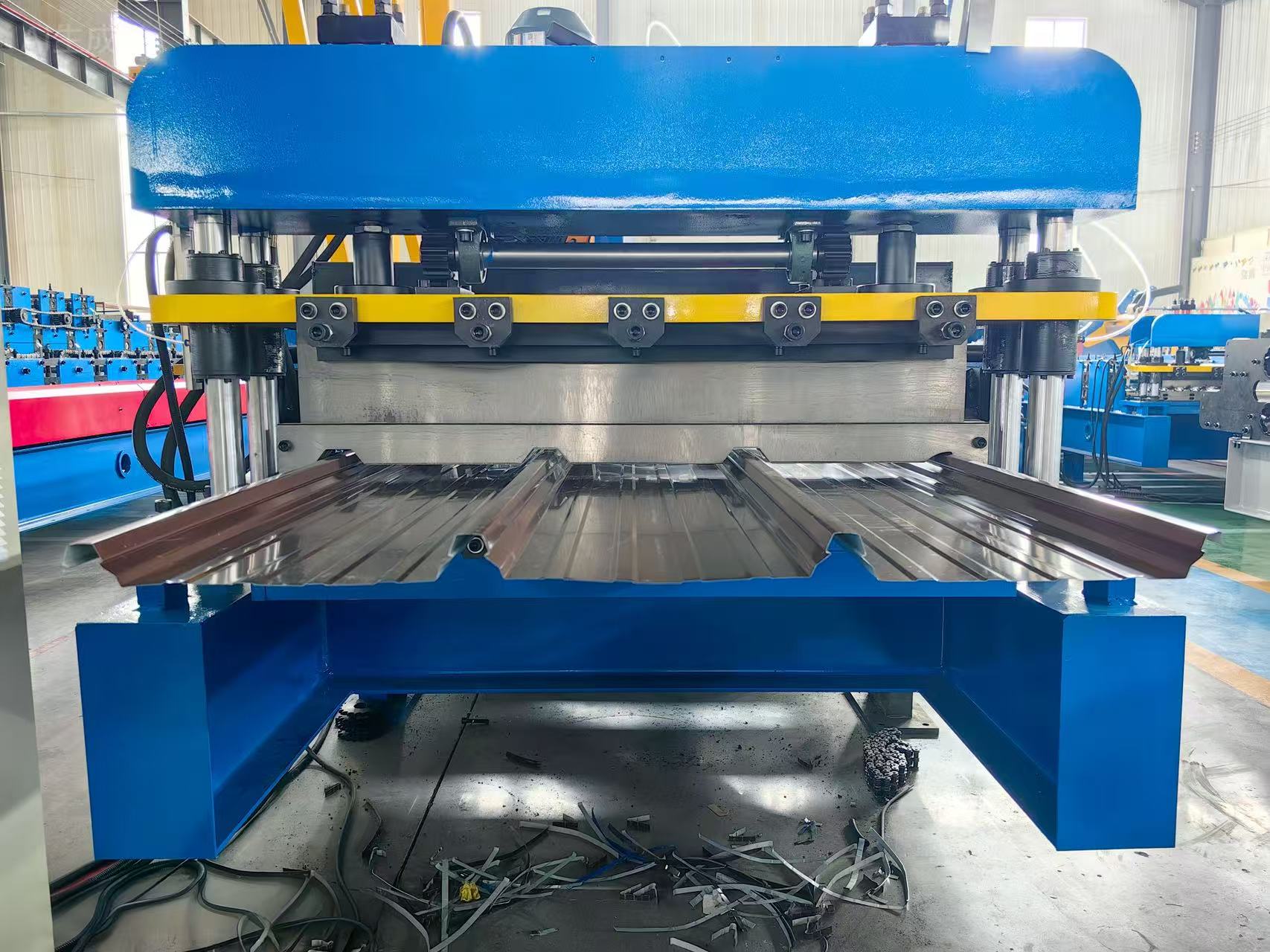

2. Precision is the god! The quality is so strong that it doesn’t need to be repaired for ten years

The leakage and deformation of roof panels are often due to insufficient machining accuracy. The imported alloy rolling mill of this machine is precision polished by CNC, with a bite accuracy of ≤ 0.1mm. The formed trapezoidal board has full wave peaks, flat surface, tight locking edges, increased compressive strength by 30%, strong weather resistance, and almost zero maintenance rate in the later stage, giving more confidence in delivery.

3. Versatile adaptation! Top N units per unit, saving money and effort

The demands of construction projects are constantly changing, and this machine can be called a “versatile”. Supports thicknesses of 0.4-1.2mm, wave spacing of 80-300mm, and width of 100-500mm. The material and size can be customized with just one click to switch specifications. From industrial plants to light steel villas, one device can adapt to all scenarios, saving 50% of equipment investment costs.

4. Intelligent to a “foolproof” level! Even beginners can become ‘masters’

No need for professional technicians for operation, 7-inch touch screen with PLC intelligent system, built-in 100+preset parameters, input size automatic adjustment. Automatic feeding, cutting, and counting can be operated by 1-2 people, and can be mastered within 1 hour of training, reducing labor costs by 60%.