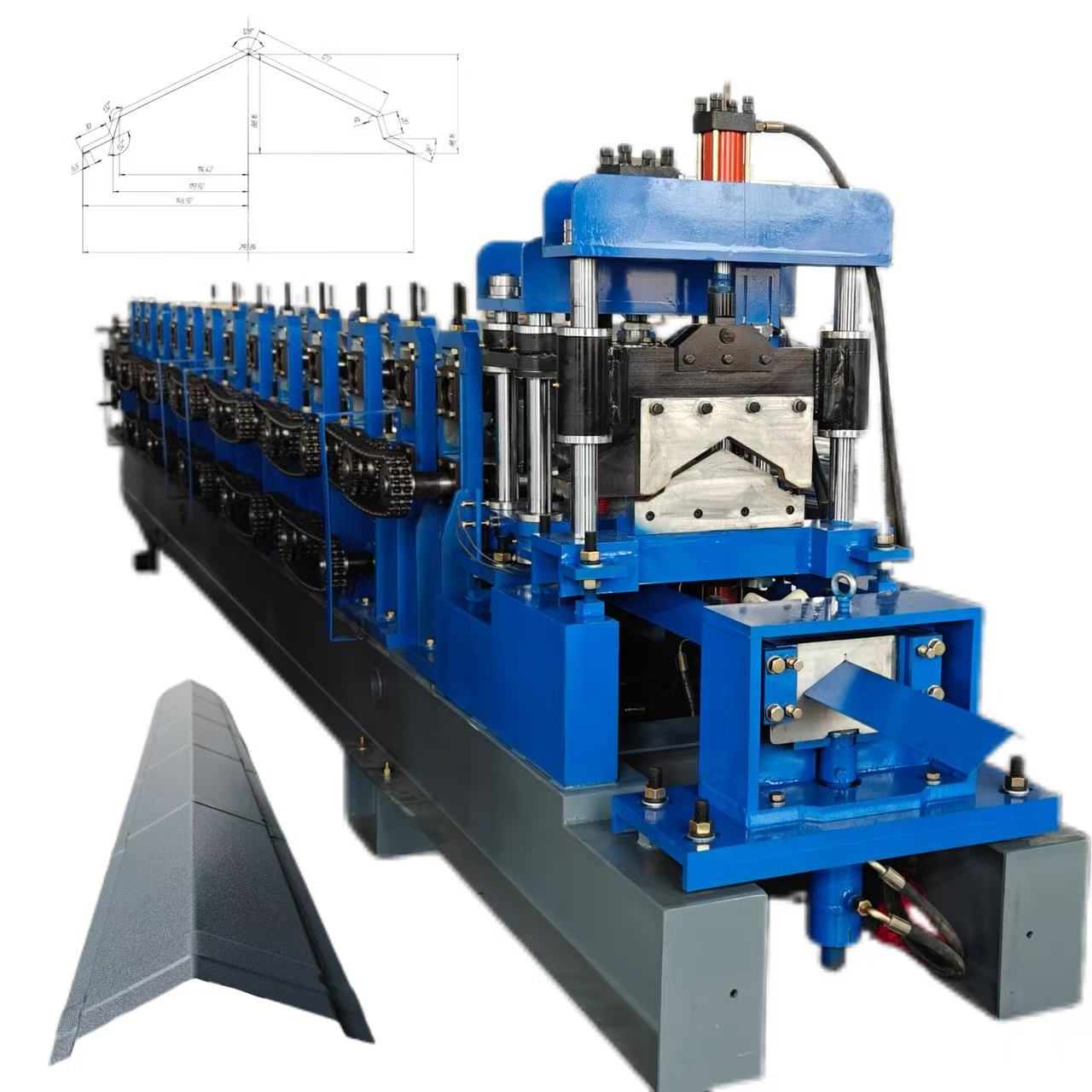

The villa keel machine is a light steel keel equipment for producing “villa keels”, mainly used in light steel villa buildings such as private apartments and detached villas. It can produce keels for supporting shapes and fixing structures by continuously cold rolling strip steel, and is an important component of the frame of light steel villa buildings. It is generally composed of a feeding machine, a guide frame, a forming host, a calibration device, a cutting part, a receiving platform, an electrical control part, etc. Among them, the feeding machine is used to place steel strip raw materials, and the guide frame guides the steel strip into the forming host. The forming host processes the steel strip into a dragon bone shape through multiple passes of roll forming technology. The correction device corrects the formed dragon bone shape, and the fixed length cutting part cuts the dragon bone according to the set length. The receiving platform is used to collect the finished dragon bone, and the electrical control part realizes the automation control of the entire equipment operation.

Pattern drawing:

Performance Characteristics:

1.Strong material adaptability:

It can handle various specifications of metal sheets and meet the requirements of different villa buildings for the strength and specifications of the keel.

2.High molding accuracy:

By adopting advanced rolling technology and precise molds, bending, punching, and cutting are formed in one go to ensure the dimensional accuracy and quality stability of the keel, which is conducive to improving the overall structural strength and installation accuracy of villa buildings.

3.High production efficiency:

Some equipment has a fast production speed, capable of processing 1 roll of steel strip per hour and producing 6-8 tons of keel in 8 hours, which can meet the needs of large-scale villa construction.

4.High degree of intelligence:

Many villa keel machines are equipped with intelligent control systems, allowing engineers to remotely monitor and adjust equipment parameters in real time. Their data neuron warning function can also issue accurate warnings before faults occur, enabling fully automatic changeover and flexible production, greatly reducing operational difficulty.

5.Diversified functions:

In addition to the basic keel forming function, it can also achieve various punching, chamfering and other processing techniques, support the production of various hole types such as nail holes, through holes, and combination holes, and some equipment can also automatically generate drawings for seamless integration between design and construction.

Product Attributes :

|

1. Profile shape

|

C shape

|

|

2. Profile size

|

C140、C89 C150mm

|

|

3. Material thickness

|

0.7-1.2mm, G300-G550 Zinc-Alum steel coil

|

|

4. Operation syatem

|

17 inches touchable screen

|

|

5. Production control system

|

Self-devoloped FrameMac LGS machine Controlling Software

|

|

6. Design software

|

Optional Architectural design software of well-known domestic and foreign brands

|

|

7. Standard machine speed

|

300-900m/h

|

|

8. Max. machine speed

|

1m/s

|

|

9. Main machine motor power

|

7.5 KW

|

|

10. Power suppiler

|

380V 50Hz 3P, customized

|

|

11. Hydraulic motor power

|

5.5 KW

|

Product images: