In the fields of architectural decoration, light steel villas, curtain wall engineering, storage shelves, etc., angle steel keel serves as the core load-bearing and supporting component, and its processing quality and efficiency directly determine the project schedule and cost. The traditional manual cutting, drilling, and bending methods are not only time-consuming and labor-intensive (single keel processing takes more than 30 minutes), but also prone to problems such as size deviation and rough cutting, high rework rates, and soaring labor costs, becoming a production “pain point” for many enterprises.

Today, an intelligent Wall Angle Steel Iron Angle Corner Roll Forming Machine that subverts traditional processing modes is injecting new momentum into the industry with its core advantages of “efficiency, precision, and peace of mind”, helping enterprises reduce costs and increase efficiency, and seize market opportunities!

Applicable scenarios:

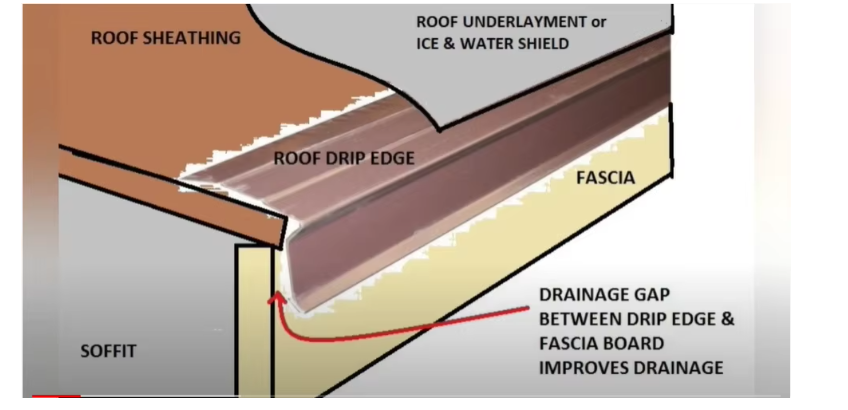

1.Construction field:Processing of light steel villa keel and building curtain wall support keel

2.Decoration field:Indoor ceiling, partition keel processing

3.Storage field:Processing of load-bearing keel for storage shelves

4.Other fields:Industrial plant support, display rack keel processing, etc

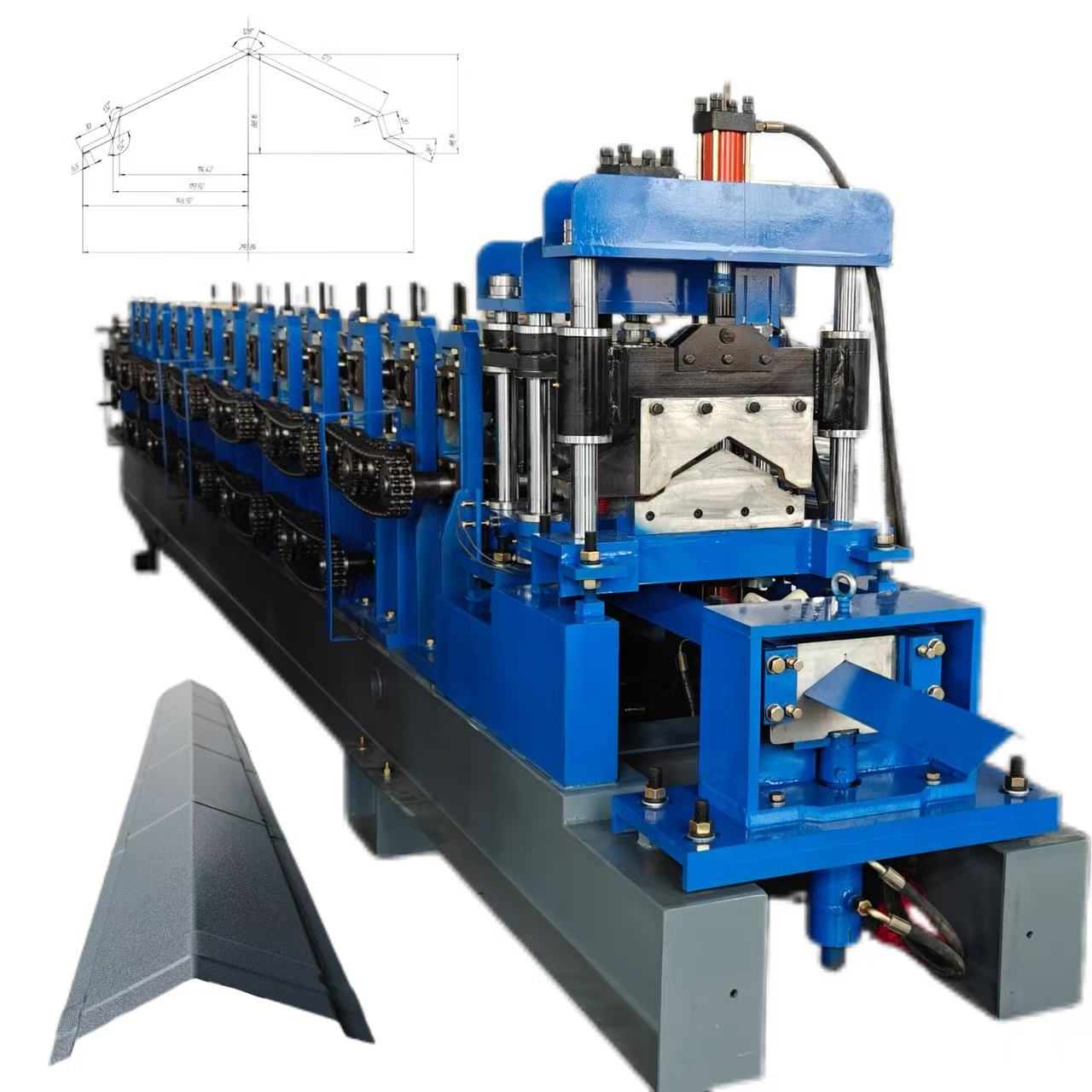

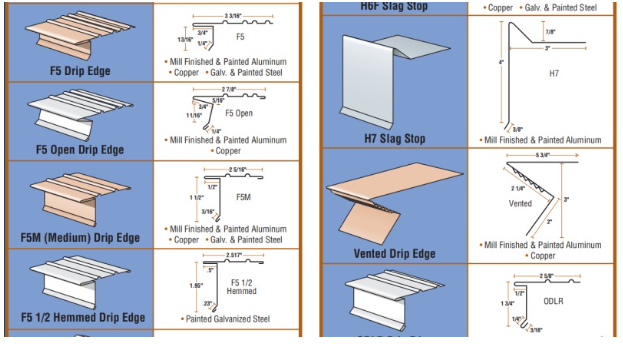

Pattern diagram:

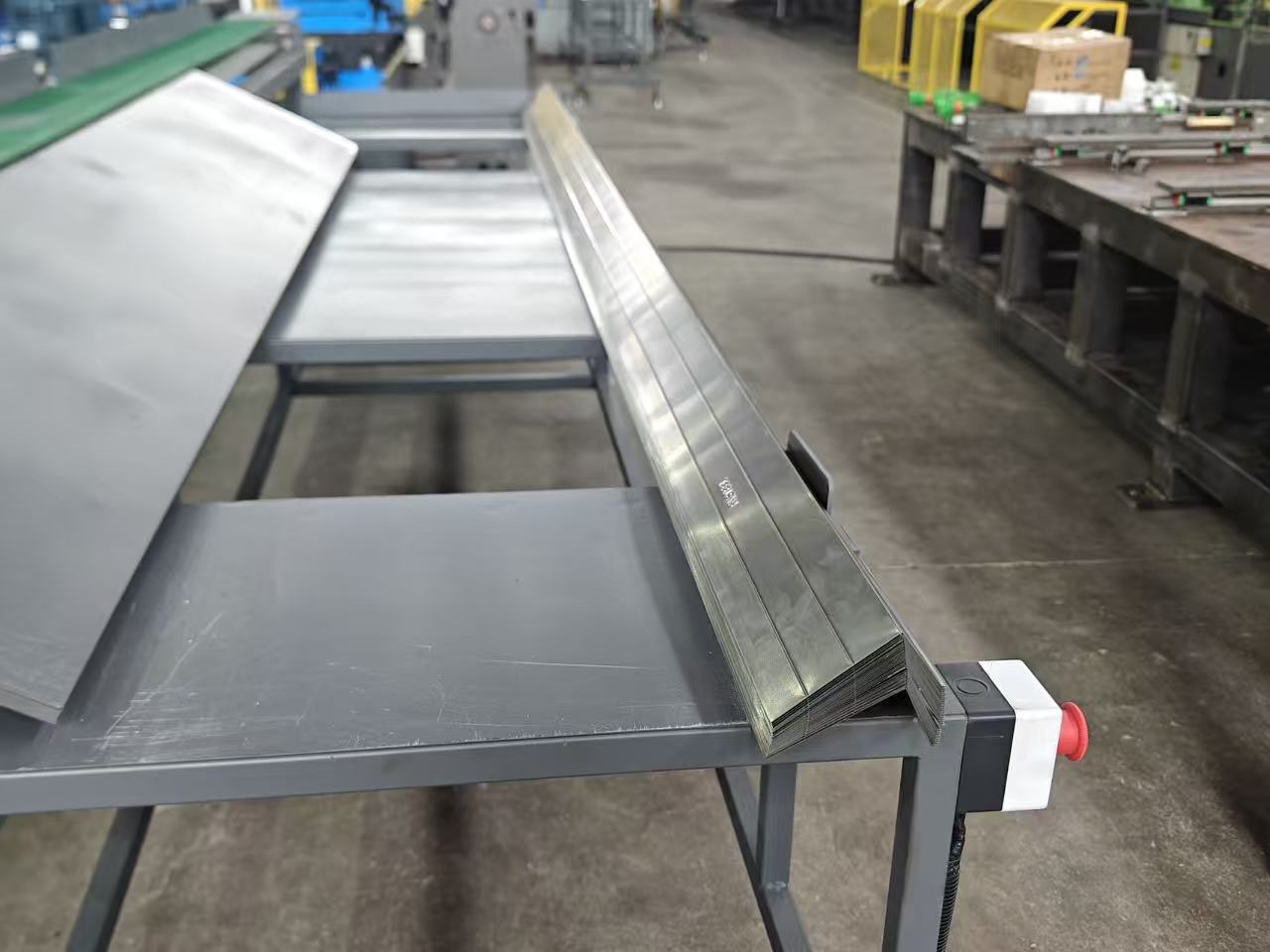

Finished product image :

Finished product image :

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.2-0..4mm (customized)

|

||

|

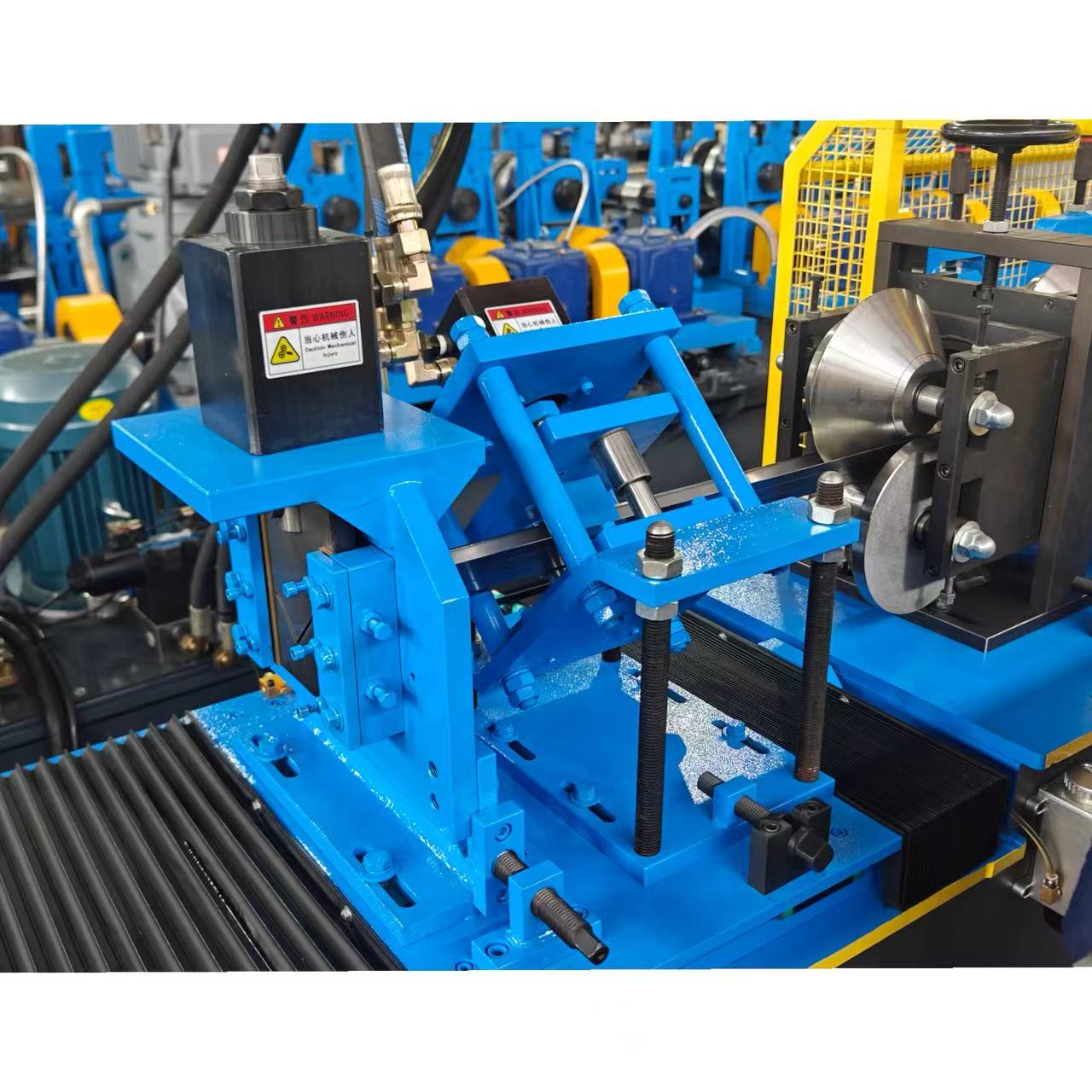

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

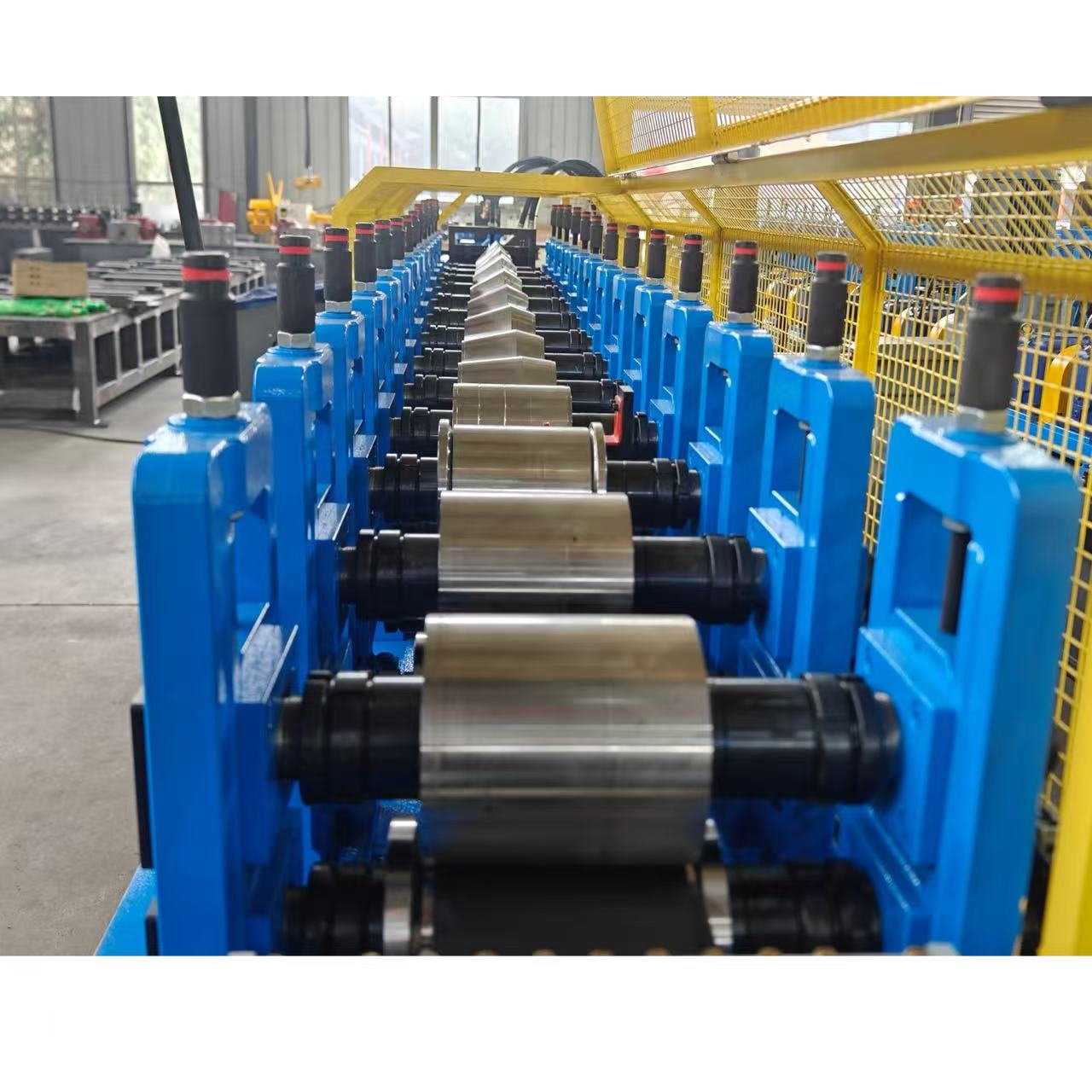

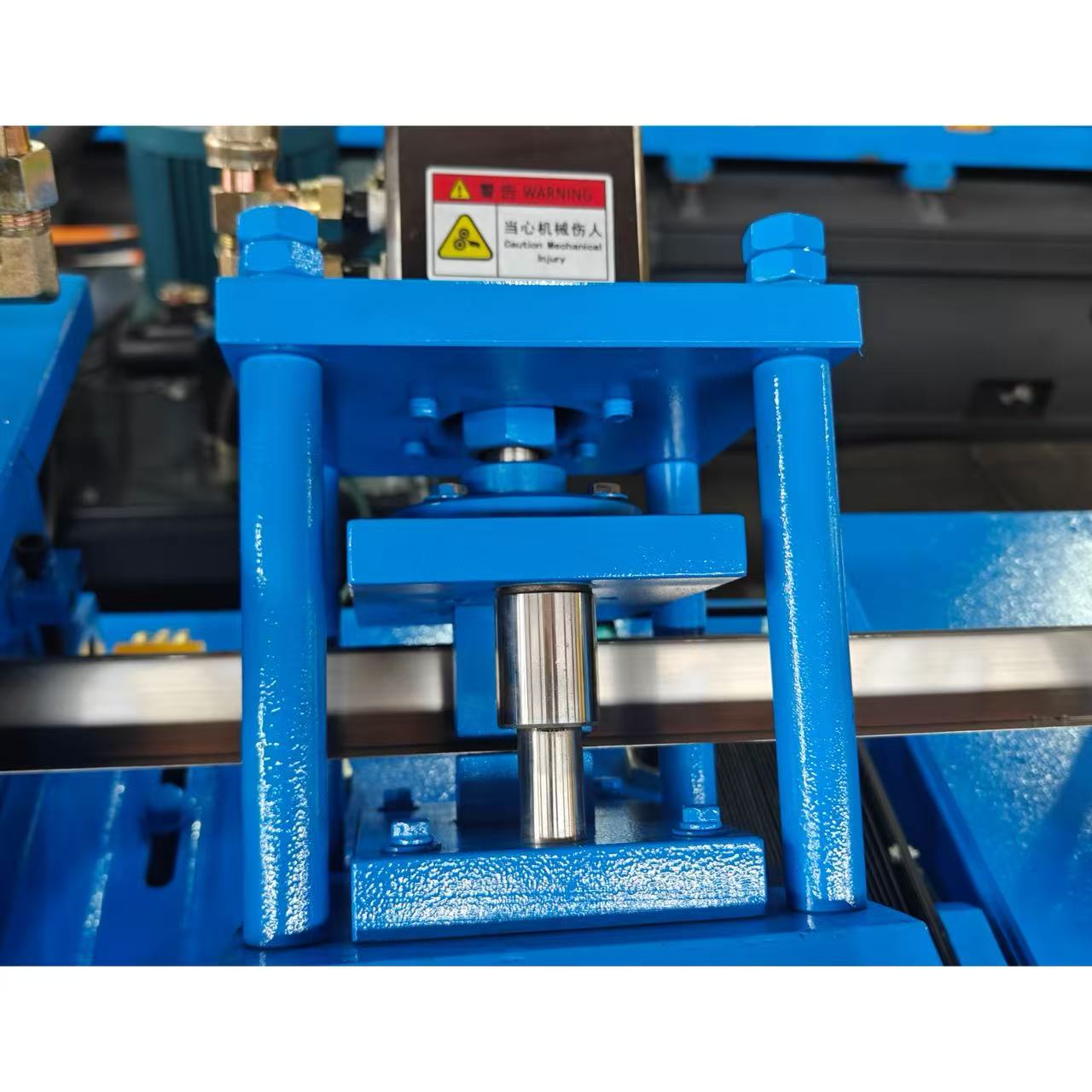

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3.5T

|

|||

|

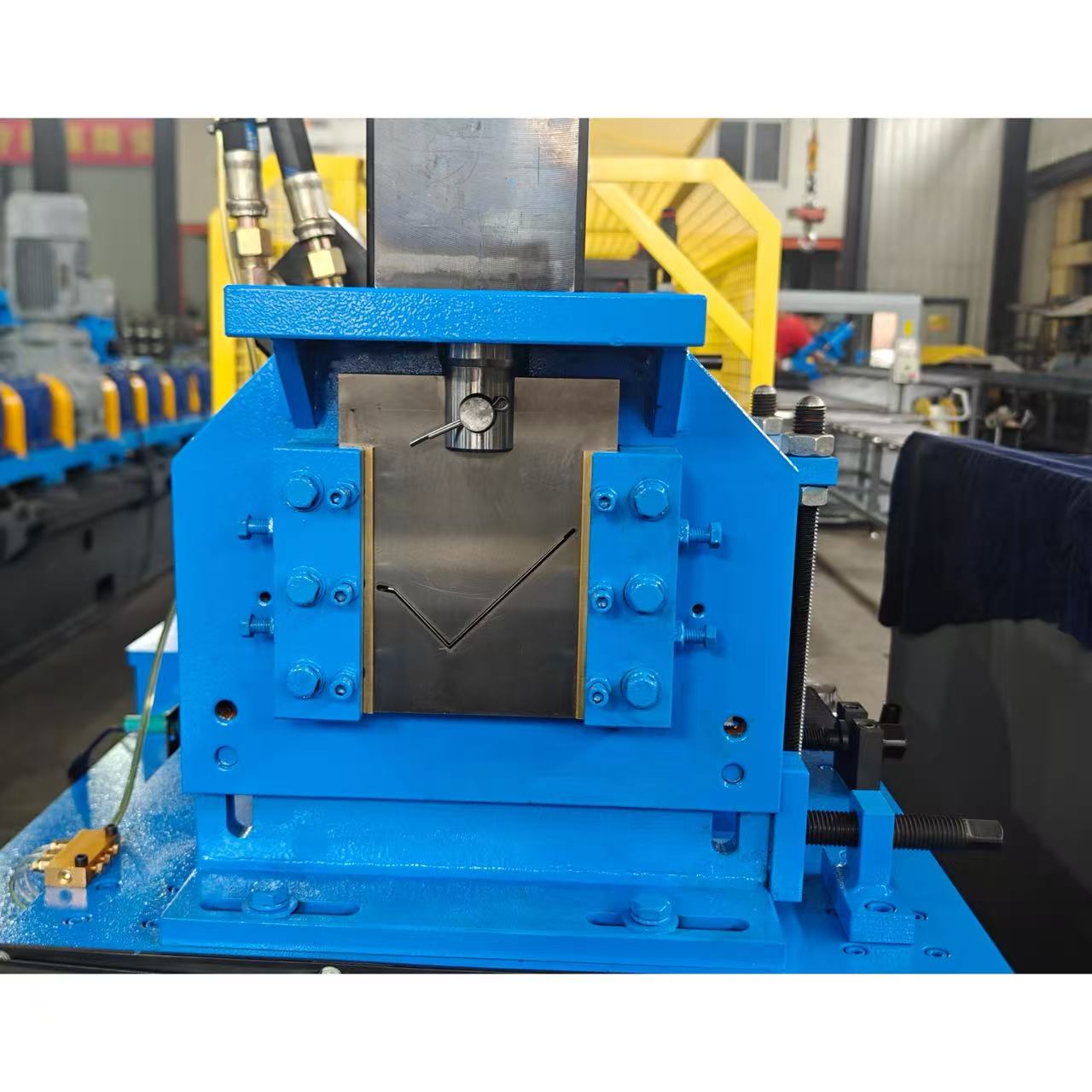

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Efficient processing: You can do the work of three days in a day, no longer have to stay up late to rush work

Previously, we relied on manual labor to make angle steel keels, which was slow and tiring. We could only make 20 to 30 pieces in 8 hours. Our angle steel keel machine is amazing. It automatically completes the entire process from placing angle steel to cutting, drilling, and forming, without the need for human intervention! You can make 80 to 100 standard dragon bones in one hour.

Based on working 8 hours a day, we can produce 640 to 800 roots per day, doubling our output directly! Whether it’s taking on large projects or urgent delivery orders, we can easily handle them without having to work overtime every day just to meet deadlines!

Ultra high precision: The error is finer than a strand of hair, making installation particularly convenient

The accuracy of the keel directly affects the installation effect later. Our machine has a “servo motor+CNC positioning system”. As long as the processing requirements are entered into the computer, the cut edges are flat and smooth, and the drilling errors are smaller than a hair thread, only 0.1 millimeters! The keel is the same size, and the radian is particularly accurate.

During installation, the keel can be seamlessly assembled without the need for polishing or adjustment, saving installation time and preventing material waste due to incorrect dimensions. The project quality is guaranteed, and customers give it a thumbs up!

Easy to operate: Beginners can learn in just ten minutes without the need for a master craftsman

Are you afraid that the machine will be too difficult to use and you will have to spend a lot of money hiring a master? Don’t worry at all! This angle steel keel machine has a 7-inch touch screen. As long as you select the template, enter the size, and click “start”, the machine will start working on its own.

No need to learn complex programming, new employees can operate on their own in just ten minutes! If you encounter special sizes of dragon bones, you can also set your own processing requirements, which is simple, easy to handle, and flexible, helping you save a lot of labor costs!

Super reliable quality: Core components are guaranteed for five years and production does not stop

The durability of machines is the key to our production. This angle steel keel machine has put a lot of effort into the parts:

The cutting blade is made of imported alloy material, which is particularly wear-resistant and can cut over 10000 dragon bones without changing;

The body is welded with thick steel plates, which have strong load-bearing capacity and will not deform even after prolonged use;

The electrical system is made of branded components that are waterproof and dustproof. When placed in a complex environment like a workshop, the probability of failure is less than 0.5%!

We promise: free 5-year warranty for core parts, lifetime maintenance service, and 24-hour response at any time! Ensure stable operation of the machine, reduce downtime losses, and ensure smooth production for you!