In the architectural decoration industry, as the core material for exterior walls and interior partitions, the processing accuracy and installation efficiency of horizontal hanging panels directly affect the quality and cost of the project. The 90 Degree Horizontal Hanging Board Wall Cladding Panel Roll Forming Machine, as a professional forming tool, is driving industry upgrading through technological innovation. This article will comprehensively analyze its core value from four aspects: device advantages, application scenarios, technological breakthroughs, and service value.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-0.8mm

|

||

|

2.Decoiler

|

Hydraulic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

28 rows(As your requirement)

|

||

|

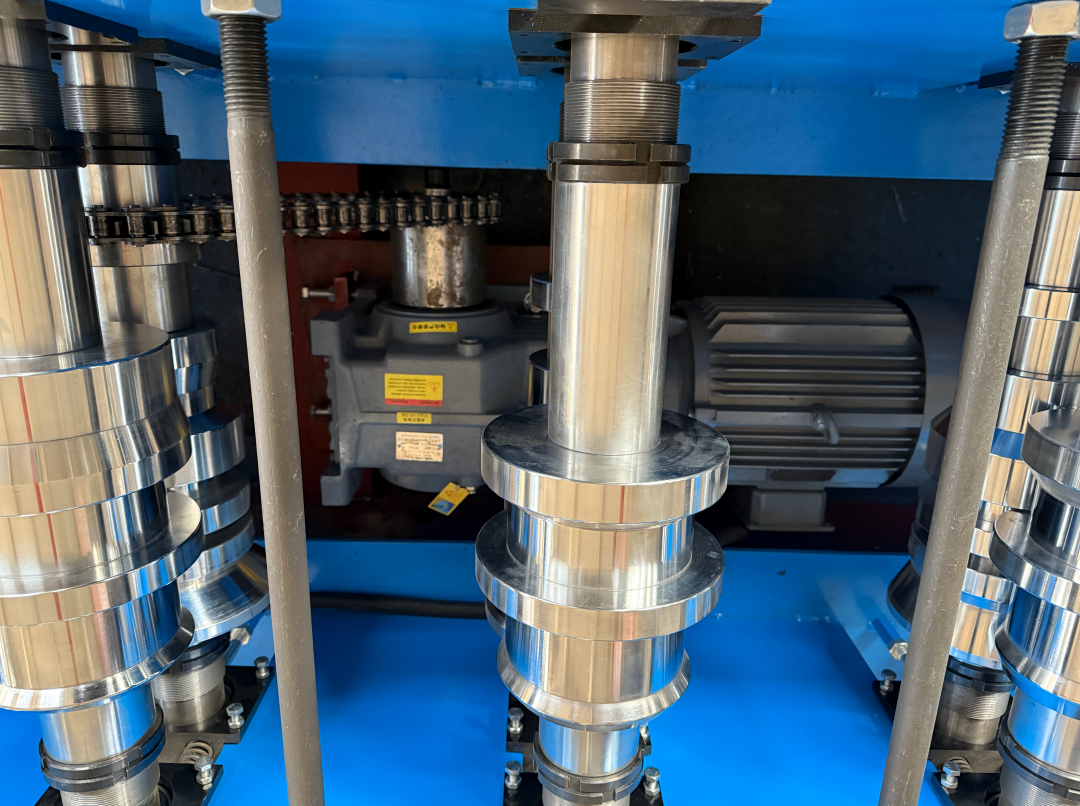

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine frame

|

350 H steel

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*1600*1600mm

|

|||

|

Weight

|

7.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

Support multiple languages

|

|||

|

PLC

|

Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min

|

The speed is adjustable

|

||

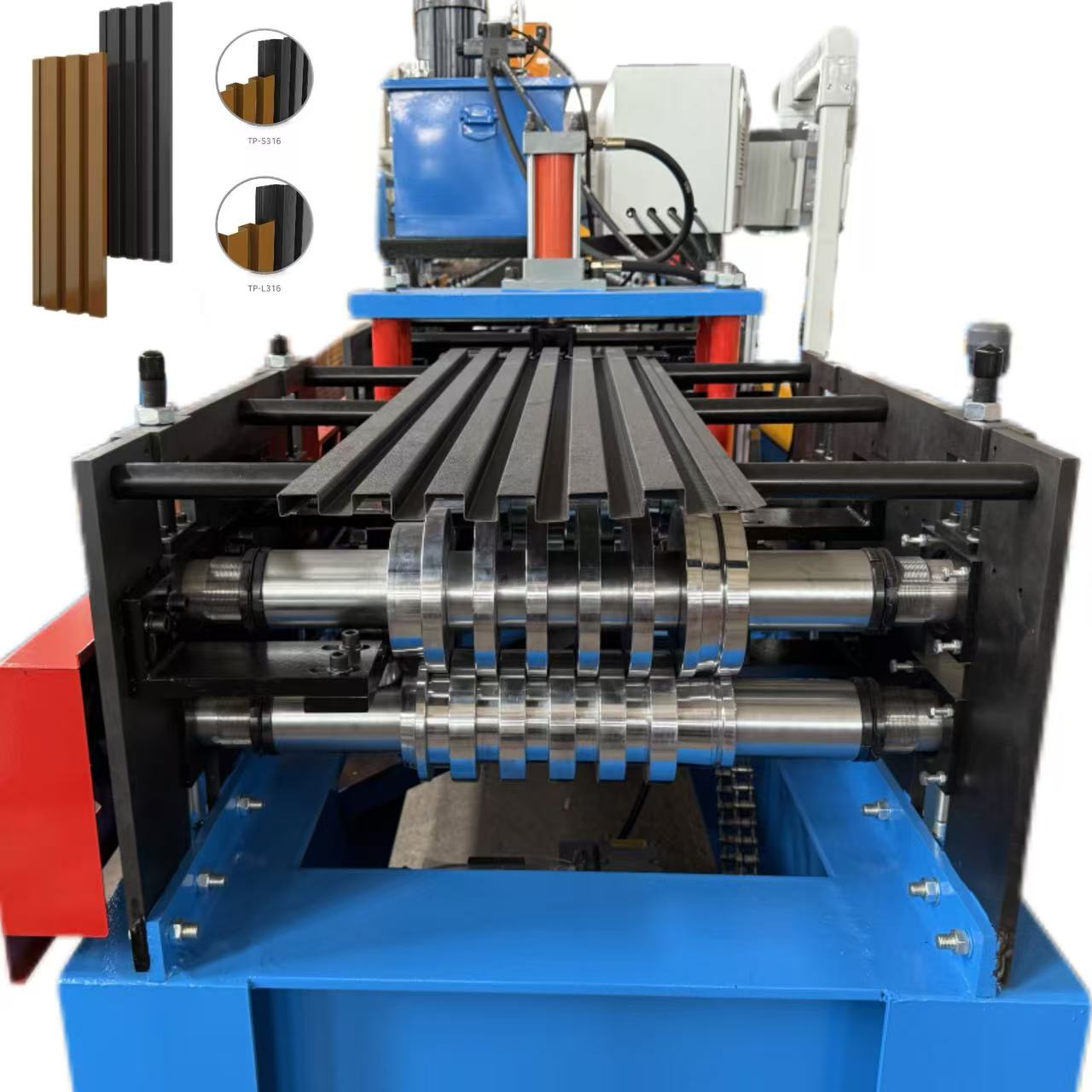

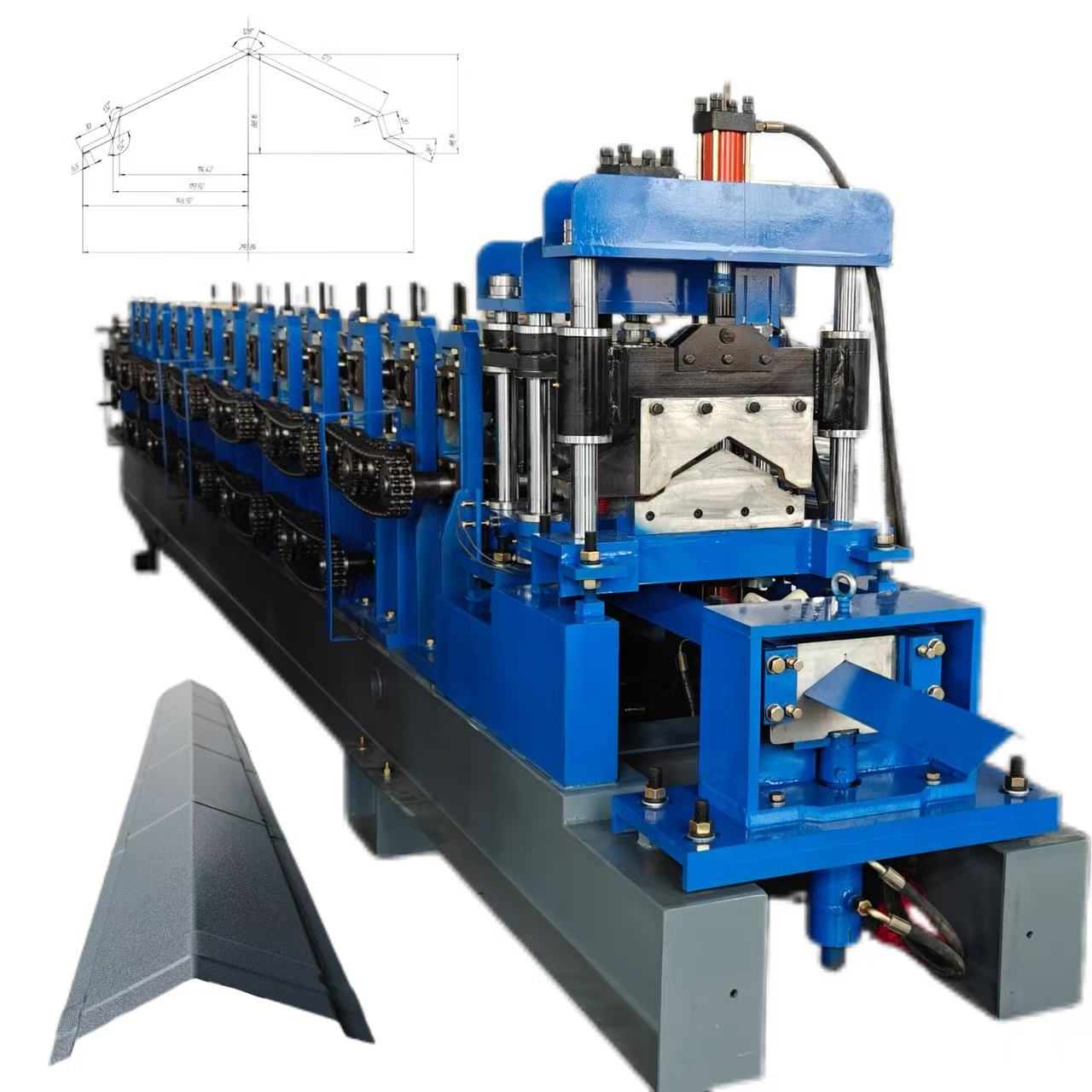

Equipment Advantage: Dual Breakthrough in Accuracy and Efficiency

The 90 Degree Horizontal Hanging Board Wall Cladding Panel Roll Forming Machine uses hydraulic or mechanical pressure systems to accurately bend metal sheets into 90 degree right angles. Its core advantages are reflected in:

1.High precision molding:

using CNC programming and servo motor drive to ensure angle error is controlled within ± 0.3 °, meeting the stringent requirements of high-end building curtain walls.

2.Efficient production mode:

The fully automatic model integrates feeding, bending, and cutting functions, with a single shift production capacity of 800-1200 pieces, which is four times more efficient than traditional processes.

3.Wide material adaptability:

Supports various materials such as aluminum plate, stainless steel, galvanized plate, etc., with a thickness range of 0.5-3mm, meeting the requirements of lightweight and high-strength.

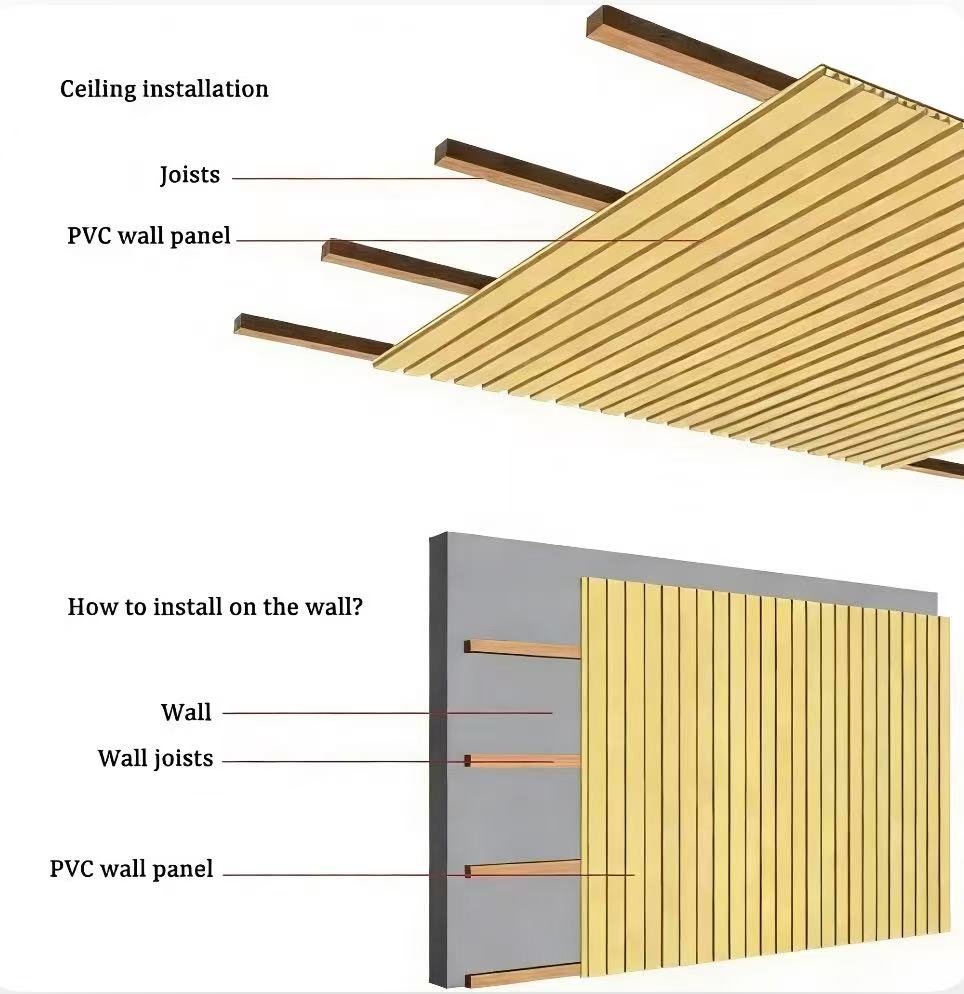

Application scenarios: Multi domain empowerment cases

• Building Curtain Wall: Quality Assurance for High end Projects

In super high-rise buildings, 90 degree horizontal hanging plates are used to make corner components.

• Indoor partitions: a powerful tool for optimizing space

In commercial space design, 90 degree horizontal hanging boards can achieve large-span partitions without columns.

• Industrial plants: a solution for rapid construction

In the field of logistics and warehousing, equipment supports modular production.

Pattern diagram:

Technological breakthrough: Intelligent and customized dual wheel drive

1. Intelligent control system

Equipped with PLC and touch screen interface, supporting one click parameter adjustment and fault self diagnosis.

2. Modular design concept

The rapid mold changing system can complete mold switching within 5 minutes, adapting to small batch production of multiple varieties. Actual test data shows that the mold changing time has been reduced from 30 minutes in traditional processes to 5 minutes. Customized services cover special needs, such as developing specialized models for photovoltaic brackets for new energy enterprises, with a bending accuracy of ± 0.1 °.