Here is the working video of this machine for everyone to watch:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

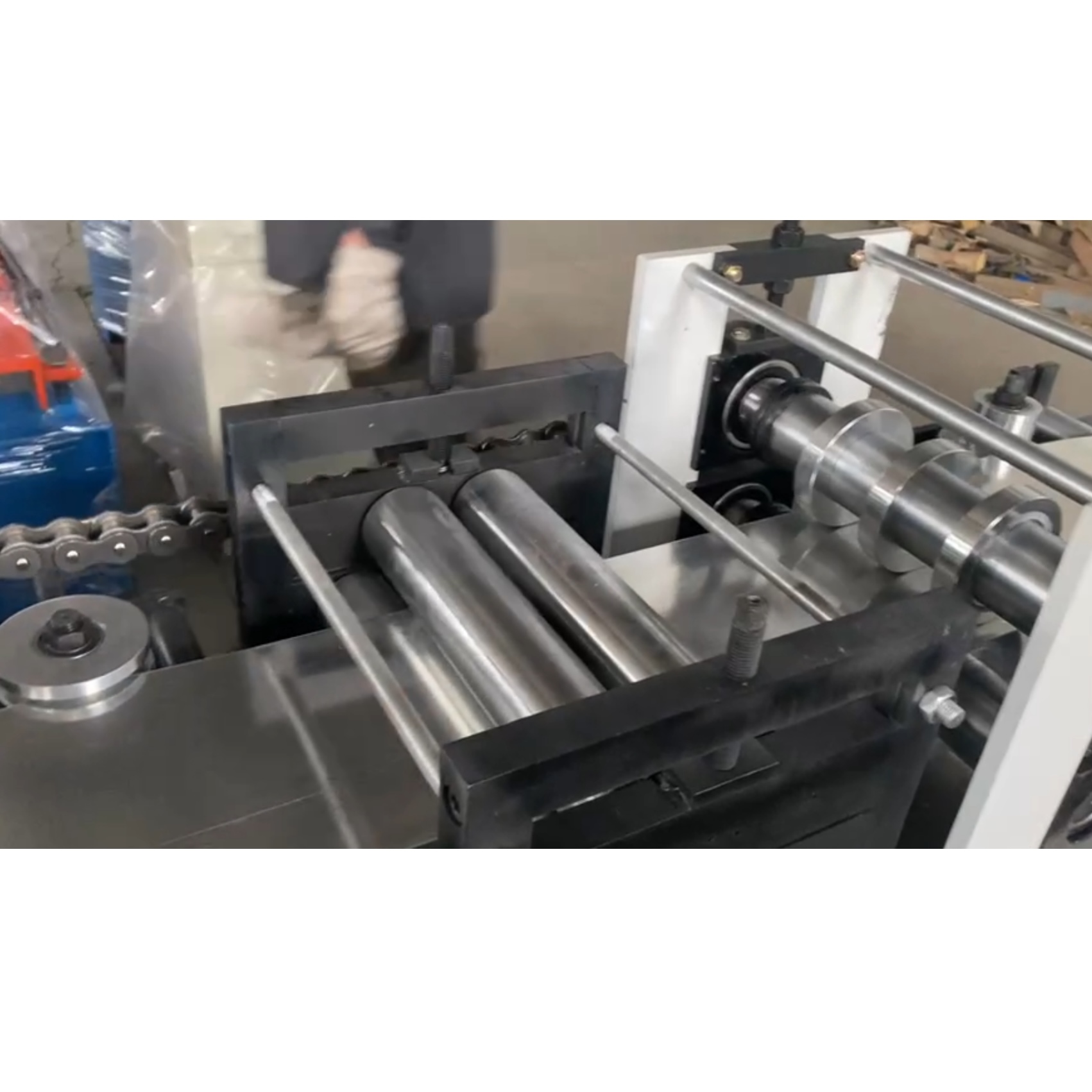

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

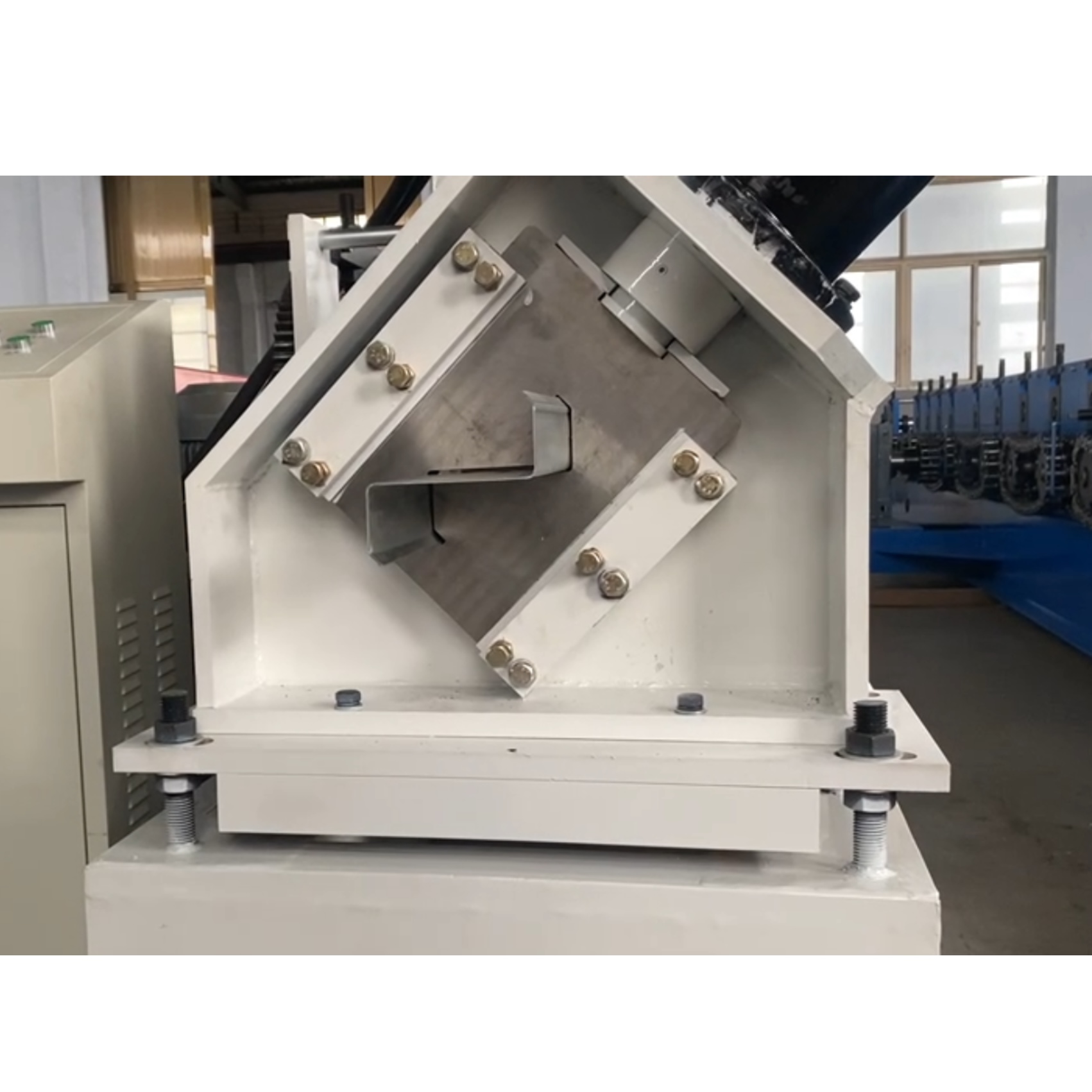

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

6.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

7.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Product Description:

Z Purlin Automatic Changeable Cold Roll Forming Machine is a mechanical equipment used for producing Z-shaped steel, widely used in large and medium-sized industrial and civil buildings as well as various industrial fields. The Z Purlin Automatic Changeable Cold Roll Forming Machine shapes steel plates or strips into Z-shaped steel through cold bending processing. Its production process includes cutting and punching steps, and can produce various profiles with uniform wall thickness but complex cross-sectional shapes, as well as cold-formed steel of different materials. Z-shaped steel mills have the advantages of high production efficiency, high degree of automation, and low cost, and are widely used in civil buildings, factories, locomotive depots, sports venues, exhibition halls, and other large and medium-sized enterprises.

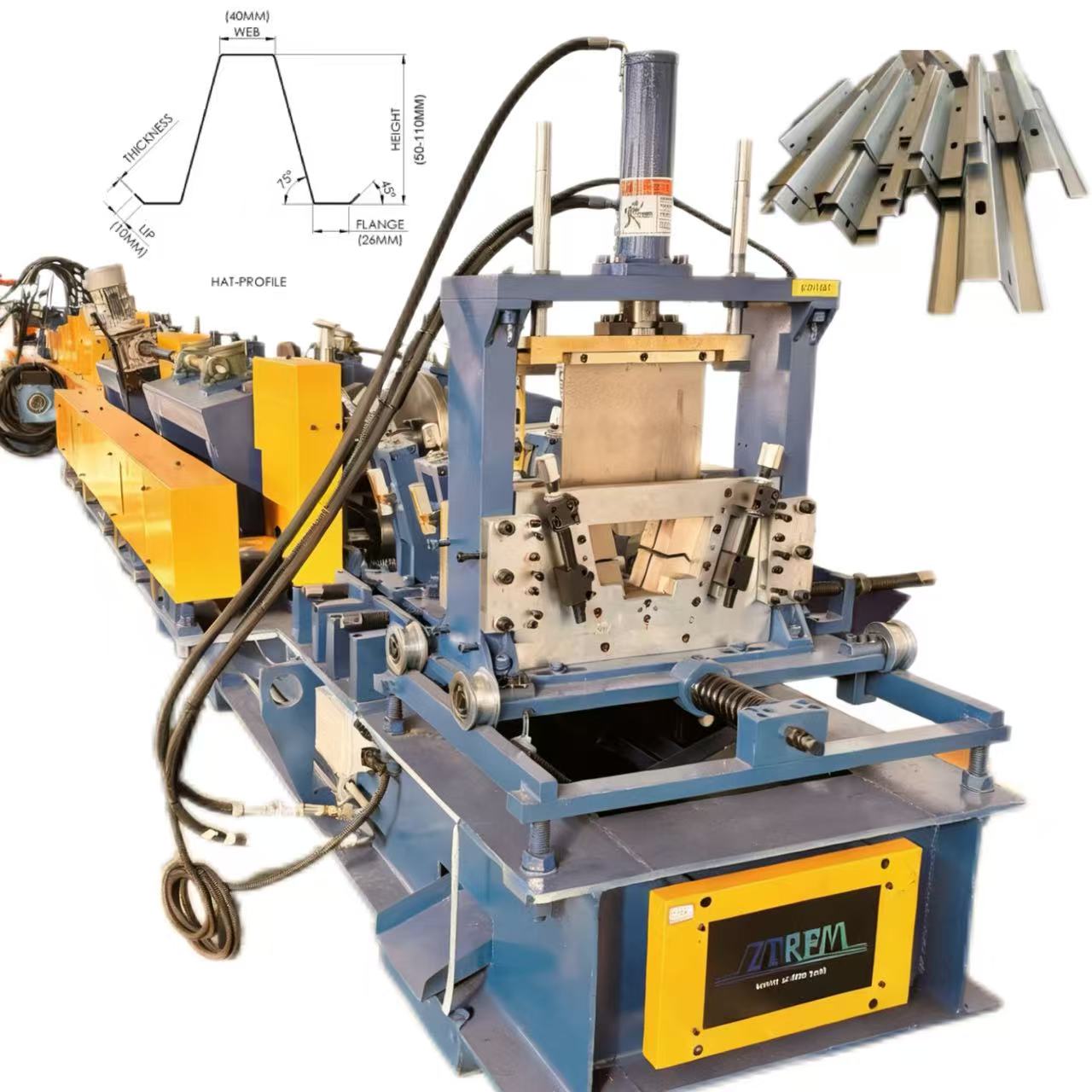

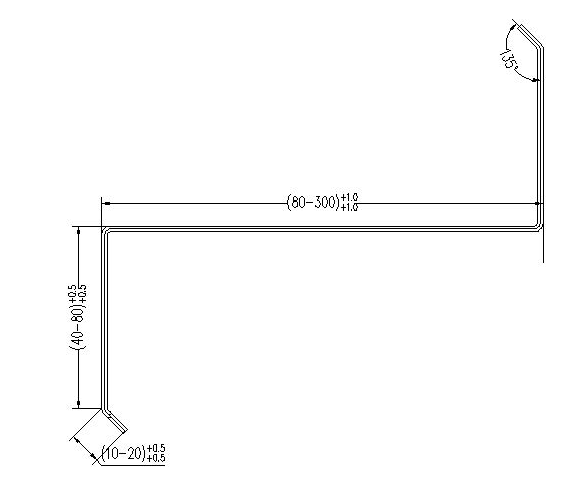

Pattern diagram:

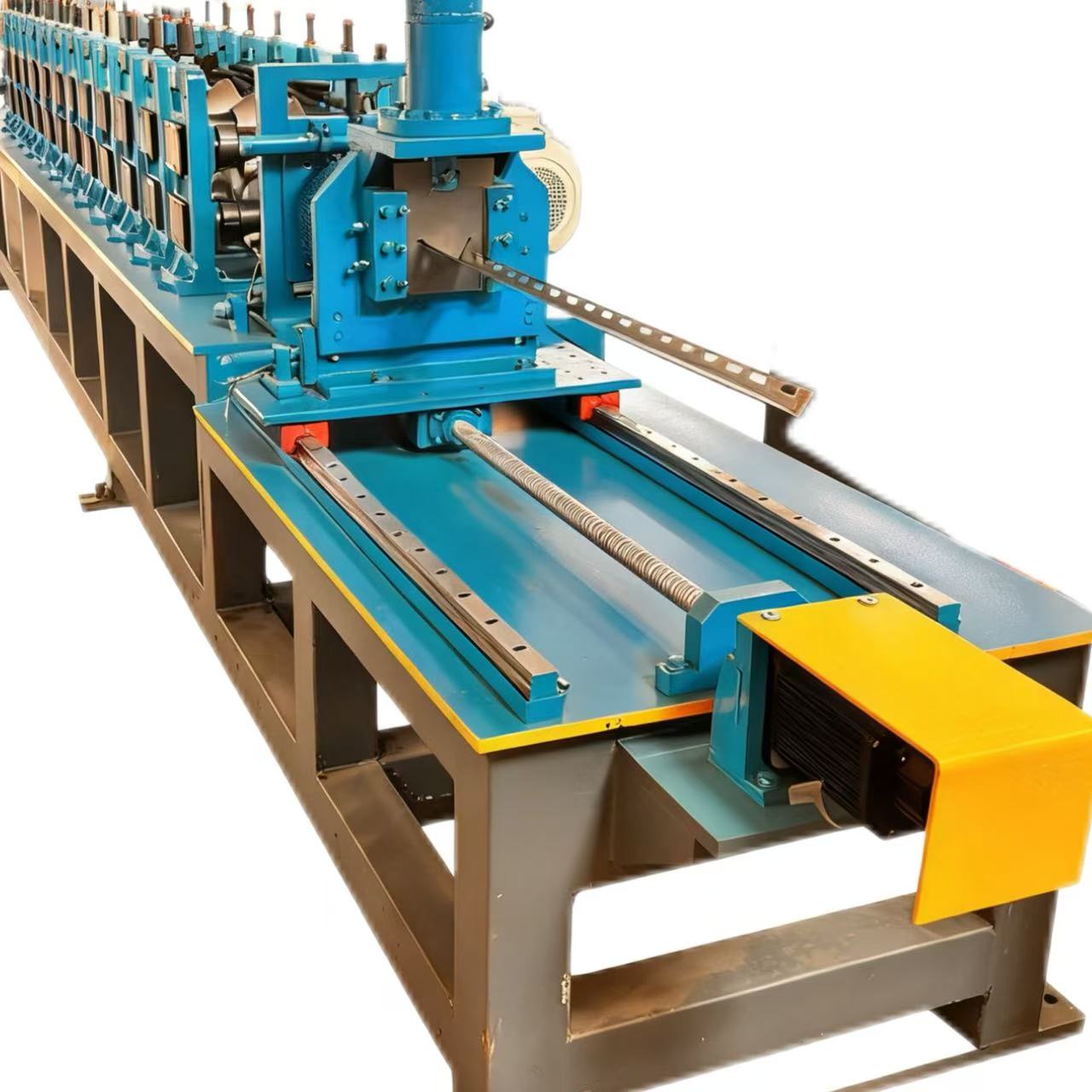

Products Display: