In the field of modern industrial manufacturing, Z-beam machines play an indispensable role as a key piece of equipment. It is capable of processing sheet metal into Z-beams with specific shapes and dimensions, and is widely used in many industries such as construction, machinery manufacturing, transportation, and more. This article will introduce the structural composition, working principle, performance parameters and application fields of Z-beam machines in detail, and give you an in-depth understanding of this powerful assistant for industrial manufacturing.

Applications:

Due to the advantages of Z-beam steel with good bending and compressive performance, good straightness, fast and convenient installation, Z-beam produced by Z-beam machine is widely used in the following fields:

1.Construction:

As the purlins and wall beams of the house surface and wall of the steel structure factory, they can bear large loads and improve the stability of the building. At the same time, Z-beams can also be combined into lightweight roof trusses or brackets, which are used in long-span buildings, such as stadiums, convention and exhibition centers, etc., which can not only save materials, but also improve construction efficiency.

2.Industrial and machinery manufacturing:

It is used to manufacture equipment supports and frames such as machine tool bases and storage facility supports, as well as load-bearing parts such as columns, beams, and arms as mechanical components. The high strength and lightweight advantages of Z-beam make it widely used in industrial manufacturing.

3.Bridges and infrastructure:

play an important role in bridge deck support components, highway facilities (such as high-speed guardrails, isolation piers), etc. Its good bending performance can meet the requirements of bridge and highway facilities for material strength and stability.

4.Other fields:

It can also be applied to solar brackets, shelving systems, agricultural greenhouses and other scenarios, which fully reflects the multi-field adaptability of Z-beam machine products.

Advantages of the machine:

1.Efficient production:

the use of automatic control, fast production speed, can meet the needs of large-scale production. Compared with the traditional manual processing method, the production efficiency is greatly improved and the production cycle is shortened.

2.Precise machining:

Through advanced PLC frequency conversion control technology and high-precision roll design, the dimensional accuracy and shape consistency of Z-beam can be guaranteed, and product quality can be improved.

3.Flexibility:

The processing parameters can be adjusted according to different needs to produce Z-beams of various specifications to meet the diverse needs of different industries. At the same time, additional functions such as punching also increase the flexibility of the equipment.

4.Material saving:

In the processing process, the metal plate can be used rationally, reducing the waste of materials and reducing production costs.

5.Easy operation:

The design of the computer control cabinet allows the operator to easily master the operation method of the equipment, reducing the requirements for the skill level of the operator.

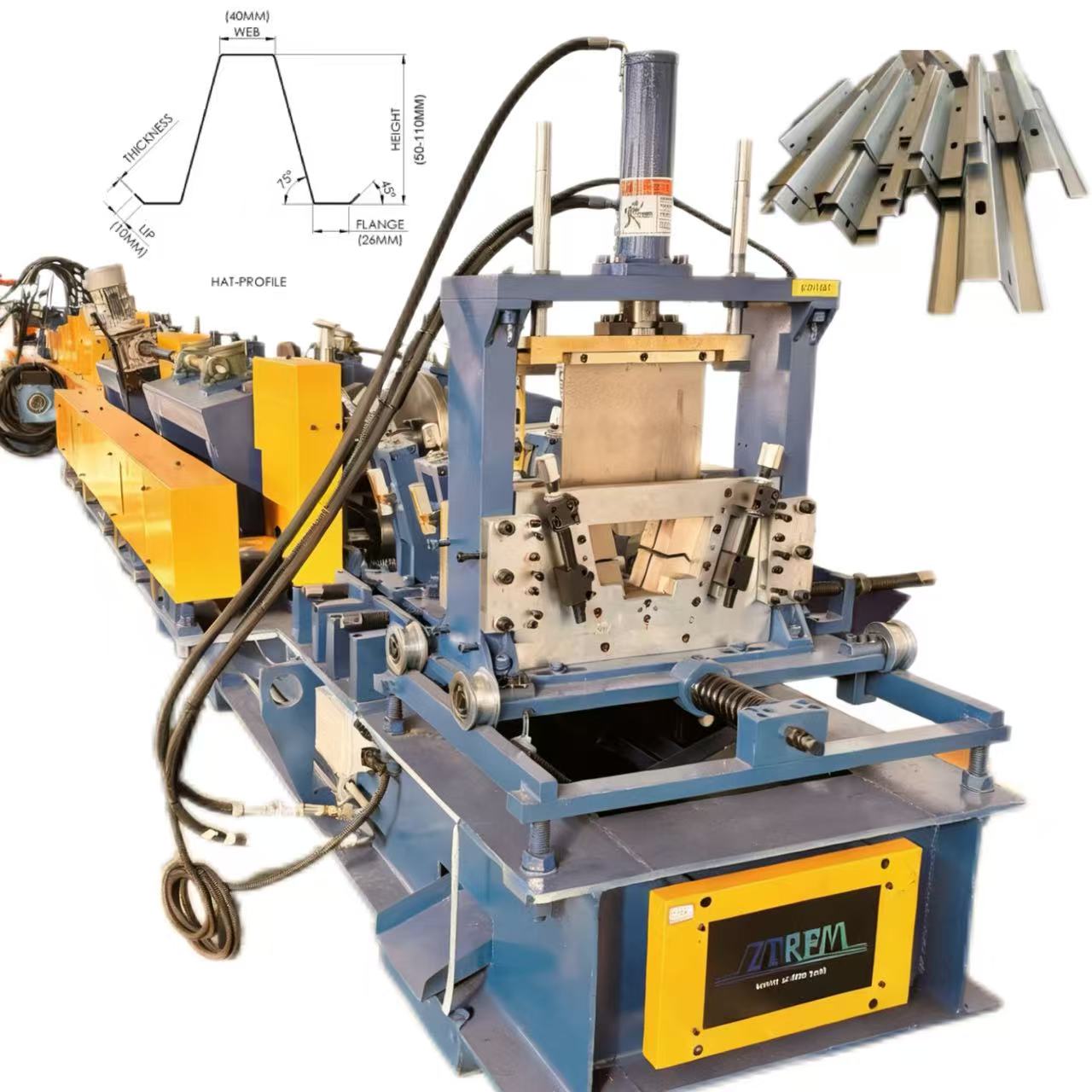

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission | |||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

6.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

7.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

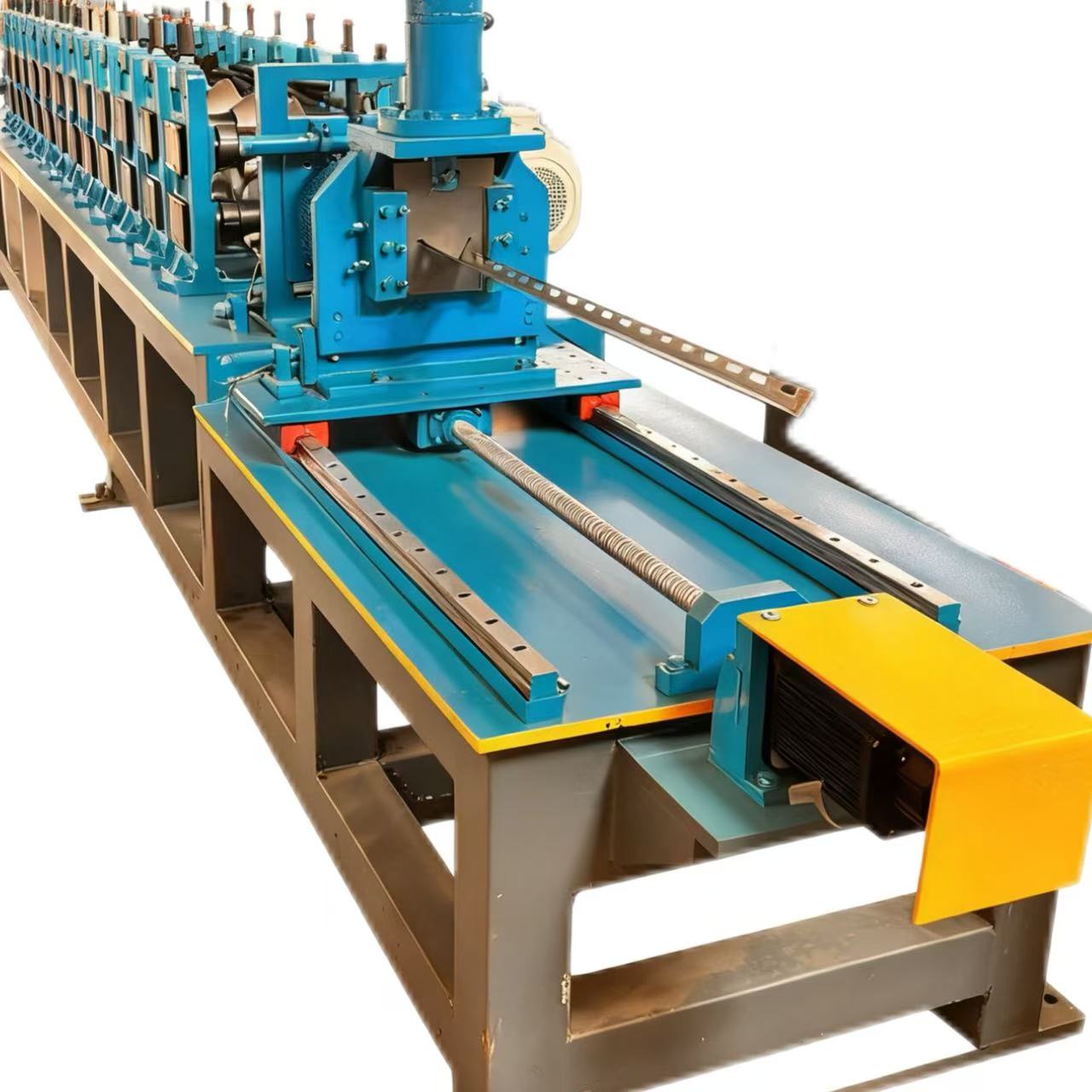

Products Display: