Forklifts, as the core equipment of modern logistics and warehousing, have a direct impact on the operational efficiency of enterprises in terms of safety and efficiency. The Zhongtuo Cold Bending’s 8mm Forklift Sliding Rail Roll Forming Machine, as a key component of the forklift, plays a decisive role in improving forklift performance and ensuring operational safety.

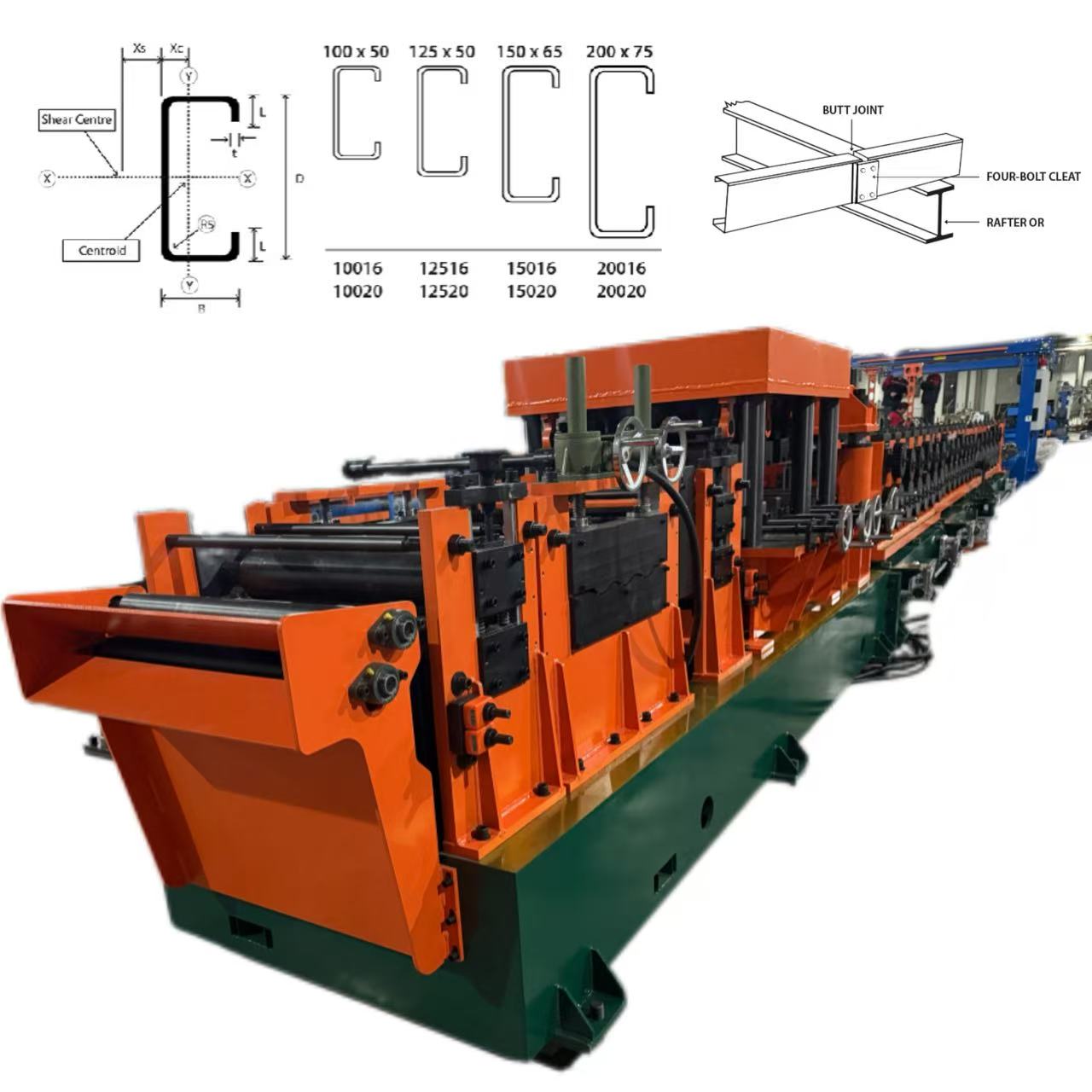

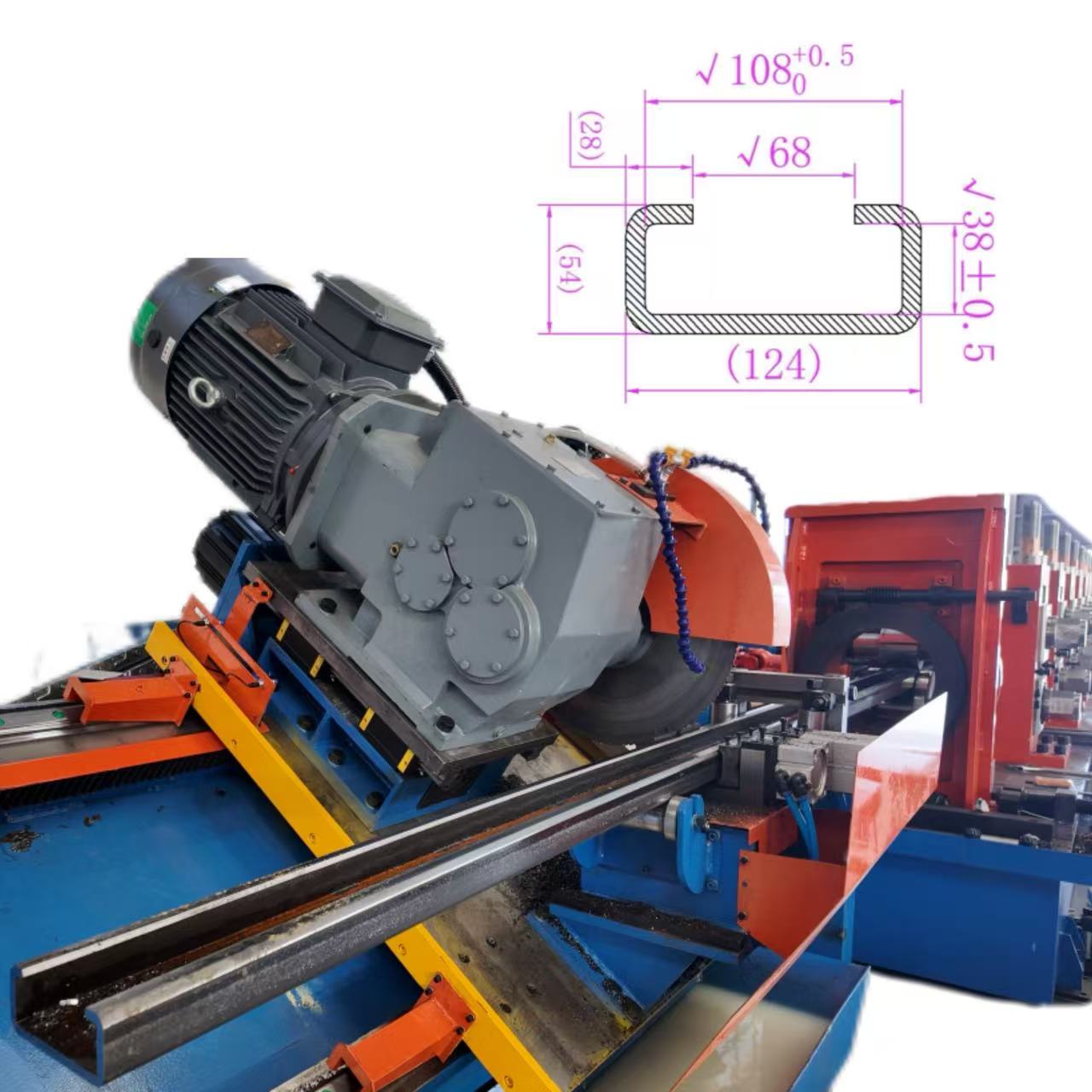

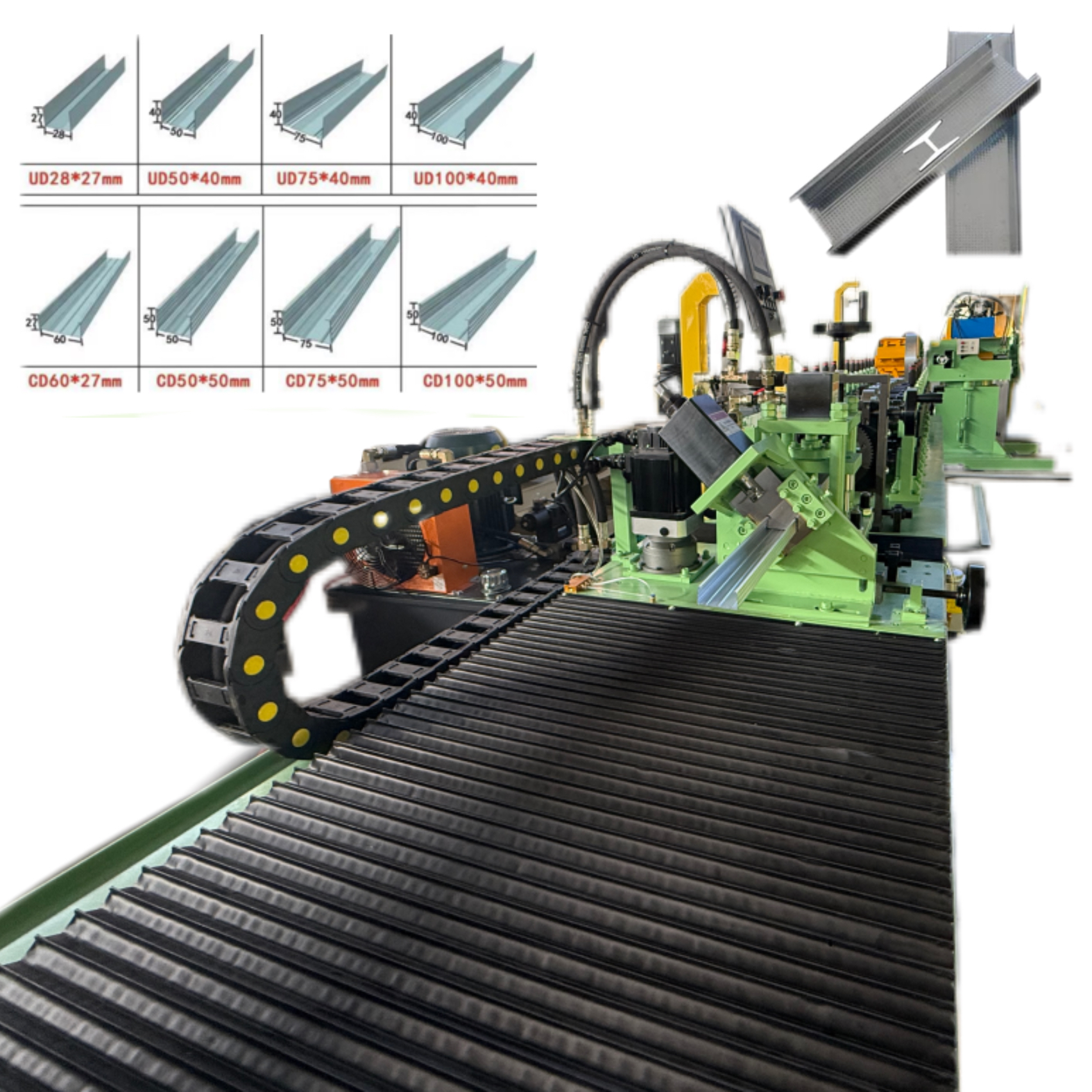

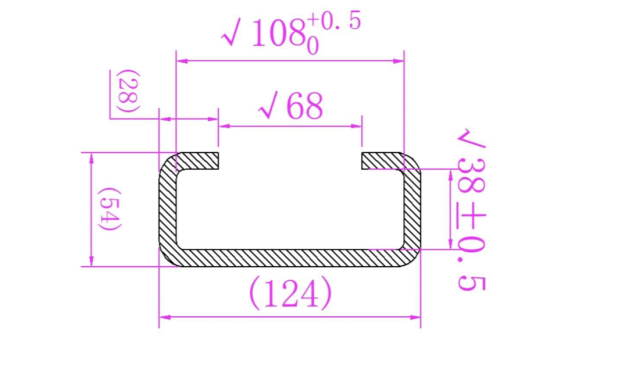

Profile drawing as below:

Core advantages of C-shaped steel equipment

1. Structural design: the cornerstone of safety and efficiency

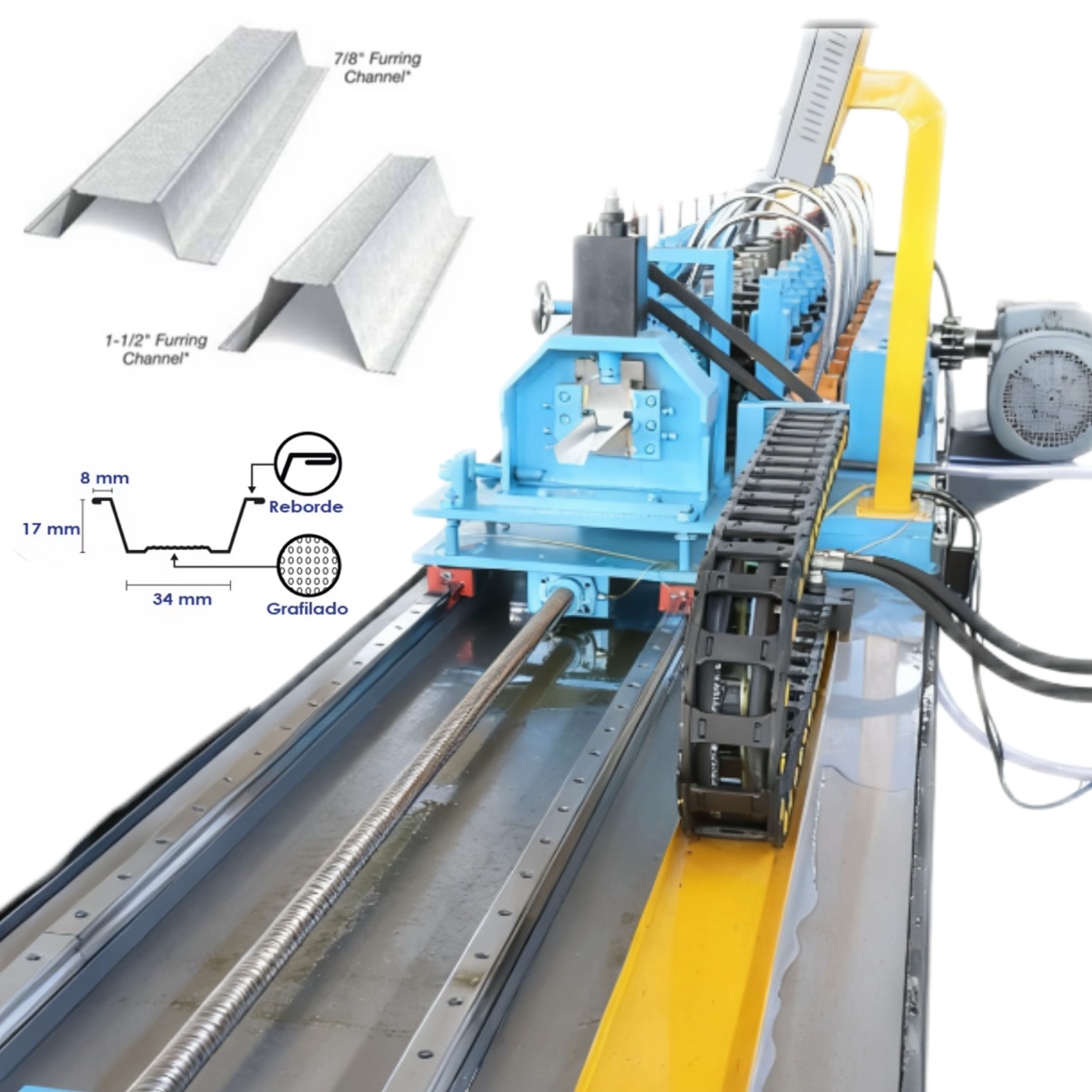

The C-type forklift door frame channel steel adopts a unique “C” section design, which is an innovative structure that enables it to withstand huge axial and lateral loads. When transporting heavy objects with a forklift, this design effectively disperses various forces, ensures the stability of the gantry, prevents deformation under heavy loads, significantly reduces operational risks, and ensures the safety of personnel and equipment. In addition, lightweight design reduces material usage, makes the gantry more compact, improves the maneuverability of forklifts in narrow spaces, and optimizes energy utilization efficiency, providing a physical foundation for efficient operations.

2. Operational flexibility: Adapt to complex scenarios

The design of C-shaped steel not only enhances the load-bearing capacity of forklifts, but also improves operational flexibility. Its structural characteristics allow forklifts to move flexibly in complex environments such as warehouses, workshops, etc., reducing operational difficulty and improving work efficiency. This flexibility is particularly important for scenarios that require frequent adjustment of work positions, ensuring that forklifts can quickly respond to production needs and reduce work delays.

3. Load bearing and stability: dual guarantee

The belly plate of the C-shaped channel steel is designed vertically to the ground, which can effectively resist the bending stress generated by the gravity of the goods, and the stress distribution is uniform and not easy to concentrate. The outward extension of the two wing edges increases the connection area, making the installation of the gantry more stable, effectively dispersing lateral forces, reducing shaking, and improving overall stability. This design is particularly important when handling heavy objects, ensuring the safety of goods and reducing accidents caused by unstable equipment.