Purlin making machines have become a game-changer in the metal construction industry, offering unparalleled efficiency and precision in producing purlins. These specialized machines automate the purlin manufacturing process, delivering consistent and high-quality results. In this article, we will explore the benefits and applications of purlin making machines, highlighting their role in revolutionizing metal construction processes.

Understanding Purlin Making Machines:

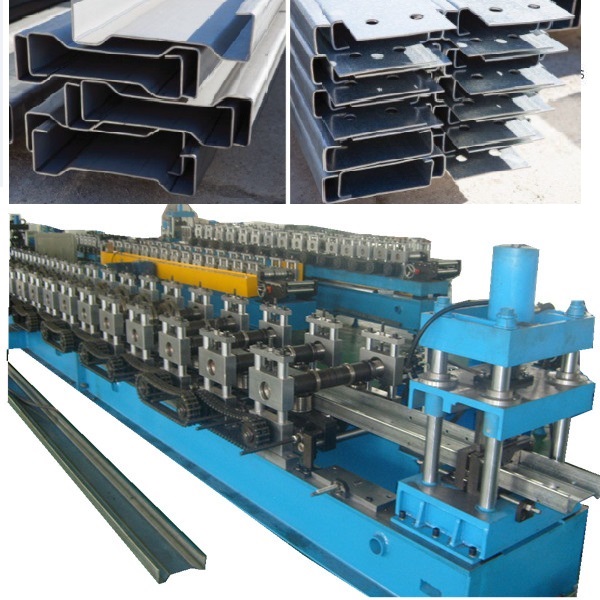

Purlin making machines are advanced equipment designed to streamline the production of purlins, which are essential structural components used in metal construction. These machines utilize a combination of roll forming technology, cutting mechanisms, and automated controls to transform metal coils into accurately shaped purlins. Purlin making machines are capable of processing various metals, including galvanized steel, ensuring strength and durability in construction projects.

Enhanced Efficiency and Productivity:

One of the key advantages of purlin making machines is their ability to significantly enhance efficiency and productivity in purlin production. These machines automate the entire manufacturing process, eliminating the need for manual intervention and reducing labor-intensive tasks. With high-speed production capabilities, purlin making machines can process metal coils rapidly, resulting in increased output and shorter lead times. The improved efficiency and productivity allow construction companies to meet project deadlines and handle larger volumes of work effectively.

Precision and Consistency:

Purlin making machines offer exceptional precision and consistency in purlin production. The machines are equipped with precision-engineered rollers and cutting mechanisms, ensuring accurate shaping and precise measurements. This results in uniformly shaped purlins with tight tolerances, ensuring dimensional accuracy and consistency throughout the manufacturing process. The precise and consistent production capabilities of purlin making machines contribute to the structural integrity and reliability of metal buildings.

Versatility in Design and Dimensions:

Purlin making machines provide versatility in design and dimensions, enabling manufacturers to produce a wide range of purlins to suit different construction requirements. These machines can be customized to create various purlin profiles, including C-shaped, Z-shaped, and custom designs. Additionally, the machines can accommodate different dimensions and thicknesses of purlins, allowing flexibility in adapting to architectural designs and structural specifications. Purlin making machines offer the freedom to produce purlins that align with specific project needs.

Material Efficiency and Cost Savings:

Purlin making machines optimize material usage and contribute to cost savings in metal construction. The machines are designed to minimize material waste by efficiently utilizing the metal coils. They often incorporate features like nesting optimization software, which intelligently arranges the purlin profiles on the metal coil to maximize material utilization and reduce scrap. This material efficiency not only reduces material costs but also promotes sustainable construction practices.

Applications of Purlin Making Machines:

Purlin making machines find applications in various metal construction projects, including:

Industrial and commercial buildings

Warehouses and storage facilities

Agricultural structures such as barns and sheds

Residential roofing and wall systems

Prefabricated metal buildings

Renovation and retrofit projects

Conclusion:

Purlin making machines have transformed the metal construction industry by offering enhanced efficiency, precision, and versatility in purlin production. These machines streamline the manufacturing process, reduce labor requirements, and deliver consistent and high-quality results. By investing in purlin making machines, construction companies can optimize their production processes, save costs, and deliver structurally sound buildings. With their numerous advantages and wide range of applications, purlin making machines are essential tools in modern metal construction.