In the realm of modern construction, efficiency and precision are key elements in achieving superior structural integrity. One of the technological marvels contributing to this is the Floor Deck Roll Forming Machine. In this article, we will delve into the significance of this machine, its applications, benefits, and how it is revolutionizing the process of creating robust and reliable floor decks in construction projects.

Section 1: Unveiling the Floor Deck Roll Forming Machine

What Is a Floor Deck Roll Forming Machine?

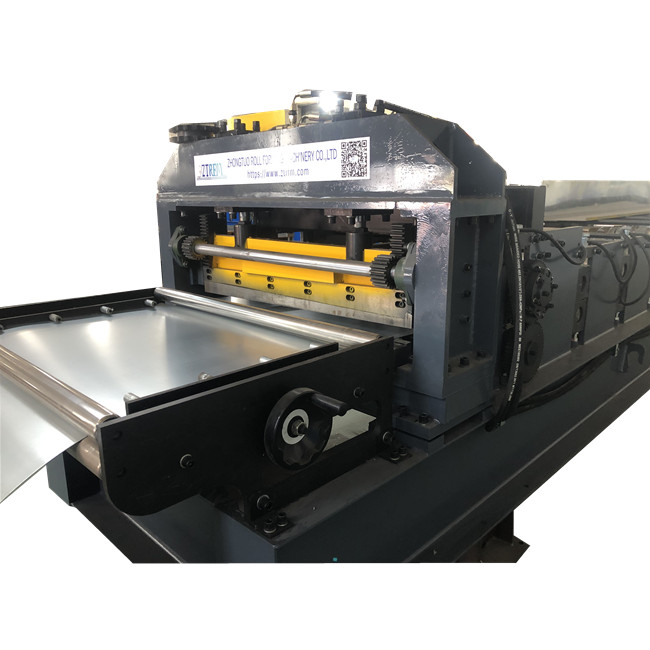

A Floor Deck Roll Forming Machine is a specialized piece of equipment designed to efficiently fabricate floor decking profiles used in construction. It operates by cold-forming continuous sheets of metal into precise shapes, creating robust and cost-effective floor decks for various building applications.

Significance in Construction

The Floor Deck Roll Forming Machine plays a pivotal role in construction projects where speed, precision, and durability are paramount. By automating the manufacturing process, it ensures the production of standardized and high-quality floor decks, streamlining construction timelines and reducing costs.

Section 2: How Floor Deck Roll Forming Machines Work

The Mechanism

This machine operates by passing metal coils through a series of rollers that gradually shape the material into the desired floor deck profile. The cold-forming process ensures the structural integrity of the metal while allowing for efficient and continuous production.

Versatility in Construction

Floor Deck Roll Forming Machines are versatile, accommodating various types of metal and producing different profiles. This adaptability makes them suitable for a wide range of construction projects, from residential buildings to large-scale commercial structures.

Section 3: Applications and Versatility

Flooring Systems

The primary application of Floor Deck Roll Forming Machines is in the creation of flooring systems for buildings. These systems provide support and stability to the structure, contributing to its overall strength and load-bearing capacity.

Roof Decks

In addition to flooring, these machines are utilized in the production of roof decks, providing a durable and reliable solution for roofing structures. The profiles created by the machine contribute to effective water drainage and weather resistance.

Section 4: Advantages of Floor Deck Roll Forming Machines

Speed and Efficiency

Floor Deck Roll Forming Machines significantly accelerate the manufacturing process compared to traditional methods. The continuous and automated nature of the machine ensures swift production, reducing construction timelines.

Precision and Consistency

The cold-forming process guarantees precise shaping of the metal, resulting in consistent and high-quality floor decks. This uniformity enhances the structural integrity of the building, reducing the likelihood of issues related to uneven surfaces.

Cost-Effectiveness

By automating the manufacturing process and minimizing material waste, Floor Deck Roll Forming Machines contribute to cost savings in construction projects. The efficiency of these machines translates to a reduction in labor costs and optimized use of materials.

Section 5: The Future of Floor Deck Roll Forming Machines in Construction

Technological Innovations

Ongoing advancements in Floor Deck Roll Forming Machines include the integration of smart controls, real-time monitoring, and improved material handling capabilities. These innovations contribute to enhanced performance and operational efficiency.

Sustainable Construction Practices

As the construction industry embraces sustainability, Floor Deck Roll Forming Machines play a vital role. Their efficiency in material usage, coupled with the ability to recycle and reuse metal, aligns with the global commitment to environmentally responsible construction practices.

The Floor Deck Roll Forming Machine stands as a technological cornerstone in modern construction, embodying efficiency, precision, and cost-effectiveness. Its ability to seamlessly produce high-quality floor decks and roof decks has become instrumental in shaping the skyline of cities worldwide. As construction practices evolve, Floor Deck Roll Forming Machines are set to remain indispensable, offering a sustainable and innovative solution for creating robust and reliable building components. With ongoing technological advancements and a heightened focus on sustainable construction, these machines will continue to be at the forefront of revolutionizing the construction industry.