In today’s booming development of prefabricated buildings and green energy, CZ steel, as the core load-bearing component of steel structure buildings, is widely used in industrial plant purlins, storage shelves, photovoltaic brackets, traffic noise barriers and other scenarios. From column free logistics warehouses over 30 meters to wind resistant roof systems, from multi span greenhouse skeletons to subway platform keels, the efficient production of high-quality CZ steel cannot be achieved without professional level intelligent equipment – Our Automatic Type Change C/Z Purlin Cold Roll Forming Machine, with “cold bending technology+intelligent control” as the core, realizes C/Z type free switching and multi specification precise forming, which not only meets the efficient delivery of large-scale projects, but also adapts to the flexible production of customized projects, upgrading the safety performance and construction efficiency of steel structures synchronously.

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

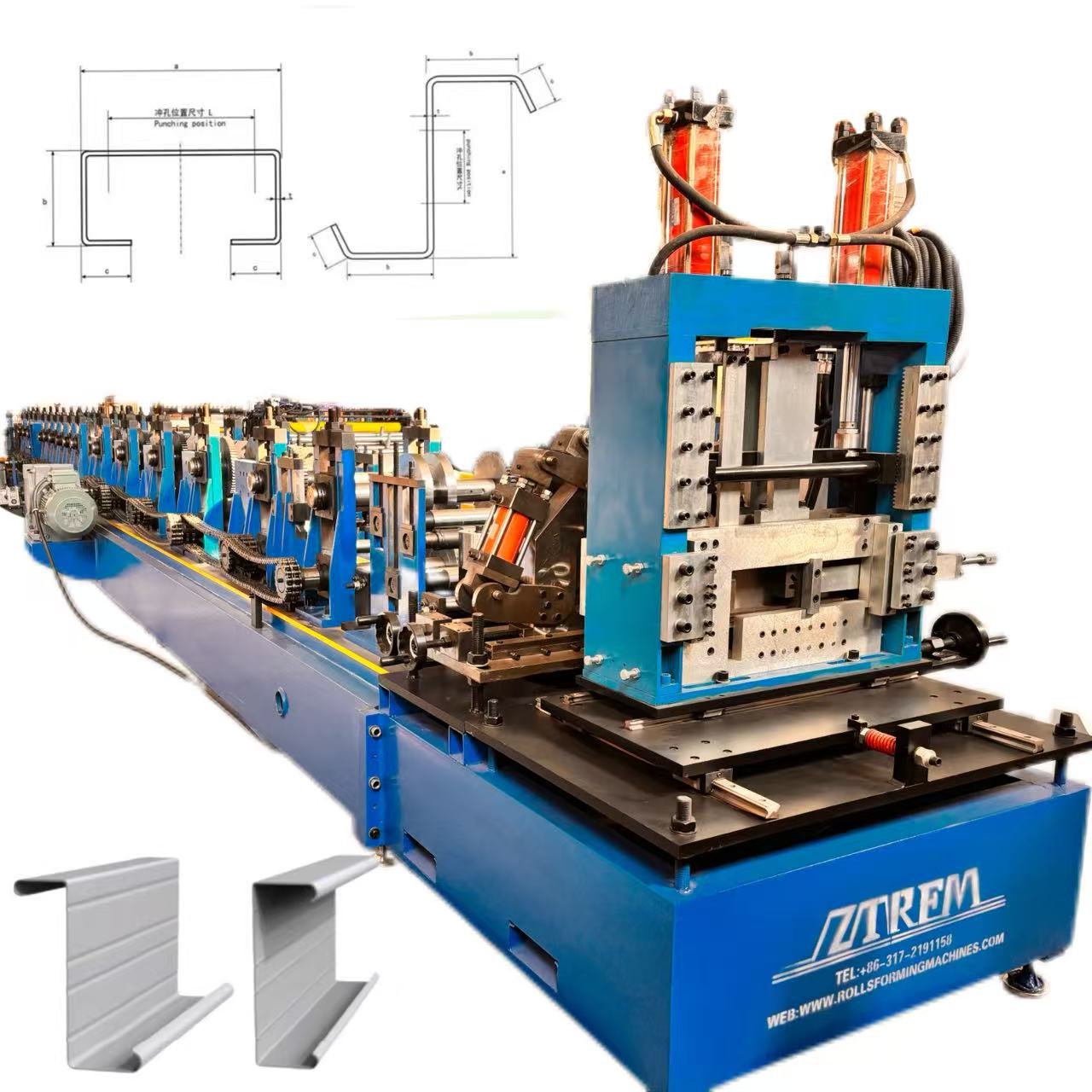

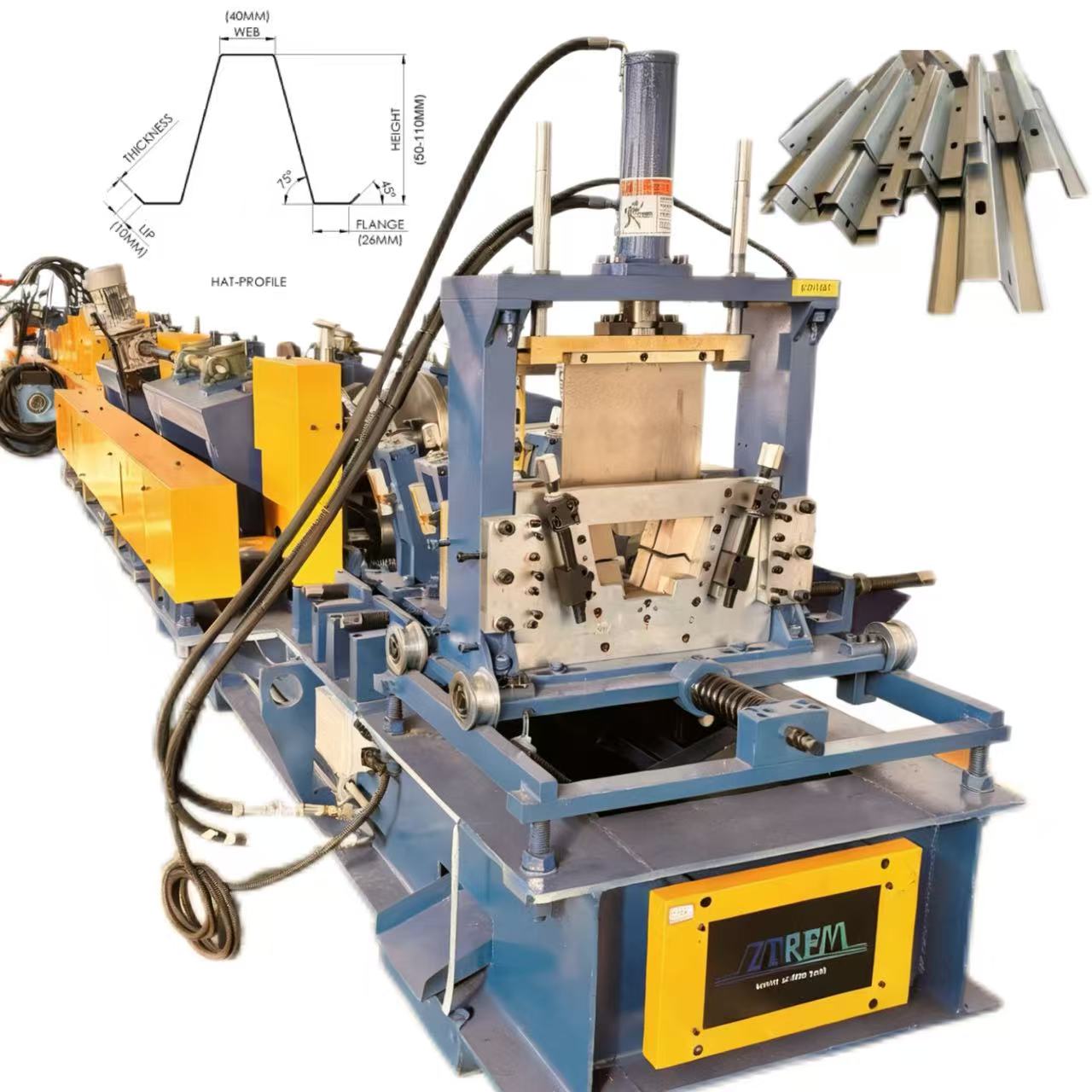

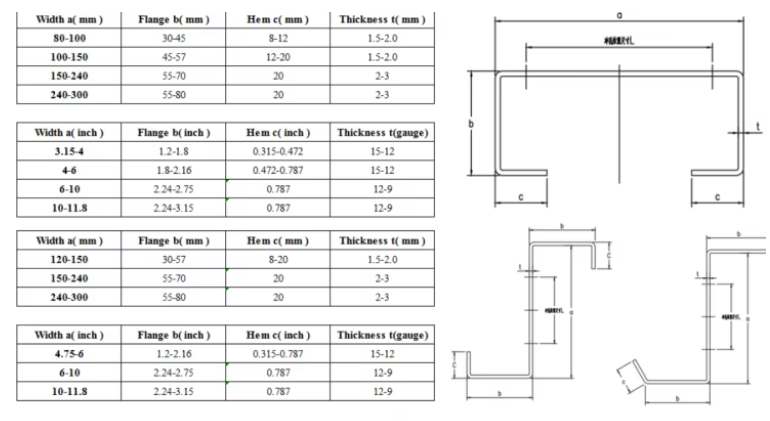

Pattern diagram:

Application Scenarios:

Widely used in the fields of construction, bridges, workshops, warehouses, etc., it is mainly used for producing C-shaped steel and Z-shaped steel to meet the load-bearing requirements of steel structure factories, warehouses, bridges and other projects. The following are specific application scenarios:

• construction field

Steel structure factory building: used for roof load-bearing and wall support, such as industrial factories, warehouses, locomotive depots, etc.

Public buildings: suitable for large-span structures such as exhibition halls, cinemas, sports venues, etc.

• Bridges and transportation facilities

Bridge components: Produce high-strength C/Z steel for bridge supports or reinforcement structures.

Workshop and Warehouse: Rapid prototyping of standardized components to improve construction efficiency.

• Other industrial uses

Equipment bracket: Customized production to meet the installation needs of special equipment.

Irregular structure: Adapt to non-standard designs such as seismic supports or guardrails through parameter adjustments.

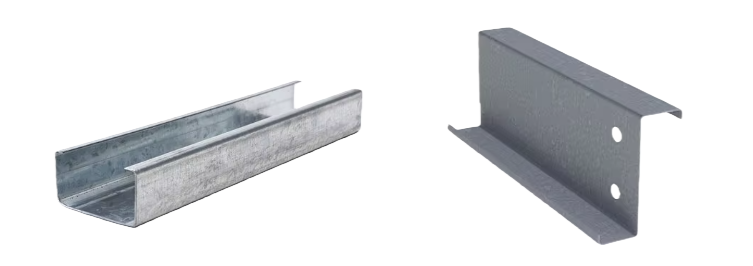

Finished product image:

Core advantages, reshaping the competitiveness of steel structure production

1. Intelligent and efficient, doubling production capacity to reduce costs and increase efficiency

• Full process automation:

The entire process from coil feeding to automatic palletizing is unmanned, with an automation rate of over 98%. One person can control the entire production line.

• High yield and stability:

driven by a 22kw servo motor, with a maximum speed of 35m/min, capable of producing 50 tons per day and increasing efficiency by 3-5 times, with a monthly output exceeding 1200 tons.

• Energy saving and material saving:

The cold bending process reduces energy consumption by 20% -40%, and the double shearing and nesting technology achieves a material utilization rate of 98%, saving over 150000 yuan in annual costs.

2. Precision quality, with a finished product compliance rate of 99.8%

• Precision molding:

16-18 roller presses, GCr15 mold forming accuracy ± 0.1mm, straightness error<1.0mm/6000mm, angle error ≤ 1 °.

• Intelligent control:

PLC touch screen precise parameter setting, dynamic correction ensures that the finished product meets the GB/T 6725 standard.

• Strong and durable:

The 400 channel steel frame and 40Cr spindle have strong deformation resistance and are compatible with high-strength steel, resulting in a 10% -15% increase in finished product strength.

3. Flexible adaptation to meet personalized production needs

• Quick switching:

Supports the production of multiple specifications of profiles with a cross-section of 80-300mm, with one click changeover and production line adjustment completed in 2 hours.

• Customization compatibility:

Suitable for various types of boards, supporting customization of web openings, etc., to meet special needs such as photovoltaics and warehousing.

• Convenient operation and maintenance:

Modular design for easy maintenance, multilingual tutorials to help beginners quickly get started, and maintenance costs reduced by 30%.