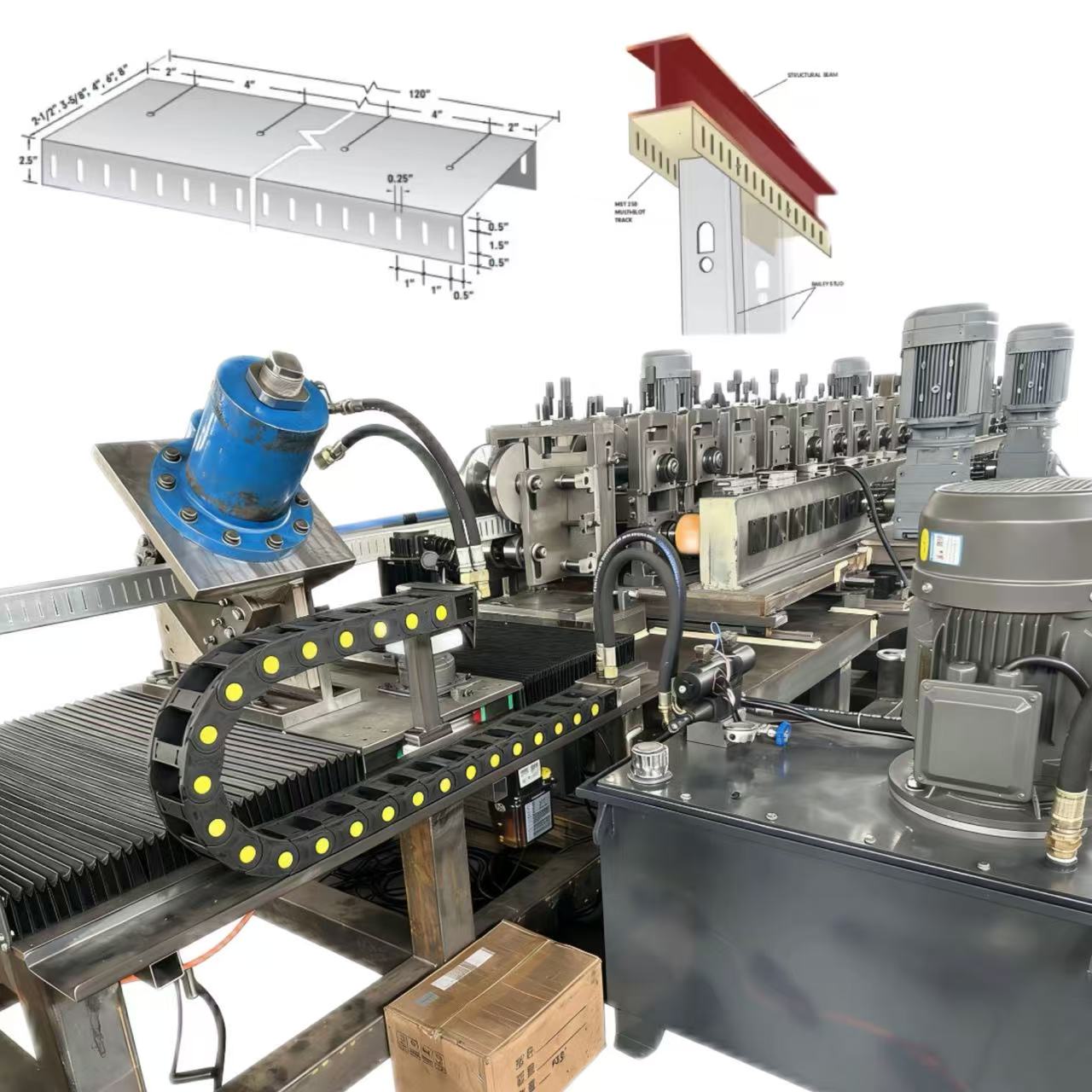

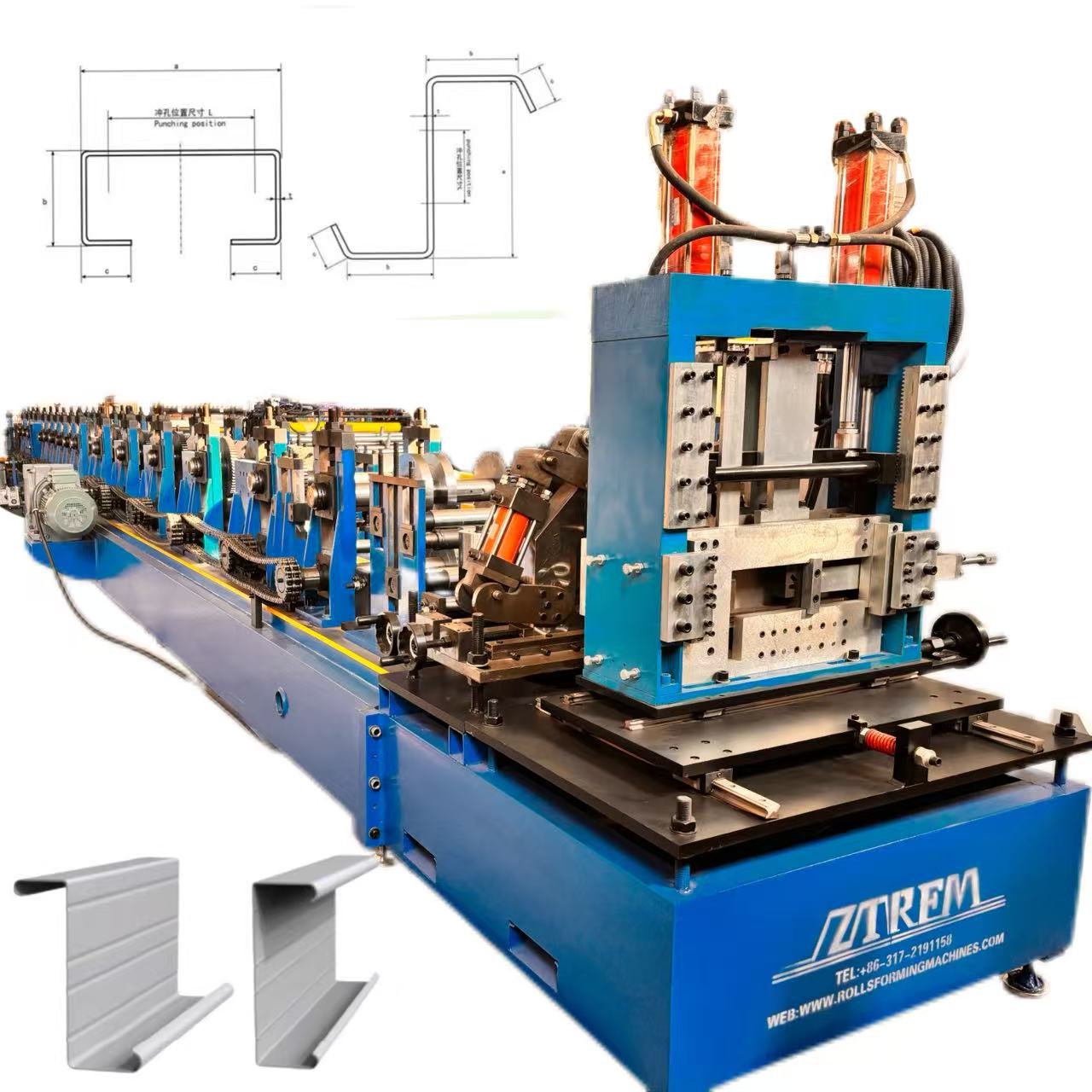

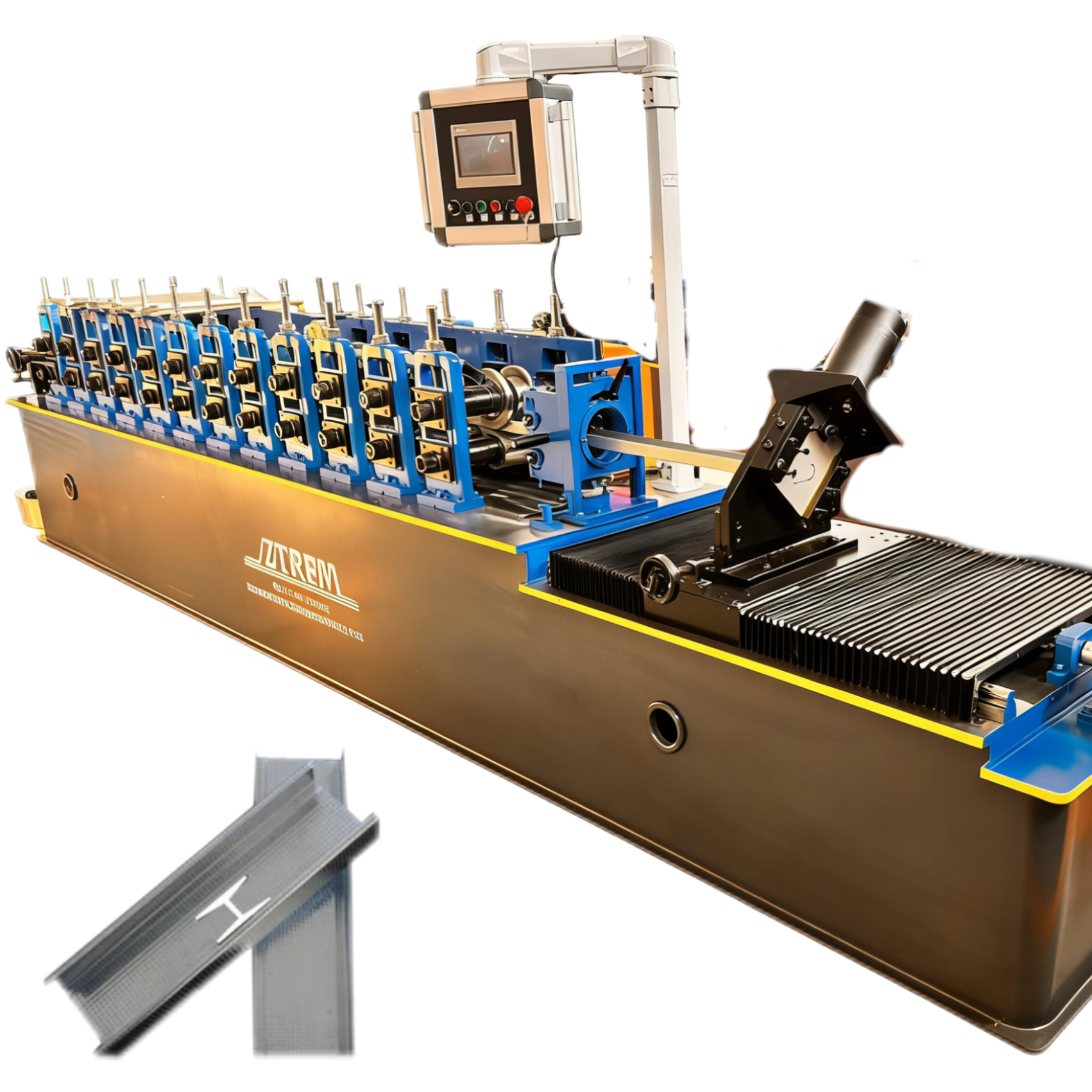

Automatic Metal Steel C Z Shape Purlin Making Machine for Roof Structure

Product Attributes :

|

Quality automatic metal steel c z shape purlin making machine for roof structure

|

||||

|

1.Formed Material

|

GI

|

Thickness:1.5-3 mm (standard)

|

||

|

2.Decoiler

|

3 Tons Hydraulic automatic decoiler

|

3 Tons Manual decoiler(will give you as free)

|

||

|

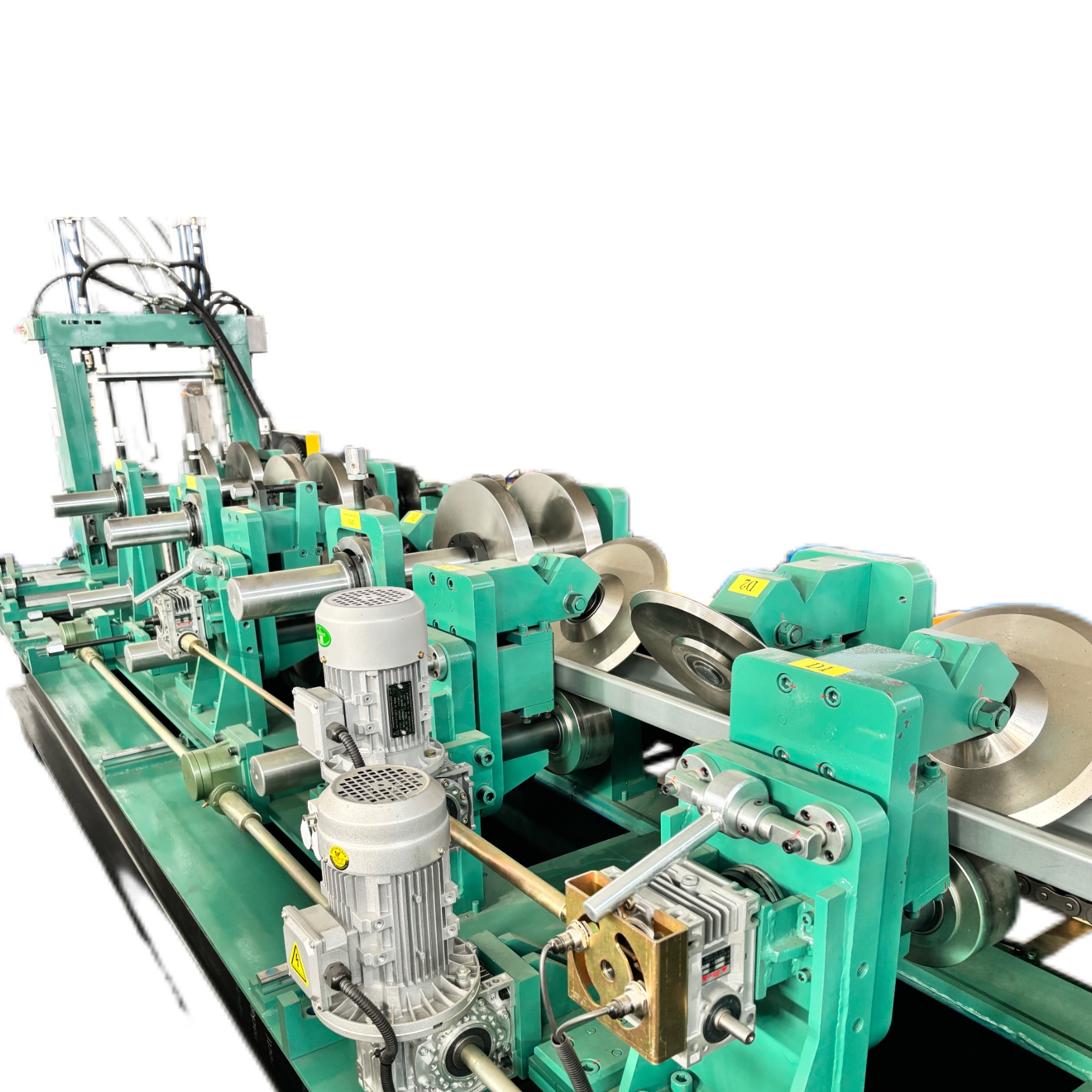

3.Main body

|

Roller station

|

18 rows (As your requirement)

|

||

|

Diameter of shaft

|

80 mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

400 H steel

|

|||

|

Drive

|

as your requirement

|

|||

|

Dimension(L*W*H)

|

15000*1800*1600(customize)

|

|||

|

Weight

|

5T

|

|||

|

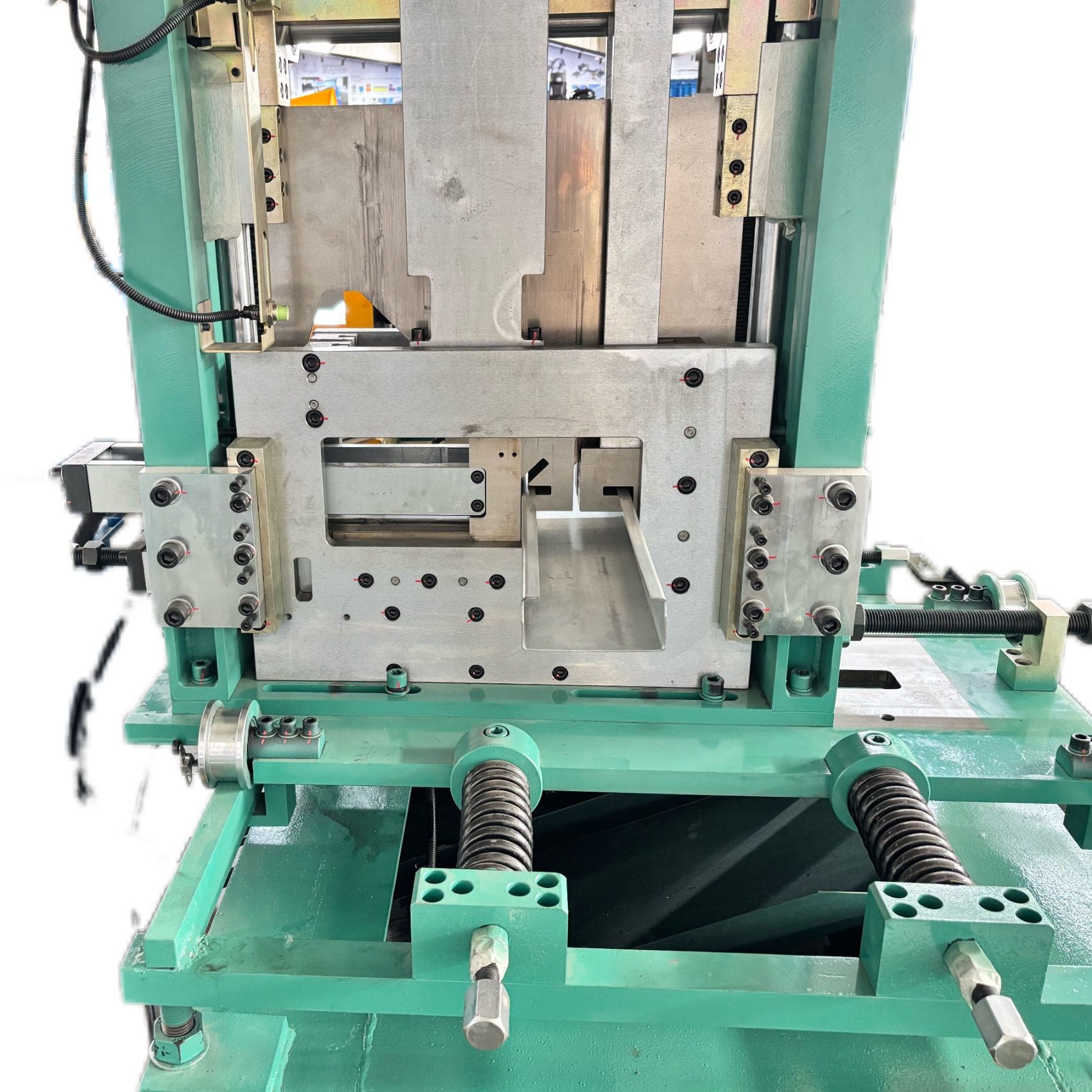

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

8.Forming Speed

|

25 m/min

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

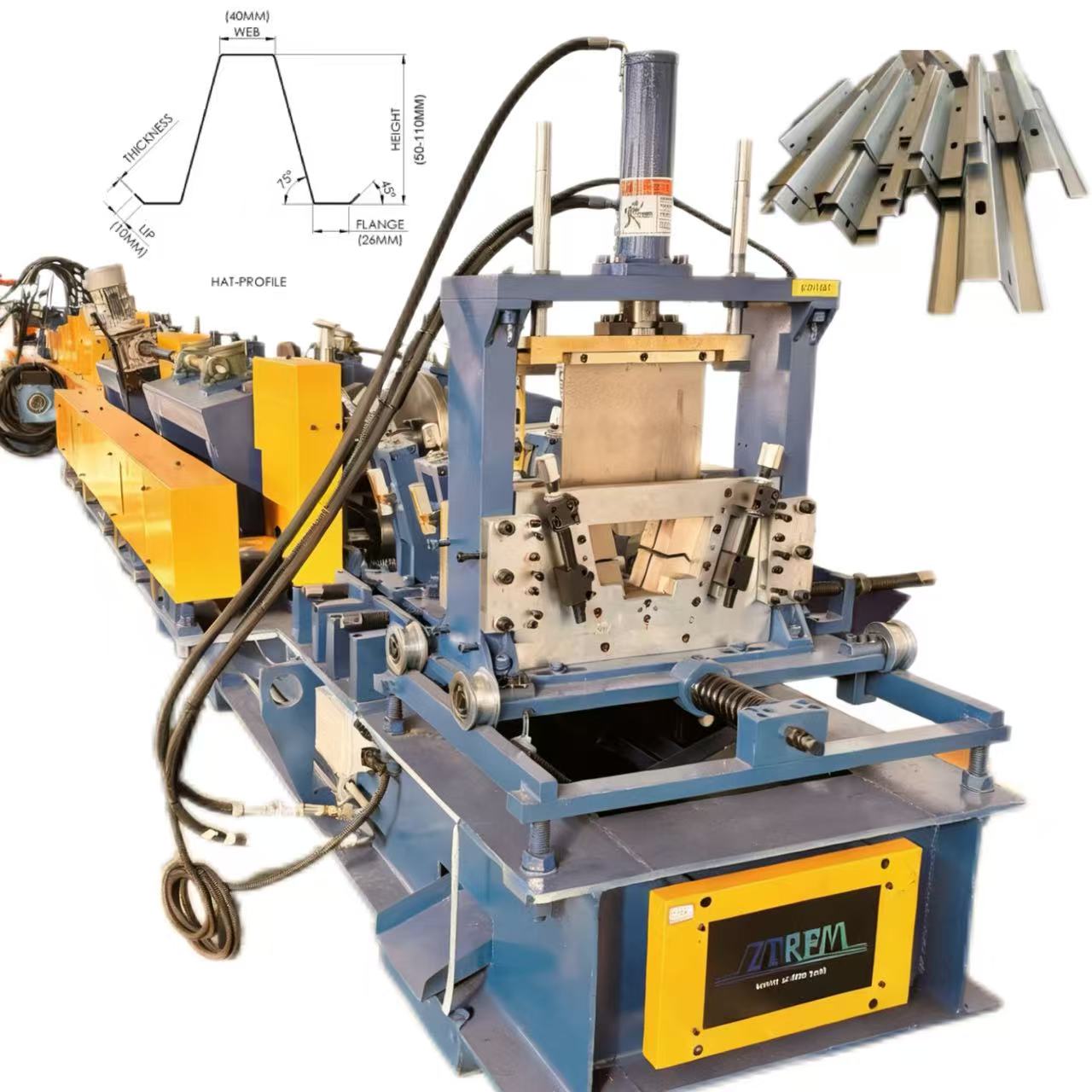

The advantage of Automatic Metal Steel C Z Shape Purlin Making Machine for Roof Structure:

- Efficient changeover and adjustability:

The fully automatic C Z shape purlin making machine can achieve rapid changeover, usually completing the changeover operation within three minutes, greatly improving production efficiency. In addition, the machine has adjustability, and components such as belly plates, flanges, and edge flanges can be adjusted in millimeters to meet different production needs. - Reduce the problem of broken shafts:

Adopting a coaxial design reduces the problem of uneven height on both sides of the broken shaft, improving the stability and durability of the equipment. - High precision and automation:

Fully automatic C Z shape purlin making machine are usually equipped with servo motor control, which can achieve stepless adjustment and precise control, making operation very convenient and improving product accuracy and production efficiency. - Multifunctionality:

This machine can perform operations such as punching and cutting, and cutting does not require changing cutting tools, further simplifying the operation process and reducing maintenance costs.

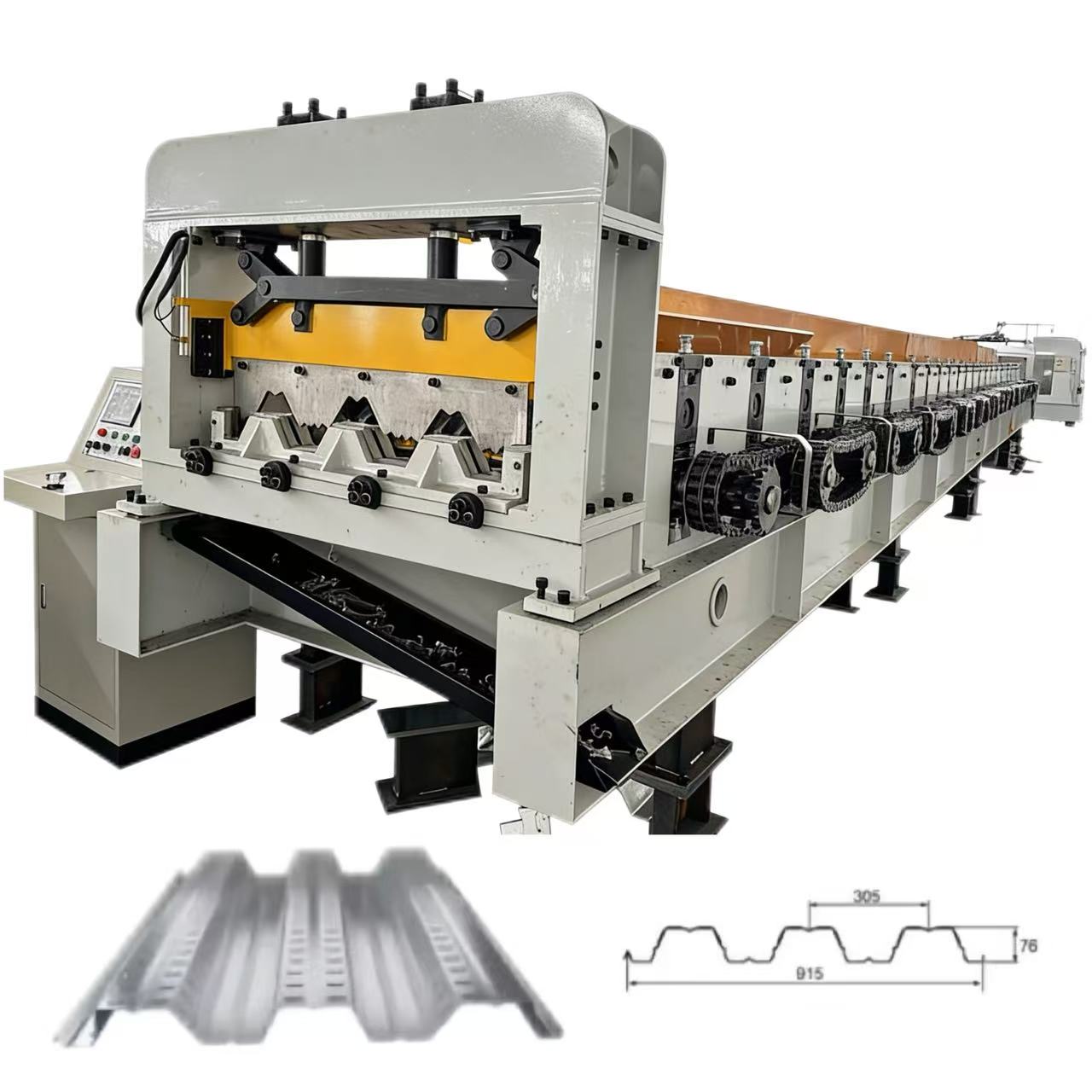

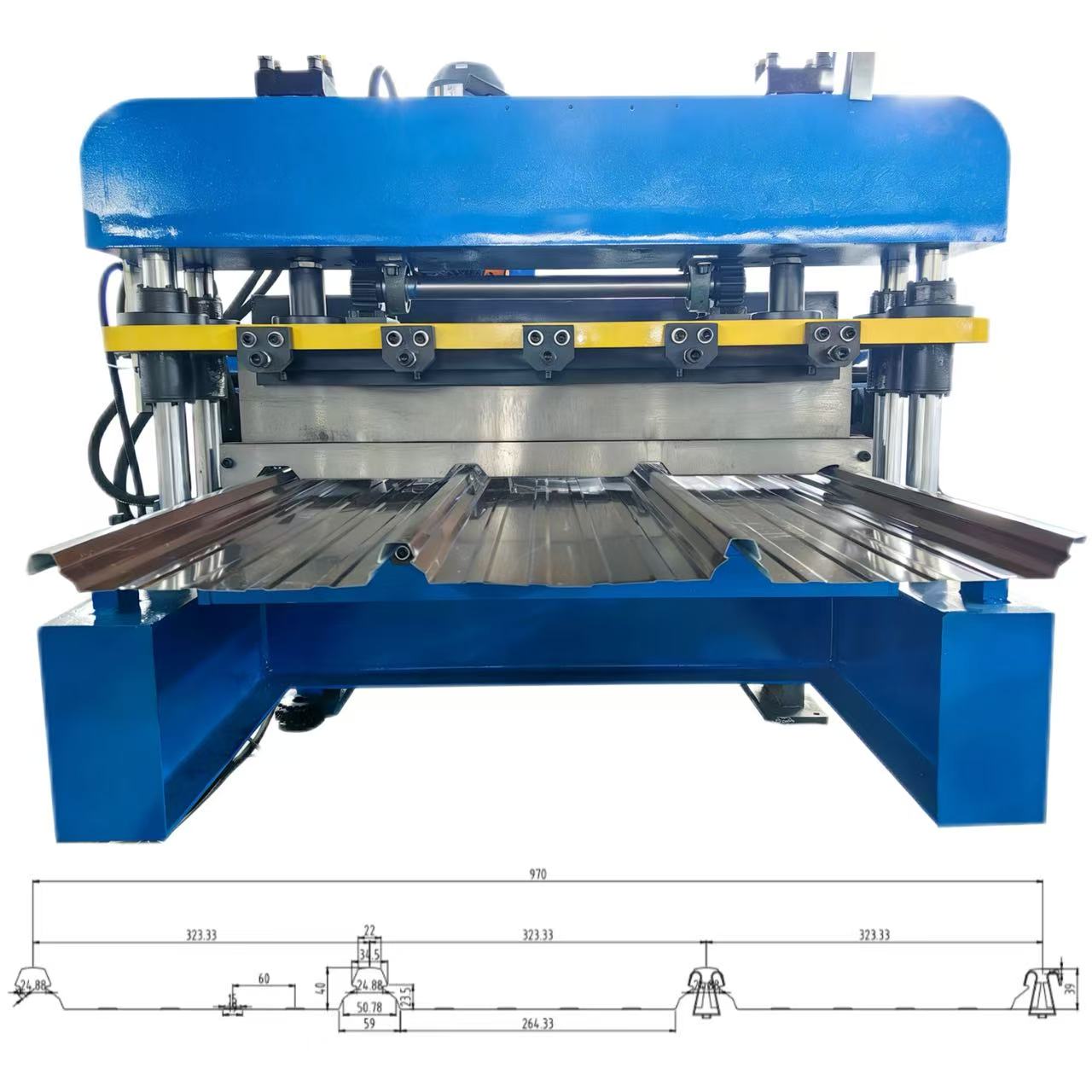

Product Description:

The C Z shape purlin making machine uses cold bending technology to press steel into CZ steel. Its main components include feeding system, leveling device, forming system, punching device, shearing system, and hydraulic control system. The equipment adopts infinite transformation technology, which can continuously adjust within the specification range to produce standard and non-standard CZ steel.