The Ceiling System Furring Channel Roll Forming Machine is a state-of-the-art and versatile solution for manufacturing furring channels for ceiling systems. This cutting-edge machine is specifically designed to produce high-quality furring channels with precision and efficiency. With automated controls and precision engineering, it ensures seamless and accurate roll forming, resulting in consistent and precise furring channels. The machine is compatible with various materials like steel, aluminum, or other alloys, making it suitable for a wide range of ceiling system applications. Experience superior furring channel production and elevate your ceiling system projects with this reliable and high-performance Ceiling System Furring Channel Roll Forming Machine.

The Furring ceiling system is a suspended steel framing system, clad with gypsum boards. Its grids are concealed behind the ceiling board. The finishing surface would be smooth and may receive direct decoration such as painting and pasing wall paper. It is mostly used in where plain ceiling is required.

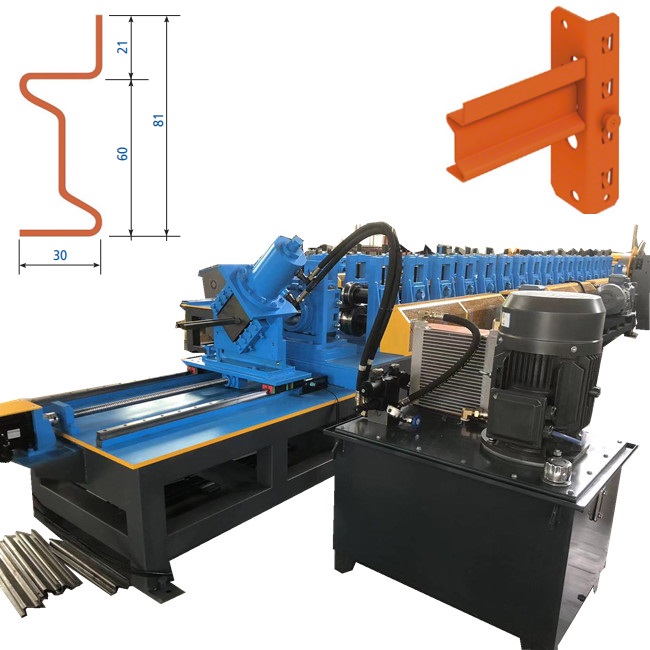

The profile drawing of furring channel:

The application of the furring channel:

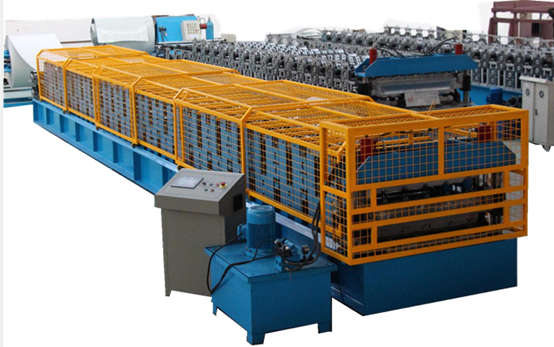

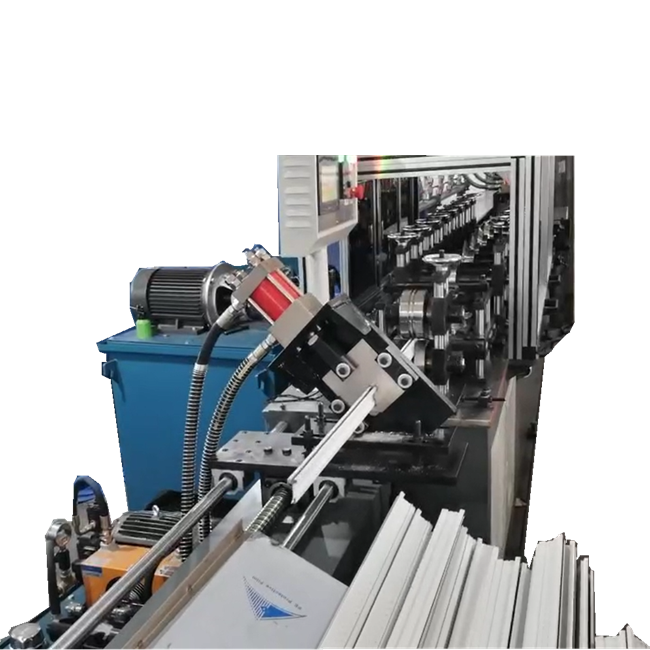

The pictures of the Furring channel machine:

The components of the whole production line:

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The Technical specifications of the whole production line:

| Item | Name | Specifications |

| 1 | Raw material | Galvanized steel |

| 2 | Raw material thickness | 0.3-0.6mm |

| 3 | Decoiler | Manual/Hydraulic decoiler |

| 4 | Roller station | 12 station(according to profile drawing) |

| 5 | Roller material | Cr12 steel with quenched treatment |

| 6 | Shaft diameter | 50mm |

| 7 | Shaft material | 45# steel with tempered |

| 8 | Transmission | by chain |

| 9 | Motor power | 5.5kw |

| 10 | Machine frame | 350H steel welded |

| 11 | Cutting type | Electric motor cutting |

| 12 | Hydraulic power | 5.5kw |

| 13 | Cutting blade material | Cr12 with quenched treatment |

| 14 | Cutting tolerance | +/-1mm |

| 15 | Control system | PLC |

| 16 | Brand | PLC:Delta/Siemens/Mitsubishi Touch screen:Delta/Siemens/Mitsubishi Encoder:Omron |

The working video of the furring channel roll forming machine: