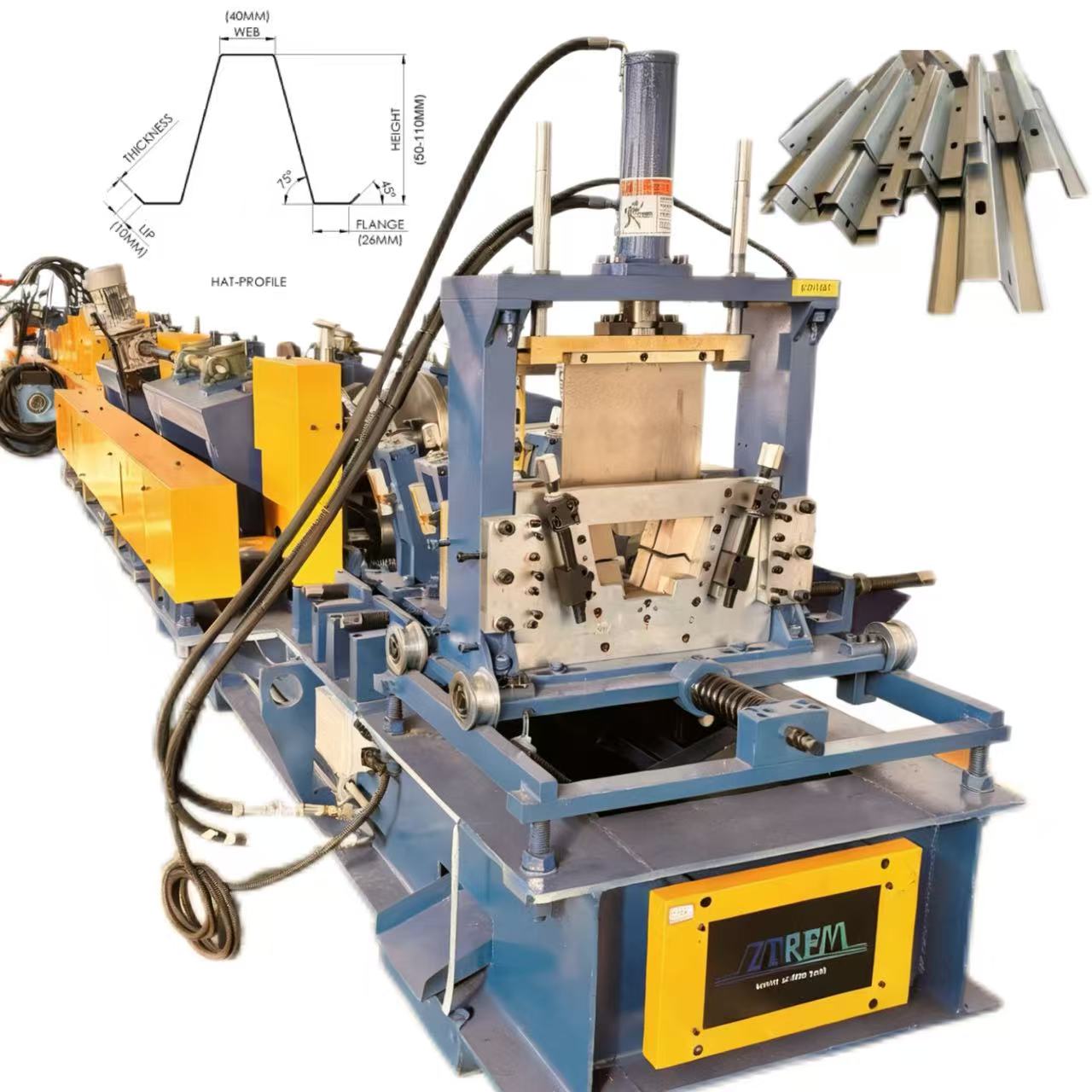

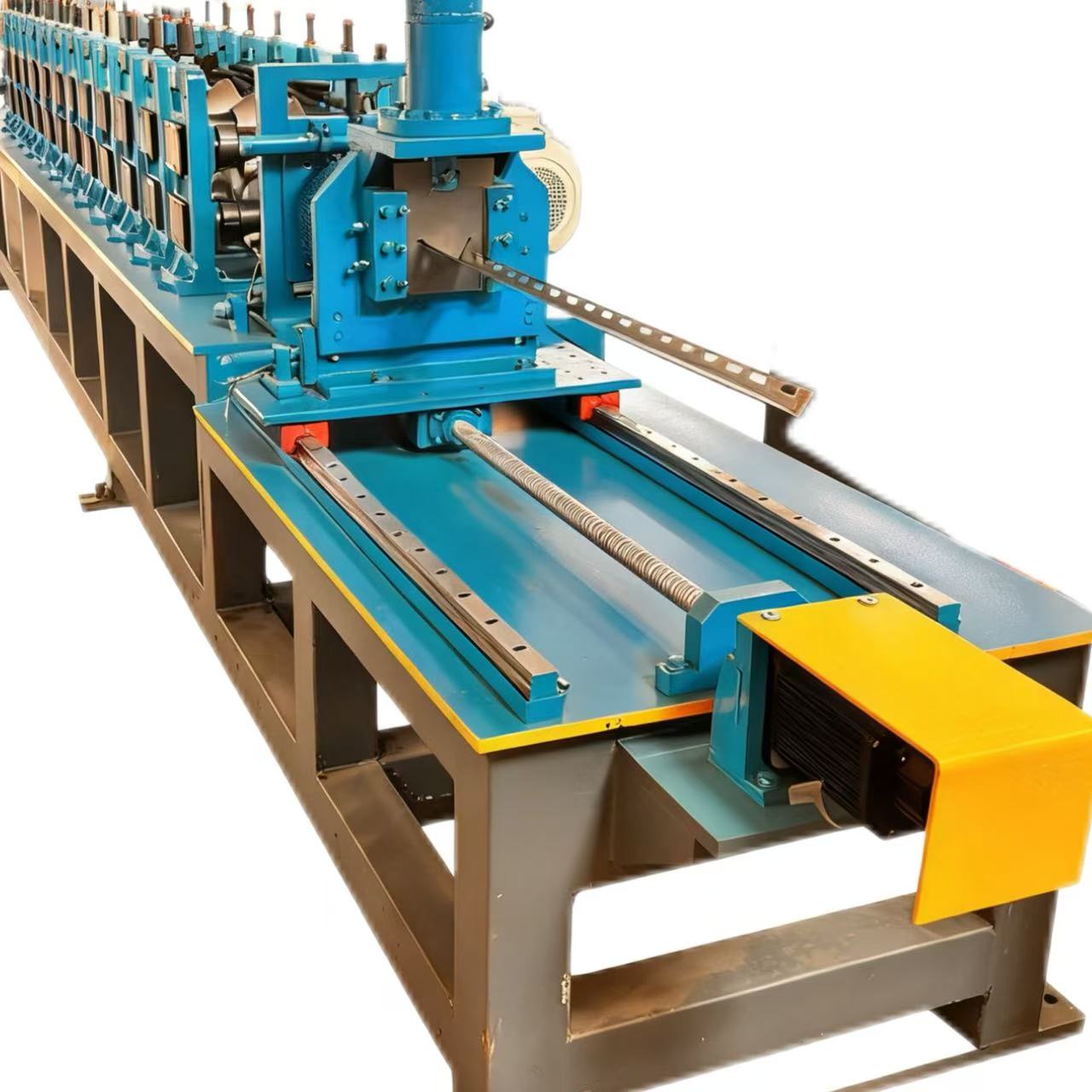

The Ceiling T grid Wall angle system making roll forming machine is a cold bending forming equipment specifically used for producing T-shaped keels. Through the cold rolling forming process, the strip steel raw material is continuously processed into T-shaped section keel profiles. Its workflow mainly includes processes such as feeding, guiding, forming, cutting, and receiving. The T-shaped keel produced by the Ceiling T grid Wall angle system making roll forming machine is mainly used for building ceiling systems, as the main keel of the ceiling keel frame, supporting and fixing ceiling panels such as gypsum board, mineral wool board, etc. With its high efficiency, automation, and precision, it has become an indispensable production equipment in the building decoration industry.

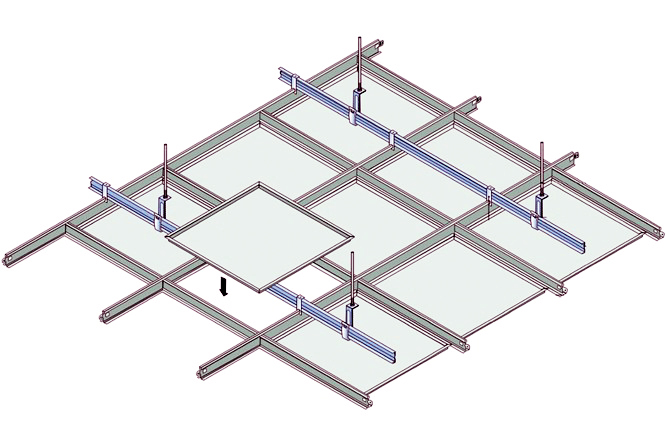

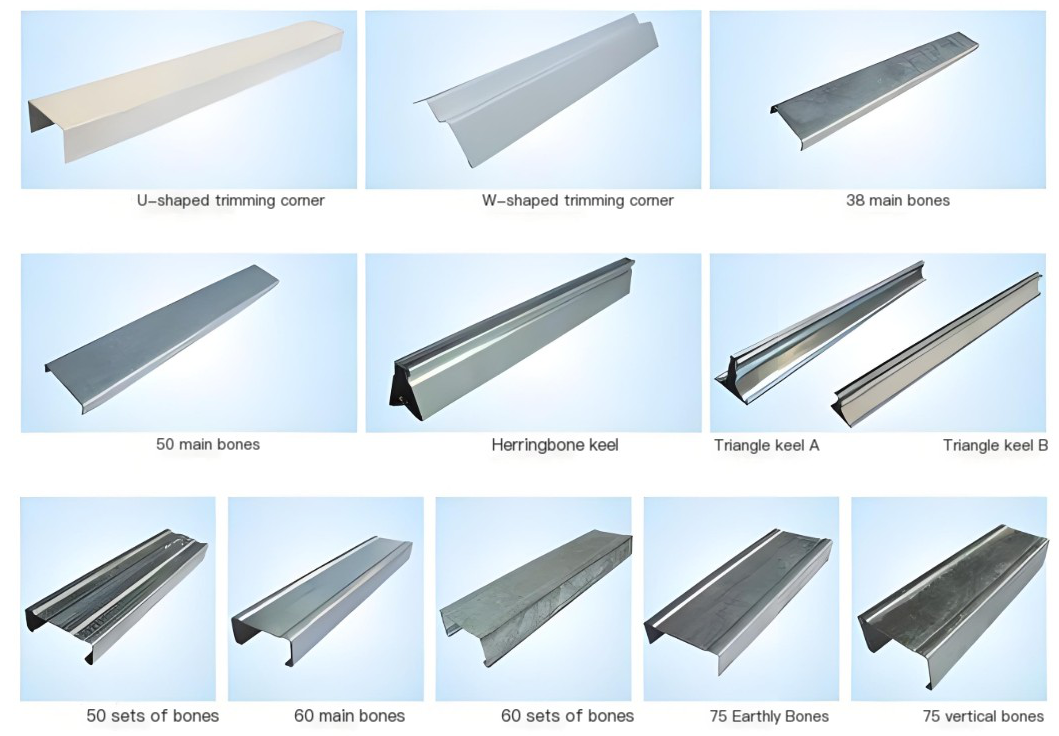

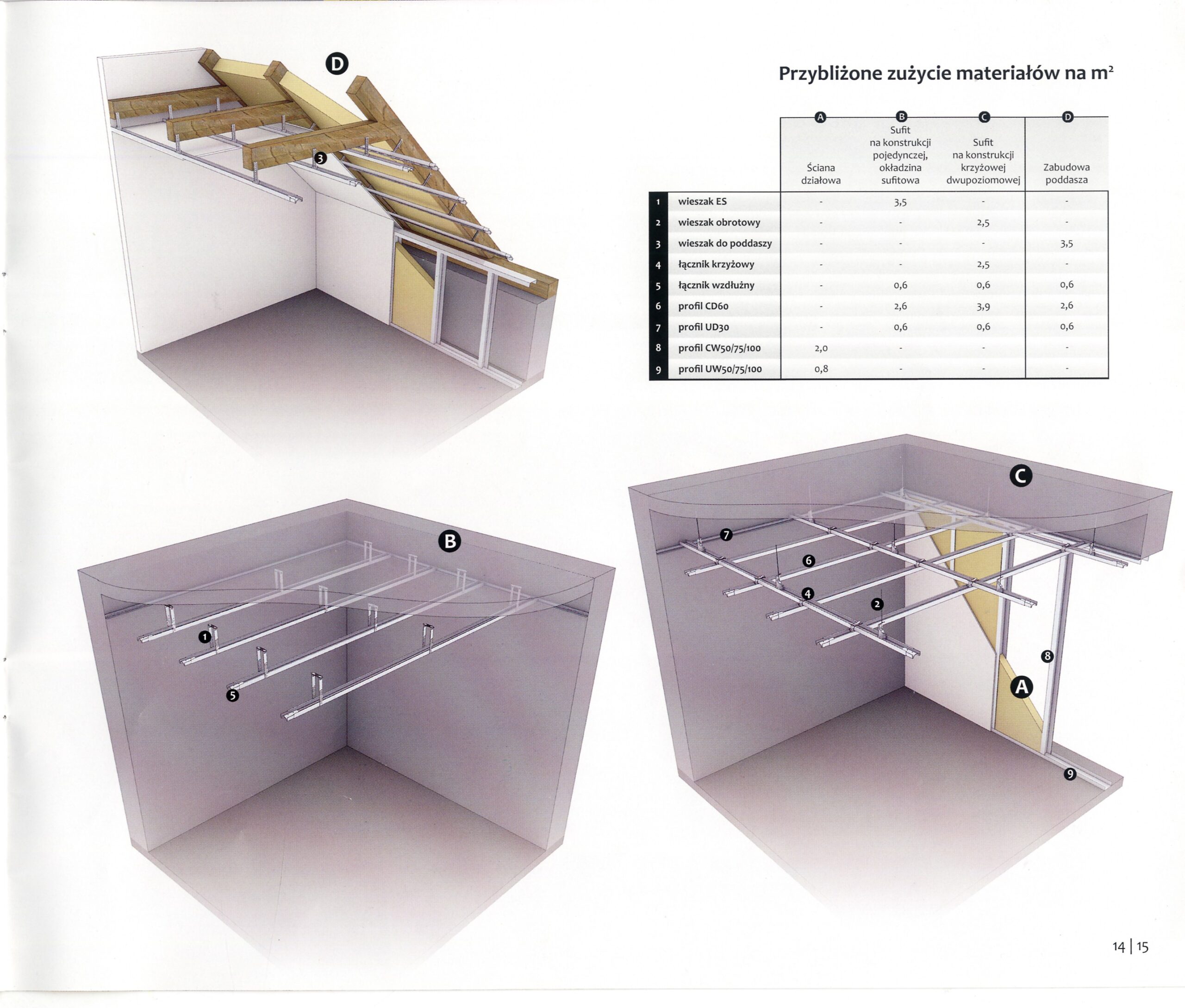

Ceiling T grid is a commonly used main material in ceiling engineering, mainly used to support and fix ceiling panels. It is suitable for various types of ceiling panels, such as mineral wool board, silicon calcium board, gypsum board, aluminum buckle board, etc. In the ceiling system, the Ceiling T grid plays the following roles:

1.Load bearing support:

The Ceiling T grid cross-section design of the Ceiling T grid gives it good load-bearing capacity and can effectively support the weight of the ceiling panels.

2.Fixed function:

By cooperating with hanging systems such as suspension rods and hooks, Ceiling T grid can firmly fix ceiling panels, ensuring the stability of the ceiling.

3.Adjusting the height difference:

During installation, the Ceiling T grid can adjust the height of the ceiling by adjusting the length of the suspension system to meet different building space requirements.

Other uses:

- Partition engineering:

In the construction of some lightweight partition walls, Ceiling T grid can also be used as skeleton materials. - Skirting decoration:

Ceiling T grid is also used for the installation of skirting due to its high strength and resistance to deformation.

Advantages:

1.Convenient construction:

T-shaped keel installation is simple, using standardized and modular construction processes, which can improve construction efficiency and shorten the construction period.2.Environmental performance:

T-shaped keels are usually made of metal materials, which are non radiative, environmentally friendly, and do not pose safety hazards such as moisture deformation and insect infestation.3.Long service life:

T-shaped keel is not easy to deform or fall off, and has a long service life.Product Attributes :

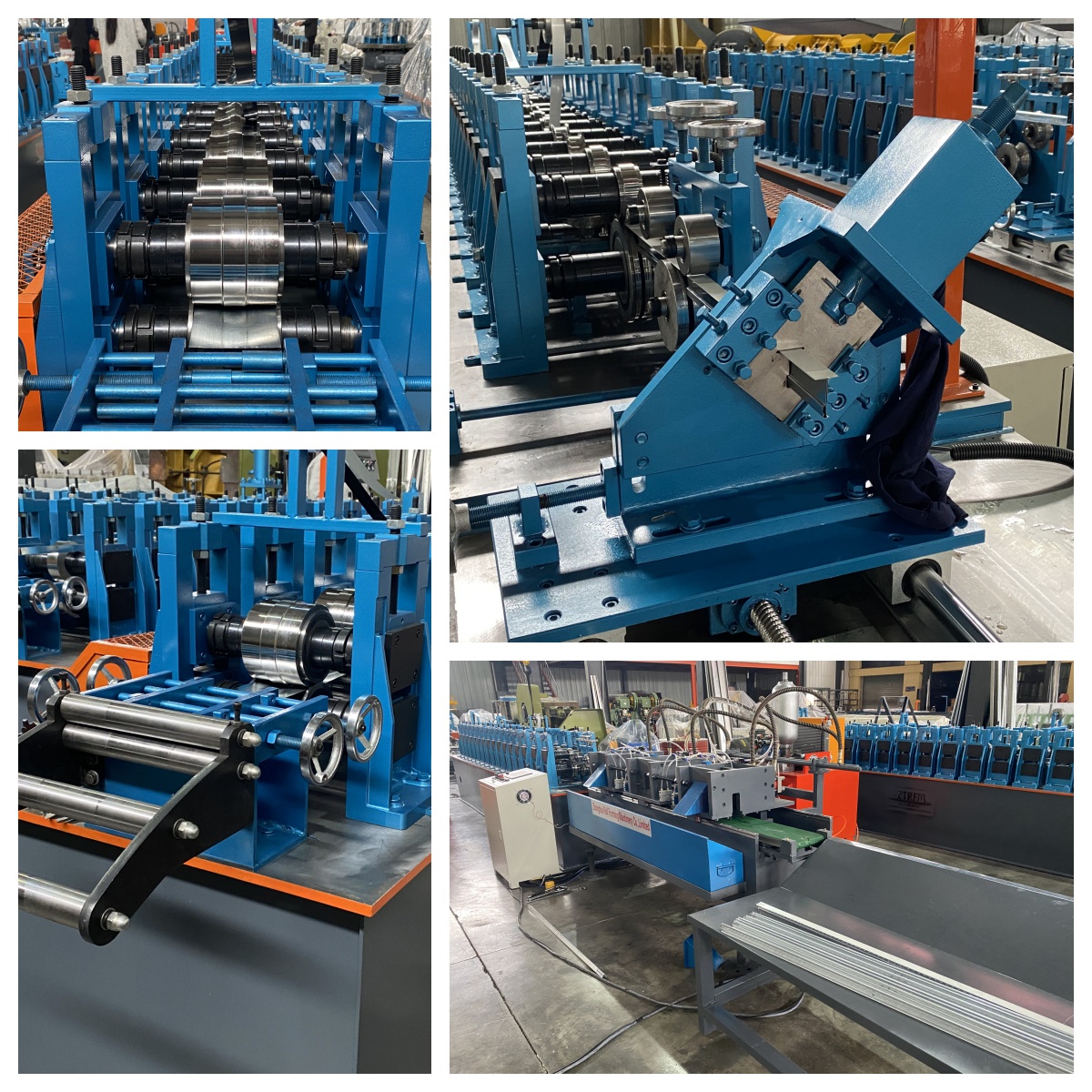

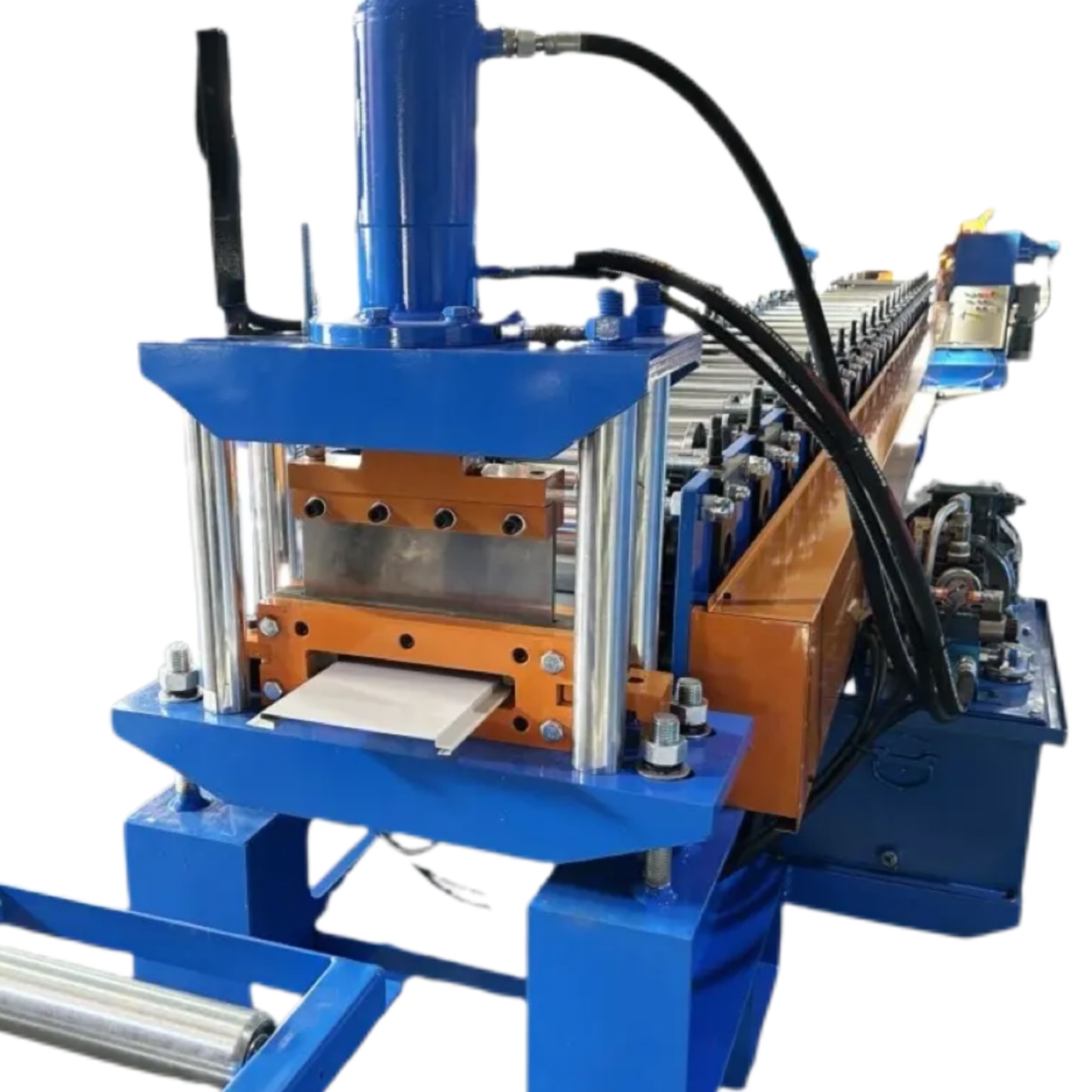

1.Formed MaterialGIThickness:0.18-0.5mm2.DecoilerHydraulic automatic decoilerManual decoiler(will give you as free)3.Main bodyRoller station12 rows(As your requirement)Diameter of shaft50mm solid shaftMaterial of rollers45# steel, hard chrome plated on the surfaceMachine body frameMetal steel weldedDriveGearbox transmissionDimension(L*W*H)5500*800*1200(customize)WeightAbout 3T4.CutterAutomaticcr12mov material, no scratches, no deformation5.PowerMotor Power7.5KWHydraulic system power5.5KW6.Voltage380V 50Hz 3PhaseAs your requirement7.Control systemElectric BoxCustomized(famous brand)LanguageEnglish(Support multiple languages)PLCAutomatic production of the whole machine. Can set batch, length, quantity, etc.18.Forming Speed70m/min(customized)Speed is adjustable according to customer’s requestProducts Display:

Here is the working video of this machine for everyone to watch: