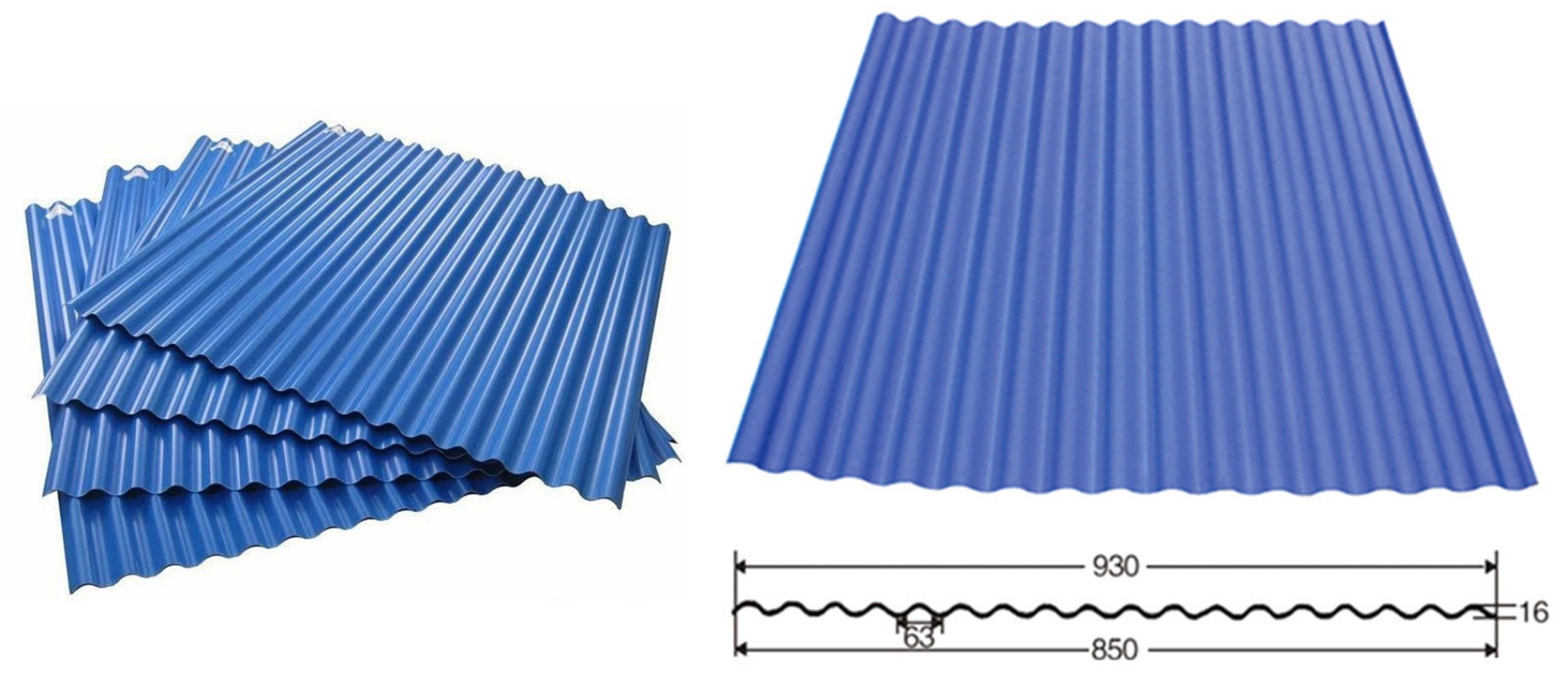

The corrugated roof sheet panel cold roll forming machine is mainly used for producing corrugated roof tiles, which can meet different architectural styles and design requirements. This machine processes metal sheets into tiles with specific curvature through precise molding techniques, suitable for various complex roof systems.The corrugated roof sheet panel cold roll forming machine has accurate cutting and forming functions, and can produce tiles into various arc shapes to meet the design needs of different roofs. The equipment adopts an automated control system, such as a PLC computer control system, to achieve automation of the production process, improve production efficiency, and reduce labor input.The corrugated roof tiles produced can be installed in various ways such as horizontal, vertical, or diagonal to achieve a layered effect of light and shadow interweaving, enhancing the aesthetics of the building. Circular roof tiles have good waterproof performance and high strength, can withstand the test of harsh weather conditions, and have a long service life.

Applicable scenarios:

- Modern architecture:

Arc tiles are suitable for various modern buildings such as government, schools, hospitals, etc. Its quaint Chinese style and rounded appearance make it particularly harmonious in these places. - Villas and resorts:

Due to its natural beauty and warm texture, curved tiles are also commonly used in villas and resorts, which can add a natural atmosphere and ecological style to the building. - Industrial and commercial buildings:

Arc tiles are not only suitable for modern buildings, but also for industrial and commercial buildings, meeting the aesthetic and functional needs of these places.

Characteristics and advantages:

- Diverse colors:

Arc tiles come in various colors to choose from, such as clay red, dark gray, deep blue, etc., to meet different design needs. - Strong weather resistance:

This type of tile can withstand ultraviolet radiation, reduce rainwater noise, and is easy to cut and bend, making installation convenient. - Versatile functions:

Arc tiles have anti-corrosion and flame-retardant, thermal insulation, sound insulation, and green insulation functions, and are easy to install with low maintenance costs. - Environmental friendliness:

Circular roof tiles belong to environmentally friendly roof building materials, which are easy to install, waterproof, fireproof, noise reducing, able to insulate and keep warm, and crack resistant.

Product Attributes :

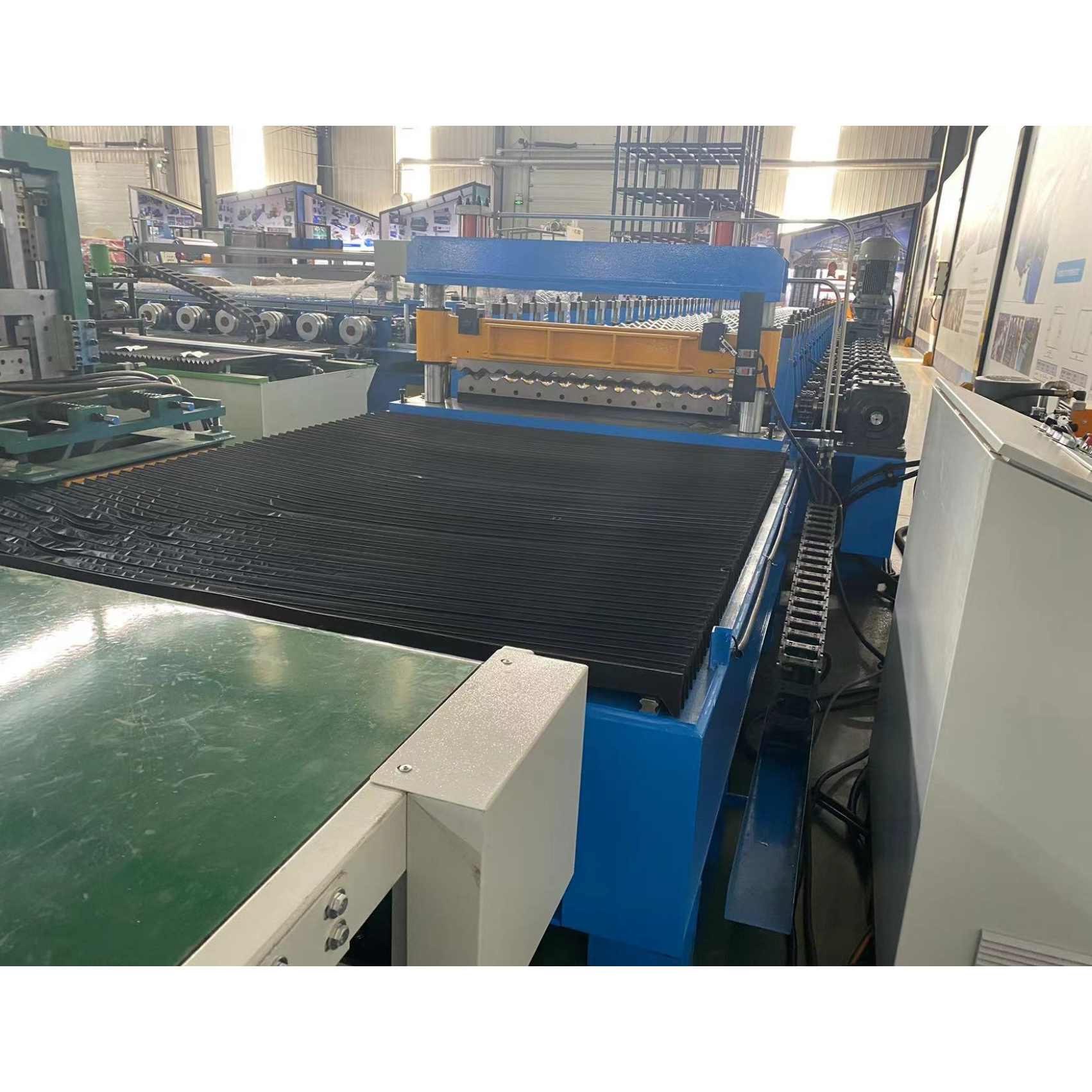

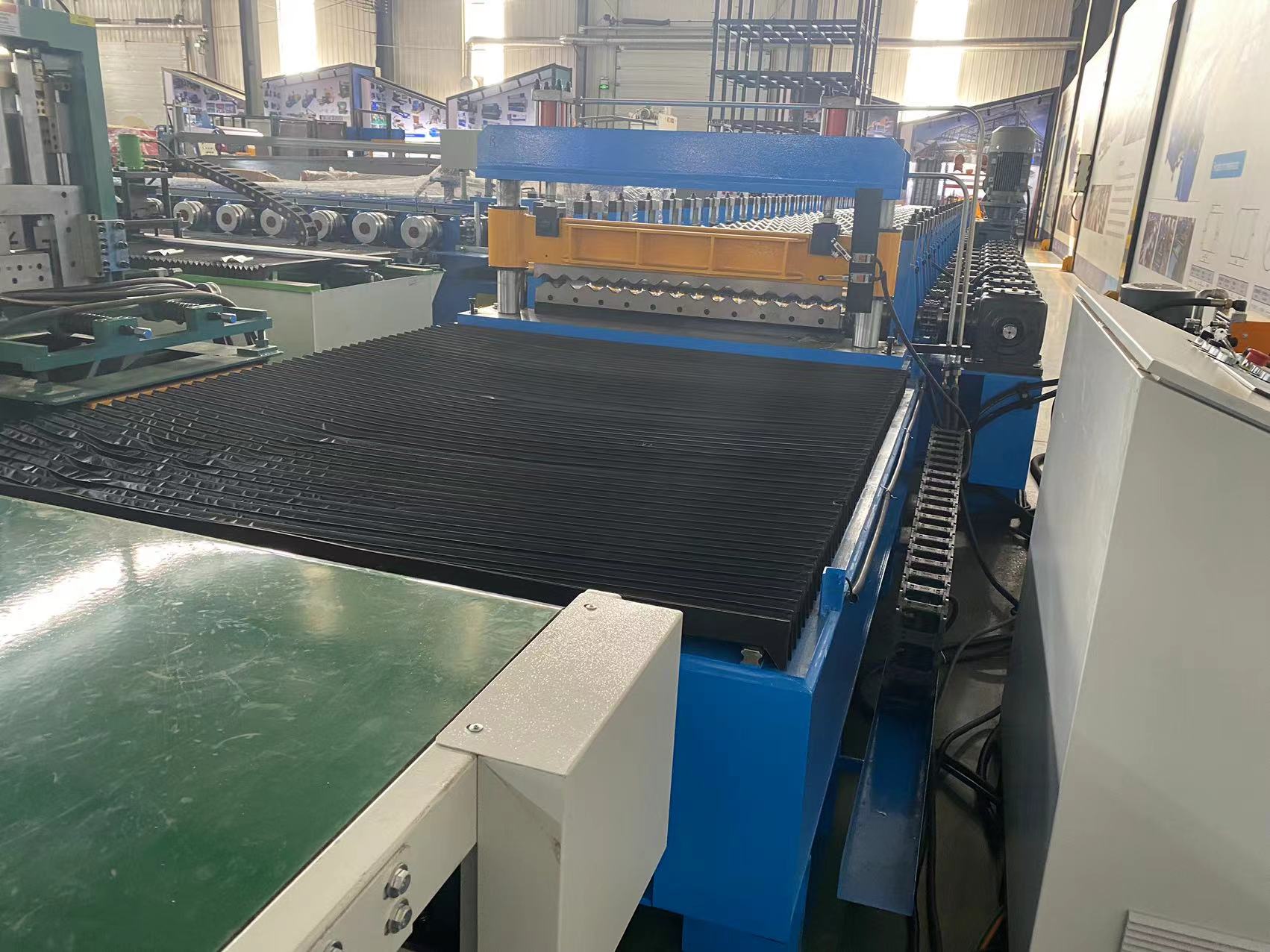

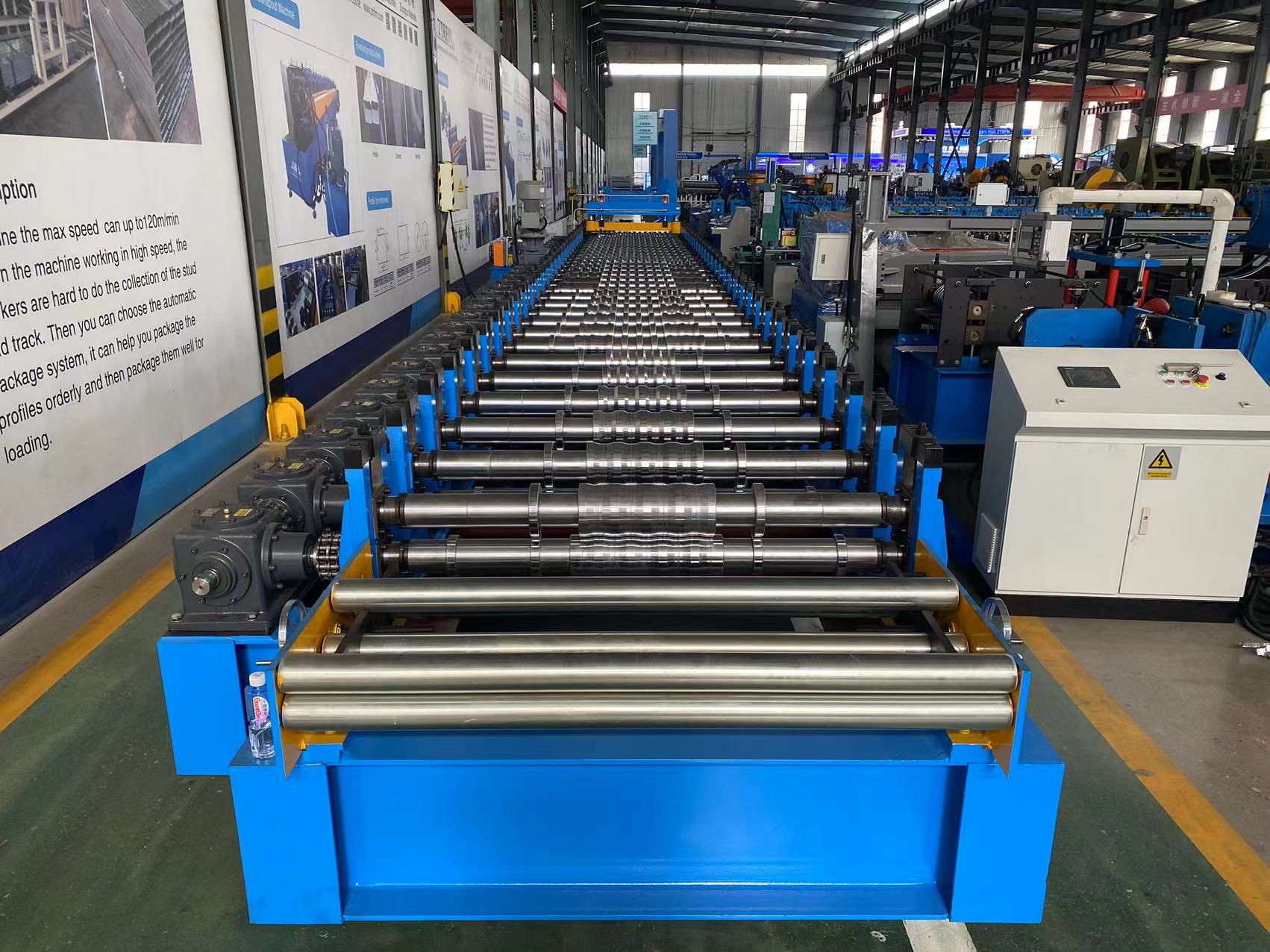

1.Formed MaterialPPGI,GI,AIThickness:0.15- 0.5mm Width:914mm/1450mm(customized)2.DecoilerHydraulic automatic decoiler5T/10T/15T3.Main bodyRoller station20 rows(As your requirement)Diameter of shaft80mm solid shaftMaterial of rollers45# steel, hard chrome plated on the surfaceMachine body frame350 H steelDriveGear box transmissionDimension(L*W*H)10500*1650*1400 mm(customize)Weight15T4.CutterAutomaticcr12mov material, no scratches, no deformation5.PowerMotor Power5.5KWHydraulic system power5.5KW6.Voltage380V 50Hz 3PhaseAs your requirement7.Control systemElectric BoxCustomized(famous brand)LanguageEnglish(Support multiple languages)PLCAutomatic production of the whole machine. Can set batch, length, quantity, etc.18.Forming Speed30-40 m/minThe speed is adjustableProducts Display:

Why Choose Us:

Company Profile:

Zhongtuo cold roll fonming machinery is one of the leading Chinese coil handling equipment brand founded in 2006.Our mission is to provide our customers with the very best quality metad rolling automalion solutions and afer-salesservice, Our machine offers a wide range of coil feeding equipment, ineluding Decoiler, Steel Straightener, Coil Feederas well as numerous rolling automation machines like color steel roofing sheet machines, purline machines, hotflming machine and others, Mletal eoll proeessing can be eanied out more eficiently and more accurately for betterneliability, less waste, and improved productivity. Product packaging:

Product packaging:

Packing method :Main body of machine is naked and covered by plastic film(to protect of dust and corrosion),oaded into container and steadily fixed in container suitable by steel rope and lock, suitable for long-distance transportation.

Collaboration case:

Collaboration case:

Our machines have been exported to multiple countries and have established cooperation with multiple countries. At present, the product has successfully entered emerging markets such as Southeast Asia, the Middle East, Africa, and South America, and has established long-term stable cooperative relationships with well-known local construction companies. Through strict ISO and CE certification, our machines have won wide recognition from international customers for their excellent stability, efficient production efficiency, and intelligent operation interface. In the future, we will continue to deepen our global layout.