When steel structure factories pursue more durable roof protection, cultural and tourism towns crave more stylish building appearances, and high-end residential buildings expect more wind resistant and waterproof roof solutions, the shortcomings of traditional roof tile machines, such as slow efficiency, poor precision, and limited adaptability, have long been unable to keep up with market trends. The emergence of high-speed circular roof tile machines, with four core advantages of “fast, accurate, stable, and economical”, has become the “winning weapon” for building materials enterprises to seize the high-end roof market!

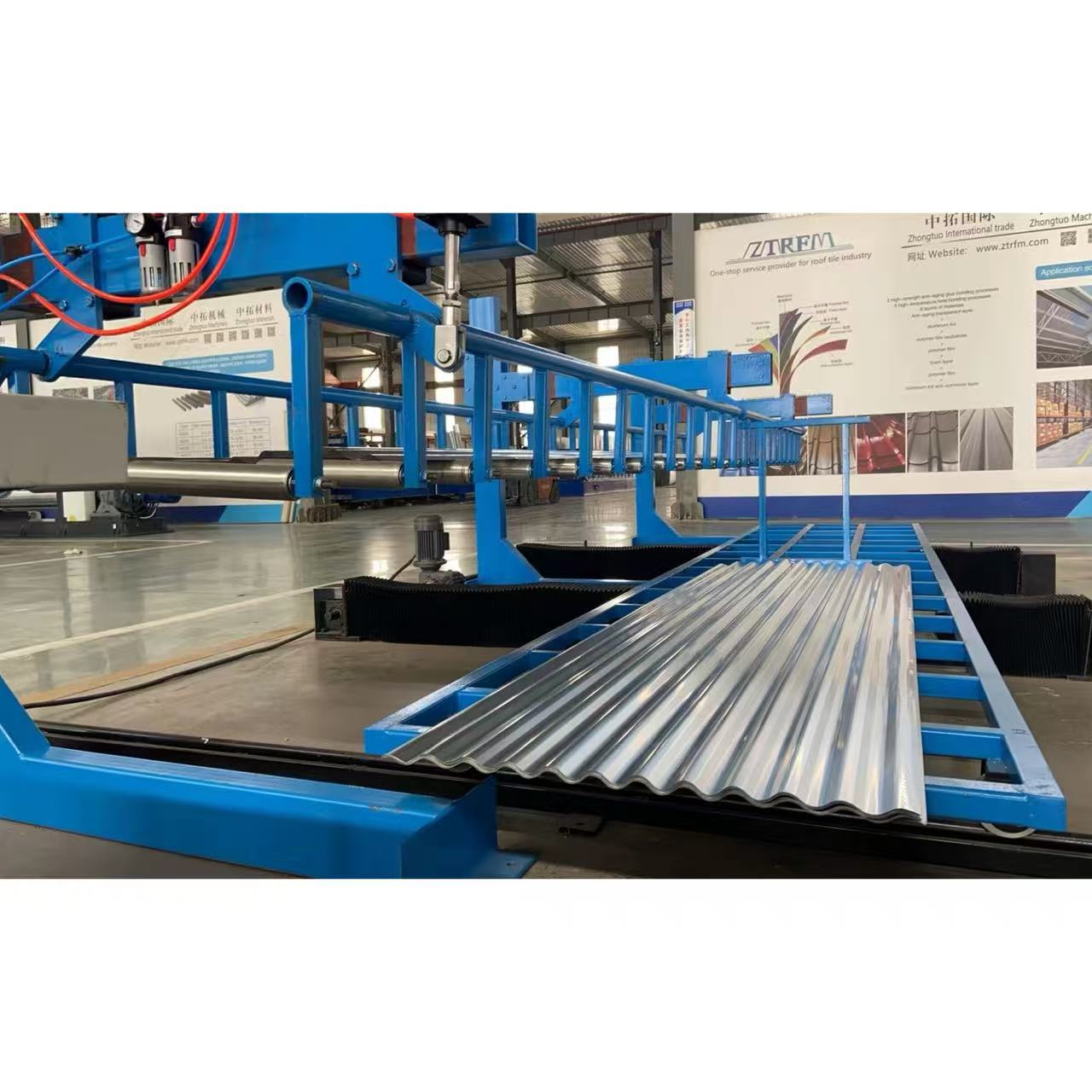

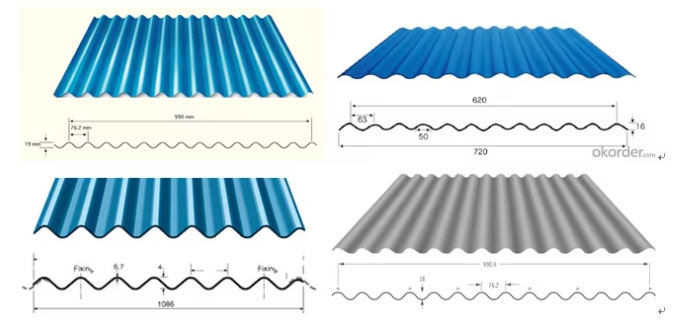

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.15- 0.5mm Width:914mm/1450mm(customized)

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

5T/10T/15T

|

||

|

3.Main body

|

Roller station

|

20 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

350 H steel

|

|||

|

Drive

|

Gear box transmission

|

|||

|

Dimension(L*W*H)

|

10500*1650*1400 mm(customize)

|

|||

|

Weight

|

15T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30-40 m/min

|

The speed is adjustable

|

||

High speed mass production, one step faster order delivery

The building materials industry is characterized by peak season order grabbing and off-season stockpiling, with production capacity being the voice of the conversation! The high-speed arc-shaped roof tile machine completely overturns traditional production efficiency, allowing you to easily cope with order peaks:

1.Ultra high speed molding, doubling production capacity:

equipped with imported servo motors and optimized transmission systems, the molding speed can reach 18-22mm/min, increasing efficiency by more than 60% compared to traditional models. Calculated based on a single shift of 8 hours, the daily production capacity exceeds 2500 square meters, and it takes only 3 days to complete the production of traditional equipment in 10 days. Urgent orders and large orders no longer have to wait for rice to be cooked.

2.Fully automated process, unmanned operation:

from raw material feeding, leveling, forming to fixed length cutting, the entire process is automated without the need for manual intervention in critical links. Equipped with an intelligent feeding correction device to prevent scrap caused by steel strip deviation, the effective production time accounts for over 98%, and labor costs have been directly reduced by 30%.

3.Precise cutting, zero waste:

Adopting laser positioning and hydraulic cutting dual guarantee, the cutting error is controlled within ± 0.8mm, and the utilization rate of raw materials is increased to 99%. Calculated based on an average daily production of 2000 square meters, it can reduce material waste by over 50 tons annually, and the cost savings are pure profits!

Circular arc boutique, with dual compression of appearance and performance

Curved roof tiles have become the “new favorite” of high-end architecture due to their smooth curves and super strong structural stability, and our equipment is the “exclusive craftsman”

1.who creates high-quality curved tiles:

Customized arcs with versatile shapes: R400-R2500mm arbitrary arc radius can be precisely customized according to project requirements. The rolling mill is made of military grade alloy steel and processed by CNC grinding. The tile curvature is uniform and full, with no indentation or wrinkles on the surface, and the visual effect far exceeds traditional flat tiles, instantly elevating the grade of the building roof.

2.Super strong wind and waterproof, with excellent quality:

Through a special lock edge structure design, the tiles are spliced to form a “double waterproof barrier”. After third-party testing, the wind resistance level reaches 13, and the waterproof performance is 40% higher than ordinary tiles. It is used in typhoon and rainstorm prone areas to eliminate potential leakage hazards and build reputation easily.

3.Multi material adaptation, widely used:

compatible with various raw materials such as 0.25-1.5mm thick color coated steel plates, galvanized plates, aluminum magnesium manganese alloy plates, etc., it can produce circular arc tiles with a width of 280-650mm. Whether it is large-span roofs in industrial plants, or irregular roofs in homestays and scenic spots, it can be perfectly adapted.