The Corrugated Roofing Sheet Roll Forming Machine is used to produce Corrugated wave shaped roof materials, which are widely used in the construction field of the Dominican Republic, including industrial and civil buildings, warehouses, special buildings, and roofs and walls of large-span steel structure houses.

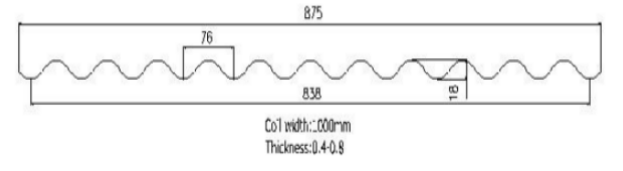

The pictures for the finished product:

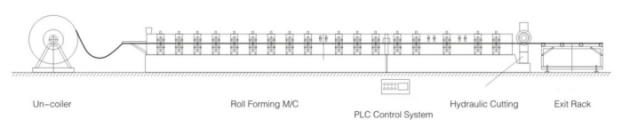

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

Packing list of the Corrugated Roofing Sheet Roll Forming Machine :

| No. | Name | Quantity |

| 1 | Manual/hydraulic Decoiler | 1 set |

| 2 | Main roll former | 1 set |

| 3 | Control system | 1 set |

| 4 | Hydraulic system | 1 set |

| 5 | Product Run-out table | 1 set |

The technical specifications of the Corrugated Roofing Sheet Roll Forming Machine :

| Item | Name | Specifications |

| 1 | Raw material | Galvanized steel,Q235 |

| 2 | Raw material thickness | 0.18-0.28mm |

| 3 | Decoiler | 5T |

| 4 | Felt device | Available |

| 5 | Roller station | 24stations |

| 6 | Roller material | High grade 45# steel,chromed treatment |

| 7 | Shaft diameter | 80mm |

| 8 | Shaft material | High grade 45#,Tempering treatment |

| 9 | Transmission | By double chains |

| 10 | Motor power | 7.5kw |

| 11 | Machine frame | 400mm H beam structure |

| 12 | Cutting type | Hydraulic cutting |

| 13 | Hydraulic power | 5.5kw |

| 14 | Cutting blade material | Gcr12 quenched treatment |

| 15 | Cutting tolerance | +/1mm |

| 16 | Control system | Delta/ Siemens PLC |

The function of the Corrugated Roofing Sheet Roll Forming Machine :

1.Strong adaptability:

The Corrugated Roofing Sheet Roll Forming Machine can adapt to different building needs, including roof covers for personal residences, private villas, and park and square buildings, providing diverse roof solutions.

2.High degree of automation:

These machines are usually equipped with PLC computer control systems, which can achieve automatic material cutting, automatic counting, simple operation, and improve the degree of production automation.

3.Economic benefits:

The use of Corrugated Roofing Sheet Roll Forming Machine can reduce production costs because they can efficiently utilize materials, reduce waste, and have fast production speed and large output.

4.The combination of aesthetics and practicality:

Corrugated Roofing Sheets not only have a beautiful appearance, but also have practicality, such as high load-bearing capacity and good seismic resistance, and are suitable for various building environments.

5.Environmental protection and energy conservation:The roofing materials produced by the Corrugated Roofing Sheet Roll Forming Machine usually have good thermal insulation and waterproof performance, which helps to improve the energy efficiency and living comfort of buildings.

Some details of the Corrugated Roofing Sheet Roll Forming Machine :