Floor decking plays a crucial role in construction projects, providing structural support and a stable base for floors in buildings. The traditional methods of floor decking were time-consuming and labor-intensive, but with the introduction of floor decking machines, the manufacturing process has been transformed. These machines streamline the production of floor decking, offering increased efficiency, precision, and cost-effectiveness. In this article, we will explore the benefits of utilizing floor decking machines and how they contribute to the advancement of construction projects.

Efficient Production Process:

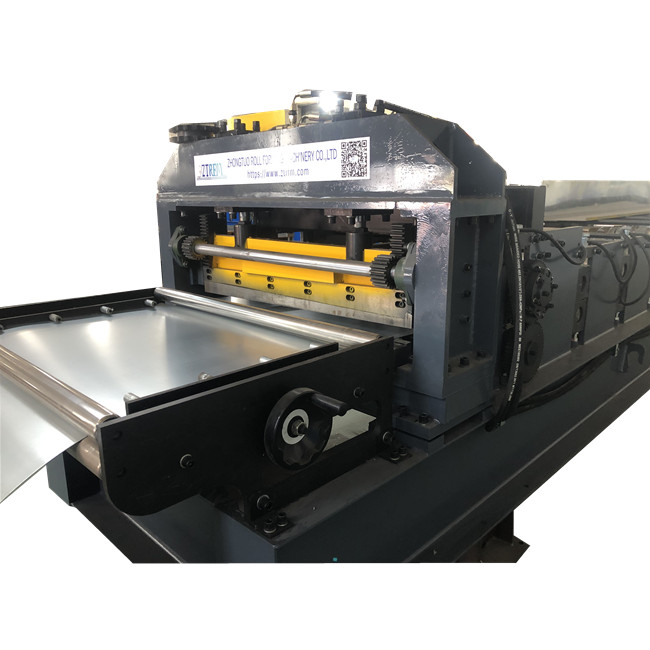

Floor decking machines automate the manufacturing process, significantly improving efficiency and reducing production time. These machines are designed to handle various stages of production, including material feeding, roll forming, cutting, and stacking. By automating these processes, manufacturers can achieve faster production cycles, optimize resource utilization, and save valuable time.

High Precision and Consistency:

One of the key advantages of using floor decking machines is the precision and consistency they offer. These machines employ advanced technologies, such as computer numerical control (CNC), to ensure accurate roll forming and cutting of floor decking panels. The precise measurements achieved through these machines result in floor decking panels with consistent dimensions, shapes, and profiles, eliminating variations and reducing the need for manual adjustments or rework.

Customization and Versatility:

Floor decking machines offer a wide range of customization options, allowing manufacturers to produce floor decking panels with different sizes, profiles, and configurations. These machines can be programmed to accommodate specific design requirements, ensuring the production of floor decking tailored to the unique needs of different construction projects. The versatility provided by floor decking machines enables manufacturers to meet the diverse demands of their customers.

Material Flexibility:

Floor decking machines can work with various materials, including metals like steel and aluminum. This flexibility in material compatibility allows manufacturers to cater to different industry requirements and create floor decking panels suitable for different environments and applications. The ability to work with different materials expands the possibilities for floor decking design and functionality, catering to the specific needs of each project.

Cost-Effectiveness:

Investing in floor decking machines can lead to significant cost savings in the long run. These machines reduce labor costs by automating the production process and minimizing the need for manual labor. The precision roll forming and cutting achieved by the machines also minimize material wastage, optimizing material utilization and reducing material costs. Additionally, the efficiency of floor decking production results in shorter construction time, reducing overall project costs.

Enhanced Structural Performance:

Floor decking panels produced by floor decking machines offer enhanced structural performance and durability. The precise roll forming and shaping processes ensure that the panels have consistent profiles and dimensions, promoting even load distribution and maximizing their load-bearing capacity. These panels provide a stable base for flooring systems, contributing to the overall strength and stability of the building structure.

Adaptability to Changing Needs:

Construction projects often require adaptability to changing design requirements and specifications. Floor decking machines offer the advantage of flexibility and adaptability to meet evolving demands. They can be easily reprogrammed or adjusted to accommodate new floor decking designs, dimensions, or profiles, allowing manufacturers to stay responsive to customer needs and market trends.

Conclusion:

Floor decking machines have revolutionized the production of floor decking, offering increased efficiency, precision, customization options, and cost-effectiveness. These machines streamline the manufacturing process, enhance structural performance, and enable manufacturers to meet the evolving demands of construction projects. By investing in floor decking machines, manufacturers can elevate their production capabilities, deliver high-quality floor decking solutions, and contribute to the advancement of the construction industry.