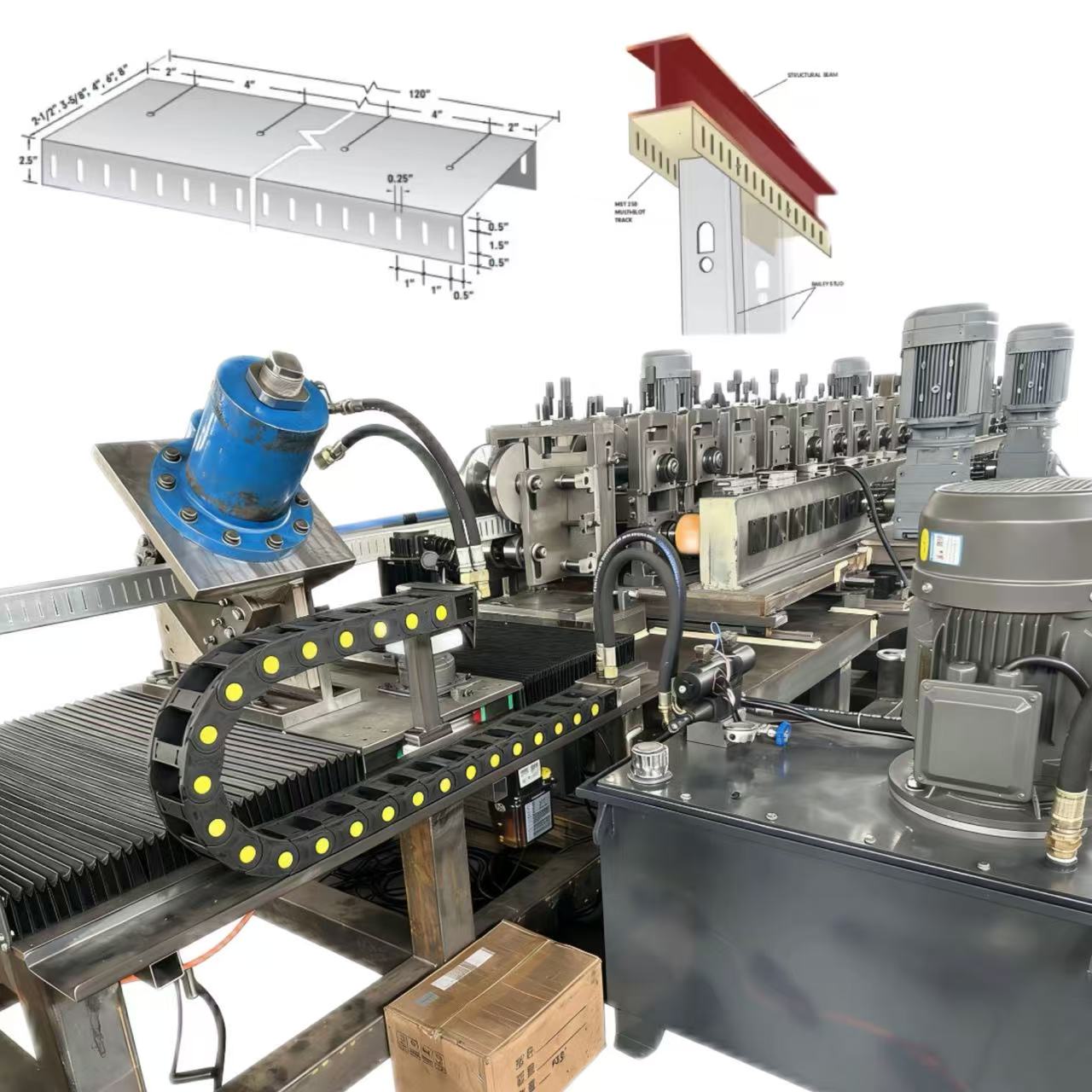

In today’s rapidly developing architectural decoration industry, light steel keel, as the core material for ceilings and partition walls, continues to see growing market demand. Traditional production methods face issues such as low efficiency and high costs, while the emergence of Metal Stud and Track Making Machine Light Keel C U Channel Roll Forming Machine has brought a revolutionary solution to the industry.

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness: 0.3-1.0mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

70m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

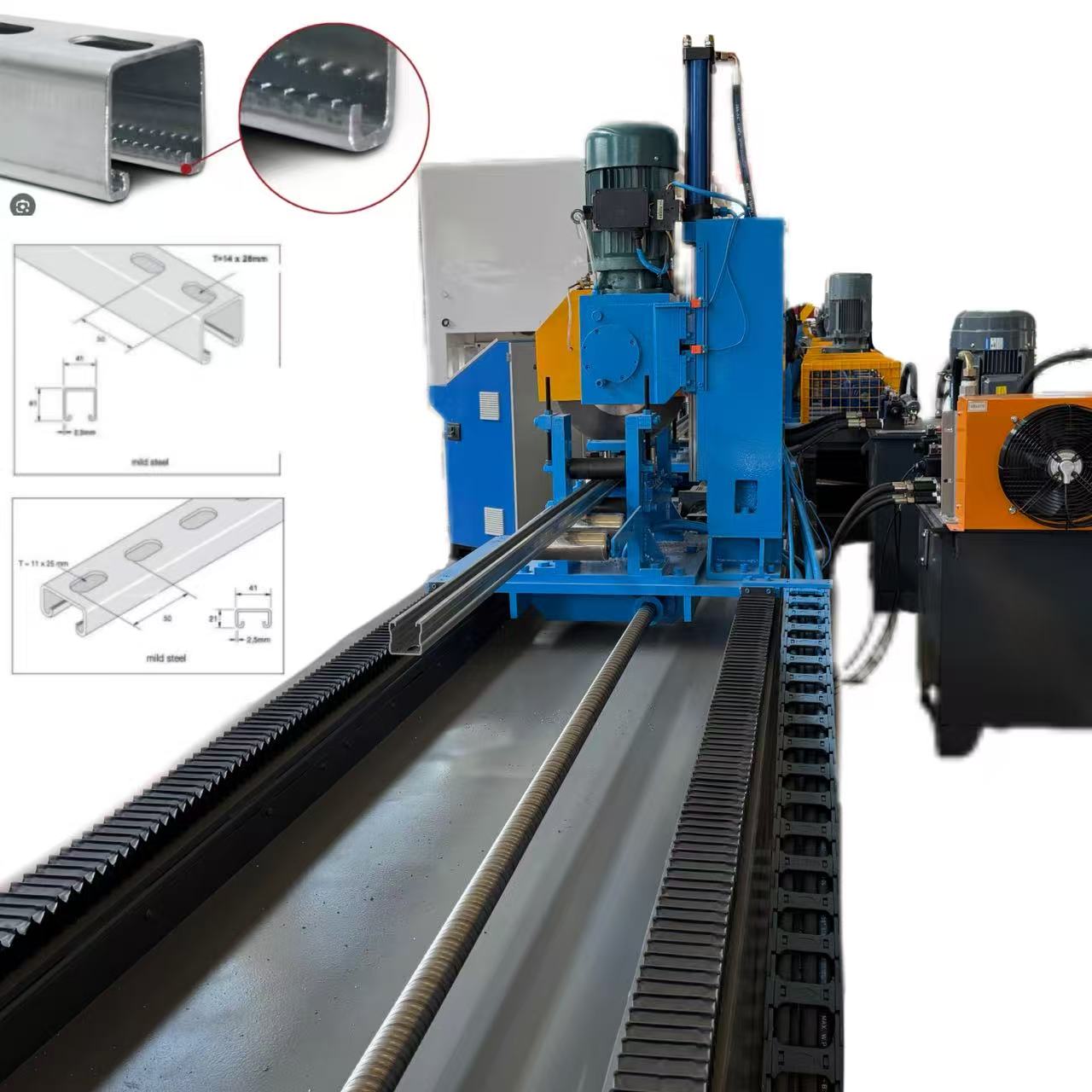

Profile drawing as below:

The core advantages of this machine

1. Multi functional production flexibility of one machine

The Metal Stud and Track Making Machine Light Keel C U Channel Roll Forming Machine adopts a modular design, and can switch production between C-type and U-shaped keels by quickly replacing molds. This design breaks through the limitations of traditional equipment with a single function, allowing enterprises to flexibly adjust production plans according to order requirements.

2. Intelligent production process

The equipment is equipped with a PLC control system to achieve fully automated operations from raw material feeding to finished product packaging. Intelligent sensors monitor production parameters in real-time and automatically adjust molding accuracy. Data shows that the scrap rate of production lines using this technology has decreased from 5% to below 1%, saving hundreds of thousands of yuan in raw material costs annually.

3. Balancing environmental protection and economic benefits

The centralized factory production mode significantly reduces dust and noise pollution during on-site operations. At the same time, automated production reduces labor costs by 40% and shortens the equipment investment return cycle to 18 months.

Application scenario:

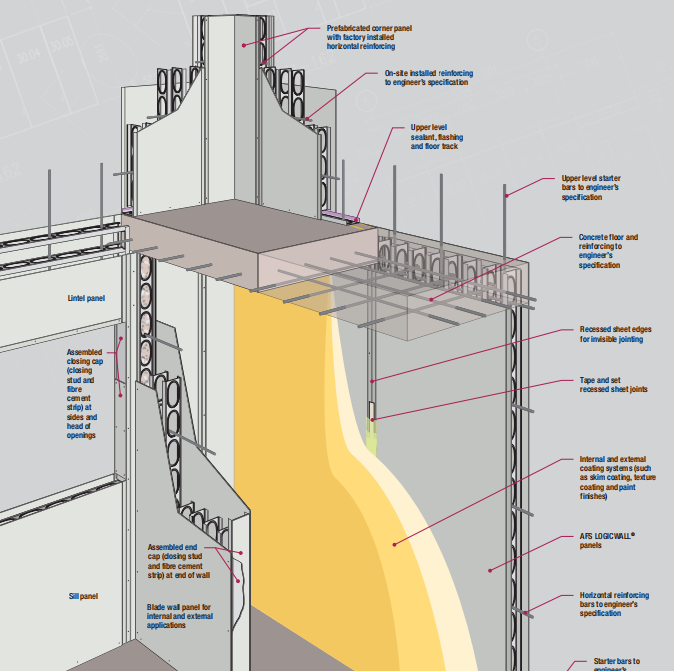

• Indoor partition wall system:

C-shaped keel serves as the vertical keel frame, while U-shaped keel is used to fix the upper and lower edges of the partition wall, forming a lightweight and fire-resistant wall structure.

• Ceiling engineering:

U-shaped keel serves as the main keel to bear the load of the ceiling, while C-shaped keel can be used as a cladding keel (secondary keel) to fix decorative panels (such as gypsum board, aluminum buckle board).

• Prefabricated construction:

In projects such as light steel villas and commercial complexes, it can improve production efficiency and meet the demand for rapid assembly.