In today’s rapidly developing construction and decoration industry, light steel keel, as a core material for ceilings and partition walls, continues to see rising market demand. Traditional production methods face challenges such as low efficiency and insufficient precision, while the emergence of Omega Profile Metal Furring Channel Roll Forming Machine is becoming a key driver of industry innovation.

Core product advantages: Precision and efficiency in perfect harmony

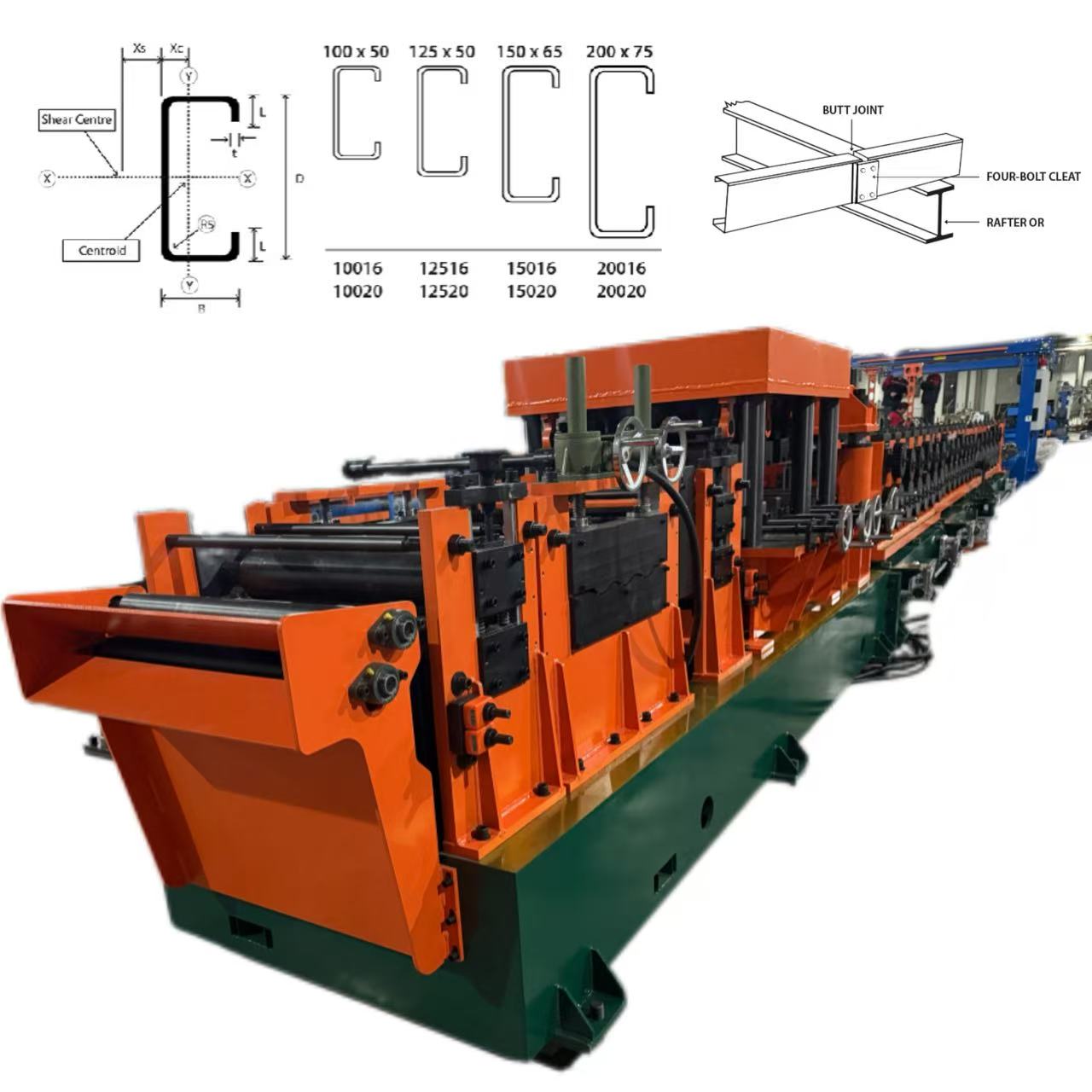

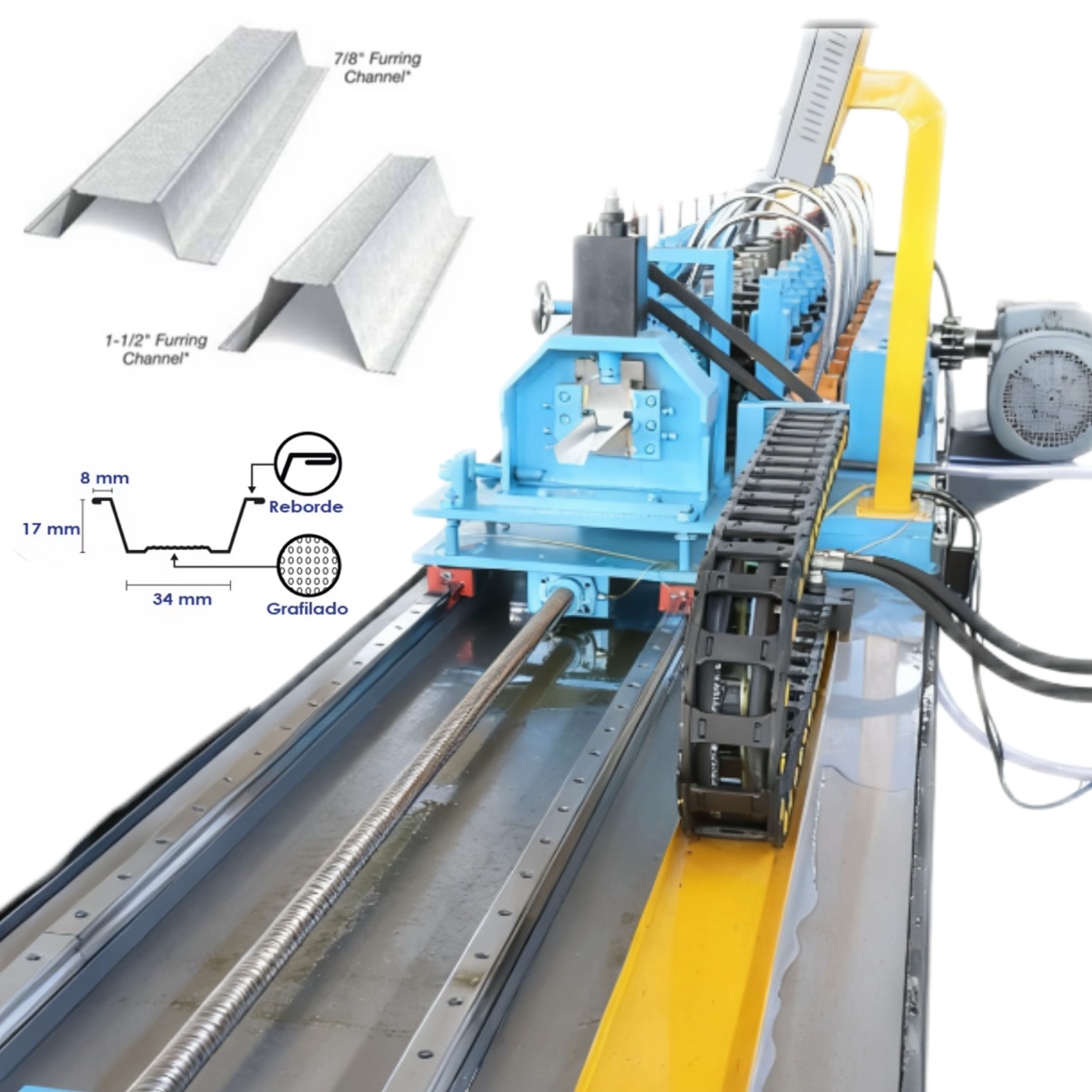

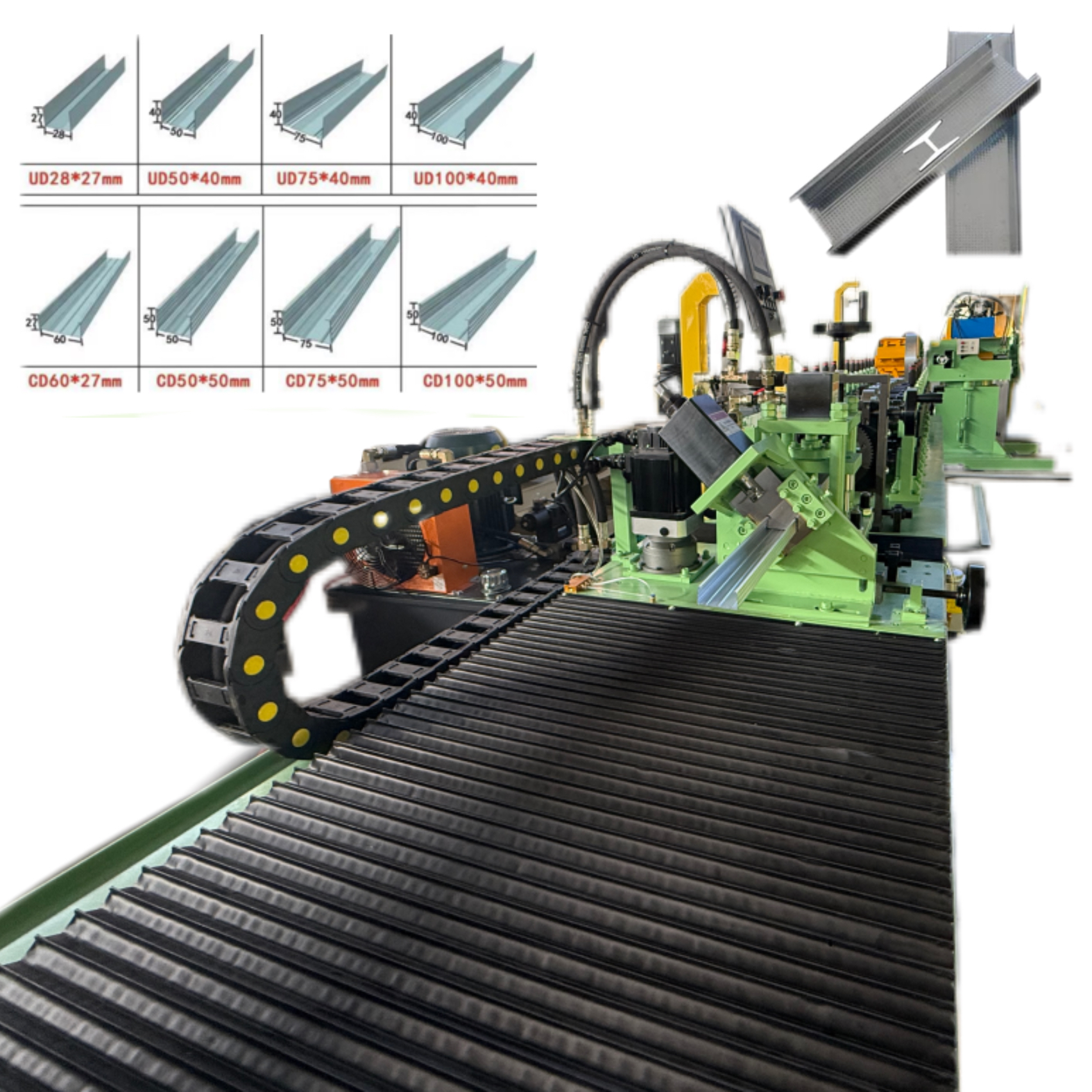

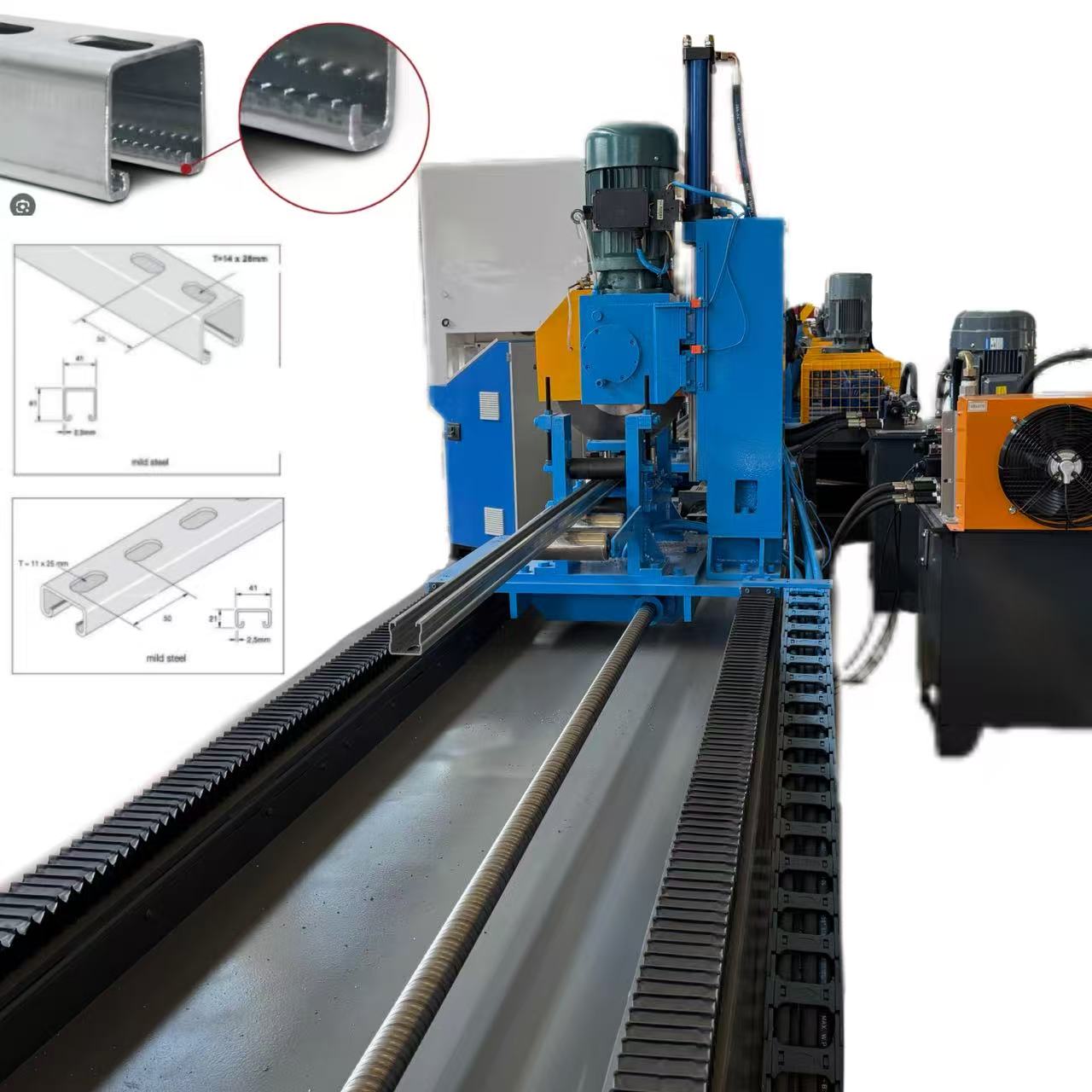

The Omega Profile Metal Furring Channel Roll Forming Machine is specifically designed for the cold bending of light steel keels. Through continuous roll forming, it transforms metal coils into “hat” or “I-beam” cross-sections. This design not only meets diverse construction needs but also significantly enhances production efficiency. The core advantages of the equipment are reflected in:

1.High-precision machining:

Ensures the flatness and structural stability of the keel, reducing the cost of subsequent adjustments.

2.Automation:

Reduces manual intervention, enhances production speed, and is suitable for batch operations.

3.Material Adaptability:

Compatible with a variety of metal coils, offering flexible thickness ranges to meet diverse project requirements.

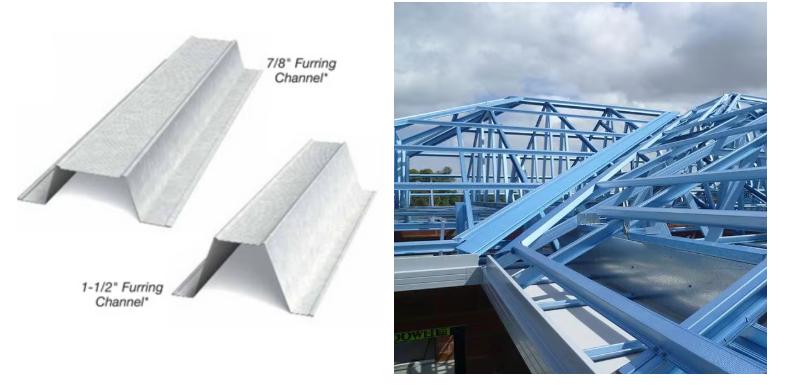

Application scenarios: From home decoration to large-scale projects

• Home decoration ceiling:

provides stable support for residential buildings and enhances spatial aesthetics.

• Commercial space partition wall:

achieve rapid installation and shorten construction period in office buildings and shopping malls.

• Steel structure enclosure:

used as roof and wall purlins to enhance building durability.

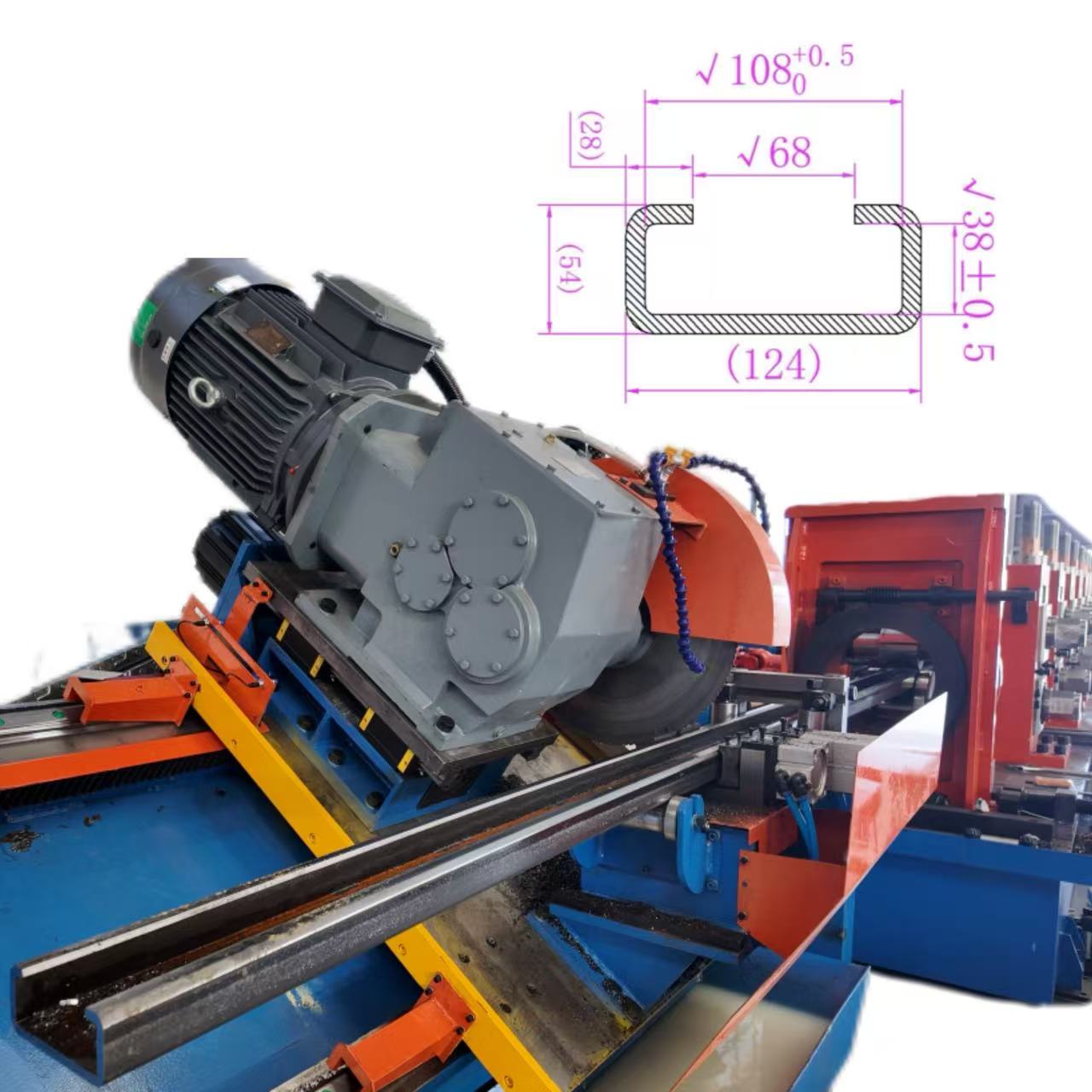

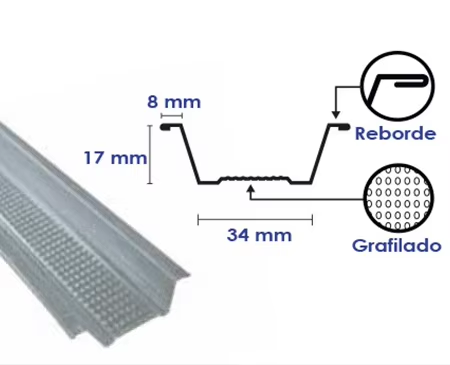

Profile drawing as below:

Product Attributes :

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.4-0.8mm

|

||

|

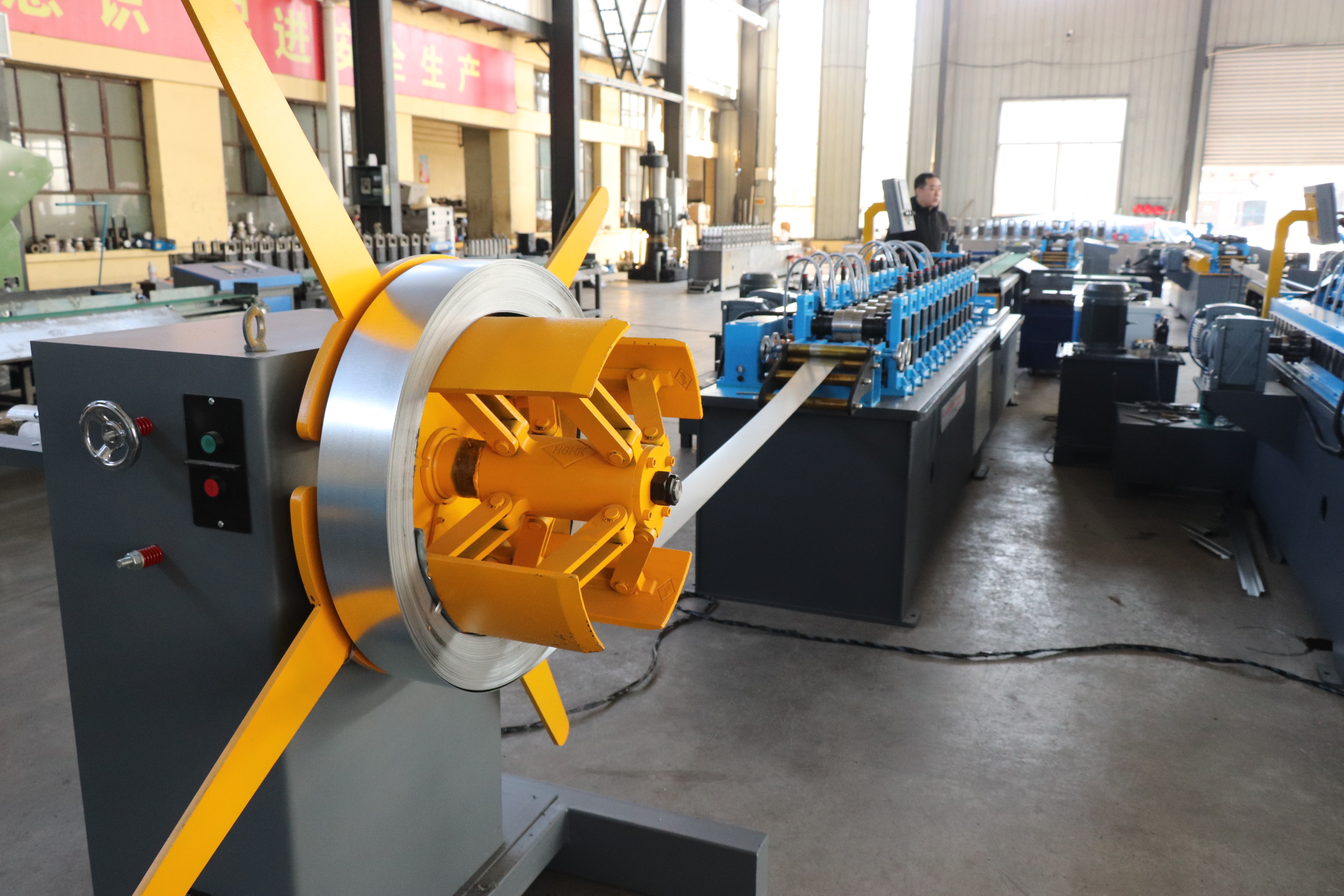

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

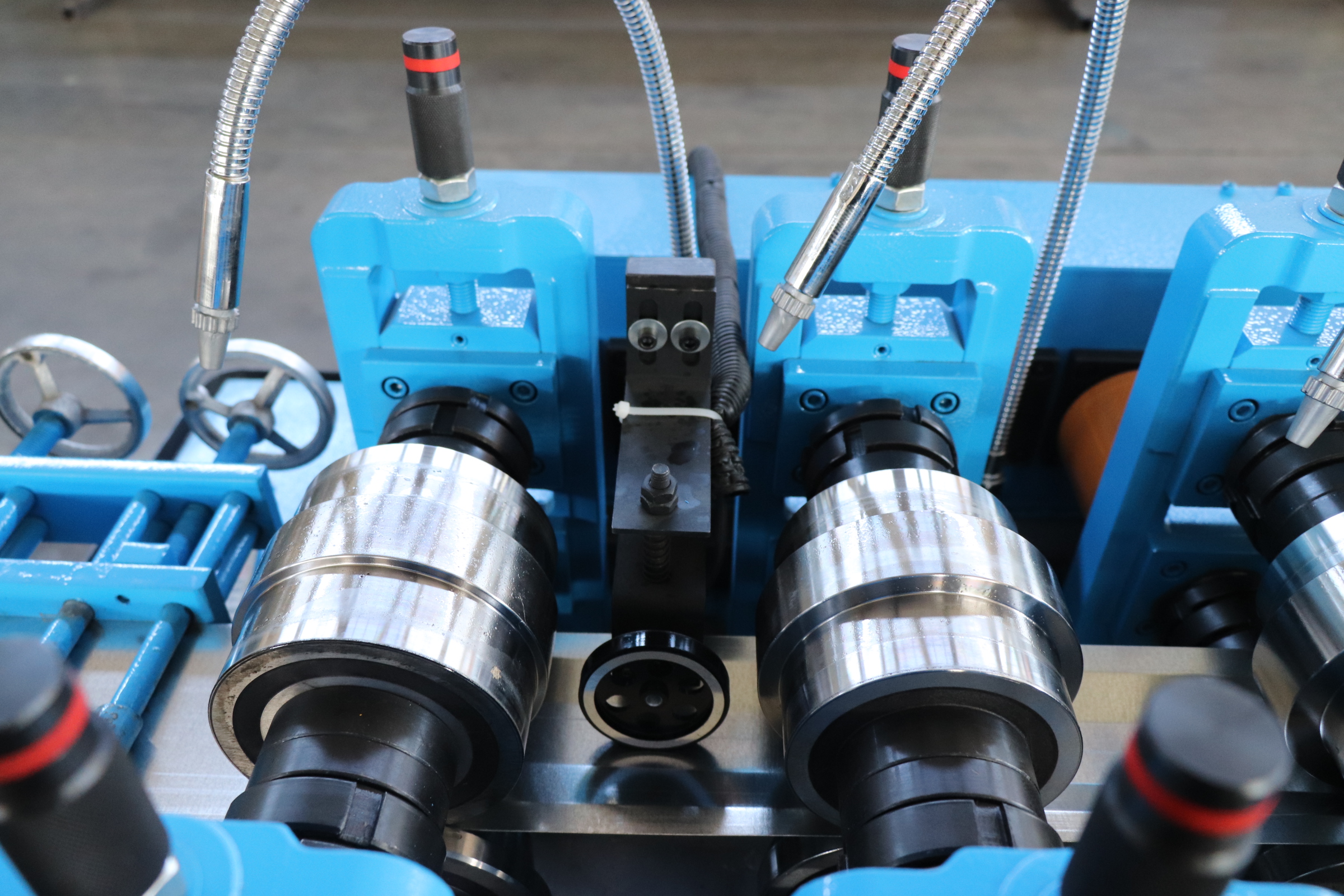

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chains transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

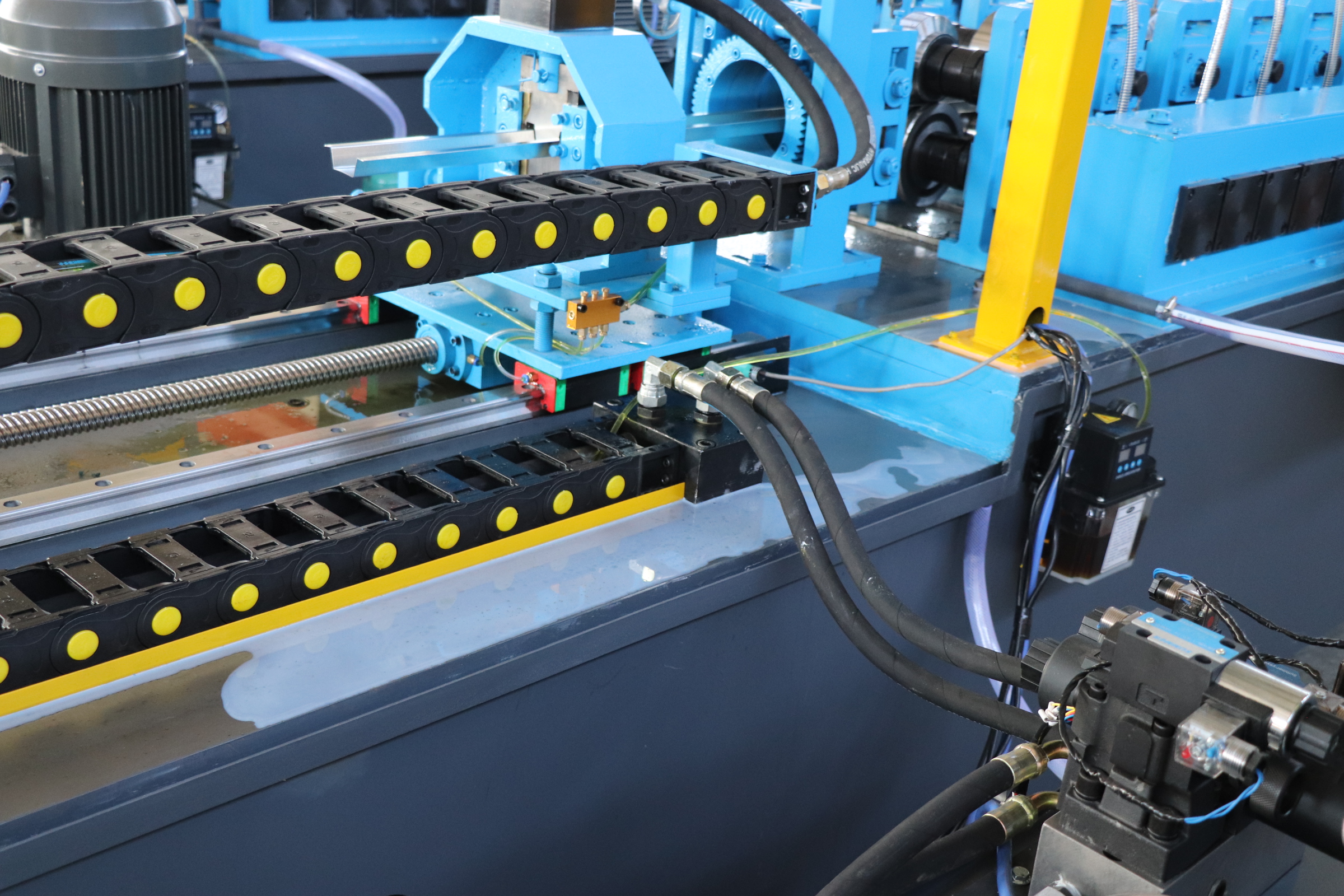

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

40-45m/min(customized)

|

Speed is adjustable according to customer’s request

|

||