Are you still worried about these issues in the fierce competition of “rushing for construction period and competing for production capacity” in the building decoration industry?

1. Low manual production efficiency, how many days does it take to produce 100 square meters of board?

2. Is it difficult to deliver orders in a crowded manner, and are you afraid to accept the demands of large customers?

3. Can’t production capacity keep up with the market and miss out on millions of orders?

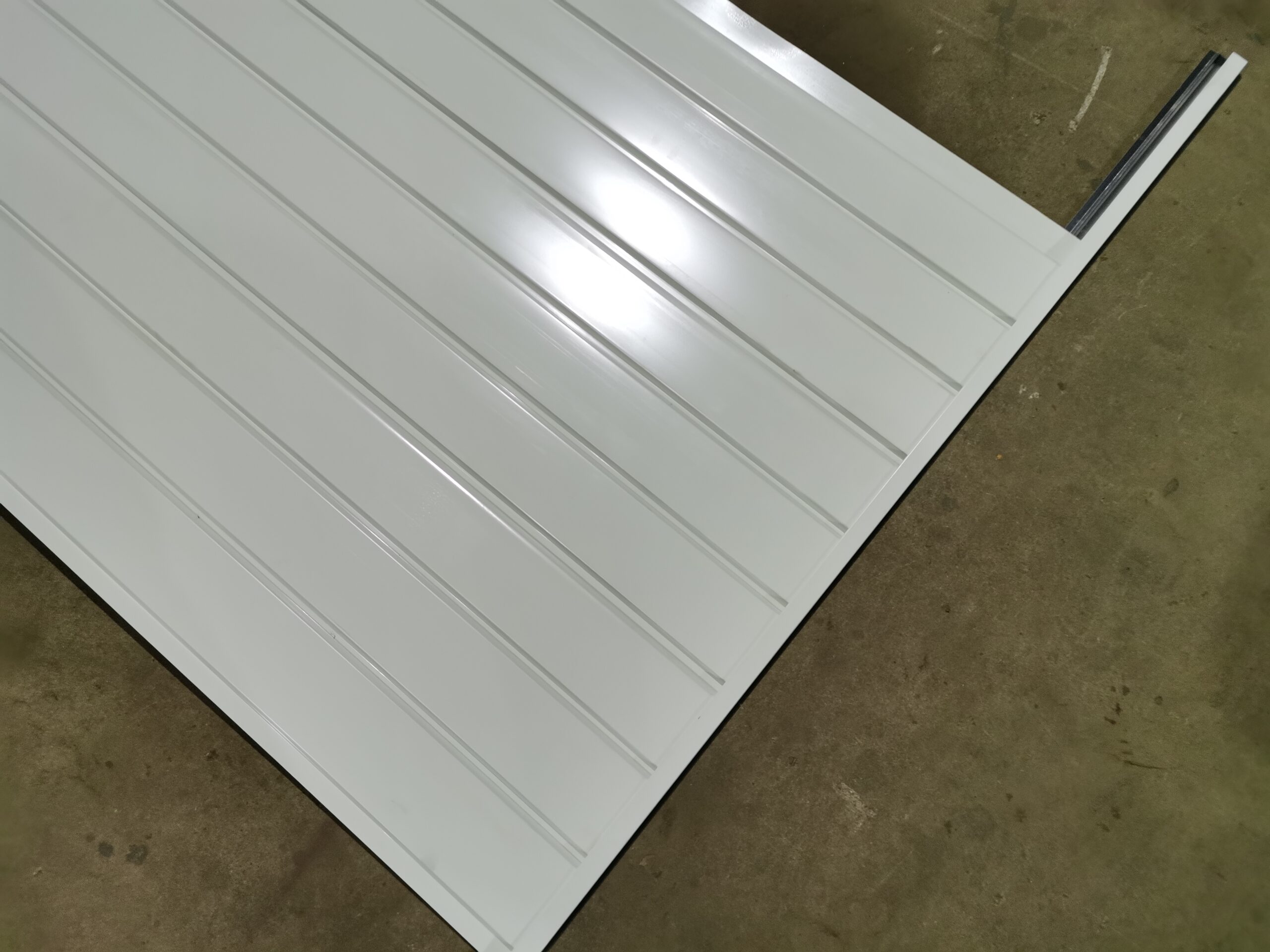

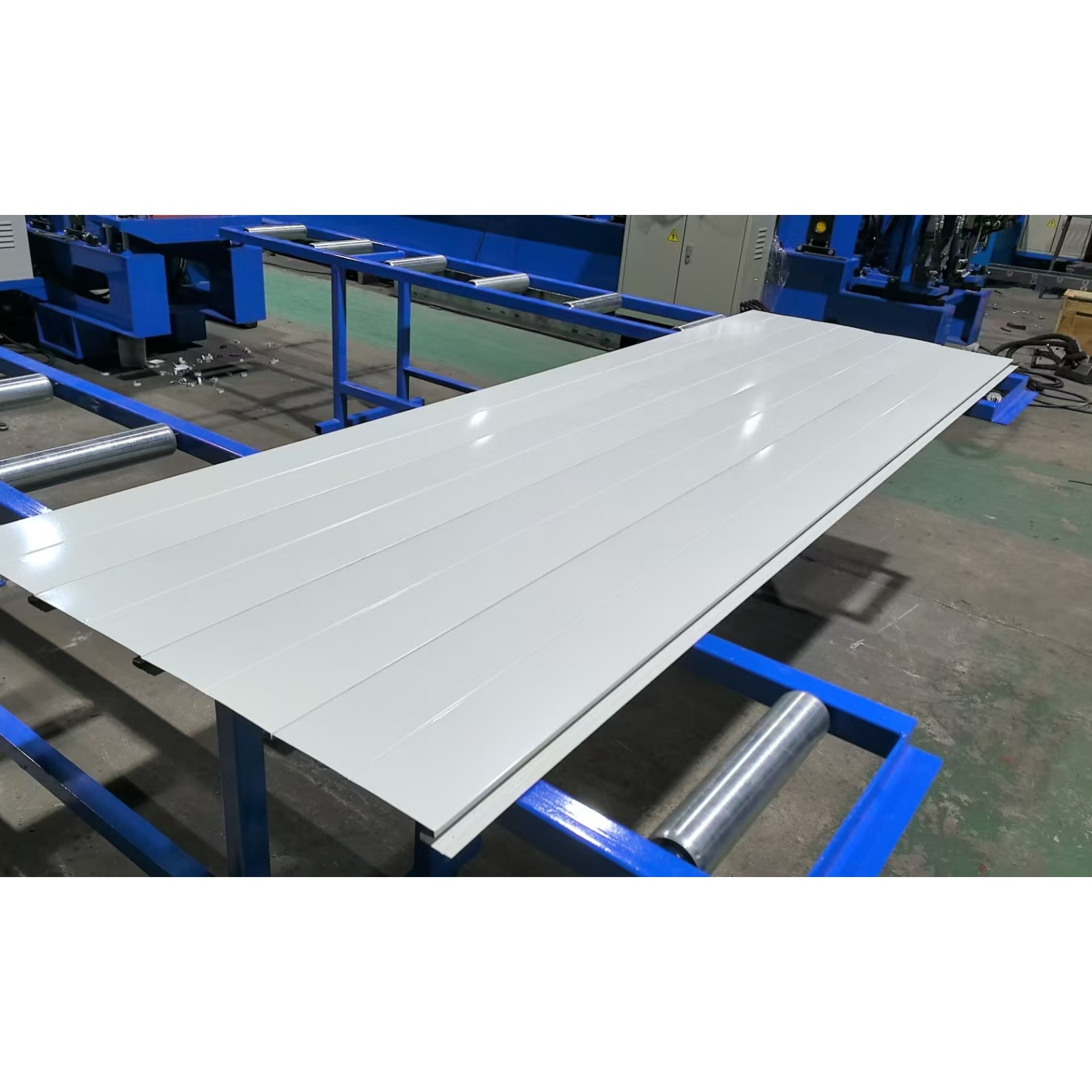

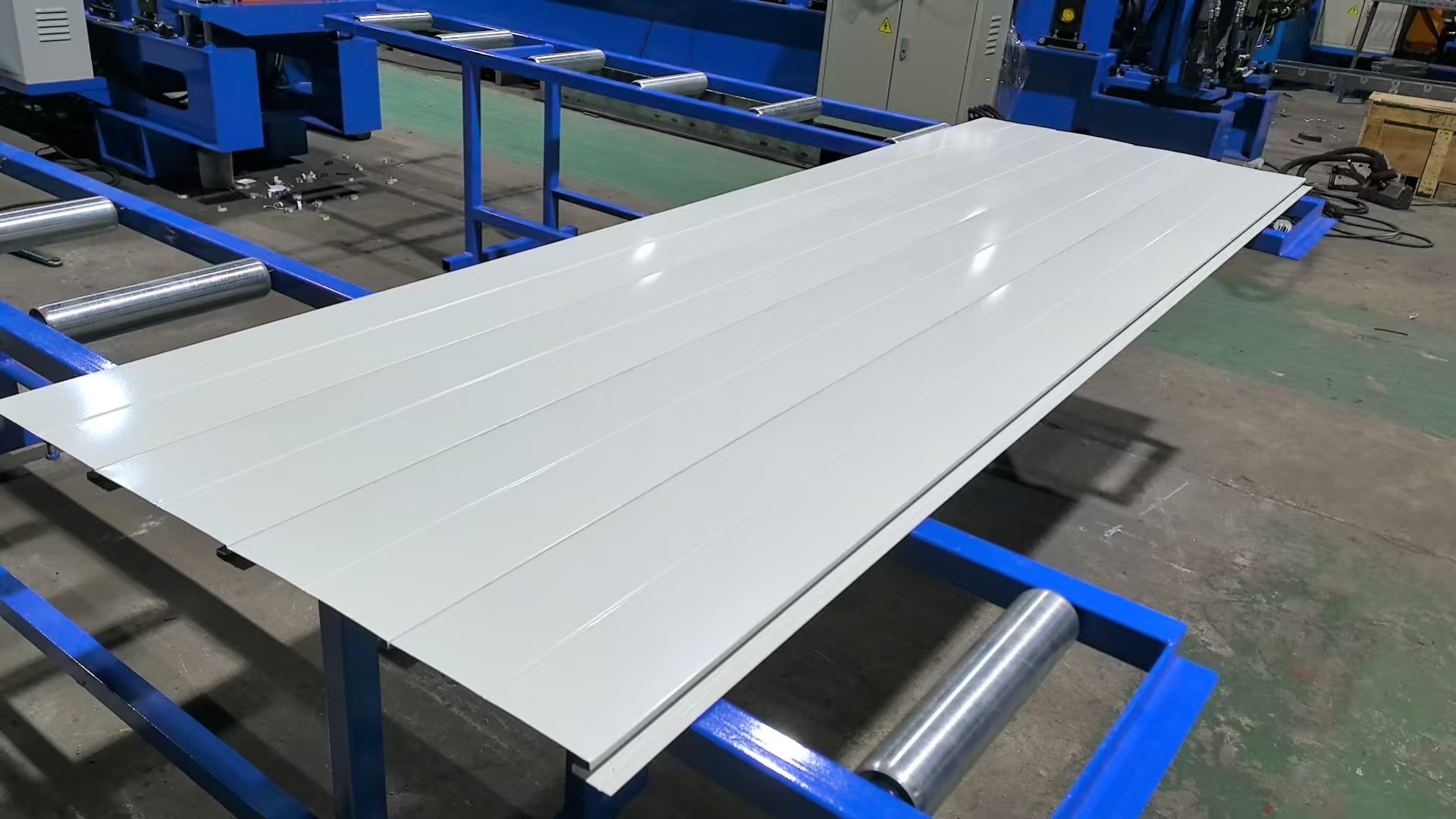

Don’t let the shortage of production capacity drag down business! The Hot Sale Metal Roof Ceiling Panel Roll Forming Machine, with “efficient mass production” as its core killer, reconstructs the production logic of ceiling panels, allowing production capacity to soar exponentially and helping you easily handle various bulk orders!

The ceiling of mass production efficiency, every hour is a ‘harvest season’

Fully automated assembly lines break the bottleneck of low efficiency, with no human intervention in the entire process from raw materials to finished products, and mass production capabilities far exceeding traditional modes:

• A single production line can achieve a maximum output of over 500 square meters per hour, with an efficiency 100 times that of traditional manual labor

• The daily production capacity of gypsum/metal sheet is 8000-12000 square meters, and the PVC sheet exceeds 15000 square meters, meeting the needs of large-scale projects

• 24-hour continuous operation, intelligent diagnosis reduces downtime by 80% and capacity utilization rate by 95%

Choosing it means choosing ‘capacity freedom’!

When your peers are still worried about production capacity, you have already swept orders and seized the market with the efficient mass production capability of intelligent ceiling board machines! At present, the equipment has served over 2000 building materials enterprises nationwide, helping customers increase their annual production capacity by 300% and increasing order amounts by over 5 million!

Product Attributes

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

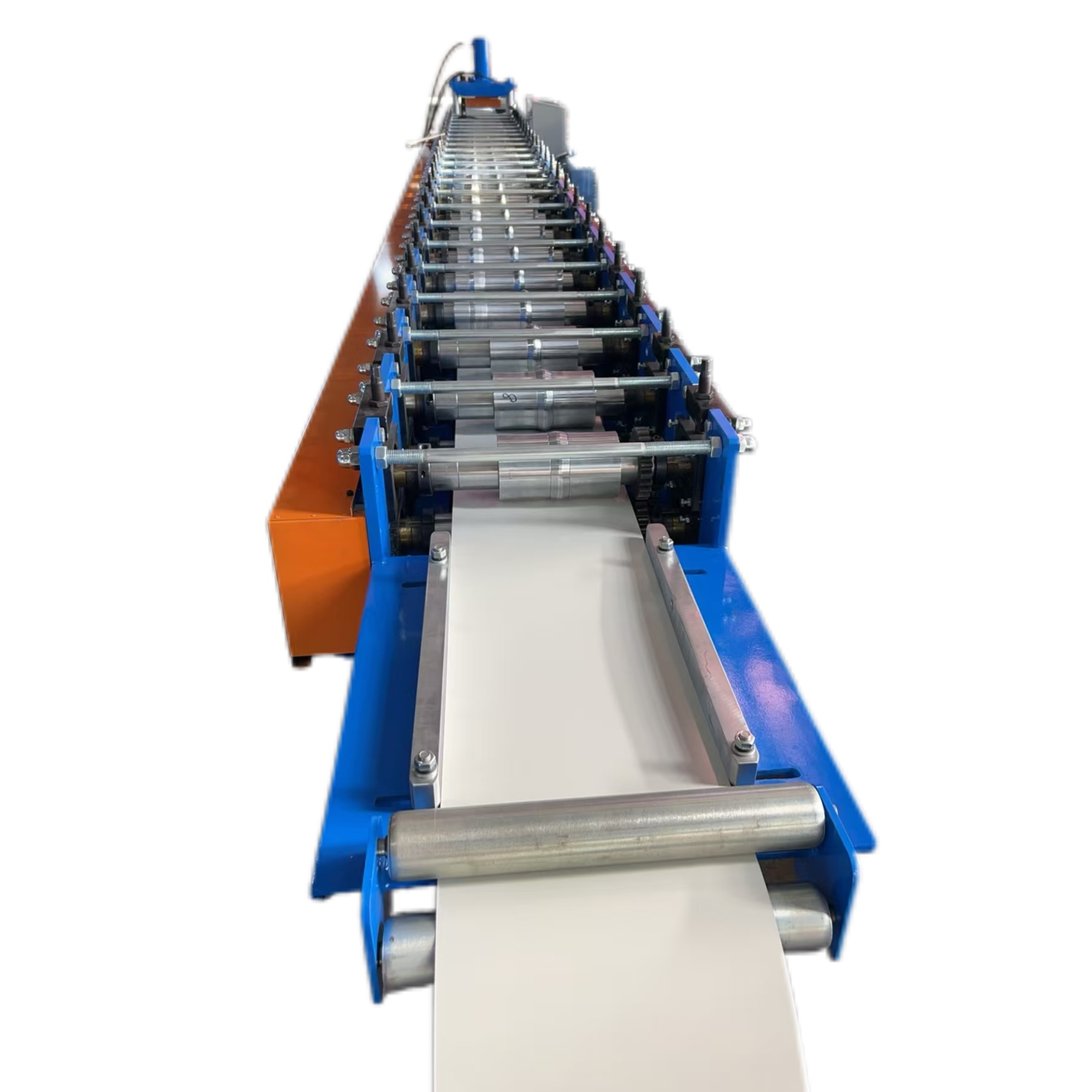

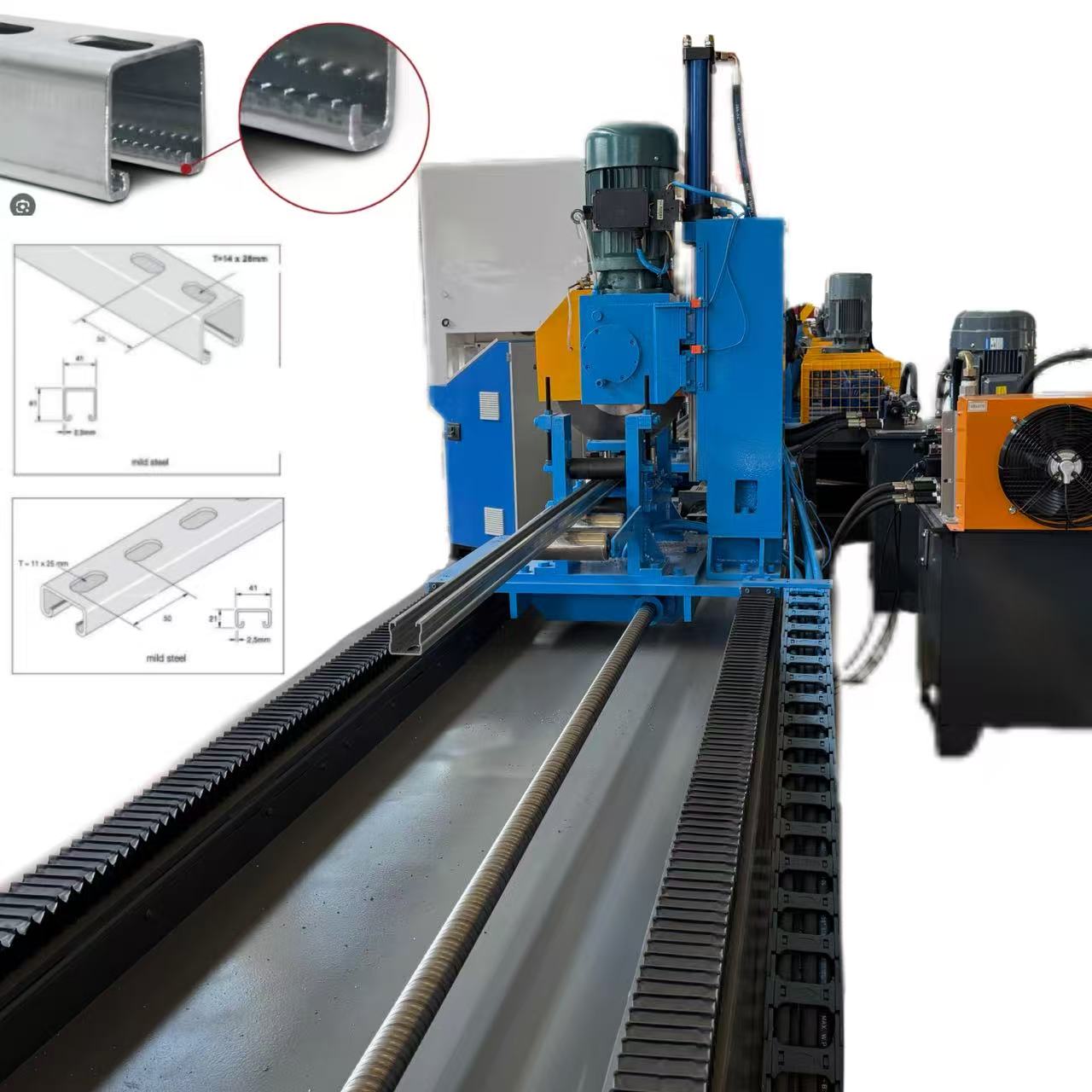

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive way

|

gear

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 8T

|

|||

|

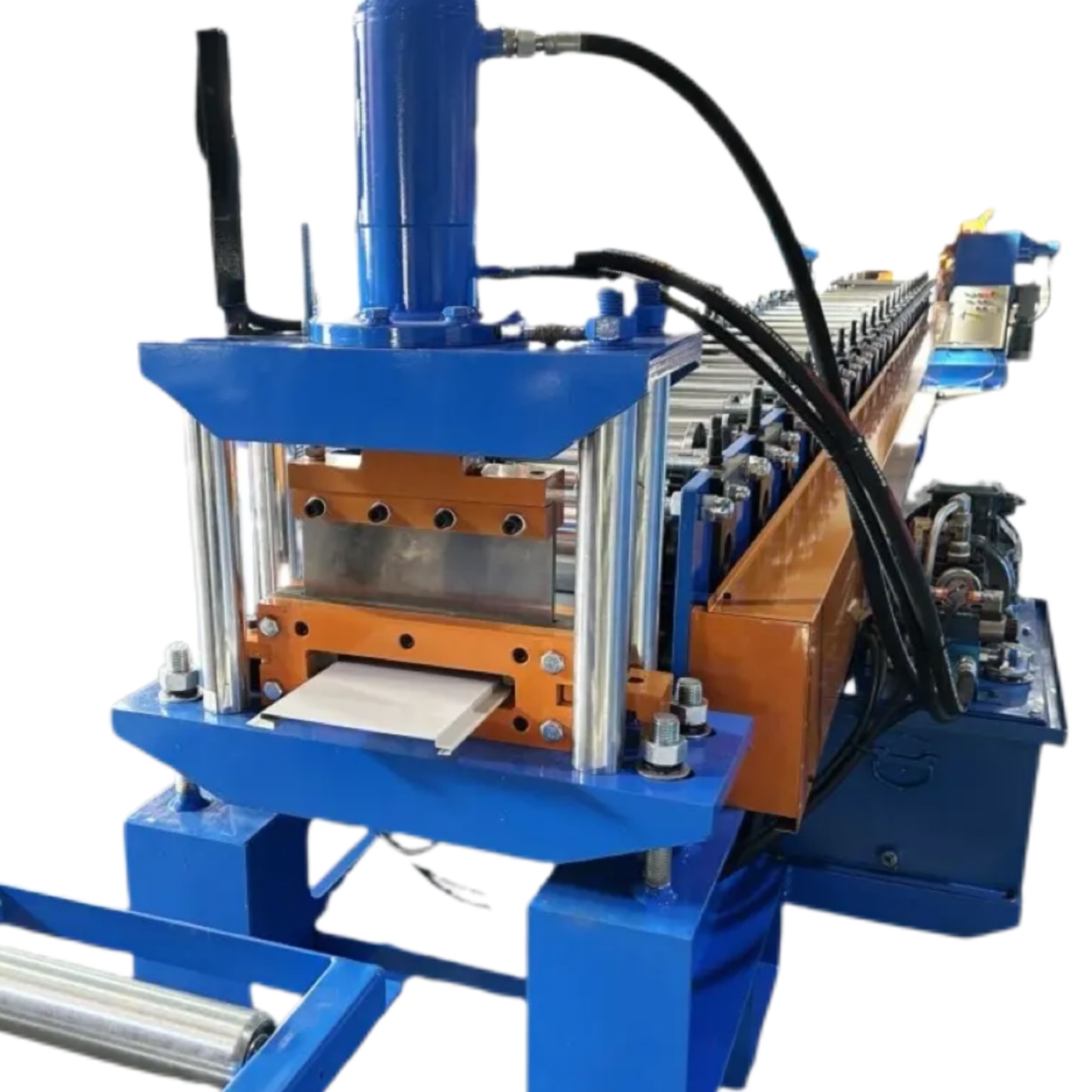

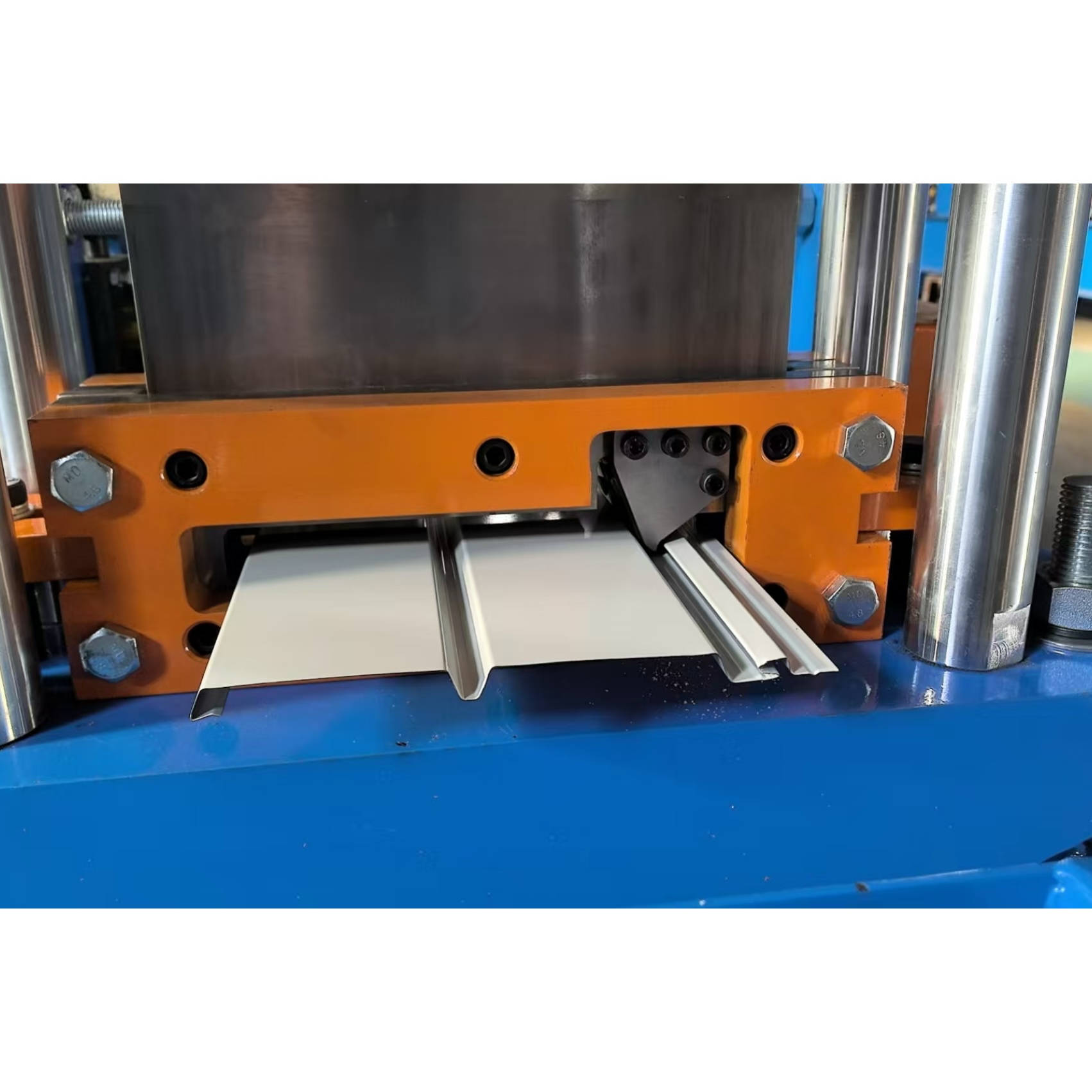

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

When optimizing processes to reduce consumption, the supply cycle is cut in half and then in half again

Whole process optimization significantly shortens delivery cycle:

• Integrated raw material processing and palletizing, reducing production cycle by 60%

• PLC intelligent control enables mold changing time to be less than 10 minutes, seamless switching of multi specification orders

• 99.8% high pass rate avoids rework and accelerates delivery

Bulk orders can be easily accepted, and the speed of making money is like stepping on the accelerator

Efficient production capacity enhances order capacity:

• Multiple models of equipment are compatible with orders of different scales, and projects ranging from 1000 square meters to 100000 square meters can be undertaken

• Capacity increase reduces costs, raw material utilization rate is 95%, labor costs are reduced by 70%, and price competitiveness is enhanced

• Fast delivery helps win high-end orders and seize market share

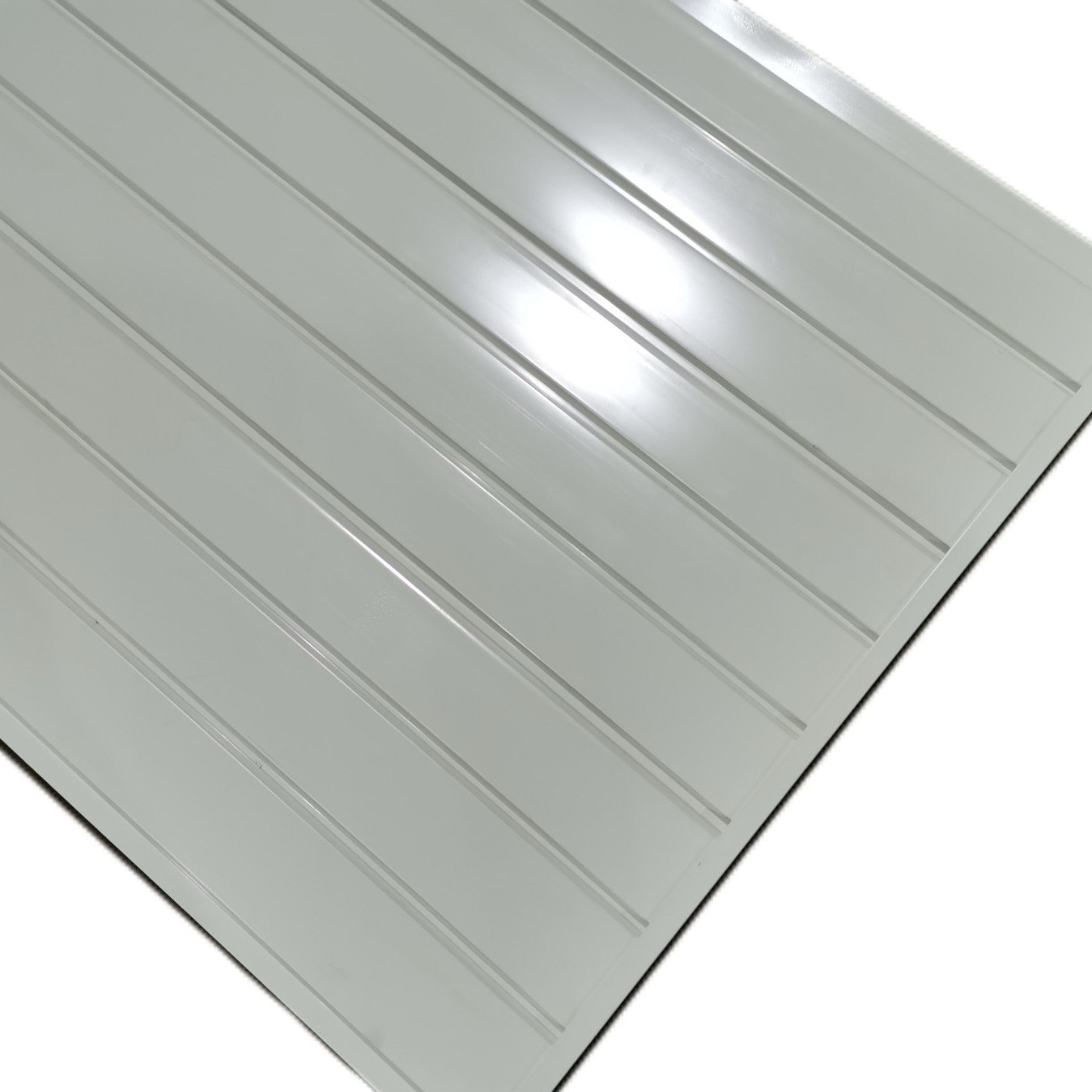

In addition to high efficiency, there is also a hardcore guarantee

Balancing speed and quality in equipment:

• Millimeter level accuracy (error ≤± 0.3mm) ensures worry free installation

• Compatible with various materials such as gypsum and metal, achieving full category production

• Reduce energy consumption by 30%, recycle scraps, environmentally friendly and cost-effective