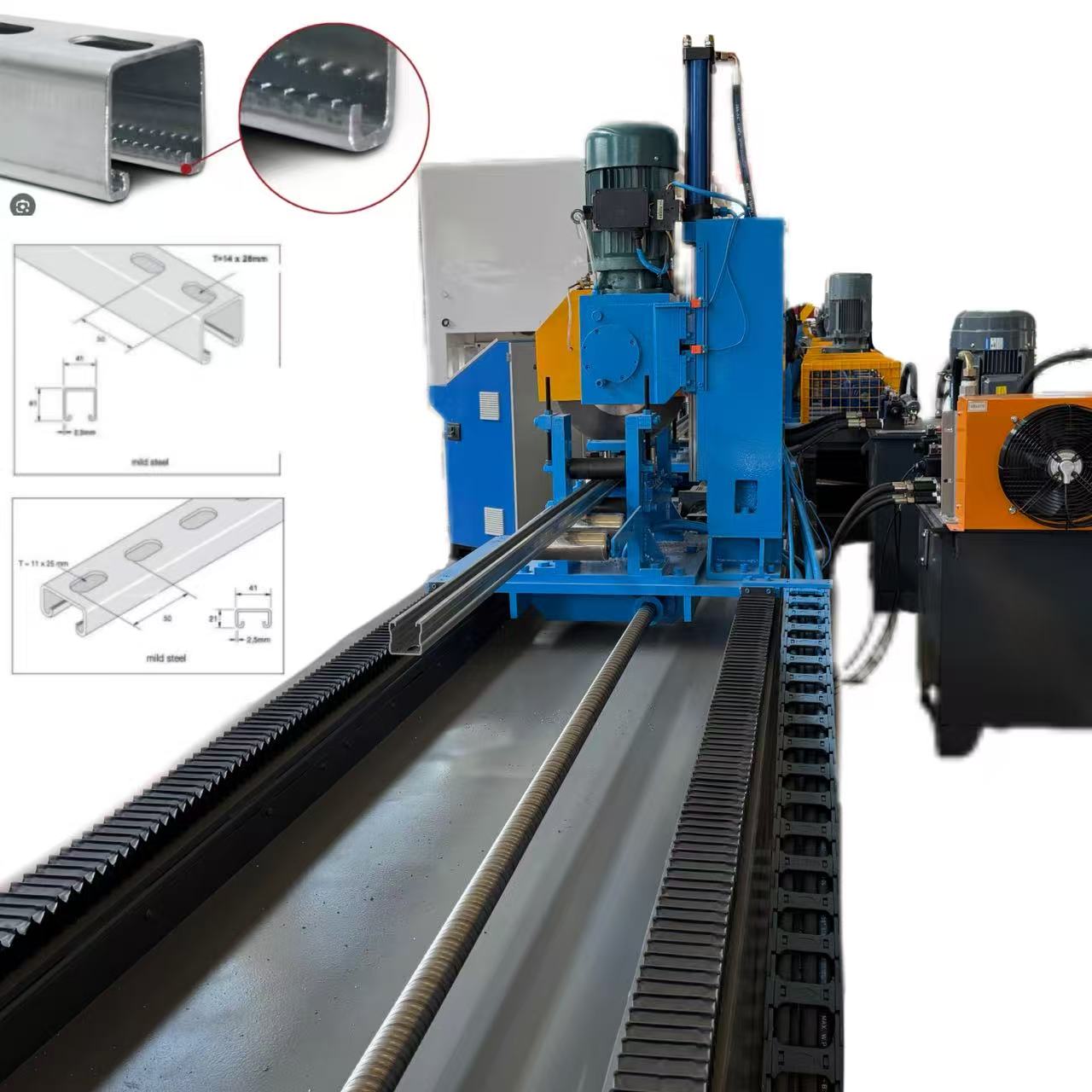

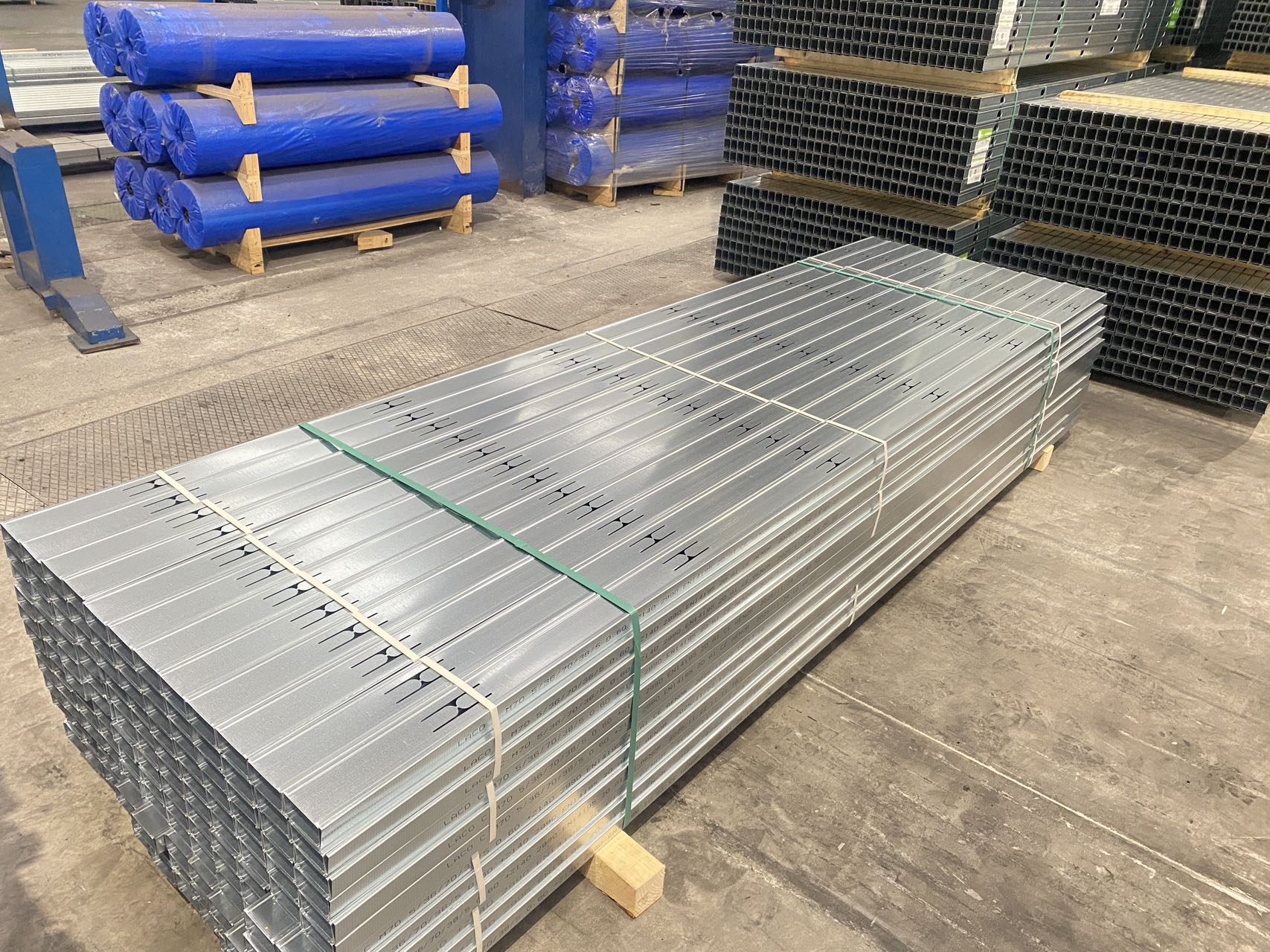

The entire intelligent production line of the Metal Stud and Track Roll Forming Machine Multi Profile Auto Size Changing Roll Former consists of a double headed unwinding machine, an automatic opening and closing forming machine, a servo tracking cutting machine, a conveyor, a flipping buckle machine, a palletizing machine, a strapping machine, and a bundling machine, seamlessly connecting to achieve efficient and continuous production. From design to implementation, Zhongtuo uses exquisite craftsmanship and intelligent technology to create high stability and precision light steel keel solutions for customers, helping the European building materials industry improve quality and efficiency!

Key technical features

1.Efficient integration:

With integrated punching and cutting design, the molding speed can reach 30m/min, and the maximum output per shift (8 hours) can reach 2400 meters, which is 3-5 times higher than traditional equipment;

2.High forming accuracy:

The rolling mill adopts precision grinding technology, combined with servo drive system, the cross-sectional size error of the profile is ≤± 0.2mm, and the punching position deviation is ≤ 0.5mm, meeting the accuracy requirements of building assembly;

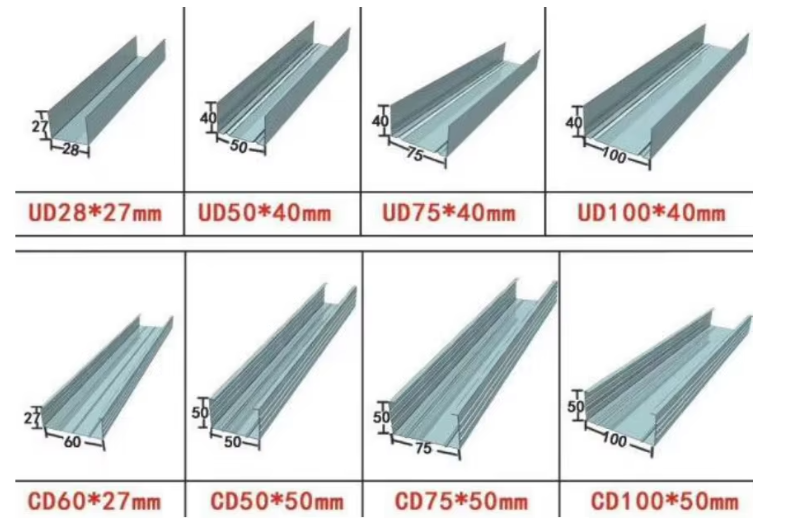

3.Multi specification compatibility:

The equipment comes with 5 sets of forming mold wheels, which can be quickly replaced with roller sets (about 1.5 hours) to adapt to various types of keel production such as U-shaped, C-shaped, and card type, reducing equipment investment costs;

4.Strong operational stability:

The bed is made of 16mm thick iron plate welded and tempered, and the slide rail and ball screw are high-precision components. The equipment has a service life of more than 10 years.

Main application scenarios

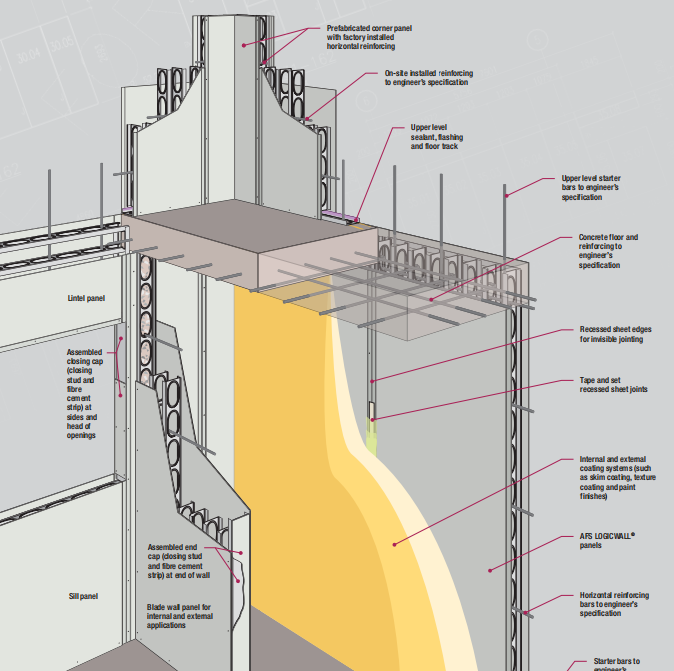

• Ceiling engineering:

Production of main keel (U-shaped, cross-sectional width 38-60mm) and auxiliary keel (C-shaped, width 50-75mm), suitable for large-scale space ceiling skeleton construction such as shopping malls and office buildings, using galvanized sheet material for rust prevention and durability;

• Partition wall system:

Processing vertical keel (C-type, thickness 0.5-0.6mm) and horizontal keel, used for lightweight partition wall construction in hospitals and residential areas, can be combined with rock wool filling to achieve sound insulation and thermal insulation function;

• Integrated Decoration:

Production of baked paint keel and card type keel, with a surface treated with baked paint and uniform color, suitable for decoration scenes such as hotels and exhibition halls that require high aesthetic standards;

• Special scenario:

In response to the requirements of fire protection engineering, fire-resistant steel plate keels can be processed, and the compatibility between profiles and fire-resistant seals can be ensured by adjusting the roller pressure.

Pattern diagram:

Product Attributes:

|

1.Formed Material

|

GI

|

Thickness:0.8-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gearbox transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3.5 T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

5.5KW

|

||

|

Hydraulic system power

|

4.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-20m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Packing list- C/U roll forming machine:

|

No.

|

Name

|

Unit

|

Quantity

|

Remark

|

|

Part 1

|

3T decoiler

|

set

|

1

|

Manual

|

|

Part 2

|

Main roll forming machine

|

set

|

1

|

High speed

|

|

Part 3

|

PLC control station

|

set

|

1

|

Mitsubishi brand

|

|

Part 4

|

Cutting system

|

set

|

1

|

Hydraulic

|

|

Part 5

|

Hydraulic station

|

Set

|

1

|

45# oil

|

|

Part 6

|

Product table

|

set

|

1

|

Regular

|