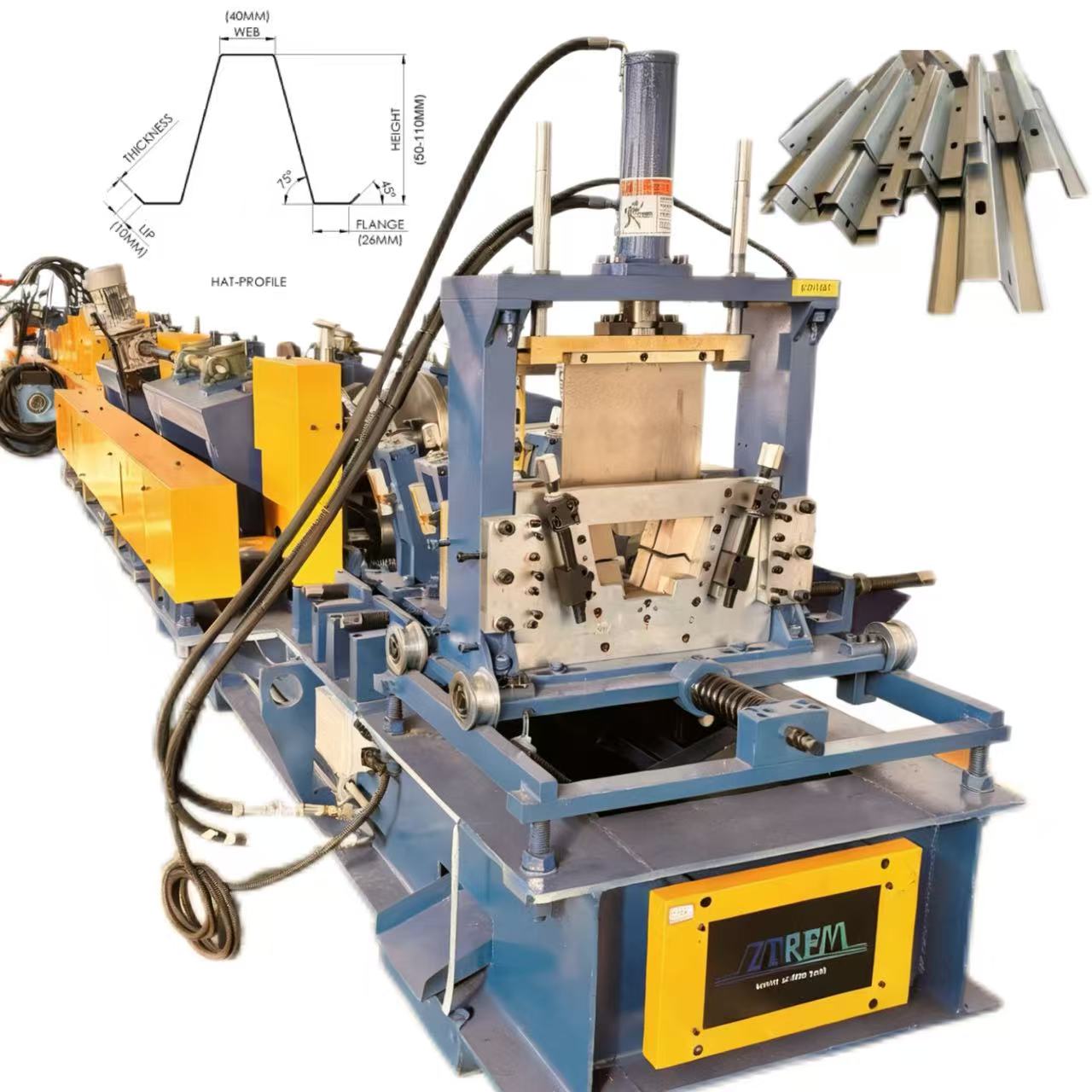

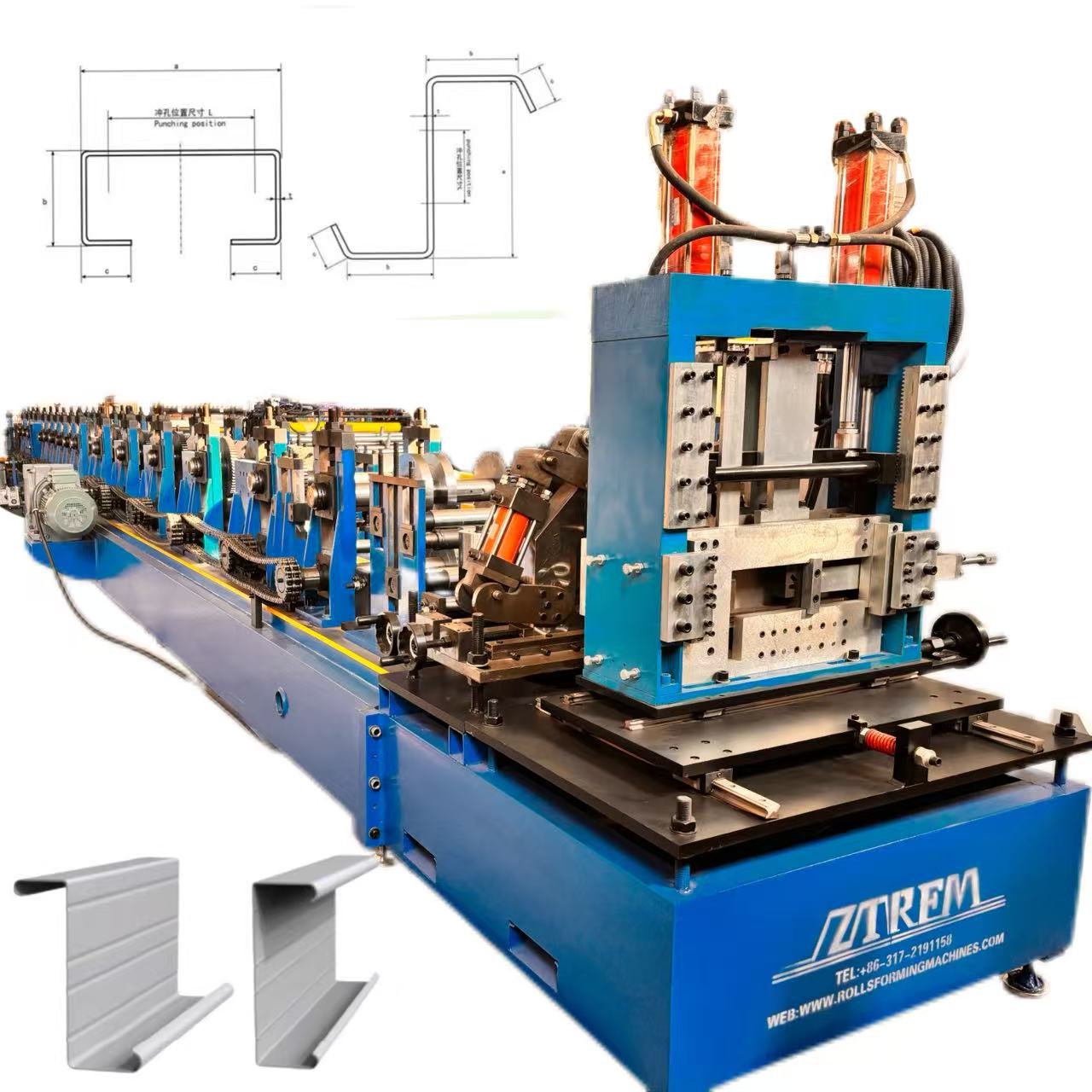

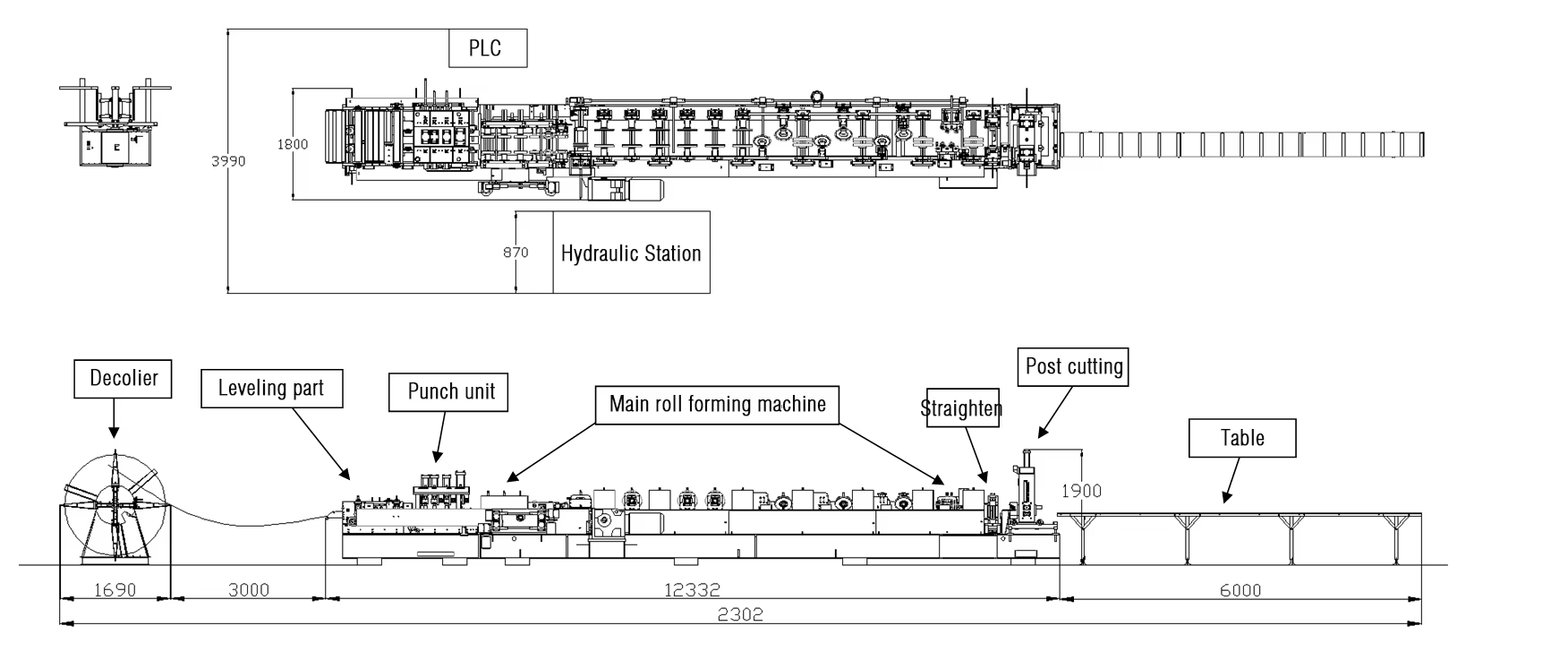

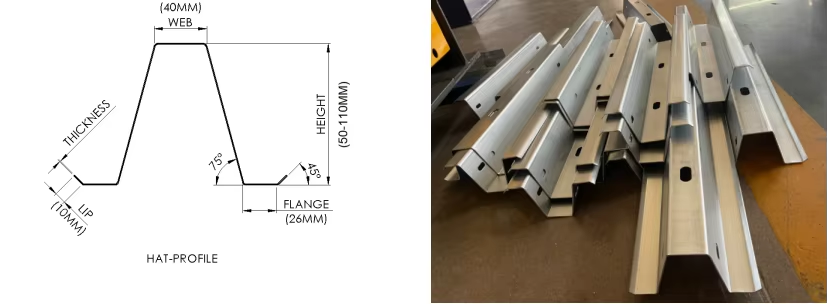

The Automatic Steel Machine Manufacture Omega Profile Drywall Machine Top Hat Roll Former that processes hot-rolled or cold-rolled strip steel and other metal plates into hat-shaped cross-section steel through continuous cold bending. Its core function is to achieve automated, high-precision forming of metal plates. The produced hat-shaped steel is widely used in construction, transportation, machinery, and other fields as support components, reinforcement elements, or load-bearing structures.

Product Attributes:

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-3mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

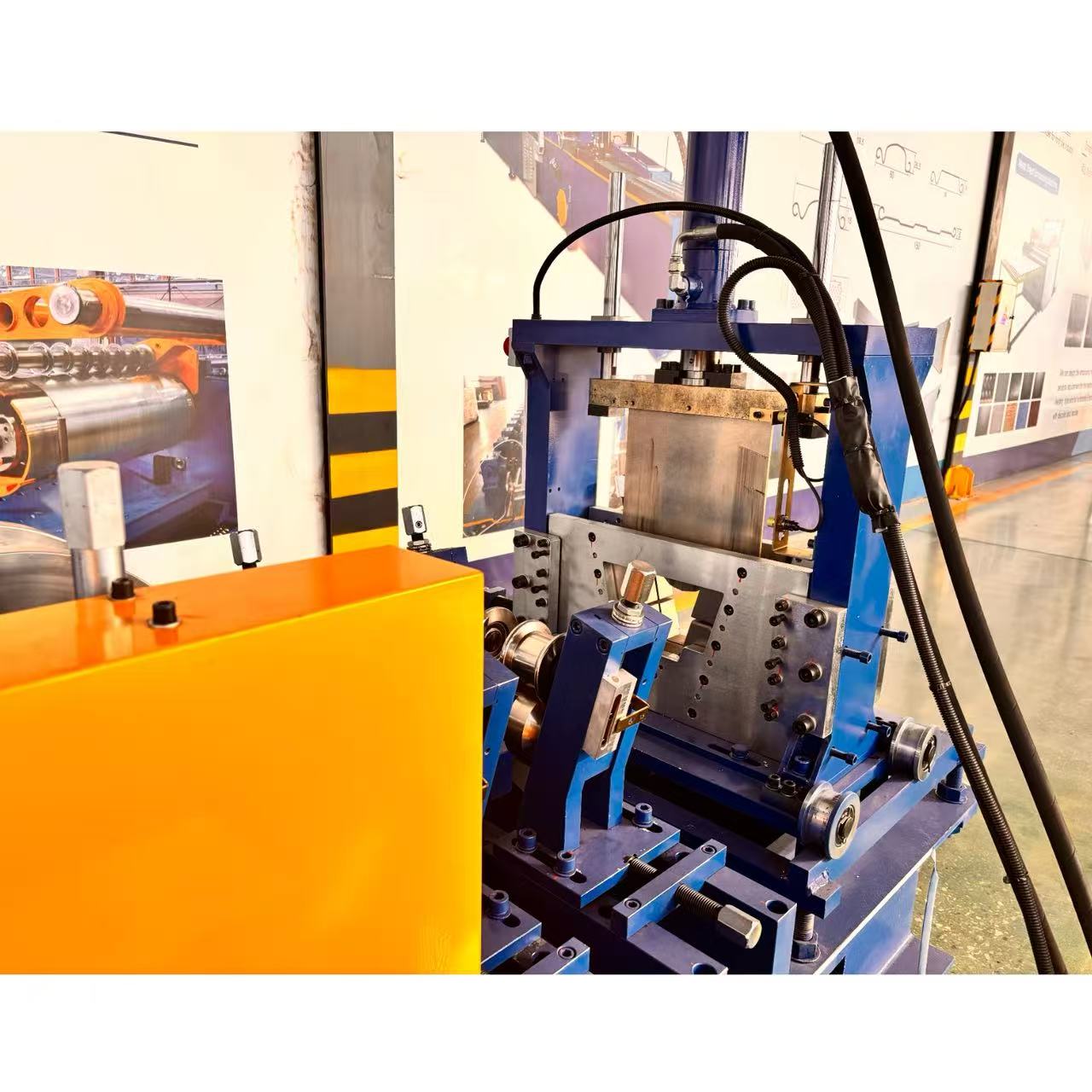

3.Main body

|

Roller station

|

16 rows(As your requirement)

|

||

|

Diameter of shaft

|

80mm solid shaft

|

|||

|

Material of rollers

|

Gcr 15 with quenched teeatment

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

9500*800*1200(customize)

|

|||

|

Weight

|

About 7T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

60-70m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

working flow:

Core advantages of equipment

1.Efficient and energy-saving:

Cold bending process does not require heating, saving more than 60% energy compared to hot rolling forming, and the continuous production mode greatly improves production capacity;

2.High forming accuracy:

The forming roller is made of GCr15 bearing steel precision machining, strengthened by heat treatment, ensuring that the cross-sectional dimension tolerance of the steel is ≤± 0.5mm and the surface is scratch free;

3.Flexible adaptation:

supports the production of various specifications of hat shaped steel, and the product cross-section can be adjusted by replacing the forming roller group to meet personalized needs;

4.Easy to operate:

PLC touch screen visual operation, preset multiple sets of production parameters, beginners can quickly get started, reducing manual dependence;

5.Durable and stable:

The body is made of welded steel structure, which has undergone aging treatment to eliminate stress, resulting in minimal vibration during operation. The service life of core components is ≥ 8000 hours;

6.Safe and reliable:

equipped with emergency stop button, protective fence, overload protection and other devices, in compliance with industrial safety standards.

Applicable industries and application scenarios

• Construction industry:

steel structure factory support beams, curtain wall keels, floor load-bearing components, and movable panel house skeletons;

• Transportation field:

Bridge crash barriers, tunnel support structures, highway noise barrier brackets;

• Mechanical manufacturing:

equipment racks, conveyor line guides, and storage rack crossbeams;

• Other fields:

container accessories, agricultural machinery frames, photovoltaic bracket accessories, etc.