As the “finishing touch” of architectural roofing, ridge tiles not only fulfill core functions such as sealing, waterproofing, wind resistance, and roof reinforcement but also embody the aesthetic appeal and durability of buildings. Amid the wave of intelligent and efficient construction material production, PLC Control Metal Roofing Ridge Cap Roll Forming Machine has become a core tool for enterprises to seize market share and enhance competitiveness. Leveraging years of technical expertise in the construction material equipment sector, we have developed ridge tile machinery that integrates precision forming, high-efficiency mass production, and intelligent control, injecting robust momentum into various construction material production enterprises.

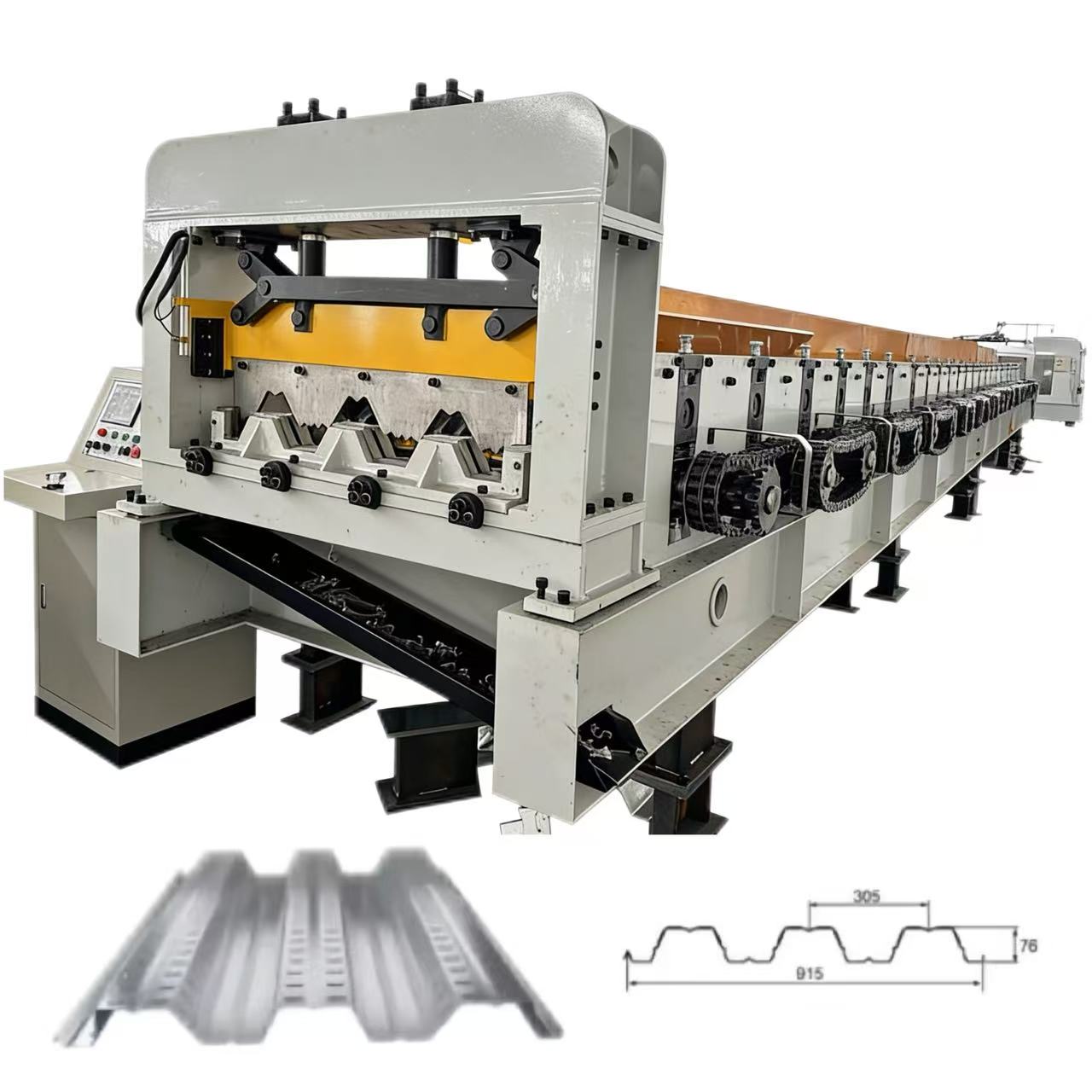

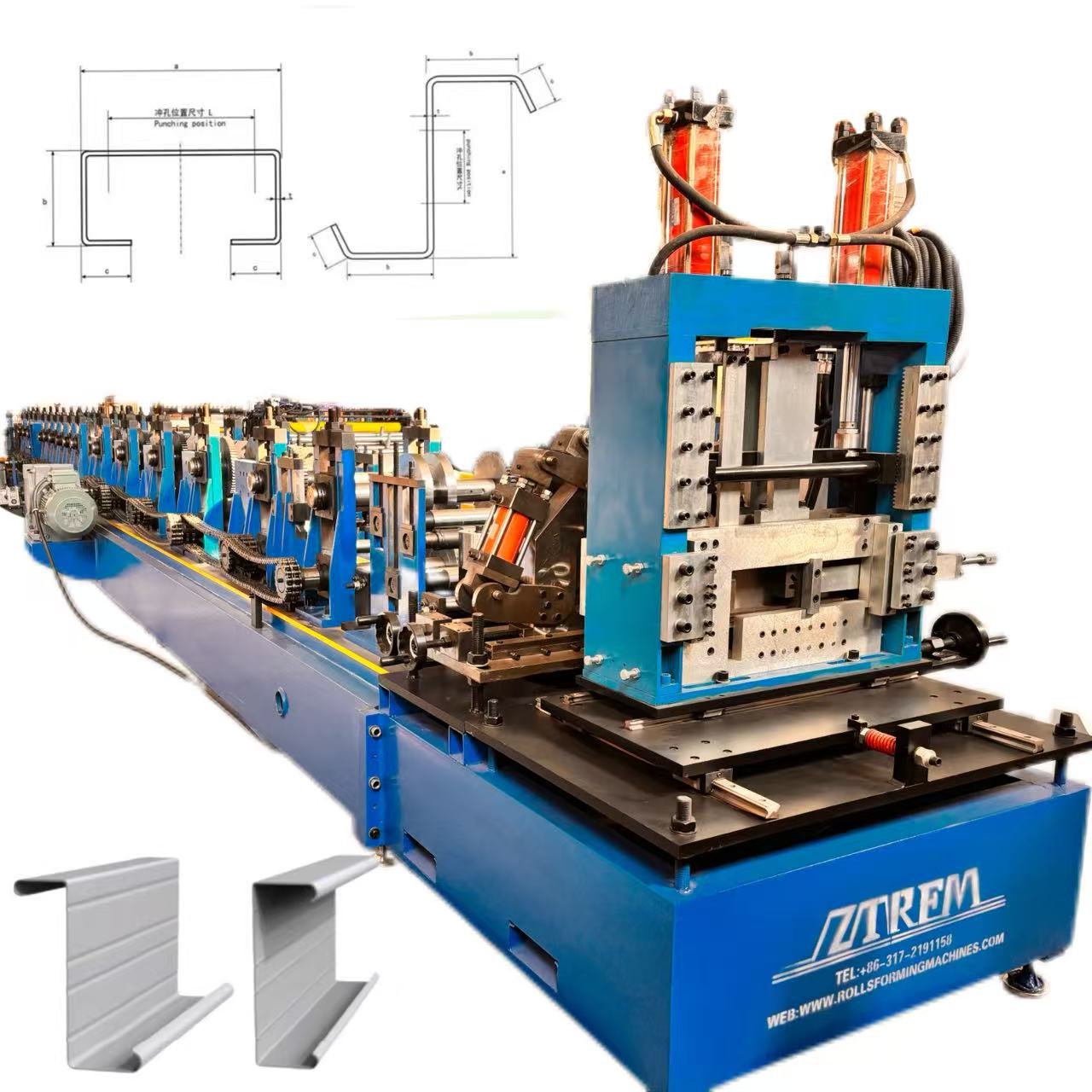

Product Attributes:

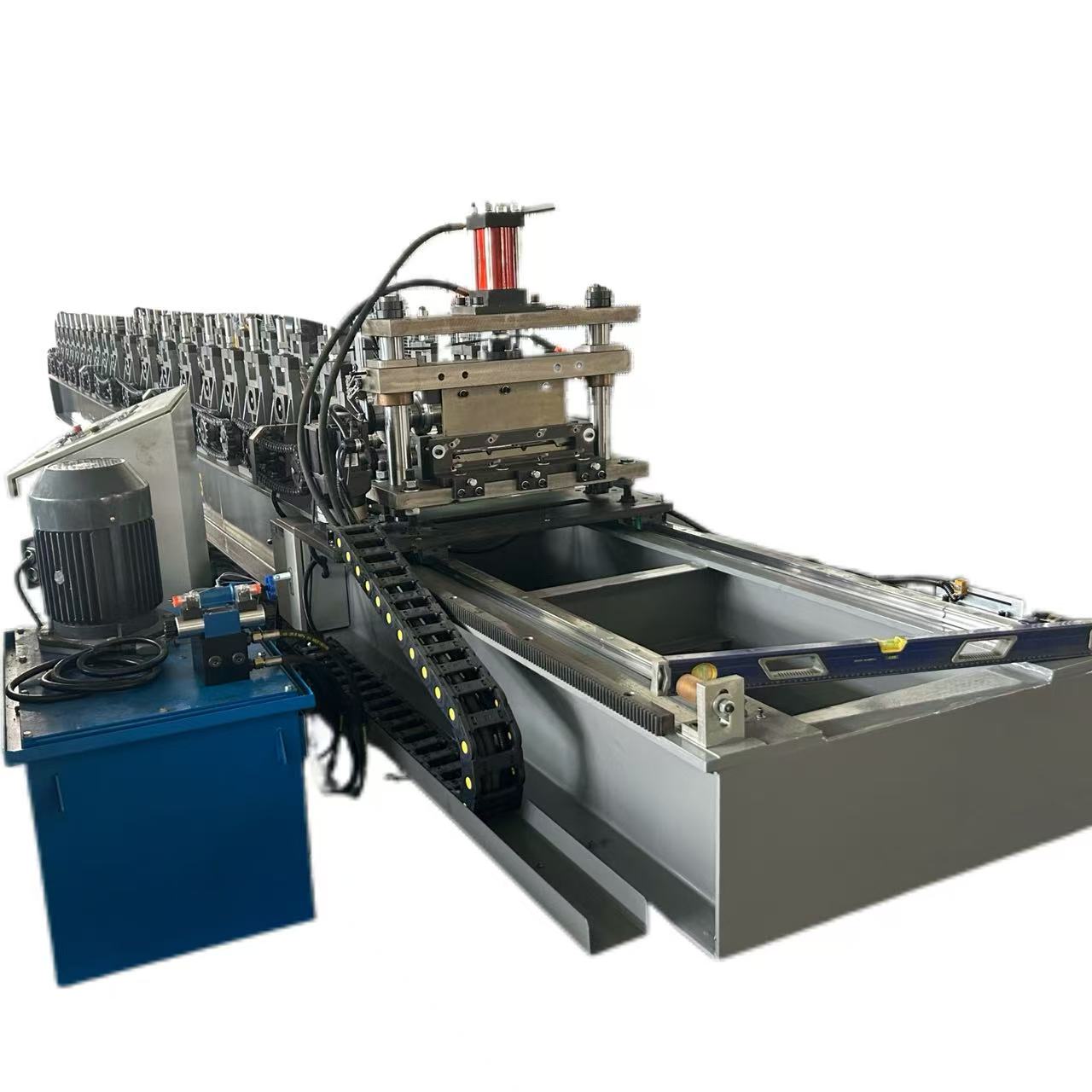

| 1.Formed Material | PPGI,GI | Thickness:0.4-0.7mm | ||

| 2.Decoiler | Hydraulic decoiler | 3 tons | ||

| 3.Main body | Roller station | 14 rows(As your requirement) | ||

| Diameter of shaft | 65mm solid shaft | |||

| Material of rollers | 45# steel,with quenched and tempering | |||

| Machine frame | 350mm H | |||

| Drive | Chain transmission | |||

| Dimension(L*W*H) | 9500*1600*1600mm | |||

| Weight | 7.5T | |||

| 4.Cutter | Automatic | Gcr12 steel | ||

| 5.Power | Motor Power | 5.5KW | ||

| Hydraulic system power | 4KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | Support multiple languages | |||

| PLC | Can set batch, length, quantity, etc. | |||

| 18.Forming Speed | 15-20m/min | The speed is adjustable | ||

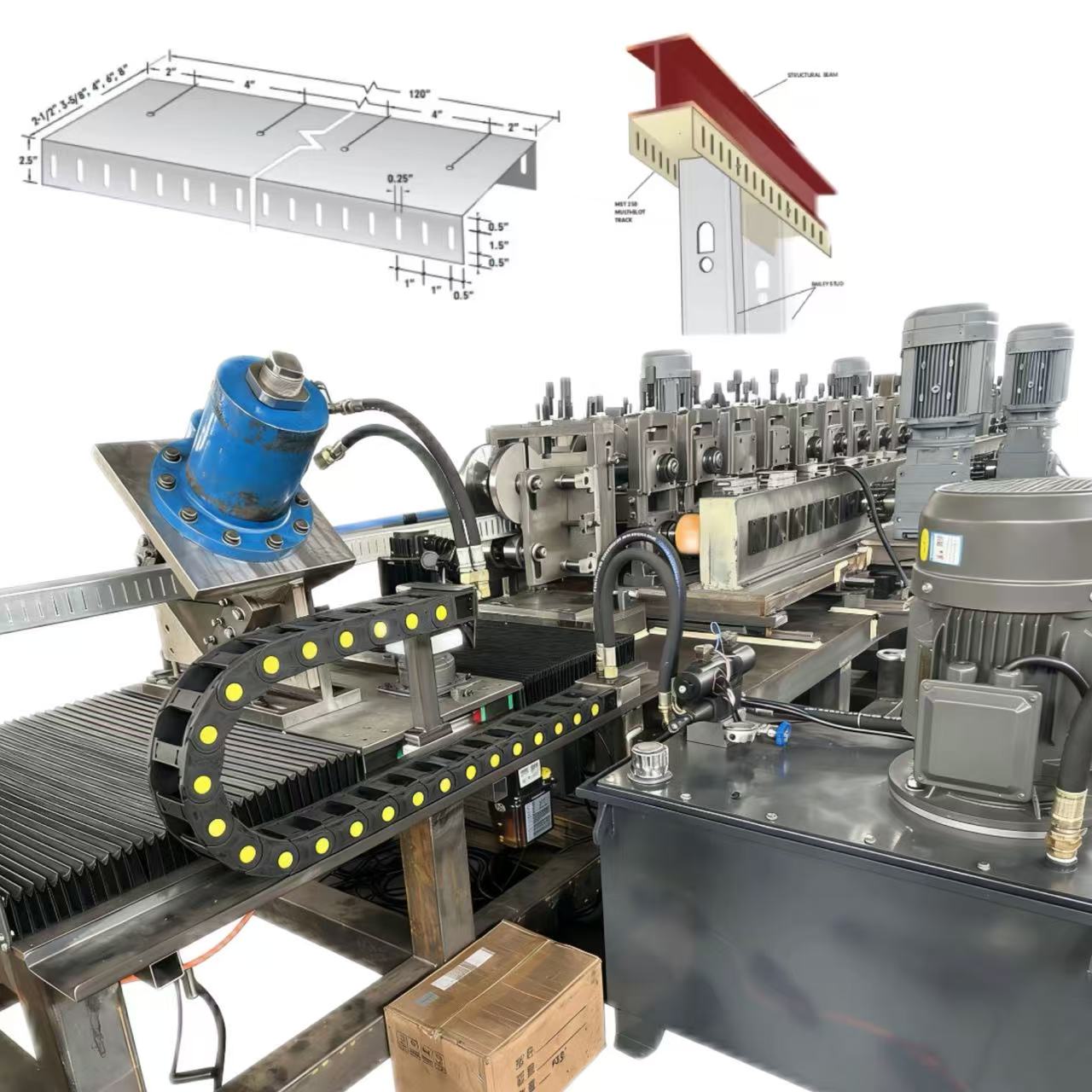

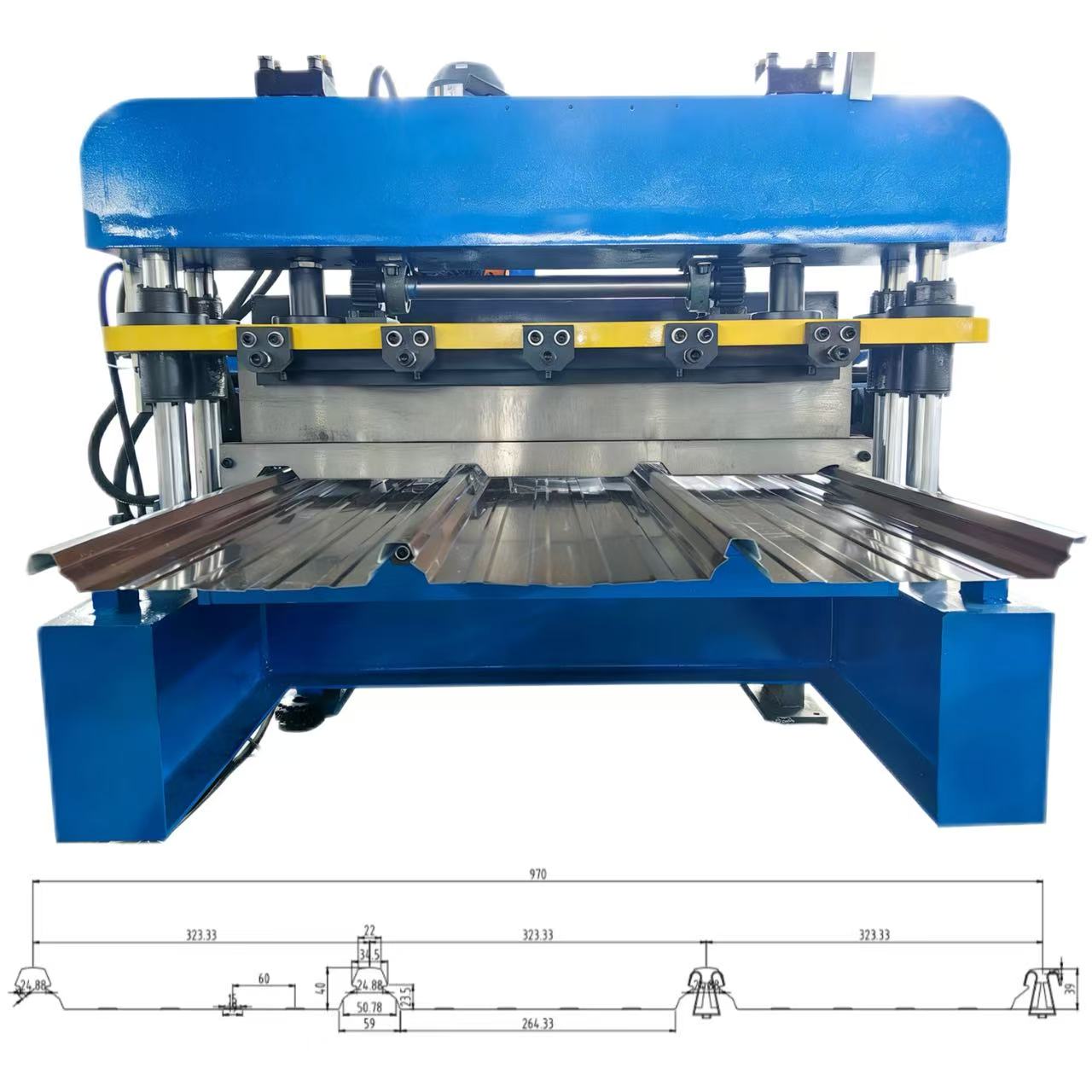

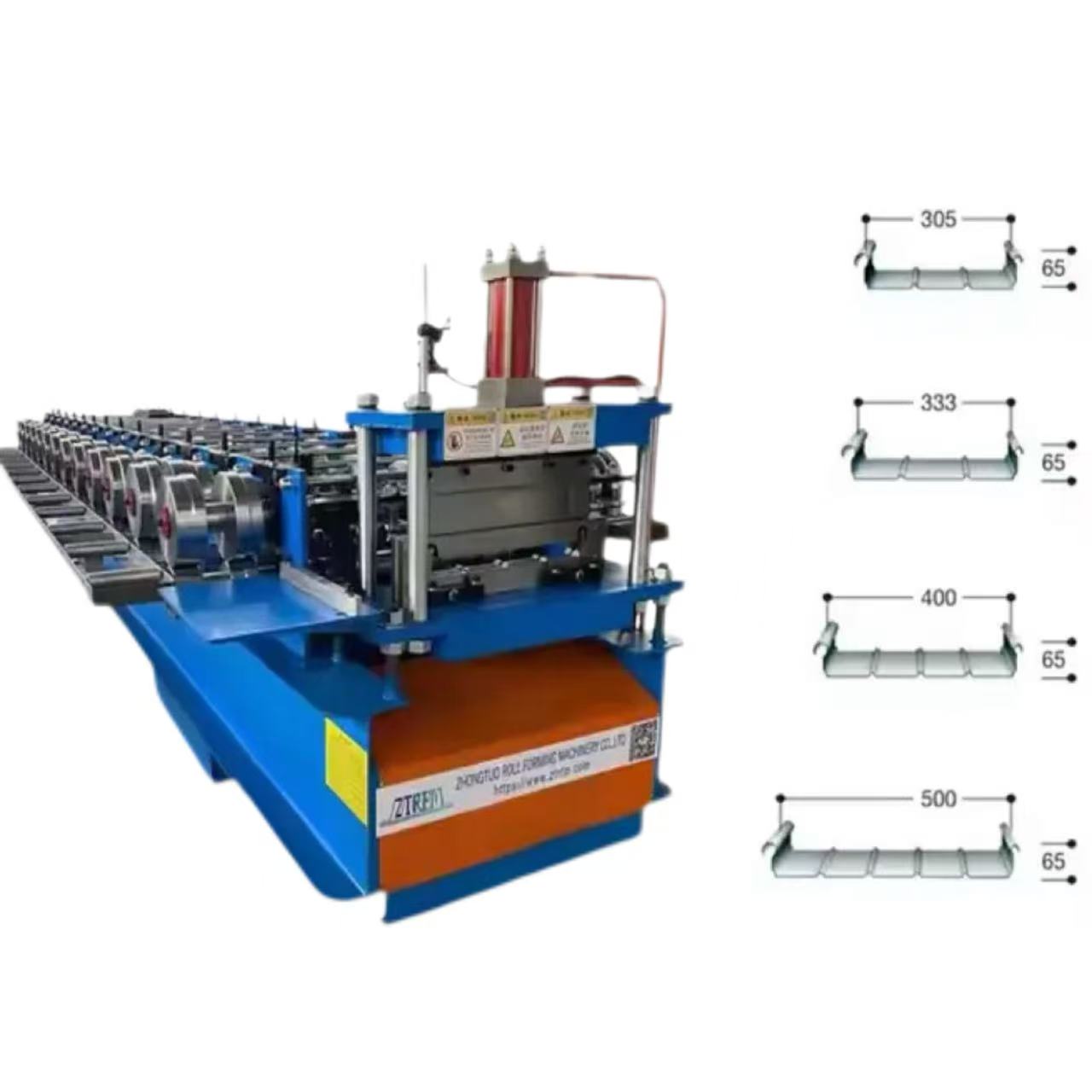

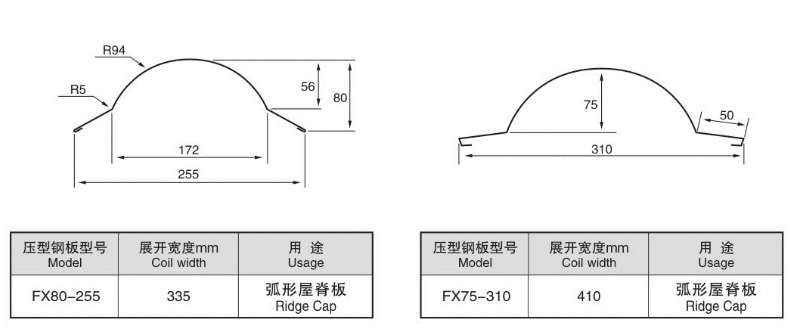

Pattern diagram:

Application Scenario:

- Traditional architecture

In the restoration of ancient buildings or the renovation of cultural districts, it is often necessary to replicate historical forms such as dragon kisses and animal head components to continue the historical style. For example, palace architecture adopts a hipped roof with animal faced tiles placed at both ends of the main ridge, serving both sealing and decorative functions. - Modern architecture

The modern architectural style is diverse, and the spine tiles can be customized to match the architectural language. For example, minimalist architecture may use abstract ridges made of metal or glass materials, emphasizing contour lines. - Private residence

Private residences often incorporate family crest or cultural symbols through customized ridge tiles, such as the use of glazed ridge tiles in new Chinese style residences, giving the building cultural charm.

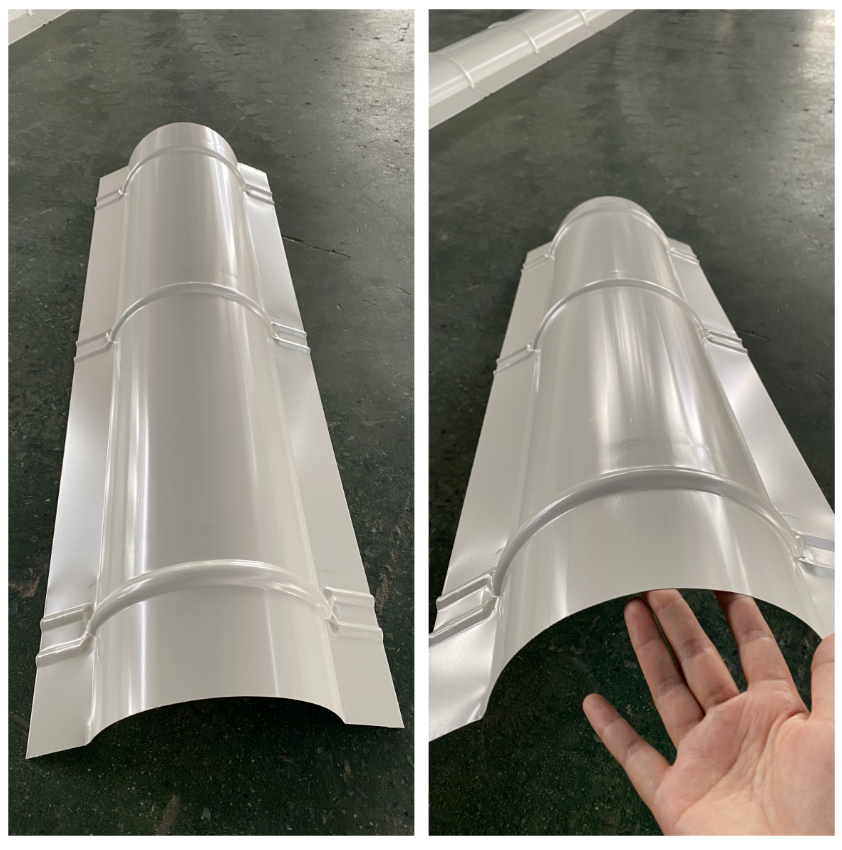

Finished product image:

Core Advantage: Technological Breakthroughs to Reshape Production Efficiency

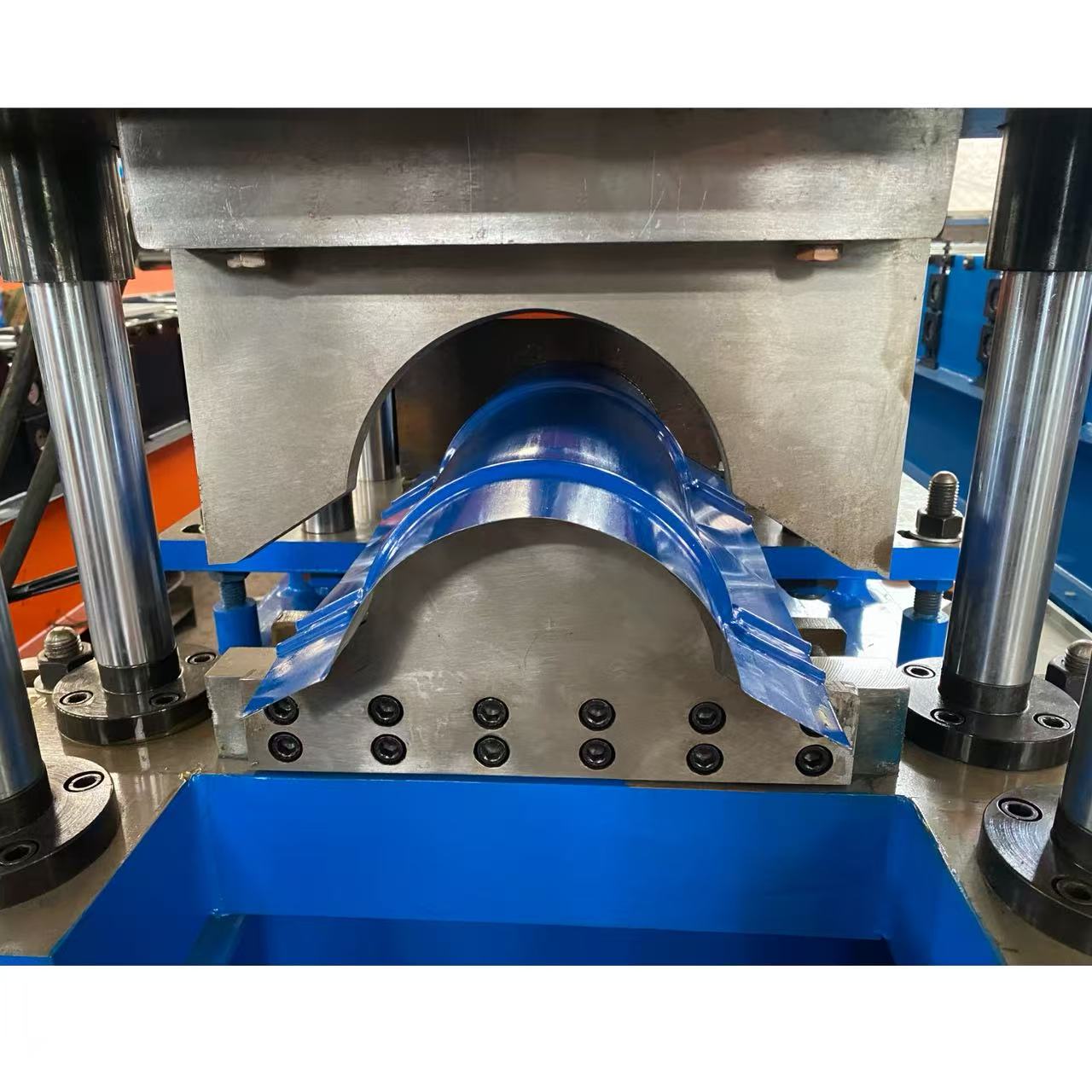

1.Precision Molding, Consistent Quality

The equipment employs high-precision CNC forming technology and customized mold sets, suitable for the production of ridge tiles in various specifications and materials. The molds undergo precision machining and heat treatment, ensuring strong wear resistance and enabling dimensional deviations to be controlled at the millimeter level. Paired with a multi-stage pressure adjustment system, it balances strength and texture, guaranteeing the product meets industry premium standards.

2.High-efficiency mass production, cost reduction and efficiency improvement

The fully automated production process covers everything from material feeding to finished product output, requiring minimal manual intervention. With a daily output capacity of thousands of pieces, it achieves 3-5 times higher efficiency compared to traditional equipment. Equipped with energy-saving motors and an intelligent power consumption management system, it reduces costs across multiple dimensions—labor, electricity, and raw materials—while boosting profit margins.

3.Intelligent control, easy operation

The high-definition touchscreen, paired with an intelligent system, features built-in parameter preset schemes for one-click production startup, ensuring easy operation. It enables real-time monitoring of production data, automatically alarms and shuts down in case of anomalies, supports data storage and export, and achieves production visualization and traceability.

4.Stable and durable, with hassle-free operation and maintenance

The main body is made of high-strength steel and undergoes aging treatment for strong stability. Core components are selected from renowned brands and feature sealed protection, ensuring a long service life. A maintenance access port is provided for convenient daily upkeep and fault diagnosis, significantly reducing operation and maintenance difficulty as well as downtime.