Slotted Angle Roll Forming Machine, the perfect solution for producing high-quality and versatile slotted angle profiles. This advanced equipment is designed to meet the demands of diverse industries, delivering precision and efficiency in slotted angle production. The precision-engineered rollers ensure consistent shaping, providing sturdy and adjustable angles for various applications like shelving, racks, and frameworks. With user-friendly controls and adjustable settings, the machine allows for easy customization, accommodating different angle sizes and hole patterns. Built with top-quality materials, our Slotted Angle Roll Forming Machine guarantees durability and reliable performance, optimizing your production and delivering exceptional results for your projects. Elevate your manufacturing capabilities with this high-quality roll forming machine and unlock the potential of slotted angle profiles in your applications.

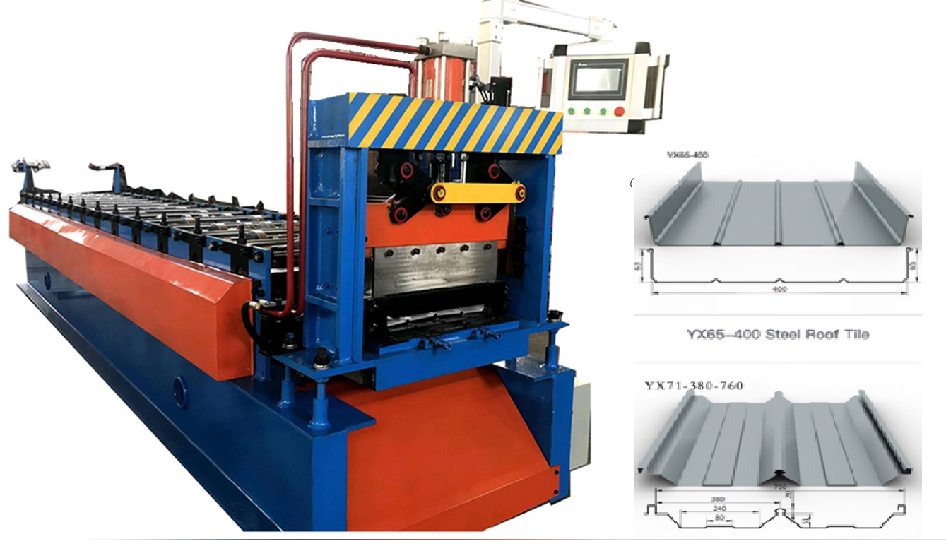

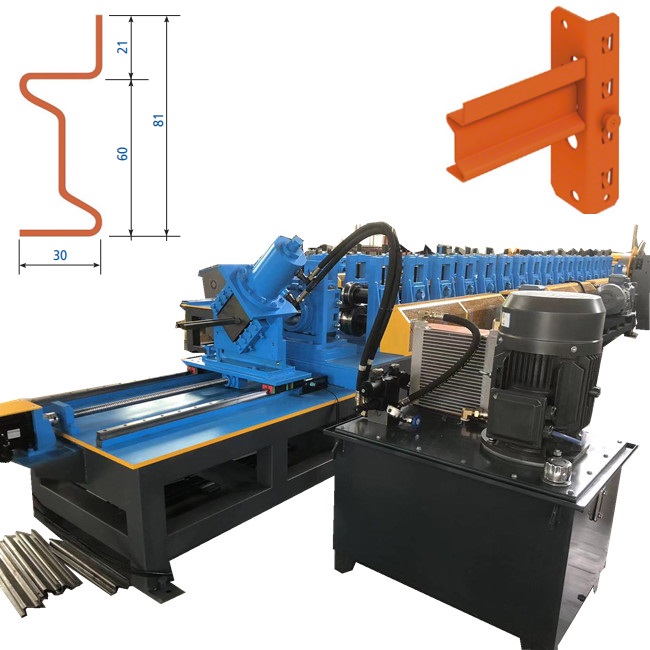

Slotted angle light duty and heavy duty rolling forming machine is designed to make the slotted angles in batch fully automatically. Slotted angle helps you build an efficient framing system for a variety of uses from machine guards to hand rails. Slotted Angle is the most versatile, time and cost effective construction material available for building carts, ladders, benches, shelving, cases, racks or any other type of structure. Made of either 12 or 14 gauge roll-formed steel. Here are some drawing profile for your reference:

Features of slotted angle profile:

- Easy to use… Just measure, cut and bolt together.

- Scientifically designed pattern of holes and slots are perfectly positioned for bolting pieces together at various angles.

- without needing to drill holes.

- No special tools required but our slotted angle cutter cuts completely through with one fast easy stroke.

- Available in 96”, 120” and 144” lengths in 14 gauge and 12 gauge steel.

- 100% reusable. Even short pieces of angle can be used as a cleat to join together angle lengths into longer ones.

- Old outmoded structures can be unbolted and reassembled into new ones.

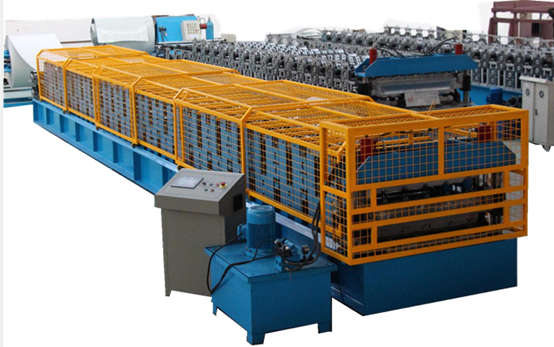

Slotted angle light duty and heavy duty rolling forming machine

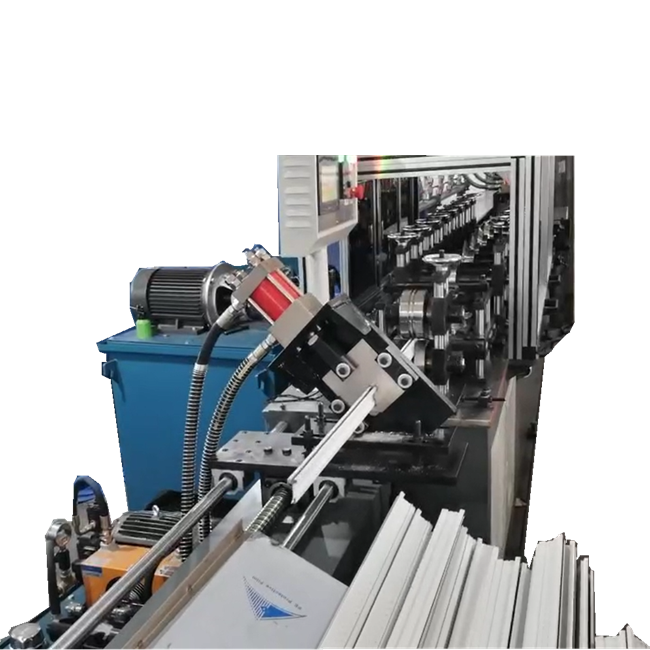

For the punching part, we have two options for your reference:

Option A:

If you do not have speed requirements, you can choose the CNC punching machine. The speed is around 15 to 20 meter per minute.

Option B:

If you do have speed requirements, you can choose ROTARY punching machine. The speed is around 50 to 80 meter per minute.

| Rotary device | Material width | 70mm |

| Material thickness | 1.0mm-1.2mm | |

| Speed | 0-60m/min | |

| Punching material | DC53 with quenched treatment,HRC61-63° | |

| Shaft material | 45Cr steel with treatment | |

| Shaft diameter | 150mm | |

| Motor power | 15kw | |

| Control system | PLC | |

|

Roll forming machine | Feeding device | Bearing brand:Harbin |

| Shaft material | 45# STEEL | |

| Shaft diameter | 60mm,solid shaft | |

| Roller material | GB-Cr12 mould steel with quenched treatment | |

| Roller station | 12 stations | |

| Bearing | China famous brand Harbin | |

| Work speed | 0-60m/min(including cutting process) | |

| Work power | 11 kw | |

| Transmission | By gear(more precision and faster than chain) | |

| Voltage | AC 415V,50Hz,3Phases(Or as customers’ request) | |

| Appearance | Good appearance with no burrs in steel body nor traces of rust or defects in painting. Good electrical and hydraulic cable organization Car painting make the machine more glossy |

Slotted angle light duty and heavy duty rolling forming machine working videos for your reference: