In the architectural decoration industry, light steel keel serves as a key material for supporting structures such as suspended ceilings and partition walls, with its processing precision and production efficiency directly impacting project quality and cost control. As a specialized machine for manufacturing C-shaped light steel keels, ZTRFM Metal Steel Stud and Track C Channel Roll Forming Machine is becoming a core tool for enhancing the competitiveness of architectural decoration enterprises due to its high precision and efficiency.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.7-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Gear transmission

|

|||

|

Dimension(L*W*H)

|

7800*800*1200(customize)

|

|||

|

Weight

|

About 4.5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW*2 sets

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

40-100m/min(customized)

|

Different speed designs for options.

|

||

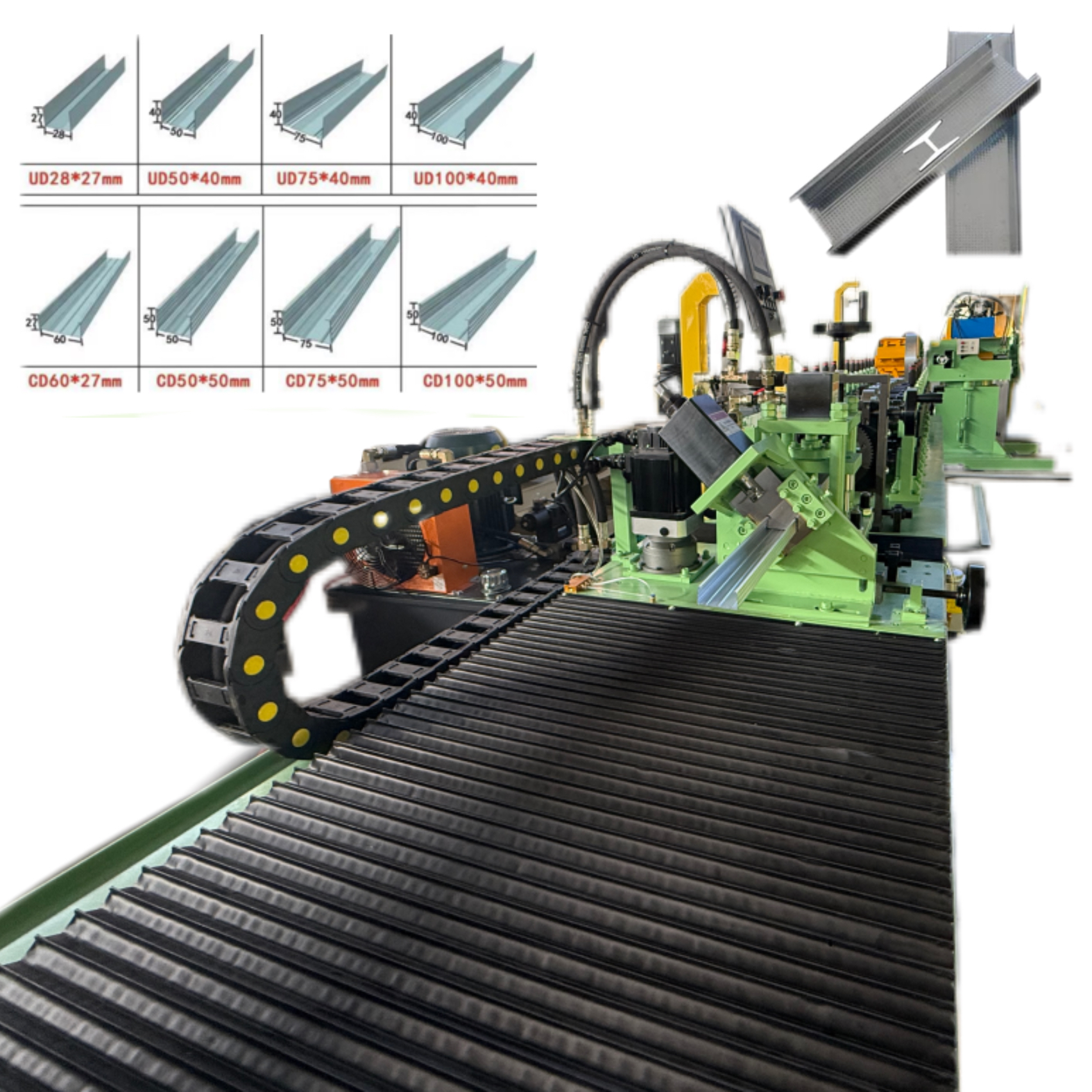

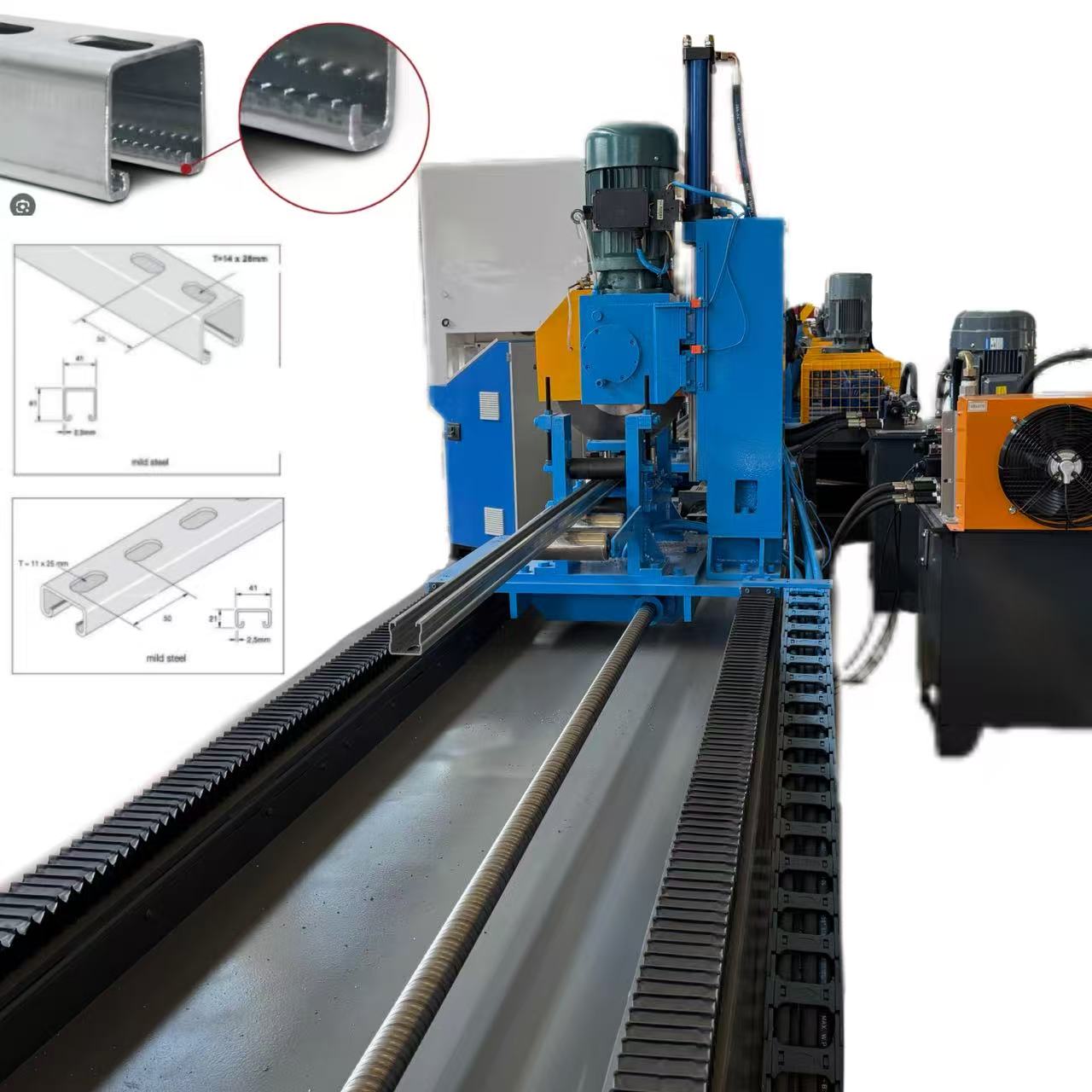

Profile drawing as below:

Technical Advantage: Dual Breakthrough in Accuracy and Efficiency

The ZTRFM Metal Steel Stud and Track C Channel Roll Forming Machine adopts cold bending forming technology and achieves full process automation production through PLC control system. Its core advantages are reflected in:

1.High precision machining:

The equipment is equipped with servo motors and intelligent correction systems, with molding accuracy errors controlled within ± 0.1mm and straightness errors less than 0.5mm/meter, ensuring the accuracy of the fit between the keel and the connecting parts and reducing adjustment time during construction.

2.Efficient production:

The single shift production capacity can reach 8000 meters, and the production speed can reach 60 meters per minute, which is 40% higher than traditional equipment and meets the needs of large-scale industrialization.

3.Modular design:

supports quick mold change and parameter adjustment, compatible with the production of different specifications of 50-300mm C-shaped keel, and adapts to non-standard customization needs.

4.Stability guarantee:

The key components are made of high-strength alloy steel material, which has undergone precision machining and heat treatment processes. The equipment has a service life of over 8 years and a failure rate of less than 0.5%.

Application scenarios: From industrial plants to commercial complexes

The ZTRFM Metal Steel Stud and Track C Channel Roll Forming Machine is widely used in multiple fields of architectural decoration:

• Industrial plant:

In steel structure engineering, C-shaped keel is used as a vertical keel frame to support partition walls and ceiling systems.

• Commercial complex:

In ceiling decoration, C-shaped keel and U-shaped keel are used in combination to form a stable ceiling frame.

• Prefabricated building:

With the promotion of green building policies, the light steel keel produced by ZTRFM Metal Steel Stud and Track C Channel Roll Forming Machine has become the core material of prefabricated housing, meeting the requirements of rapid construction and environmental protection.