In today’s continuously rising logistics costs, warehousing efficiency has become a core element of enterprise competitiveness. Traditional warehousing systems commonly suffer from pain points such as low space utilization, insufficient shelf stability, and high installation and maintenance costs. As the “skeleton” of the storage system, Full Automatic Steel Supermarket Shelves Storage Rack Upright Pillar Roll Forming Machine directly affects the operational efficiency of the entire storage system.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:1.5-2.7mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

will give you as free

|

||

|

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

As your requirement

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gearbox transmission

|

|||

|

Dimension(L*W*H)

|

customize

|

|||

|

Weight

|

About 75T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

customized

|

The speed depends on the shape of the tile and the thickness of the material.

|

||

Application Scenarios :

• In the field of warehousing and logistics

The shelf system supported by shelf columns is suitable for pallet storage and forklift access scenarios. For example, in a three-dimensional warehouse, the combination of columns and beams forms multiple layers of cargo spaces, supporting equipment such as balanced weight forklifts and forward moving forklifts to directly access goods, improving space utilization and warehousing efficiency; This configuration is common in distribution centers in e-commerce, retail, and other industries, used to store boxed goods, small and medium-sized standardized products (such as electronic products, food packaging), or heavier items (such as automotive parts, mechanical equipment) to meet high-density storage needs.

• In manufacturing and production environments

Rack column equipment is used to store raw materials, semi-finished products, and finished products. For example, in factory workshops, the shelves supported by columns can be adapted to standard pallets (such as 1200 × 1000mm), and can flexibly store materials of different sizes by adjusting the layer height (with a step distance of 50mm or 75mm), supporting production line material distribution and inventory management. At the same time, its structural stability can withstand frequent forklift operation impacts, ensuring operational safety.

Key Features:

1.High load-bearing capacity and structural stability

2.Space utilization and adjustability

3.Easy installation and cost-effectiveness

4.Safe, durable, and adaptable to the environment

5.Industry universality and customization‘

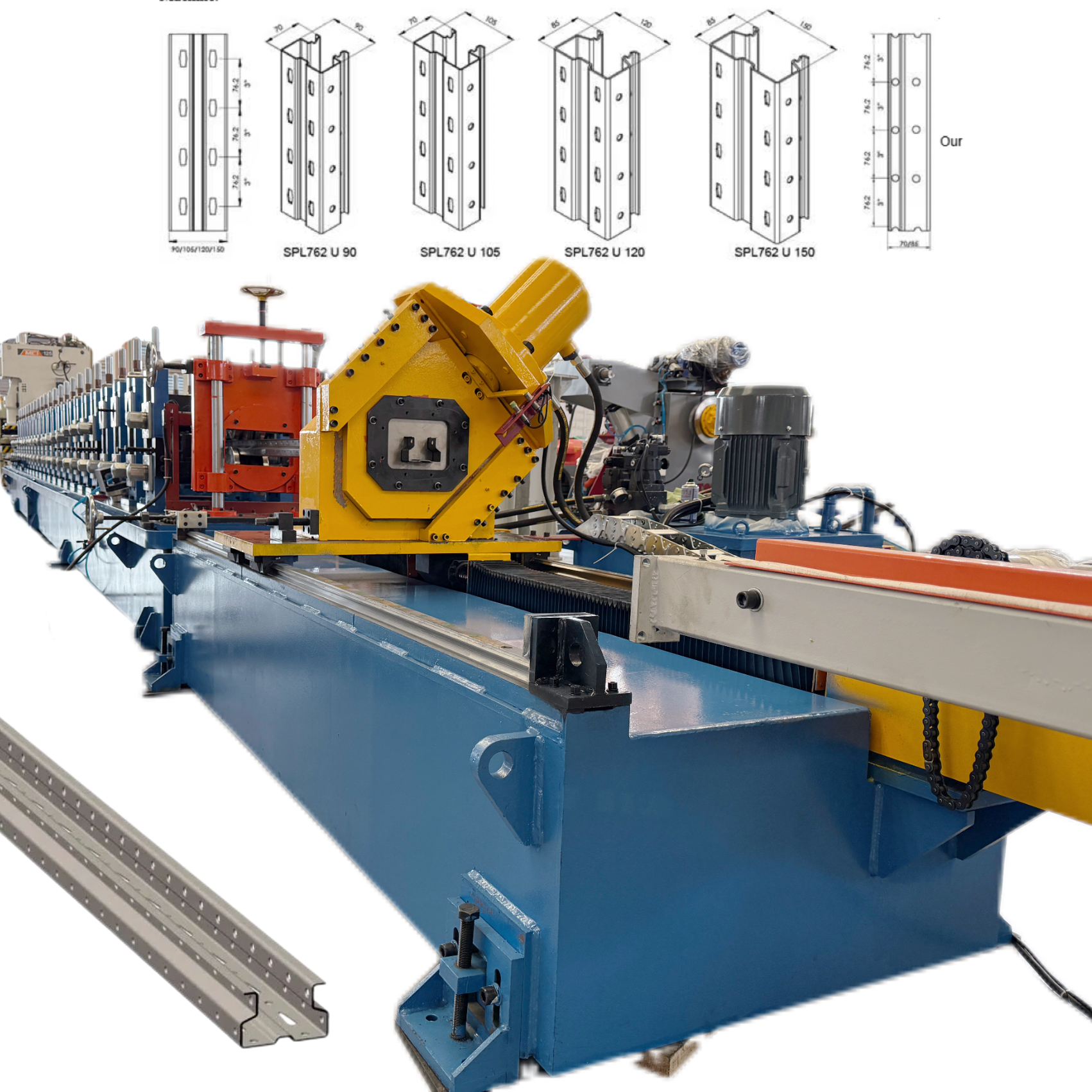

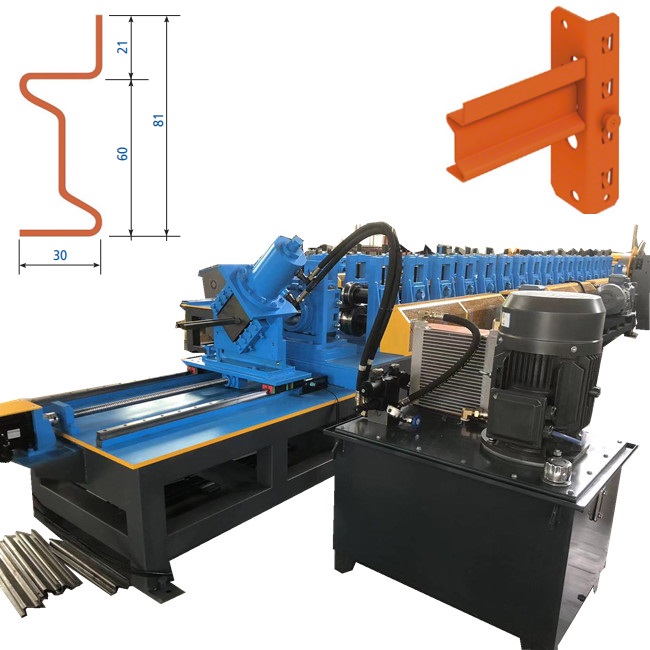

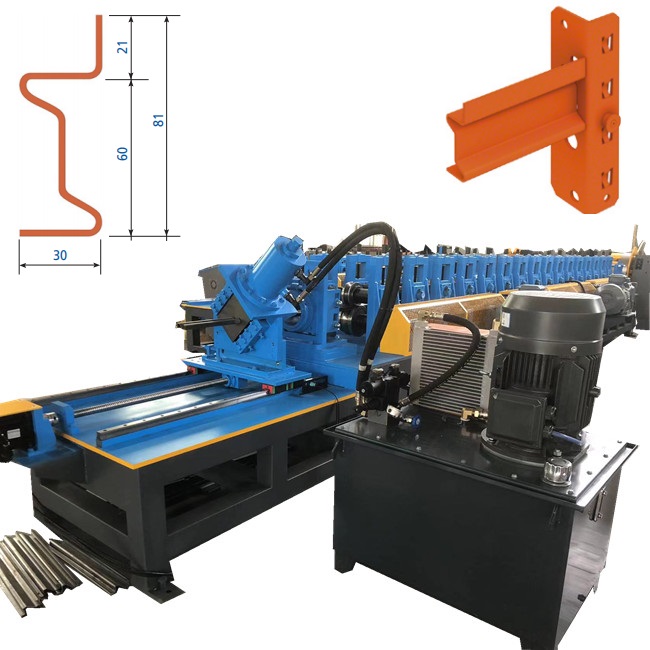

Pattern diagram:

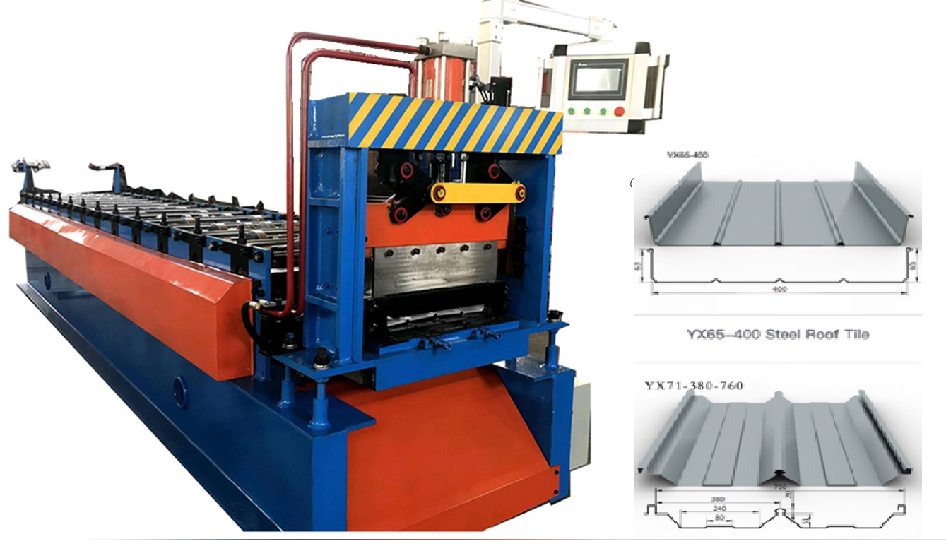

Machine image: