In the dynamic landscape of modern construction, technological advancements have revolutionized the way buildings are designed and erected. One such innovation that stands out is the double layer roll forming machine. This article delves into the significance, advantages, applications, and potential of double layer roll forming machines in the construction industry.

Double Layer Roll Forming Machines: Redefining Construction Efficiency

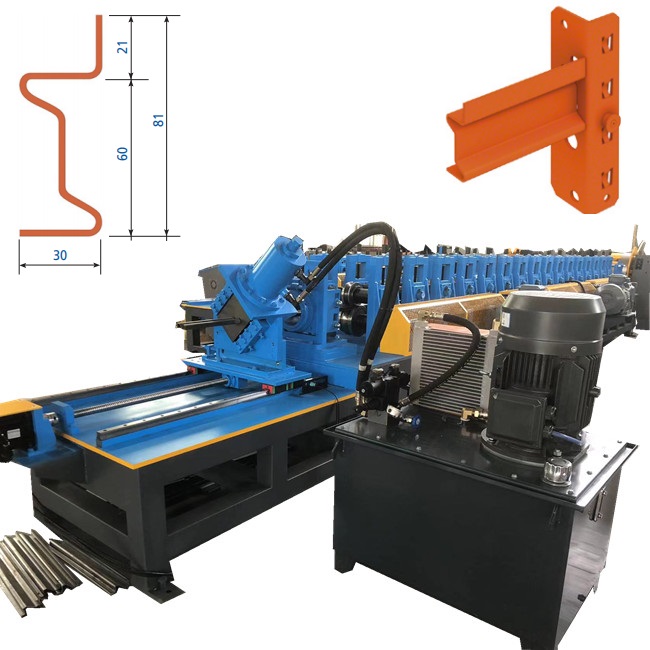

A double layer roll forming machine is a powerful equipment that streamlines the process of producing two different profiles from a single machine. This innovative solution offers unparalleled efficiency, versatility, and cost-effectiveness, making it a game-changer in the world of construction.

Advantages of Double Layer Roll Forming Machines:

- Enhanced Efficiency: Double layer roll forming machines eliminate the need for multiple machines or processes to create two different profiles. This results in significant time savings and increased production capacity.

- Cost Savings: By consolidating the manufacturing process into one machine, operational costs are reduced. Additionally, the minimization of raw material wastage contributes to cost efficiency.

- Versatility: These machines can produce a wide range of profiles, making them suitable for various applications within the construction industry. From roofing and wall cladding to flooring and partitions, the possibilities are extensive.

- Space Optimization: Double layer roll forming machines occupy less floor space compared to using two separate machines, optimizing the utilization of the manufacturing facility.

- Consistency and Precision: The automation offered by these machines ensures consistent quality and precise dimensions in the profiles produced, leading to improved structural integrity.

Applications of Double Layer Roll Forming Machines:

- Roofing and Wall Cladding: These machines are commonly used to manufacture double-layer roofing sheets and wall cladding panels, offering aesthetic appeal and weather protection.

- Flooring Solutions: Double layer roll forming machines create flooring panels with varying designs, catering to different load-bearing requirements and aesthetic preferences.

- Partition Walls: The versatility of these machines extends to producing partition wall profiles, facilitating the creation of adaptable and functional interior spaces.

- Architectural Details: They can manufacture profiles for architectural accents such as cornices, eaves, and decorative elements, adding intricate details to building exteriors.

- Custom Profiles: Contractors and builders can collaborate with manufacturers to create custom profiles that suit unique project specifications.

Future Prospects:

The future of double layer roll forming machines holds promise for even greater innovation. Advancements in technology may lead to machines that offer higher levels of automation, increased precision, and compatibility with a wider array of materials.

The advent of double layer roll forming machines has transformed the construction industry by offering a single solution to create two distinct profiles. Their efficiency, cost-effectiveness, and versatility make them indispensable tools in various construction projects. As the demand for efficient and customizable building solutions continues to rise, these machines are poised to play a pivotal role in shaping the future of construction.