Here is the working video of this machine for everyone to watch:

Product Description:

Ceiling Panel Roll Forming Machine is a professional equipment used for producing integrated ceiling modules, mainly used in the upper decoration field of kitchen and bathroom spaces. It can manufacture multifunctional components such as lighting, heating, and ventilation through modular production methods, and supports free combination to meet different needs.

Working principle and function

The working principle of the Ceiling Panel Roll Forming Machine is to achieve free combination of various functions and optimize component functions through modular development. Its main functions include:

1.Lighting module:

Optimize light source configuration to provide good lighting effects.

2.Heating module:

Breaking through traditional structures and providing efficient heating functions.

3.Ventilation module:

Adopting Archimedean spiral air duct design and ABS flame-retardant box to achieve efficient ventilation.

The Ceiling Panel Roll Forming Machine is suitable for places that require centralized air conditioning and have high requirements for indoor aesthetics, such as commercial places such as shopping malls, supermarkets, restaurants, hotels, as well as office spaces such as offices, conference rooms, reception areas, etc. Its advantages include:

1.Space saving:

Hidden within the ceiling, not occupying floor or wall space.

2.Aesthetic:

Integrate with interior decoration style to maintain a clean and beautiful interior.

3.Efficient cooling/heating:

suitable for large spaces, with good cooling and heating effects.

4.Silent operation:

Low noise during operation, providing a comfortable environment.

Main advantages:

1.Easy maintenance:

The ceiling panel machine does not require climbing ladders or dismantling aluminum buckle plates, making maintenance particularly worry free.

2.Stylish appearance:

The ceiling panel machine realizes the integrated design of ceiling, heating, ventilation, and lighting, presenting a flat and beautiful effect, significantly enhancing the decorative value of the ceiling.

3.Easy installation:

With its integrated design, the ceiling panel machine can simultaneously complete the configuration of ceiling, heating, ventilation, lighting and other functions in one installation process, which is both time-saving and worry free.

4.High safety:

The electrical part of the ceiling panel machine achieves the separation of strong and weak electricity, which not only ensures the safety of use, but also extends the overall service life of the product.

5.Good economy:

The ceiling panel machine stands out with its high cost-effectiveness, not only easy to install, but also effectively reduces procurement and installation costs.

6.Strong durability:

The buckle design of the ceiling panel machine ensures that it will not change color or deform for ten years, making it durable and long-lasting.

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:0.5-1.2mm

|

||

|

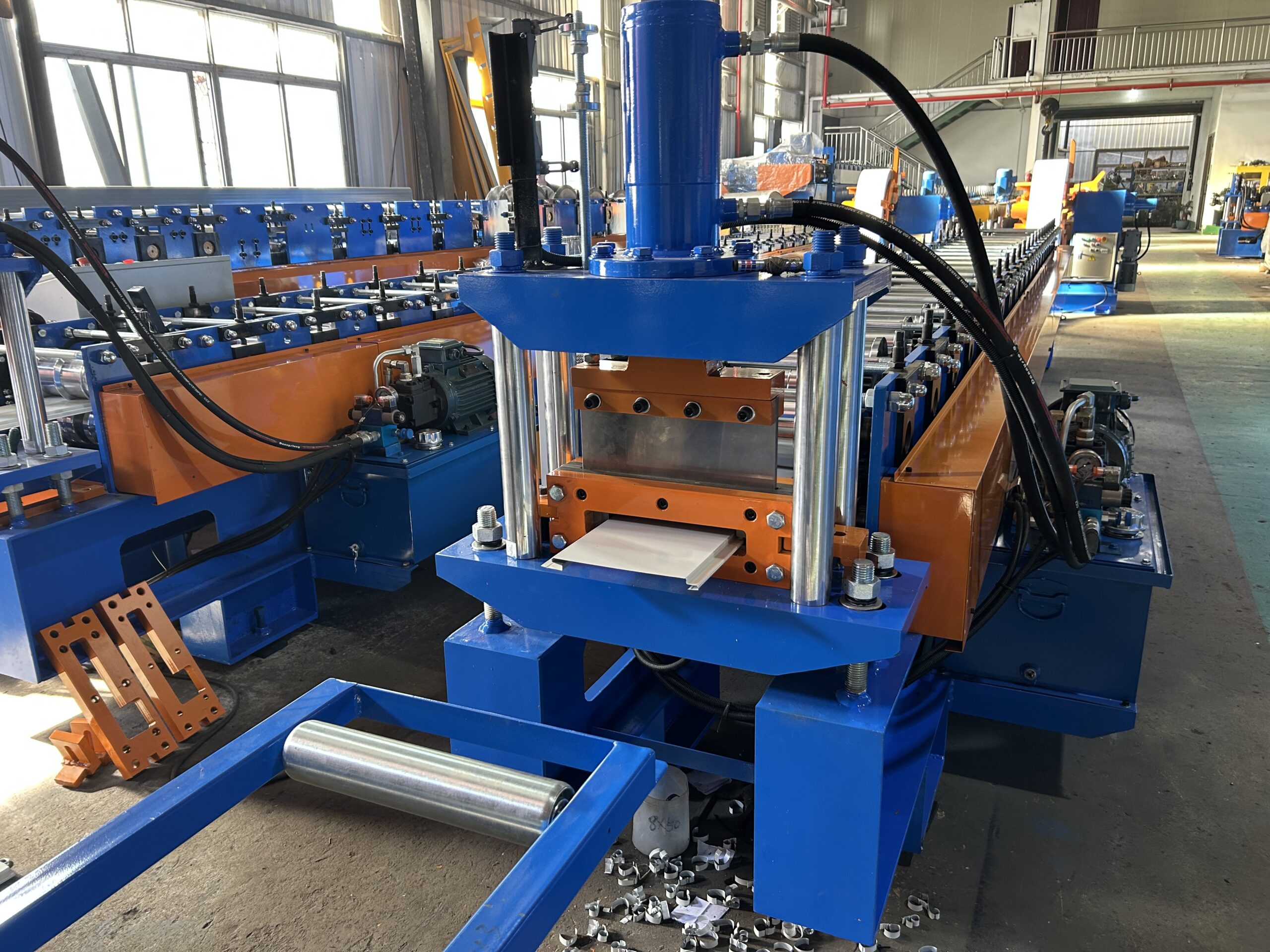

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

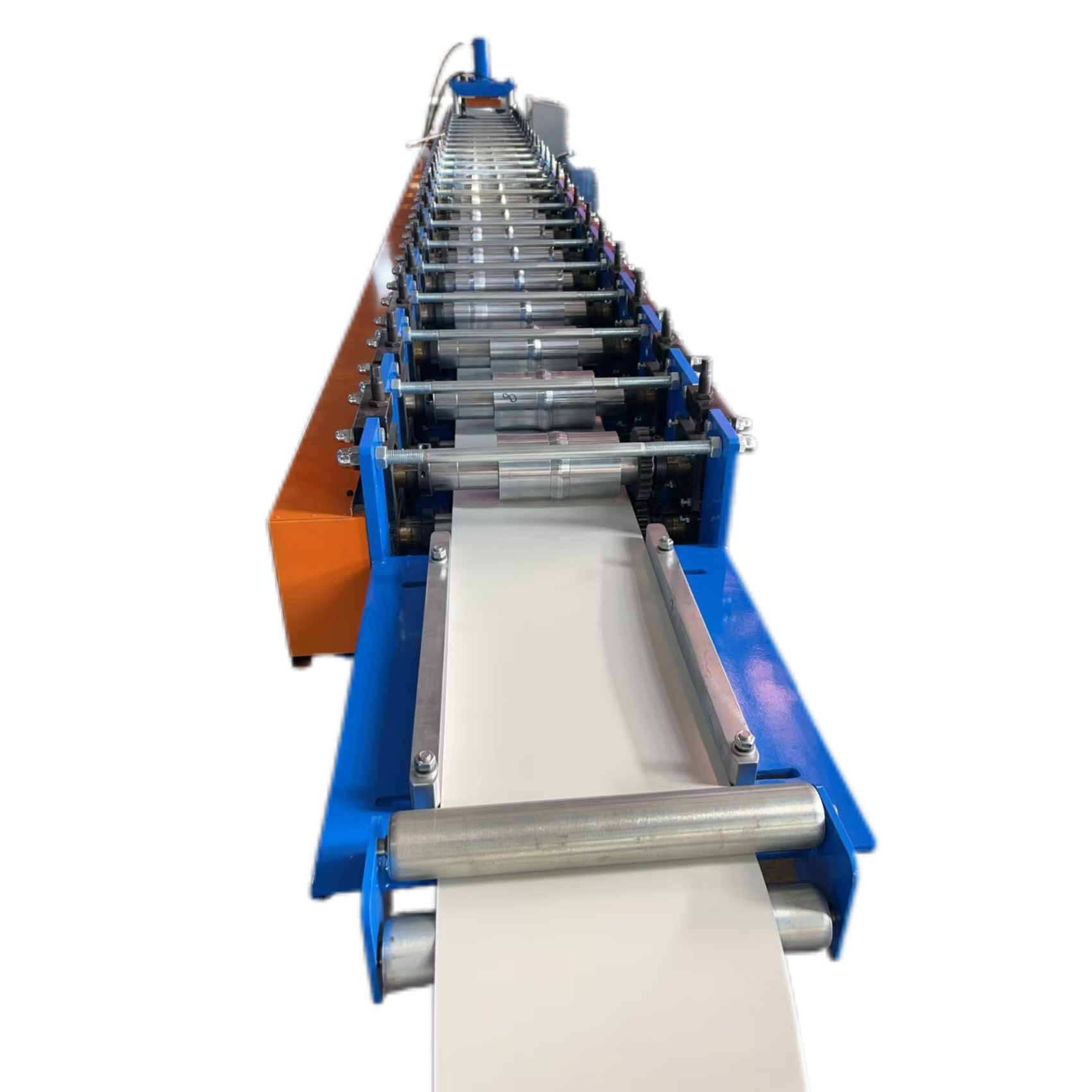

3.Main body

|

Roller station

|

As your requirement

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive way

|

gear

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 8T

|

|||

|

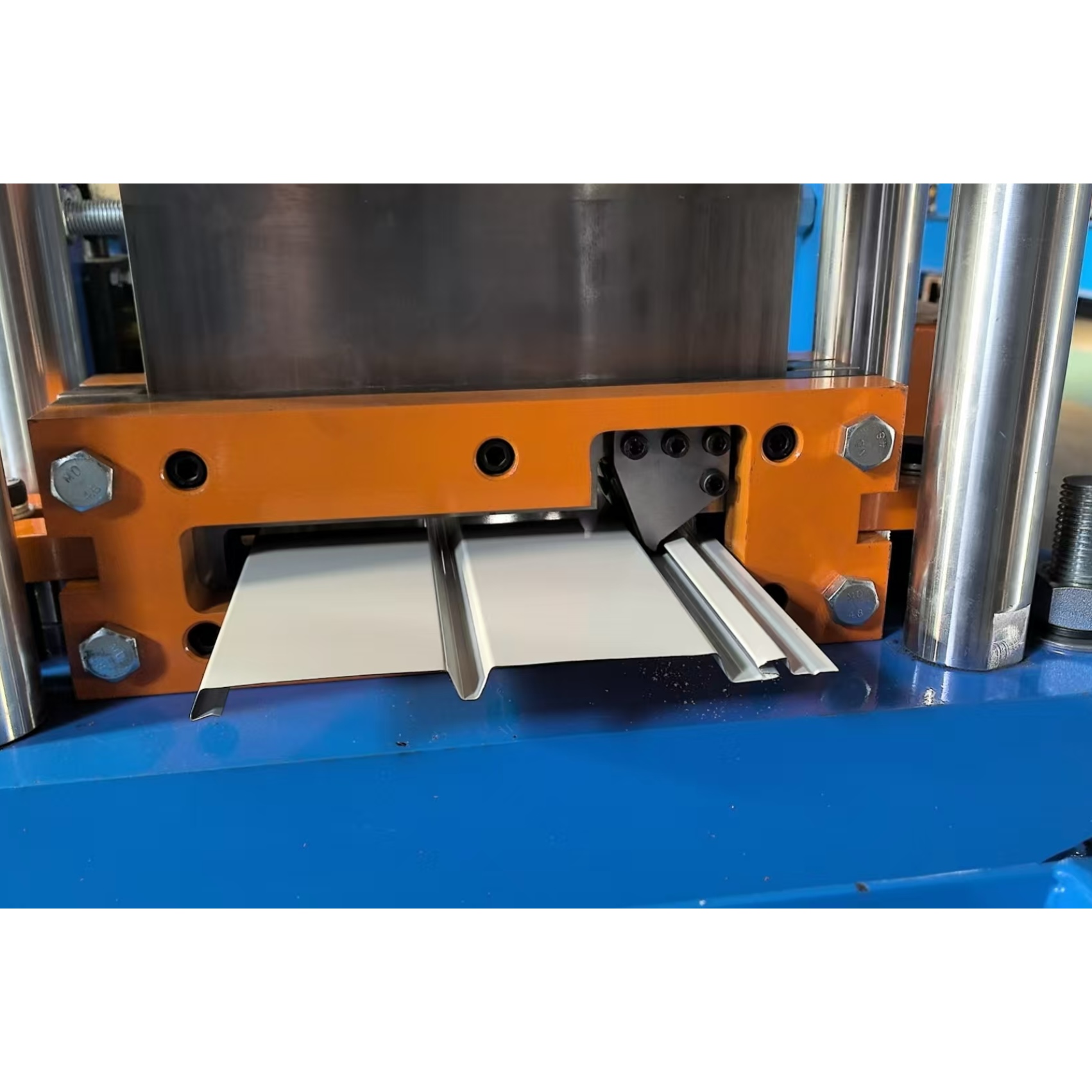

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

30m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||