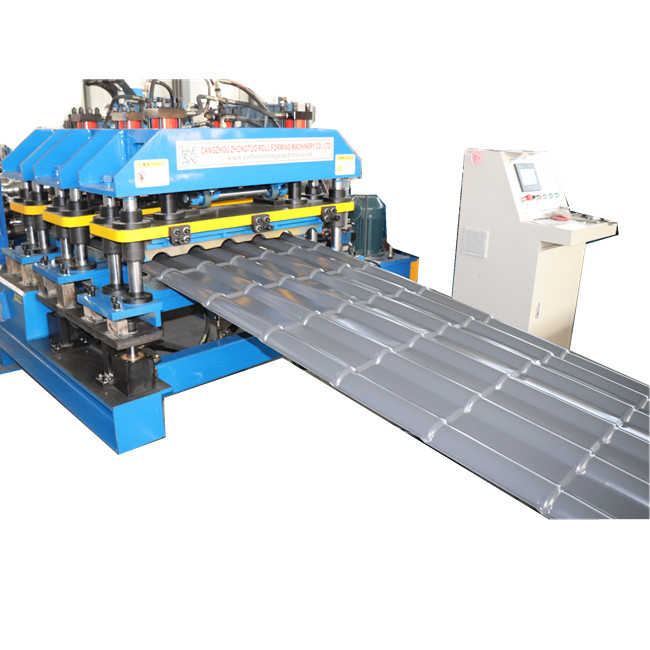

The Glazed Tile Roll Forming Machine is a cutting-edge and efficient solution for producing glazed tiles. This state-of-the-art machine is specifically designed to create high-quality glazed tiles with a smooth and attractive finish. With precision engineering and automated controls, it ensures seamless and accurate roll forming, resulting in consistent and precise glazed tiles. The machine is versatile and capable of handling various materials, such as steel, aluminum, or other alloys, making it suitable for a wide range of roofing and wall cladding applications. Experience superior glazed tile production and elevate your construction projects with this reliable and high-performance Glazed Tile Roll Forming Machine.

Brief Introduction of high speed glazed tile roll forming machine

In nowadays,many constructions become easier,lighter,more economic, this benefits from the development of metal construction materials,one of the most popular material is metal roofing sheets,also called metal tiles,this product is widely used in residents houses ,restaurants,gyms,factories,etc. Metal glazed tile is one type of roofing sheets,the advantage of metal glazed tile is light, easy to install,pretty appearance,and economical,normal glazed tile roll forming machine speed is 2-3m/min, but high speed glazed tile roll forming machine can be up to 6m/min,very strong and efficient.

DESCRIPTION

- Main Material used

Material: Color steel , galvanized steel, or Aluminum

Feeding width:1000mm

Material thickness:0.3-0.8mm

Yield strength:235-450mpa

- Machine composition

| NO. | NAME | UNIT | QUANTITY |

| 1 | 5T manual decoiler | set | 1 |

| 2 | Main roll forming machine | set | 1 |

| 3 | Hydraulic pressing part | set | 1 |

| 4 | Hydraulic cutting part | set | 1 |

| 5 | Product receiving table | set | 1 |

| 6 | PLC control station | set | 1 |

| 7 | Hydraulic oil station | set | 1 |

- Main parameters of high speed glazed tile roll forming machine

| 1 | Raw material | PPGI/PPGL/GI/GL |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Frame | Independent cast stand ,very strong |

| 4 | Roller material | 45# steel,hard chromed on the surface |

| 5 | Shaft material | 45# steel,heat treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Main machine power | 11 KW |

| 8 | Voltage | 380V/50HZ/3P (as requested) |

| 9 | Pressing mould material | Cr12 steel,quenched |

| 10 | Cutting blade material | Cr12 steel,quenched |

| 11 | Cutting type | Hydraulic stop cutting |

| 12 | Transmission type | By gearbox |

| 13 | Hydraulic station power | 7.5KW |

| 14 | Production speed | 6-8m/min |

Our Advantages

Why we have more orders than other suppliers?

In this field,we have more orders because our machines have many advantages than machines from other suppliers.

1.Hand wheels on both sides can be used to adjust the feeding width.

2.Four stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3.There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

4.Our PLC control station is stronger and more operator friendly, inside is very neat and there are some Aviation plugs for easier installation.

5.Our raw material and accessories source all use famous Chinese brand, which all have CE, ISO certificates,like bearing,screw/nuts, chain wheels, ect. though these are small parts for the machine,we will ensure the quality to avoid any problems.

Main machine pictures:

STUD TRACK ROLL FORMING

- Glazed Tile Roll Forming Machine

- PRODUCT DETAIL

Brief Introduction of high speed glazed tile roll forming machine

In nowadays,many constructions become easier,lighter,more economic, this benefits from the development of metal construction materials,one of the most popular material is metal roofing sheets,also called metal tiles,this product is widely used in residents houses ,restaurants,gyms,factories,etc.

Metal glazed tile is one type of roofing sheets,the advantage of metal glazed tile is light, easy to install,pretty appearance,and economical,normal glazed tile roll forming machine speed is 2-3m/min, but high speed glazed tile roll forming machine can be up to 6m/min,very strong and efficient.

DESCRIPTION

- Main Material used

Material: Color steel , galvanized steel, or Aluminum

Feeding width:1000mm

Material thickness:0.3-0.8mm

Yield strength:235-450mpa

- Machine composition

| NO. | NAME | UNIT | QUANTITY |

| 1 | 5T manual decoiler | set | 1 |

| 2 | Main roll forming machine | set | 1 |

| 3 | Hydraulic pressing part | set | 1 |

| 4 | Hydraulic cutting part | set | 1 |

| 5 | Product receiving table | set | 1 |

| 6 | PLC control station | set | 1 |

| 7 | Hydraulic oil station | set | 1 |

- Main parameters of high speed glazed tile roll forming machine

| 1 | Raw material | PPGI/PPGL/GI/GL |

| 2 | Raw material thickness | 0.3-0.8mm |

| 3 | Frame | Independent cast stand ,very strong |

| 4 | Roller material | 45# steel,hard chromed on the surface |

| 5 | Shaft material | 45# steel,heat treatment |

| 6 | Shaft diameter | 80mm |

| 7 | Main machine power | 11 KW |

| 8 | Voltage | 380V/50HZ/3P (as requested) |

| 9 | Pressing mould material | Cr12 steel,quenched |

| 10 | Cutting blade material | Cr12 steel,quenched |

| 11 | Cutting type | Hydraulic stop cutting |

| 12 | Transmission type | By gearbox |

| 13 | Hydraulic station power | 7.5KW |

| 14 | Production speed | 6-8m/min |

Our Advantages

Why we have more orders than other suppliers?

In this field,we have more orders because our machines have many advantages than machines from other suppliers.

1.Hand wheels on both sides can be used to adjust the feeding width.

2.Four stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3.There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

4.Our PLC control station is stronger and more operator friendly, inside is very neat and there are some Aviation plugs for easier installation.

5.Our raw material and accessories source all use famous Chinese brand, which all have CE, ISO certificates,like bearing,screw/nuts, chain wheels, ect. though these are small parts for the machine,we will ensure the quality to avoid any problems.

Main machine pictures

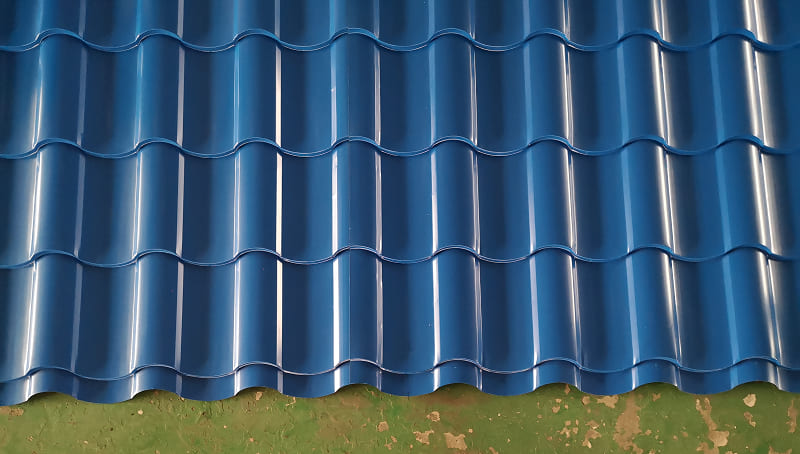

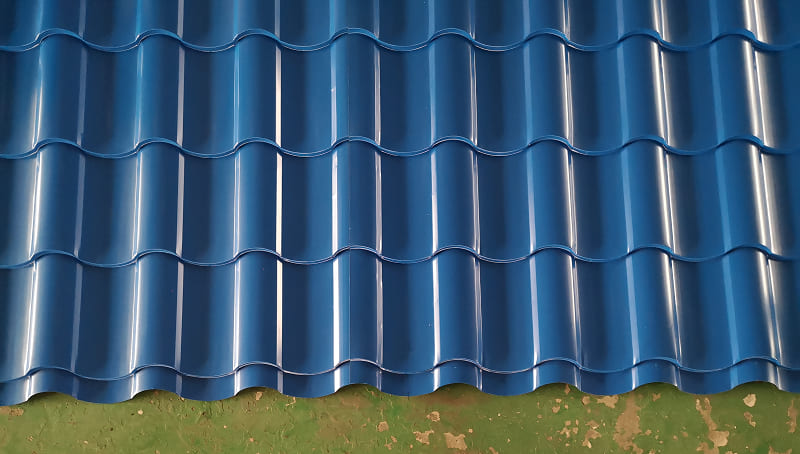

Product application: