When the first ray of sunshine in the morning shines on the city, shops open their welcoming mode, factories start their production processes, and logistics parks welcome their first batch of goods… Behind these vibrant scenes, a silently guarded “safety barrier” – metal rolling shutter door machine – cannot be separated. It is not only a divider of space, but also a guardian of safety, an enhancer of efficiency, and an optimizer of cost, providing excellent performance to safeguard commercial operations, industrial production, logistics and warehousing, and other fields.

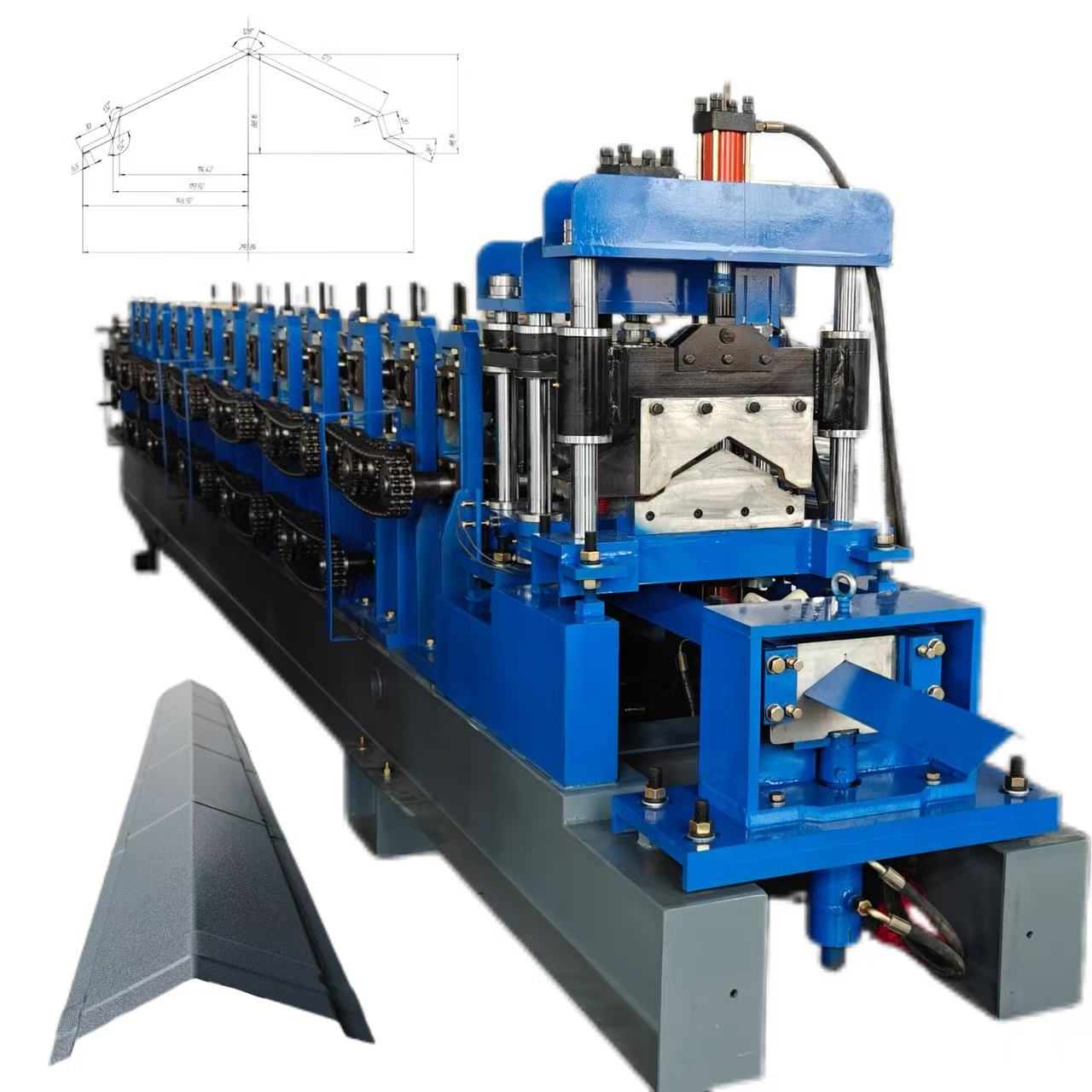

Pattern diagram:

Product Attributes :

|

1.Formed Material

|

GI

|

Thickness:0.8-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

14rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 5T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

20-25m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

Hard core protection, building a secure ‘copper wall and iron wall’

Safety is the primary prerequisite for all operational scenarios, and the performance of metal rolling shutter doors in terms of safety protection can be regarded as the “industry benchmark”. It is made of high-quality alloy steel, and the thickness of the plate has been scientifically calculated, with excellent performance in terms of impact resistance, compression resistance, and cutting resistance. In the face of unexpected collisions, it can effectively buffer the impact force and avoid deformation of the door body; Encountering malicious destruction, the hard material can form a strong barrier, buying valuable time for indoor property and personnel safety.

At the same time, the metal rolling shutter door machine is equipped with multiple safety protection systems. The intelligent anti pinch function can detect obstacles under the door in real time. Once a person or object is detected, it will immediately stop descending and rise in the opposite direction, completely eliminating the hidden danger of pinch injuries; The emergency braking system can quickly lock the position of the door body in case of power outage, malfunction, or other emergencies, preventing the door body from accidentally slipping off; Some high-end models can also be connected to security monitoring systems. When an abnormal activation is detected, an alarm will be automatically triggered and information will be synchronously pushed to the management personnel’s mobile phones, achieving 24-hour security monitoring and leaving no blind spots in security protection.

Energy conservation and consumption reduction, creating a green “low-carbon space”

In today’s era of advocating green and low-carbon development, metal rolling shutter door machine has become a “good helper” for many users due to its excellent energy-saving performance. The door body adopts a double-layer or multi-layer composite structure, with high-efficiency insulation materials filled in the middle, which can effectively block indoor and outdoor heat exchange. In hot summer, it can reduce the input of high temperatures from the outside and lower the cooling load of air conditioning; In the cold winter, it can prevent indoor heat loss, reduce heating consumption, and long-term use can significantly reduce energy costs for enterprises.

In addition, the operating energy consumption of metal rolling shutter door machine is also extremely low. By using high-precision motors and intelligent control systems, the door can be lifted and lowered smoothly with low operating noise. The motor also has high-efficiency and energy-saving characteristics, reducing power consumption by more than 20% compared to traditional rolling shutter door equipment. At the same time, the surface of the door is treated with a special anti-corrosion coating, which has excellent weather resistance and corrosion resistance, with a service life of more than 15 years, reducing the frequency of equipment replacement and further reducing resource consumption and environmental impact from the perspective of the entire life cycle.