With the continuous construction of commercial complexes, industrial plants, residential areas, and warehousing and logistics parks, rolling shutter doors that combine anti-theft, wind resistant, thermal insulation, and convenience have become a “must-have product” in the door industry market. And a high-performance rolling shutter door machine is the core equipment for you to break through production bottlenecks, create high-quality products, and seize market share!

Product Attributes:

|

1.Formed Material

|

GI

|

Thickness:0.6-1.2mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

3.Main body

|

Roller station

|

12 rows(As your requirement)

|

||

|

Diameter of shaft

|

50mm solid shaft

|

|||

|

Material of rollers

|

45# steel, hard chrome plated on the surface

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

gear and Chain transmission or gearbox

|

|||

|

Dimension(L*W*H)

|

5500*800*1200(customize)

|

|||

|

Weight

|

About 3T

|

|||

|

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

7.5KW

|

||

|

Hydraulic system power

|

5.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Siemens(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

15-45m/min(customized)

|

Speed is adjustable according to customer’s request

|

||

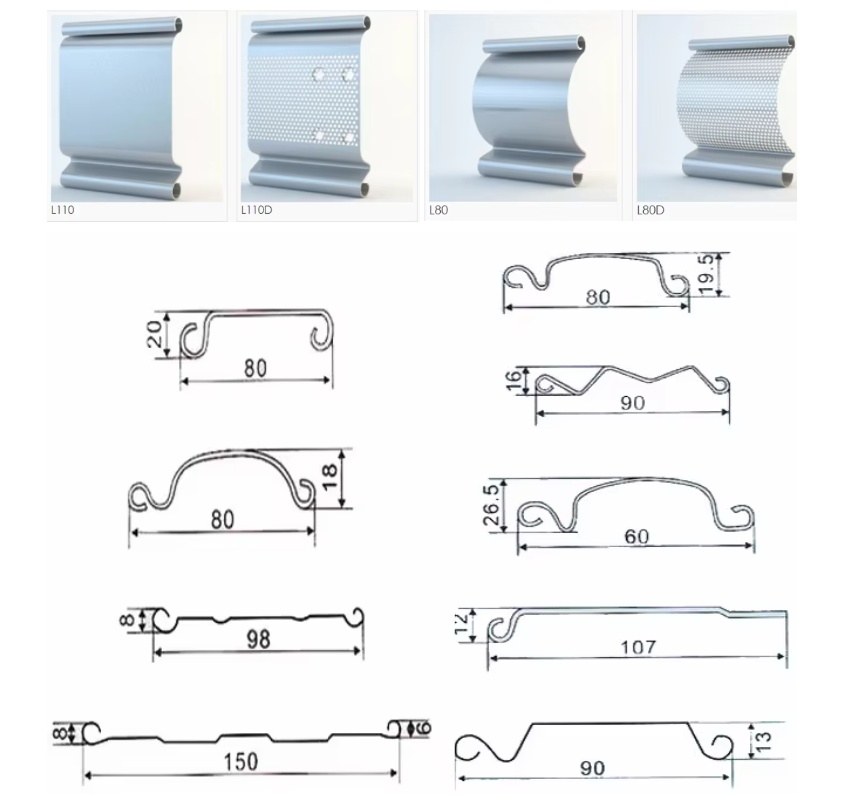

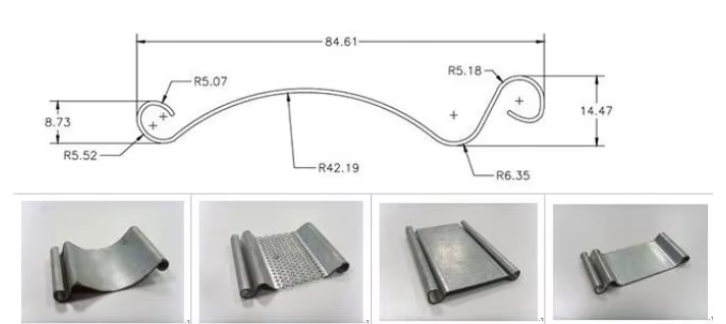

Pattern diagram:

1.Efficient production capacity, easily accepting large orders

Dual track synchronous molding+fully automated integrated process, producing 8-12 units (2m × 3m) per hour, with an efficiency increase of over 50%. Support 24-hour continuous operation, automatically avoid material jamming and size deviation, and ensure order delivery.

2.Produce high-quality products and create good doors that are recognized by the market

Numerical control molding error ≤ 0.05mm, ensuring smooth operation. Compatible with multiple raw materials, covering 4 major categories of rolling shutter doors. The product has a wind pressure resistance of 10 levels, and the fireproof model meets the national standard. It is corrosion resistant and anti-aging, with a service life of more than 15 years.

3.Intelligent operation, even beginners can quickly get started

The 10 inch touch screen comes with 20+specification templates built-in, allowing for one click start of production. The intelligent diagnostic system provides real-time alarms and prompts for solutions, and the fault can be resolved within 10 minutes. Support remote monitoring of the entire production process through a mobile app.

4.Energy saving and cost saving, enhancing profit margins

Permanent magnet synchronous motors save 30% electricity, have a raw material utilization rate of 99%, have a core component lifespan of 10-12 years, reduce maintenance frequency by 60%, and comprehensively reduce operating costs.