With the rapid development of the steel industry, the quality of steel coil packaging directly affects product transportation safety and market competitiveness. As a key piece of equipment in steel coil packaging, the performance and efficiency of the Steel Coil Inner Or Outside Edge Protector Rolling Forming Machine directly impact a company’s production costs and product quality.

Product Attributes :

| Steel Coil Inner Or Outside Edge Protector Rolling Forming Machine | ||

| 1. | Manual Uncoiler | Load Capacity: 1 ton |

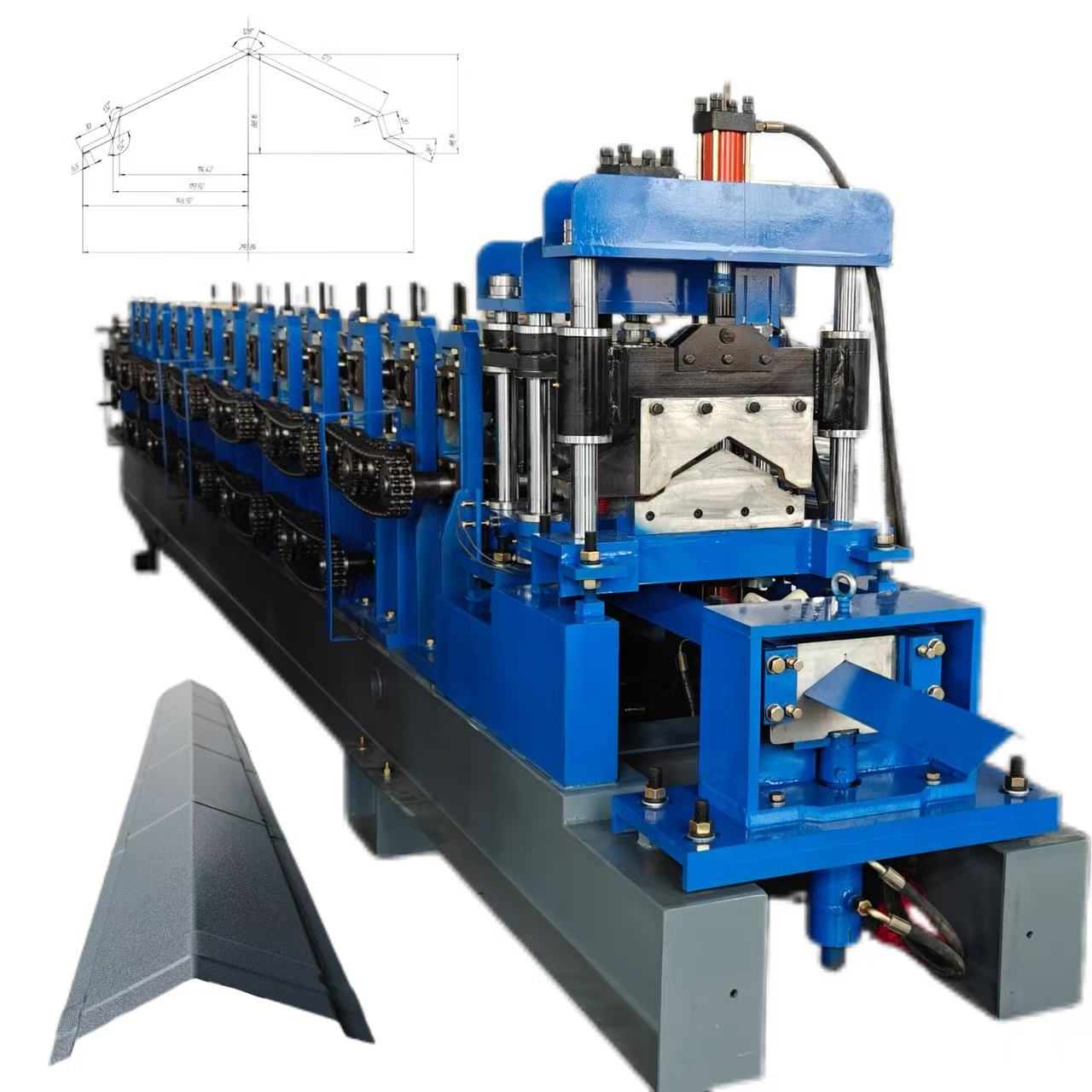

| 2. | Machine Frame | Integral structure, consisting of the roll forming section, coiling section, and integral 12# channel steel welded together, with a precision-finished worktable after welding. |

| 3. | Rollers | 8 sets |

| 4. | Roller Material | Cr12MoV, hardened to HRC59-62 |

| 5. | Shaft Diameter | 55mm |

| 6. | Shaft Material | 40Cr, heat-treated |

| 7. | Wall Plate Thickness | 25mm |

| 8. | Transmission Method | Chain drive |

| 9. | Motor | 7.5kW motor |

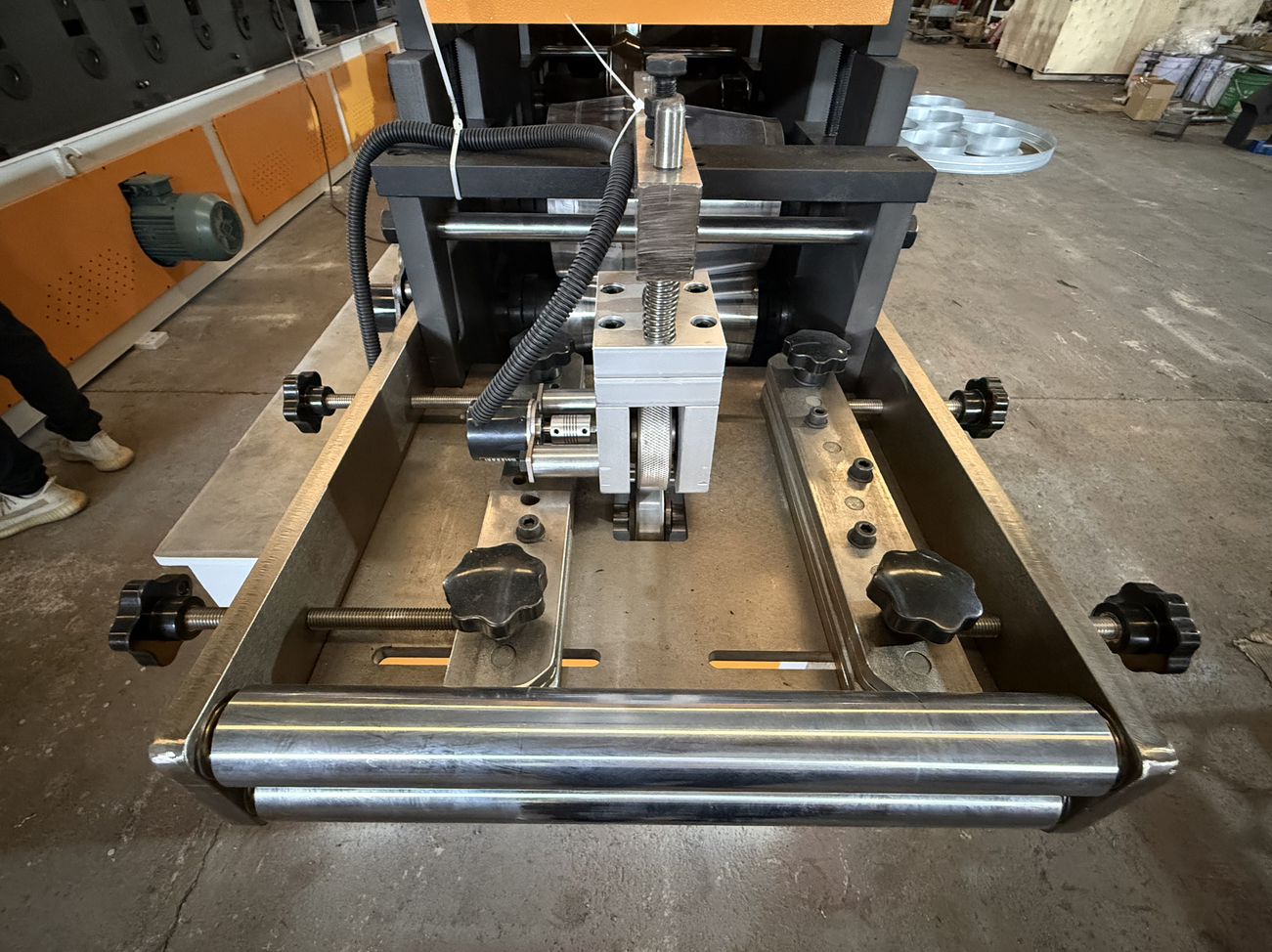

| 10. | Drilling | Hydraulic punching, hole spacing 300-600mm ± 20mm.. |

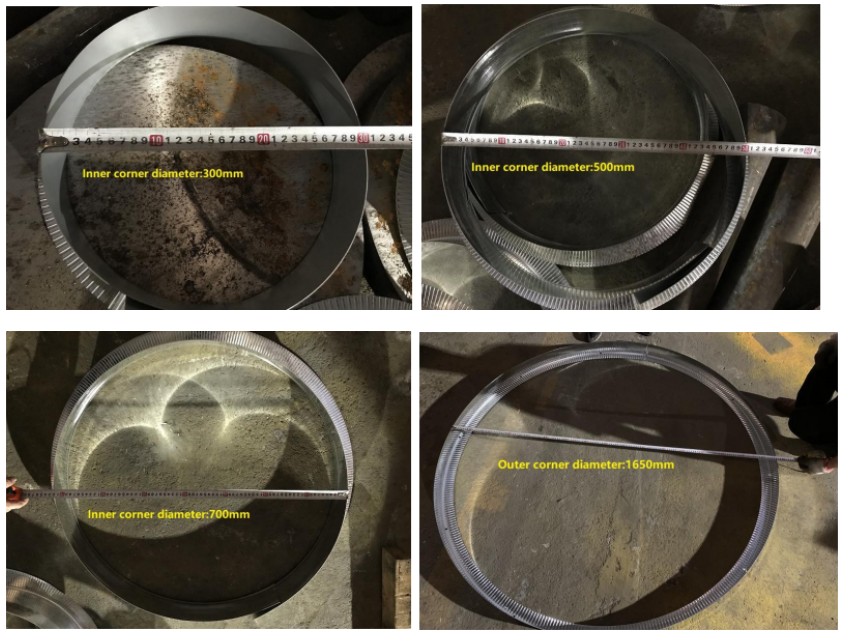

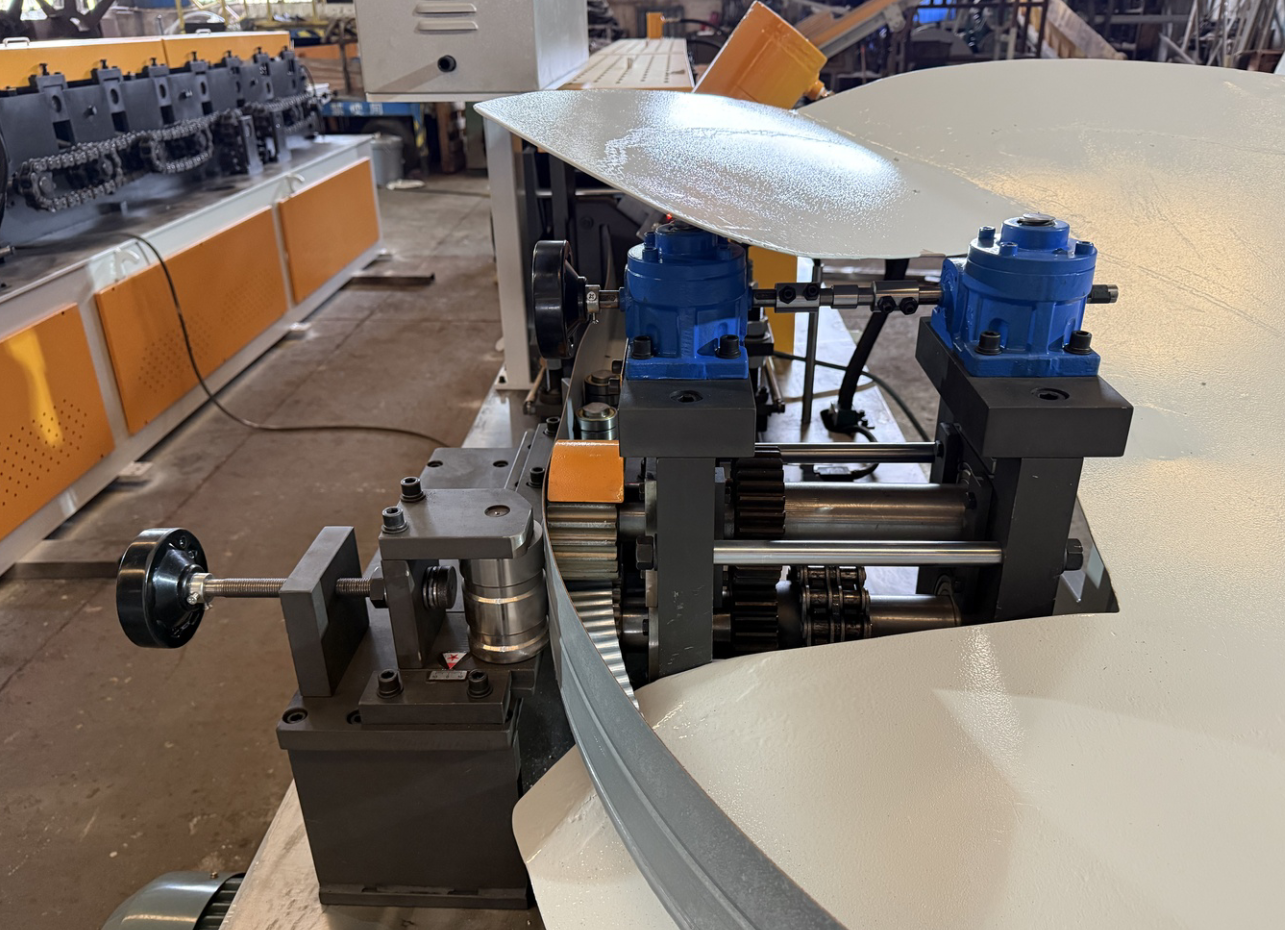

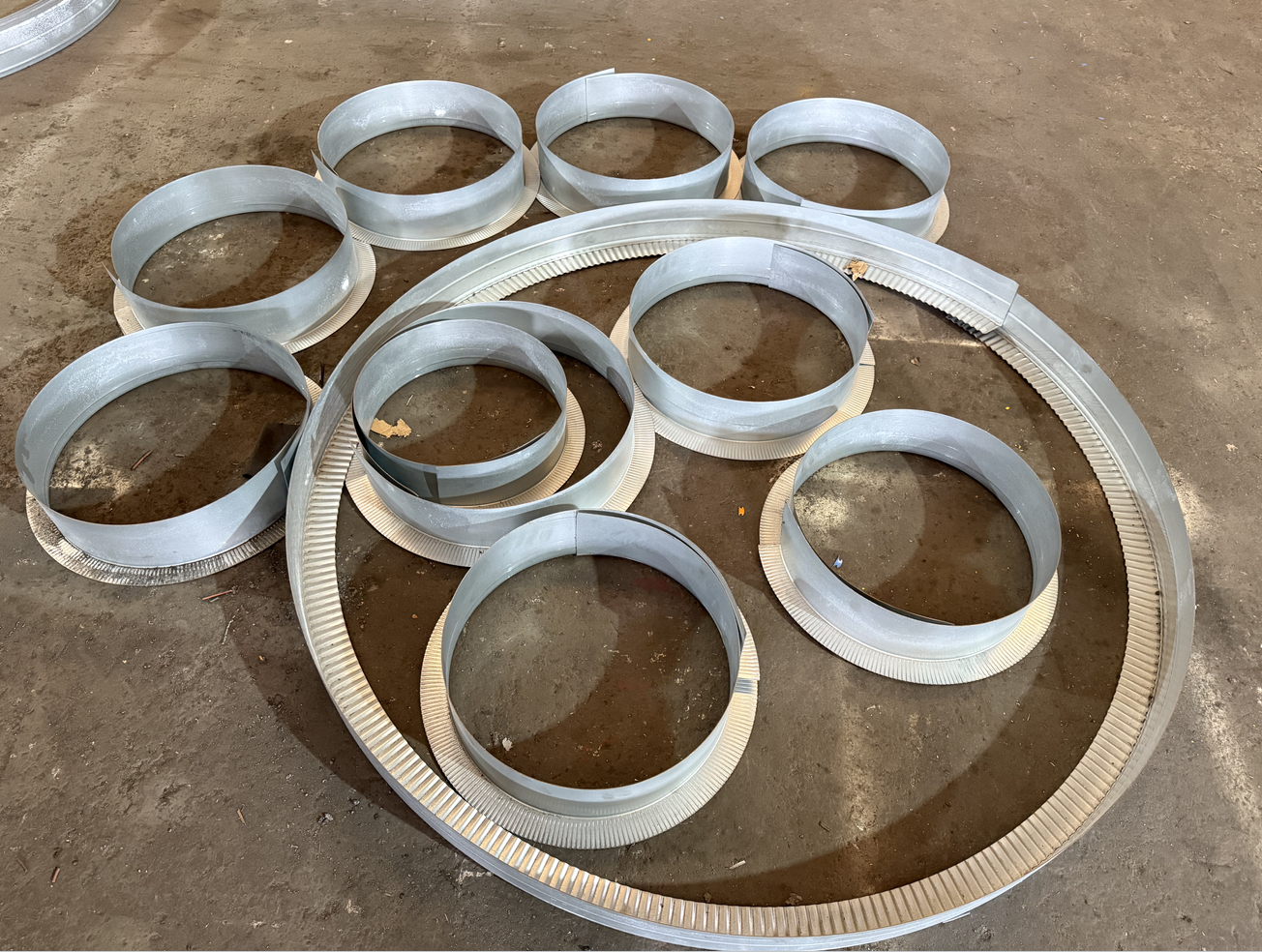

| 11. | Rounding Device | The outer coiling rollers use a pair of roll forming rollers to create wave-like folds and round the coil. Hydraulic shears automatically cut the coil. The diameter is adjusted via a scale marking. The rollers are made of Cr12MoV wire-cut teeth. The main power is driven by a 7.5kW motor. |

| 12. | Cutting Method | Hydraulic cutting |

| 14. | Blade Material | Cr12 MOV |

| 15. | Hydraulic Power | 4kw |

| 16. | Control System | Touchscreen PLC |

| 17. | Speed | Approximately 2 pieces/minute |

Application Scenarios :

1. Steel Plant Packaging Lines

In large steel plants, this equipment is integrated into automated packaging production lines, working in conjunction with coiling machines, strapping machines, and other equipment. Data sharing is achieved through a PLC network, and production rhythm is synchronized with the main production line, with a single line daily capacity of up to 2000 corner protectors.

2. Metal Processing Centers

Small and medium-sized metal processing enterprises use this equipment for customized production. By changing molds, various specifications of corner protectors can be produced. Variable frequency speed control allows it to flexibly handle small-batch orders, with mold changeover time controlled within 15 minutes.

3. Logistics Packaging Sector

In third-party logistics packaging services, the equipment’s high-efficiency production characteristics meet peak season demands. Integration with warehouse management systems enables intelligent replenishment of corner protector inventory, reducing warehousing costs by more than 30%.

Key Features:

1. Structural Stability and Forming Precision

The equipment uses high-strength alloy steel rollers, combined with a precision guide plate design, ensuring a stable and reliable forming process. The synergistic action of the upper and lower rollers achieves progressive bending of the metal sheet, avoiding material deformation defects. The guide plate system effectively controls the material flow path, reducing edge warping and keeping the corner protector dimensional tolerance within ±0.5mm.

2. Intelligent Control System

Modern models are generally equipped with a PLC control unit and a variable frequency speed control system, enabling digital management of production parameters. The operating interface integrates a touch screen, supporting real-time adjustment of parameters such as speed and pressure. The variable frequency speed control function allows for a 30% adjustable forming speed range, adapting to the processing needs of materials of different thicknesses.

3. High-Efficiency Production Capacity

The equipment boasts significantly high forming speeds, producing 3-4 inner corner protectors per minute and 4-6 outer corner protectors per minute. Optimized roller arrangement and transmission system enable continuous, uninterrupted production. The high-strength design allows the equipment to handle various metal sheets with thicknesses ranging from 0.5-3mm, achieving a material utilization rate exceeding 95%.