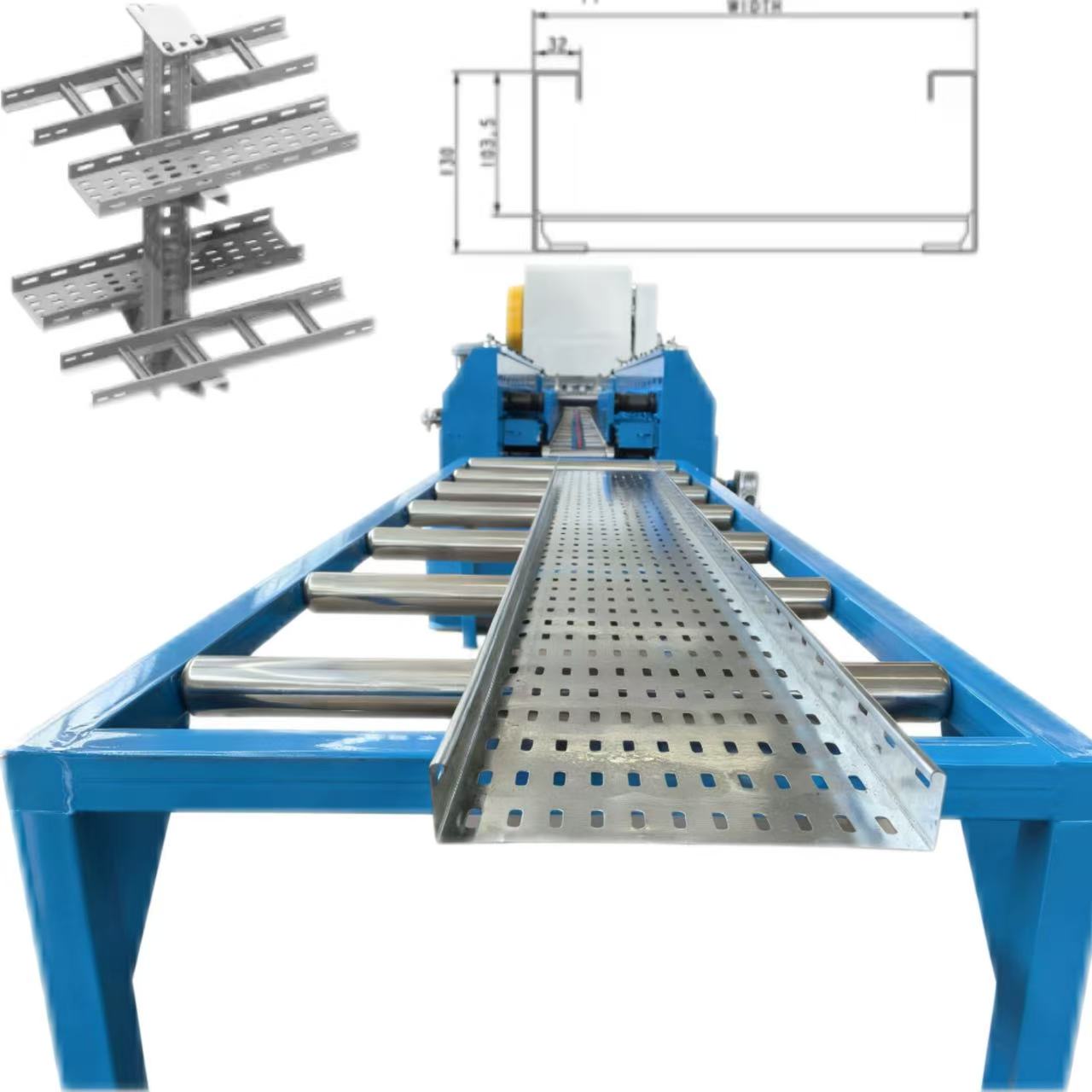

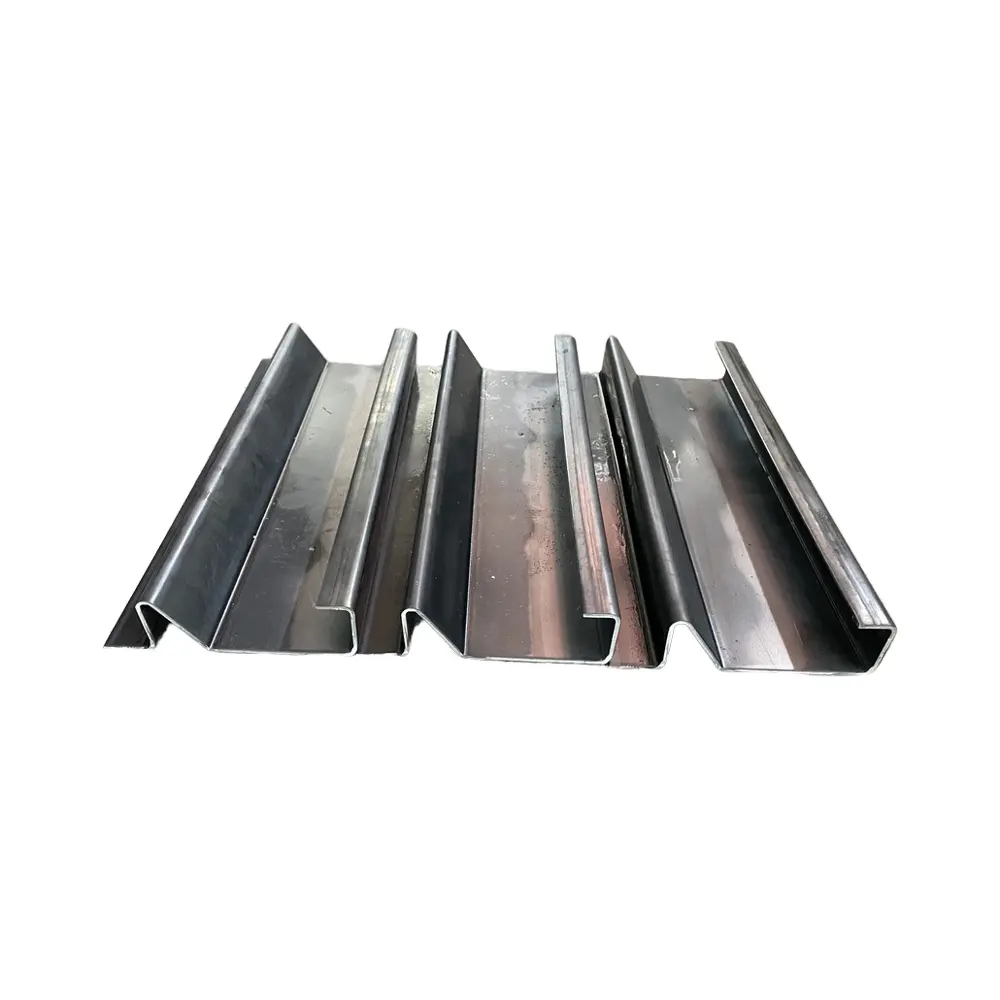

The Z-shaped beam rolling forming machine for shelf columns is a specialized equipment used for producing Z-shaped beams for shelf columns. Its main function is to process rolled or sheet-like metal materials into Z-shaped beams of specific shapes and sizes. The Z-shaped beam of the shelf column is widely used in the manufacturing of storage shelves, which can improve the stability and load-bearing capacity of the shelves. With the rapid development of logistics and warehousing industries, the demand for Z-shaped beams for shelf columns is constantly increasing, and the market prospects are broad. The efficient production and automated operation characteristics of this device give it significant advantages in industrial production.

Main features:

1.High precision molding capability:

This molding machine has high-precision molding capability, which can ensure that the size and shape of the column meet the design requirements. The forming accuracy directly affects the assembly and stability of the equipment.

2.Strength and stability:

It can produce column products with sufficient strength and stability. The column needs to have sufficient strength and stability when carrying goods to ensure the safety and stability of the shelf.

3.Efficient production:

The Z-shaped beam rolling plate forming machine for shelf columns has high production efficiency and can quickly complete the forming process of columns, reducing production costs.

4.Automation level:

It usually has a certain degree of automation functions, such as automatic feeding, automatic forming, automatic cutting, etc., which can improve production efficiency and reduce labor input.

5.Adjustable and adaptable:

able to adapt to the production of columns of different sizes, shapes, and materials. By adjusting the parameters and processes of the equipment, different customer needs can be met.

6.Convenience and safety of operation:

Easy to operate and equipped with good safety protection measures to ensure the safety of operators.

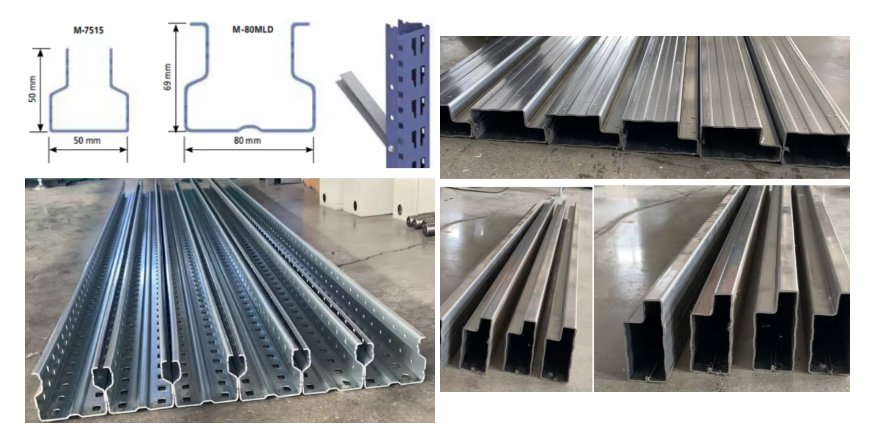

Finished product image:

Product Attributes :

|

1.Formed Material

|

PPGI,GI,AI

|

Thickness:2-2.5mm

|

||

|

2.Decoiler

|

Hydraulic automatic decoiler

|

Manual decoiler(will give you as free)

|

||

|

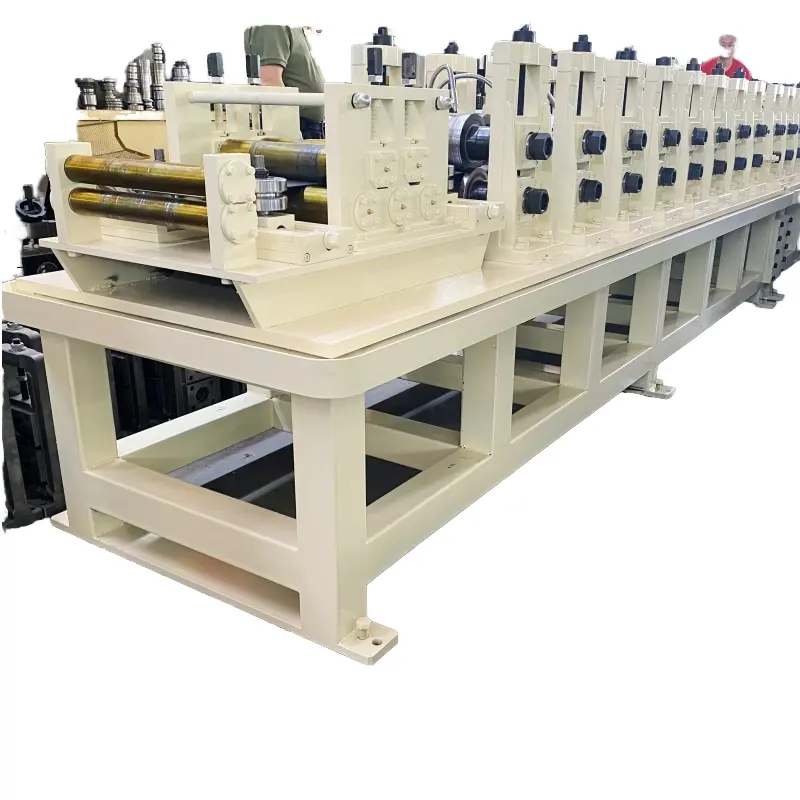

3.Main body

|

Roller station

|

14 rows(As your requirement)

|

||

|

Diameter of shaft

|

70mm solid shaft

|

|||

|

Material of rollers

|

Cr12 with quenched treatment.

|

|||

|

Machine body frame

|

Metal steel welded

|

|||

|

Drive

|

Chain transmission

|

|||

|

Dimension(L*W*H)

|

8500*1200*1500(customize)

|

|||

|

Weight

|

About 8.5T

|

|||

|

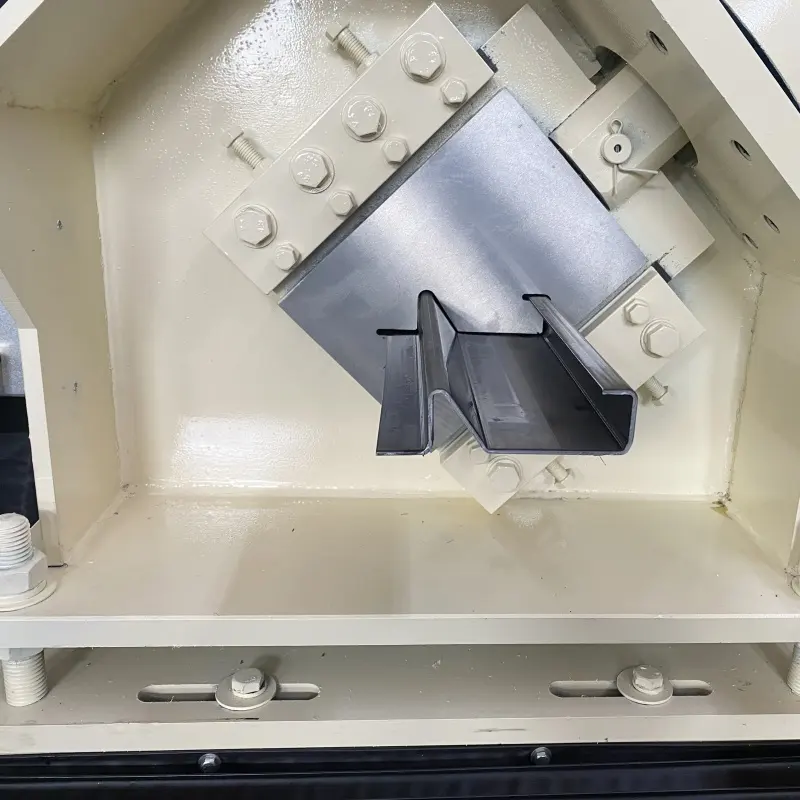

4.Cutter

|

Automatic

|

cr12mov material, no scratches, no deformation

|

||

|

5.Power

|

Motor Power

|

15KW

|

||

|

Hydraulic system power

|

7.5KW

|

|||

|

6.Voltage

|

380V 50Hz 3Phase

|

As your requirement

|

||

|

7.Control system

|

Electric Box

|

Customized(famous brand)

|

||

|

Language

|

English(Support multiple languages)

|

|||

|

PLC

|

Automatic production of the whole machine. Can set batch, length, quantity, etc.

|

|||

|

18.Forming Speed

|

20-25m/min(customized)

|

The speed depends on the shape of the tile and the thickness of the material.

|

||